Understanding pre-emergent herbicide availability, selectivity & persistence and how we can use this knowledge to predict behaviour of new herbicides.

Author: Mark Congreve (Independent Consultants Australia Network) | Date: 12 Mar 2020

Take home messages

- Chemical properties dictate herbicide;

- persistence & mobility

- Photolysis & volatility

- Solubility

- Binding co-efficient (Koc)

- Half-life (DT50)

- Know your soil type (soil texture, pH, any hard pans or changes at depth).

- Seeder set-up is very important to minimise seed and herbicide contact.

- Understand the role of soil microbes.

- Develop a plan that doesn’t rely on any single pre-emergent herbicide.

Background

Over the last 20-30 years, resistance to many post-emergent herbicides has developed to the stage where many growers are now again heavily reliant on pre-emergent herbicides as the foundation of weed control programs. This is especially the case with annual ryegrass.

During this timeframe we have also seen a change in farming practice. Most paddocks now have zero or minimum tillage, with implications for the position of weed seeds in the soil and the ability to incorporate pre-emergent herbicides.

These factors have resulted in the development of ‘incorporate by sowing’ (IBS) technology which allows for ‘grass killing’ herbicides, several of which are toxic to the cereal crop, to be used at planting in crops such as wheat and barley.

To achieve acceptable weed efficacy with minimal crop injury, users benefit from understanding the chemical properties of pre-emergent herbicides and how they interact within their micro-environment.

This paper discusses the main factors affecting pre-emergent herbicide availability, the importance of correct positioning of herbicide in the soil, and how to avoid carryover and crop damage the following year.

From 2020, numerous new pre-emergent herbicides will become available to Australian grain growers. Understanding the factors that influence pre-emergent herbicide availability will enable users to better predict how these herbicides will behave in their farming system.

Background information

This GRDC Grains Research Update paper briefly outlines the most important factors that influence pre-emergent herbicide behaviour. Users seeking more information on the behaviour of herbicides are directed to GRDC's Herbicide Behaviour publication. In particular, the publication ‘Soil Behaviour of Pre-emergent Herbicides’ and the associated videos, which expand on the concepts outlined in this paper.

Factors affecting pre-emergent herbicide behaviour and availability

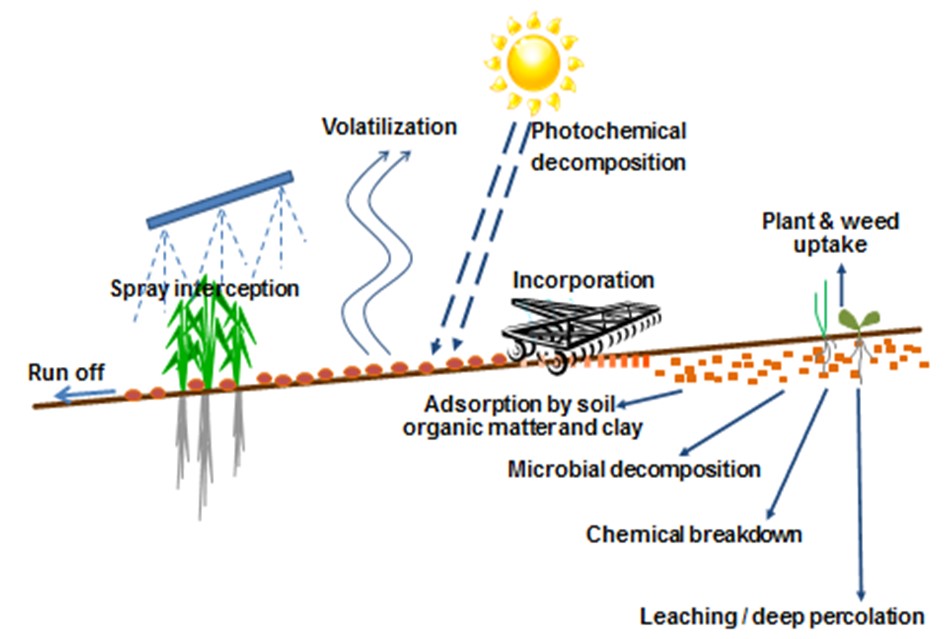

Application of pre-emergent herbicides is targeted at the soil surface, with incorporation by sowing (IBS) or follow up incorporation moving the herbicide into the soil profile, where it is then available for uptake via weed seeds. Many factors influence how herbicides enter the soil and what happens once in the soil (Figure 1).

