Maintaining profitable farming systems with retained stubble across various rainfall environments

Take home messages

- In 2017, do not let stubble compromise the big things (weeds, disease, and timeliness).

- If the intent is to retain stubble:

- Pro-actively manage the stubble for your seeding system.

- Diversify (add legumes to rotation), deep band nitrogen (N) and manage invertebrates. Mice could also be a major problem.

- For tined seeders, reduce stubble load by mulching, incorporating nutrients, baling, grazing and consider sowing at 15-19 degree angle to previous sown row.

- If stubbles are too thick to sow through, consider strategic late burn, especially before second