Figure 1. Key loss pathways for pre-emergent herbicides.

A wide range of pre-emergent herbicides are available for use Australian grain growers. There are significant differences in the chemical properties of these herbicides, so it is important to understand how they differ and the impact on each loss pathway.

Interaction with stubble

Pre-emergent herbicides are typically applied with a standard boom spray, with the target being the soil surface. As would be expected, higher volumes of stubble in the paddock will intercept a greater percentage of the applied spray.

It is important to understand if spray deposited on stubble can be washed off with subsequent rainfall or whether it will be difficult to remove from stubble once it has dried. To predict the ability to wash off stubble we need to understand the herbicide solubility and the absorption (binding) coefficient (Koc). Herbicides such as trifluralin, with low solubility and strong absorption to organic matter, will be almost impossible to remove from stubble after the spray has dried, so herbicide deposited on the stubble is effectively ‘unavailable’ for weed control. At the other extreme, herbicides with very high solubility and very weak binding to organic matter, for example Group B (Acetolactate synthase (ALS) inhibitors), will wash off stubble and into the soil following the next significant rainfall event. Other herbicides fall somewhere in between, depending upon their chemical properties.

Table 1. Relative herbicide affinity for binding to stubble.

Tight binding. | Relatively tight binding. | Low mobility. | Some mobility. | Mobile. |

|---|---|---|---|---|

Won’t wash off stubble after spray has dried. | More difficult to wash off stubble after spray has dried. | Requires significant rainfall to remove from stubble. | Will wash off stubble with adequate rainfall. | Relatively easy to wash off stubble. |

pendimethalin trifluralin | prosulfocarb tri-allate | diuron flumioxazin propyzamide napropamide isoxaben | atrazine simazine terbuthylazine pyroxasulfone | Group B Group I metazachlor s-metolachlor |

Two new pre-emergent herbicides are expected to be available in 2020. Overwatch® (bixlozone) is a Group Q herbicide and Luximax® (cinmethylin) is expected to be initially allocated to Group Z. Based on published chemical properties of these new herbicides, it is predicted that they will most likely be included into the ‘some mobility’ group (Table 1).

Where stubble is no longer standing (for example; knocked down by grazing or chaff lining) this is likely to increase spray interception and further reduce the ability of the herbicide to reach the soil. In these situations, users would be best advised to select a mobile herbicide that will be easier to wash through stubble.

When using pre-emergent herbicides that are less likely to wash off stubble, there are several tactics that can be employed during the spraying operation to reduce the proportion of herbicide captured by stubble. These include:

- Travel with the rows, ideally with a cross breeze.

- Use large (very coarse or greater), solid droplets.

- Reduce nozzle spacing to 25cm.

- Lower boom height as far as practical (double overlap to be maintained at top of stubble, weeds, crop or soil – whichever is highest)

- Narrow fan angle (for example; 65o or80o).

- Travel speed <16km/hr, and/or backward facing nozzles.

- Increase water rates. As a guide, minimum carrier volume of:

- 60L/ha - no stubble.

- 80L/ha - light stubble.

- 100L/ha - moderate stubble.

The use of water sensitive paper to pre-check herbicide deposition on the soil surface is highly recommended.

Loss pathways before entering the soil – photodegradation and volatilisation

Some herbicides are subject to degradation by ultra-violet light on the soil surface prior to incorporation. This can be a significant loss pathway for certain herbicides particularly when applied to no-till fallows in summer. However, when applied in autumn prior to planting winter crops and incorporation follows soon after application, this loss pathway is generally not significant.

Certain herbicides can be subject to losses from volatilisation, as some of the applied herbicide may transition into a gaseous phase after the spray has dried and then be lost to the atmosphere. While there are many factors that affect the rate at which volatilisation occurs, it is often useful to look at the vapour pressure of the herbicide as this can show relativity between herbicides. As a general principle, the higher the vapour pressure, the more urgent it is to have the herbicide incorporated into the soil before losses become significant. Volatility losses from herbicides with a vapour pressure below 1mPa @ 20-25oC is generally insignificant.

Table 2. Published vapour pressure of pre-emergent herbicides commonly used in grains production.

Herbicide | Vapour Pressure (mPa @ 20 or 25oC) |

|---|---|

tri-allate | 12 |

trifluralin | 9.5 |

cinmethylin | 8.1A |

s-metolachlor | 3.7 |

pendimethalin | 3.3 |

prosulfocarb | 0.79 |

flumioxazin | 0.32 |

napropamide | 0.22 |

terbuthylazine | 0.152 |

most other pre-ems used in Australian grain crops | Less than 0.1 |

(Source: Pesticide Properties Database)

A Luximax® Public Release Summary)

Of the pre-emergent herbicides used in grain crops, trifluralin is the most sensitive to losses due to volatility. Trifluralin has a relatively high vapor pressure, very low solubility and tight binding to soil and organic matter. This means that rainfall is not useful for incorporation and trifluralin requires mechanical incorporation soon after application.

The rate of trifluralin loss prior to incorporation is difficult to quantify, as there are many factors that influence this (Table 3).

Table 3. Factors influencing trifluralin volatility loss.

Conditions where losses are minimal | Conditions increasing speed of loss and reducing length of residual control |

|---|---|

|

|

It is important to understand that where volatility losses are significant, they may not be noticed via compromised weed control in the immediate weeks after application. Often, ‘enough’ herbicide will still make it into the soil to achieve weed control for the first few weeks after application. Excessive losses to volatility prior to incorporation are most likely to be expressed as a shorter effective residual life of the herbicide.

Achieving weed control and crop selectivity

Most herbicides effective against annual ryegrass can be toxic to winter cereal crops should the herbicide be taken up by the crop. It is important that the herbicide is positioned where it will come into contact with the weed seed, but not into contact with the cereal crop seed and/or emerging shoot/roots. To provide weed control and crop safety we need to understand herbicide mobility in the soil and the positioning of herbicide in relation to the weed and crop seeds.

Mobility in the soil

Mobility in the soil depends on the herbicide solubility and the absorption (binding) coefficient (Koc), soil texture and the level of soil moisture.

Herbicides with low solubility and strong binding to soil and organic matter (i.e. high Koc value) will tend to remain close to the soil surface. These herbicides are well suited to IBS application, in that the herbicide can be physically positioned away from the crop seed and will largely remain close to where it was incorporated (see section to follow on IBS). While this improves crop safety, it also means that the less mobile herbicides will not control weed seeds germinating in the crop row where the herbicide has been physically removed from the planting line.

Conversely, more mobile herbicides (high solubility, low Koc value) will be primarily positioned with the soil moisture and will move both horizontally and vertically in the soil profile with soil water movement. Rainfall after application will distribute these herbicides more widely in the soil, including potentially around the crop seed, with crop injury often observed when this occurs.

Table 4. Herbicide mobility in the soil.

Tight binding. | Relatively tight binding. | Low mobility. | Some mobility. | Mobile. |

|---|---|---|---|---|

pendimethalin trifluralin | prosulfocarb tri-allate | diuron flumioxazin propyzamide napropamide isoxaben | atrazine simazine terbuthylazine pyroxasulfone | Group B Group I metazachlor s-metolachlor |

Will stay relatively close to soil surface (unless physically moved, or excessive rainfall soon after application). Suits IBS (incorporate by sowing) with tines. | Will move horizontally and vertically with soil moisture. More likely to come in contact with the crop seed = higher potential for crop injury. | |||

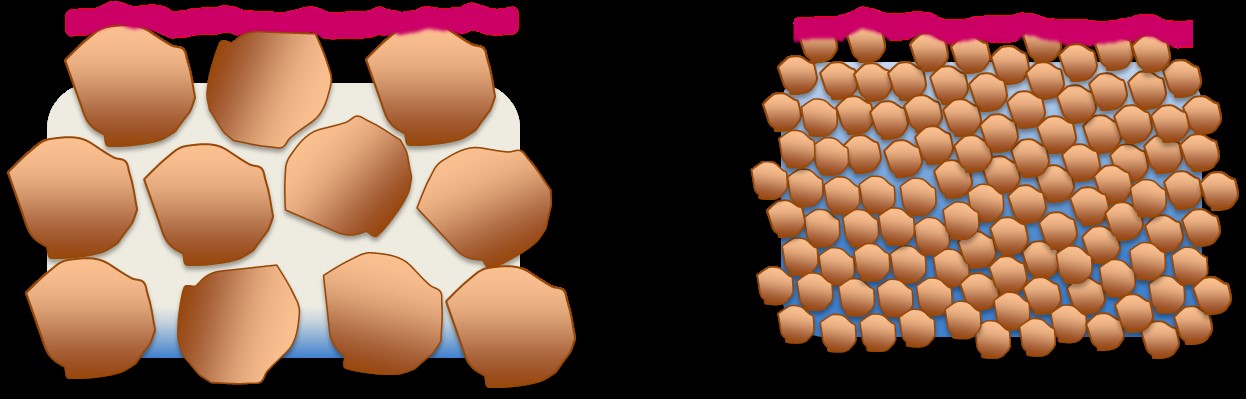

Soil type/texture and soil moisture also influence movement in the soil. ‘Heavy’ soils, or soils with high organic matter, have more physical binding sites and smaller air spaces between soil particles. This means that any herbicide movement is likely to be less in these soil types. Whereas in ‘light’ or ‘sandy’ soils, it is likely that all herbicides may move further than in a heavier soil. Risk is higher when heavy rainfall occurs soon after application in a light soil.

Figure 2. Lighter soil types (left) have more air spaces between soil colloids, resulting in greater potential for herbicide movement and less binding. Herbicide movement will be less on heavier soil types (right).

Where the herbicide is applied to a dry soil profile and there is a significant rainfall event after application, all herbicides are likely to move further than expected with a wetting front that is moving quickly down the soil profile. Conversely, if the soil moisture profile is relatively ‘full’ at application, herbicide movement is likely to be slower following the incorporating rainfall; allowing more time for soil binding to reach an equilibrium.

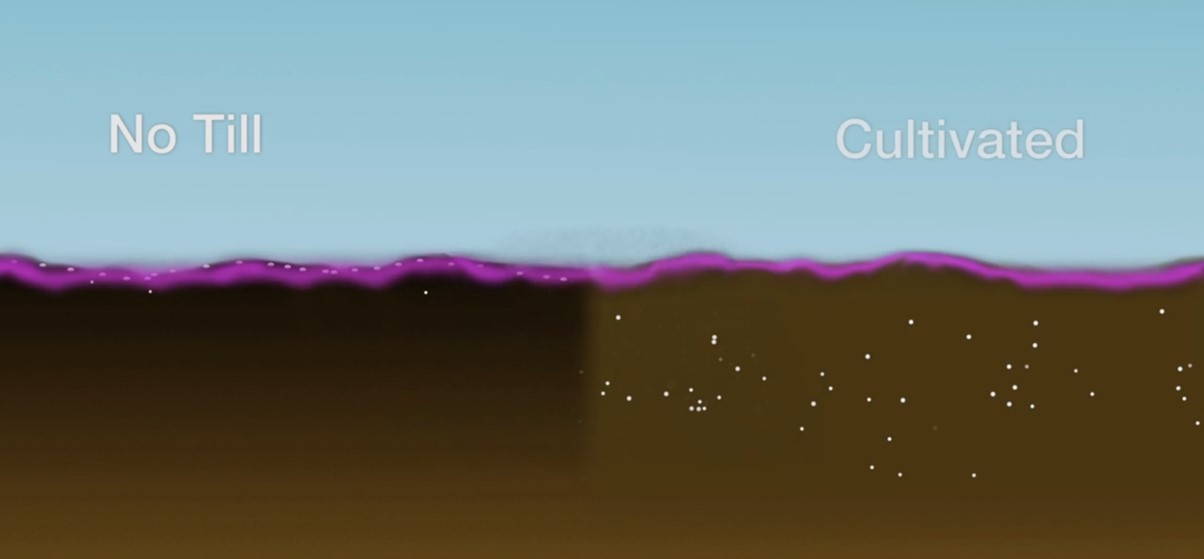

Where are the weed seeds?

Where zero till farming is practiced, it is likely most of the grass weed seeds will be very close to the soil surface (Figure 3). This is important for effective weed control when using immobile herbicides that are incorporated via the IBS technique. With IBS application, herbicide treated soil in the planting line is thrown into the interrow (see section to follow on IBS) leaving an area of ‘untreated’ soil along the planting line in which the crop can emerge. Where the weed seeds are on the soil surface, these will also be thrown out of the planting line with a correctly setup tine seeder.

Figure 3. Location of weed seeds in the soil profile (weed seeds represented by dots).

Where a paddock has been cultivated in recent years, it should be expected that weed seeds will be distributed throughout the soil to the depth of tillage. Should an immobile herbicide be used, and a tine seeder used to throw the herbicide away from the planting line, then it is likely that weed seeds at the bottom of the planting furrow will establish along the planting row.

Crop and weed physiology

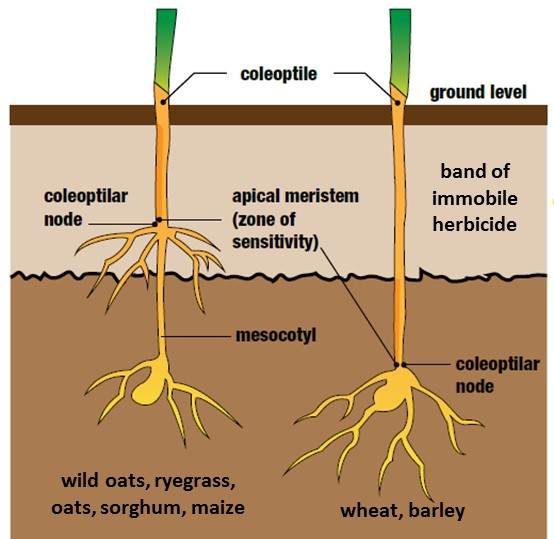

The ability to use the IBS technique in winter cereals is further enhanced by the differences in crop physiology between wheat and barley and other grass weeds (Figure 4)

Figure 4. Differences in mesocotyl elongation is important for herbicide separation in wheat and barley (Adapted from Hall, Beckie & Wolfe (1999). How Herbicides Work)

With most grass weeds (and some grass crops) the mesocotyl elongates during germination, pushing the herbicide sensitive coleoptile node and secondary roots towards the surface, and into the zone of herbicide (Figure 4). The mesocotyl does not elongate in wheat and barley, thus keeping the coleoptile node lower in the soil profile and allowing for vertical separation from the immobile herbicide at the soil surface.

Principals of IBS application of immobile herbicides

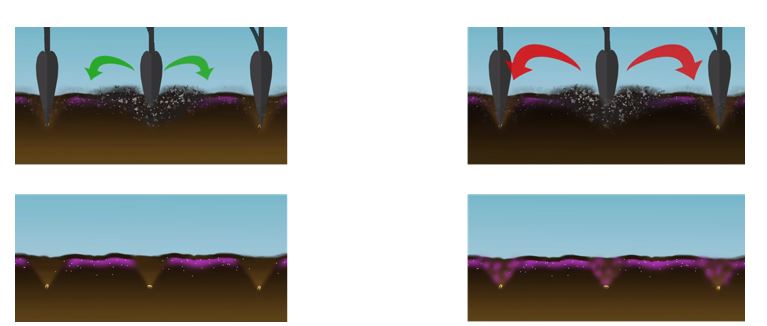

Australia has developed the IBS application technique using knife points and press wheels (Figure 5), to allow relatively immobile ‘grass killing’ herbicides to be positioned away from the wheat or barley crop. This technique relies on:

- Weed seeds being close to the soil surface, and therefore also thrown into the interrow with the pre-emergent herbicide.

- Seeder setup and soil conditions that ensure herbicide treated soil is thrown from the planting line, yet not into the adjacent crop row.

This requires close attention to seeder setup, and this should be carefully monitored and adjusted during planting with changes to soil type, level of stubble and soil moisture.

Figure 5. Correct IBS using knife points (left) removes herbicide treated soil and weed seeds from the planting line. Excessive soil throw (right) can result in unacceptable crop damage.

Herbicide persistence

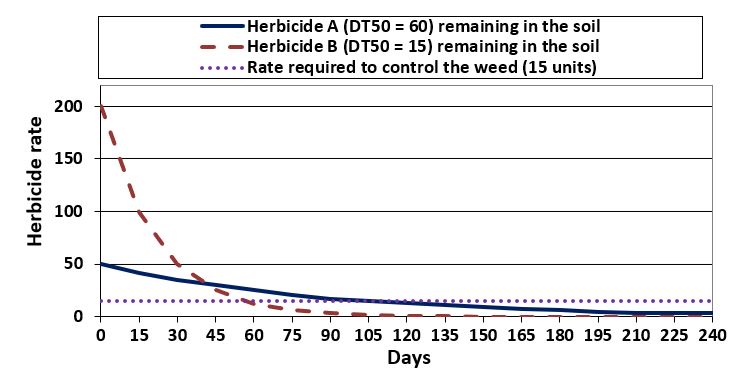

Persistence in the soil varies considerably between different herbicides. The length of persistence is a function of the speed of degradation and the application rate.

Understanding the herbicide half-life in the soil is useful in predicting length of control and likelihood of carry-over issues the following season. Herbicide half-life is normally presented as an average and a range of DT50 values (days of time for 50% of the herbicide to dissipate) when measured across several trials, environmental conditions and soil types.

Table 5. Comparison of half-lives (DT50) of certain pre-emergent herbicides.

Average DT50 | Classification | |||

|---|---|---|---|---|

< 30 | Non-persistent | Unlikely to have plant back constraints the following year. To achieve extended residual, relatively high application rates are required. | metazachlor | prosulfocarb |

imazamox | flumioxazin | |||

s-metolachlor | pyroxasulfone | |||

terbuthylazine* | ||||

30 to 100 | Moderate | Plant-back constraints likely to be required. Often there is considerable variability on different soil types and under different climatic conditions | chlorsulfuron* | clopyralid |

tri-allate | cinmethylin | |||

propyzamide | atrazine* | |||

napropamide | diuron | |||

picloram | simazine* | |||

imazapyr! | bixlozone | |||

>100 | Persistent | Long re-cropping intervals will exist to sensitive crops. | pendimethalin | isoxaben |

trifluralin | imazapic! | |||

* Persistence extended in alkaline soils; !Persistence extended in acidic soils.

Herbicides with an average DT50 of < 30 days are generally considered to be relatively non-persistent and usually have minimal plant-back constraints the following season. In order for these ‘non-persistent’ herbicides to be able to provide weeks/months of residual control, the application rate typically needs to be very high in relation to what is required to kill the weed, as they will be quickly breaking down over time (Figure 6).

Herbicides with longer half-lives (higher DT50 values) will typically provide longer, but often more variable persistence. These herbicides are likely to have plant-back constraints on the label.

Figure 6. Comparison in the length of persistence (days) of short persistent herbicide (DT50 = 15 days) and a moderate persistent herbicide (DT50 = 60 days).

Herbicide breakdown

A small number of herbicide groups have non-microbial degradation pathways that significantly contribute to herbicide breakdown. Hydrolysis is typically the primary pathway in the degradation of sulfonylurea and triazine herbicides. For these herbicides, the hydrolysis reaction requires adequate soil moisture and a neutral or acidic soil pH. As soil pH becomes more alkaline, the speed of this hydrolysis pathway slows and may stop completely. Should hydrolysis stop, the slower microbial breakdown becomes the degradation pathway for these herbicides.

The primary degradation pathway for most herbicides is microbial degradation. Sustaining soil microbe populations requires;

- Organic carbon (stubble) as a food source,

- oxygen (for aerobic species),

- a neutral pH (preferable),

- suitable temperature (not limiting in spring/summer), and

- moisture.

As a result of these requirements, microbe numbers are usually highest in the top 10-15cm and rapidly decline further down the soil profile. Microbial numbers respond rapidly to temperature and soil moisture. In cold winters, little microbial activity will occur, regardless of soil moisture. In spring/summer, very high microbial activity is likely if there is moisture in the soil profile. Where the soil is dry, microbial activity is reduced and minimal herbicide breakdown will be occurring.

Highly mobile herbicides, with moderate to long persistence, (for example, some Group B and Group I herbicides) typically cause the most problems in terms of carry-over in following seasons. This can be made worse if there is a soil impediment at depth that prevents the herbicide from leaching right through the soil profile (for example; a plough pan, significant change in soil texture or pH).

In this situation, the mobile herbicide will disperse through the soil profile with in-season rainfall. If there is a soil impediment at depth, some herbicide will concentrate above this impediment. Rainfall over the following spring/summer will sustain microbial populations near the soil surface and this will degrade herbicides residues near the surface, however herbicide lower in the profile may not be fully degraded due to low levels of microbial activity at depth. Where a sensitive crop is planted the following season it often establishes well, providing the herbicide residue in the planting zone has fully degraded. Crop effects are then seen later in the crop as roots reach the herbicide remaining at depth.

Herbicides with residual soil activity and the capacity to affect subsequent crops have recommendations on their label on recommended intervals before re-cropping. More advanced labels also have information on the amount of rainfall required during this period to reduce the risk. Understanding that these intervals and rainfall requirements are linked with microbial degradation, it is clear to see that the pattern of rain within this period can also influence the level of microbial degradation. Prolonged periods of drought/dry conditions, interspersed with short periods of very wet conditions, particularly when it is cool, could meet label requirements for herbicide breakdown., However this may not allow adequate microbial activity for herbicide breakdown to safe levels to occur.

Enhanced microbial degradation

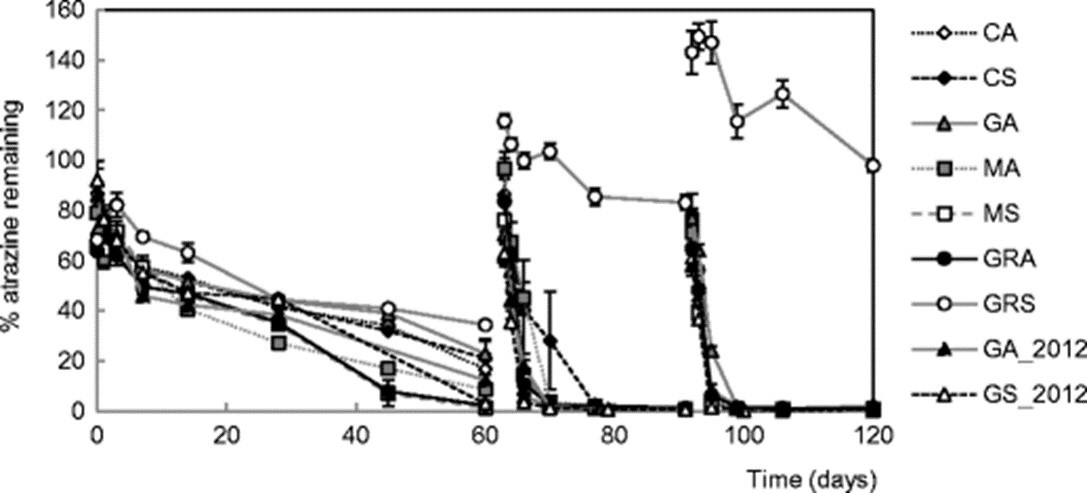

Where multiple applications of the same herbicide are made in the same paddock, the microbial species that degrade that herbicide may build up in numbers which leads to the faster degradation of subsequent applications (Figure 7). While this is likely to reduce carry-over problems the following year, it will also result in substantially reduced length of weed control.

Figure 7. Atrazine applied three times to a range of soils that had no history of triazine use for at least five years prior to the first application. (Source: Yale et al. (2017)).

2020 and beyond

Grain growers have access to a wide range of very useful pre-emergent herbicides with more herbicides to come to market in the next few years. Understanding the chemistry of these herbicides is important to understand how to best use these products in your soils and farming system.

It is likely that Sakura®, Boxer®Gold/prosulfocarb, propyzamide, trifluralin and tri-allate will continue to underpin many ryegrass management programs in winter grain crops for the foreseeable future.

Three ‘new’ pre-emergent herbicides for grains were introduced in 2017 to 2018. Two of these herbicides; Butisan® (metazachlor) and Devrinol® (napropamide) are Group K herbicides targeting ryegrass in canola. While the third; Gallery® is a unique Group O herbicide that targets wild radish in wheat, barley and triticale.

Two new pre-emergent herbicides targeting annual ryegrass are expected to be available in 2020. Overwatch® (bixlozone) is from the seldom used Group Q mode of action and will be registered for use in wheat, barley and canola. Luximax® (cinmethylin) is registered for use in wheat and will be initially placed into Group Z.

Three to six other pre-emergent herbicides are currently being evaluated in field trials (mostly from existing modes of action) and some of these are likely to come to market in the next two to five years.

With several new ‘tools’ being added to the pre-emergent ‘toolbox’ it presents a great opportunity for growers and their agronomists to rethink their herbicide rotation plans. Where possible, incorporate as many different pre-emergent herbicides as possible into a five-year cropping rotation and avoid using any herbicide more than twice in a five-year period. This will reduce the potential selection for herbicide resistance, while also reducing the likelihood of enhanced microbial degradation.

Conclusion

The chemical properties of pre-emergent herbicides play a significant role in determining herbicide persistence and mobility in the soil. In particular, an understanding of the herbicide’s solubility, propensity to bind to soil and organic matter (Koc), half-life (DT50) and losses from photolysis or volatility will assist in predicting how the herbicide will perform in the field in relation to weed control, crop safety and carry-over.

An understanding of the chemical properties helps users to select herbicide(s) that are most appropriate for their soil type and prevailing weather conditions. These properties will also guide the need for crop and herbicide separation and the best strategies to achieve this.

Herbicide degradation, and potential carry over to following seasons is most likely to be dictated by microbial activity in the soil and the climatic conditions supporting this activity.

With several new pre-emergent herbicides becoming available in the next few years, now is an extremely important time to revisit long-term herbicide rotation plans and develop programs that incorporate all appropriate pre-emergent options. Reducing overuse of any single mode of action should delay herbicide resistance, while also providing better weed control by avoiding accelerated microbial degradation.

Acknowledgements

The research undertaken as part of this project is made possible by the significant contributions of growers through both trial cooperation and the support of the GRDC, the author would like to thank them for their continued support.

Useful resources

GRDC: Herbicide behaviour

GRDC: Soil behaviour of pre-emergent herbicides in Australian farming systems: a reference manual for agronomic advisers

GRDC: Rotational crop constraints for herbicides used in Australian farming systems

References

APVMA (2019) Public Release Summary – Luximax® Herbicide

APVMA (2019) Public Release Summary – Overwatch® Herbicide

Hall, Beckie & Wolfe (1999). How Herbicides Work. Biology to Application.

Yale et al. (2017) Microbial changes linked to the accelerated degradation of the herbicide atrazine in a range of temperate soils.

Contact details

Mark Congreve

Independent Consultants Australia Network

0427 209 234

mark@icanrural.com.au

@congreve_mark

GRDC Project Code: ICN1811-001SAX,

Was this page helpful?

YOUR FEEDBACK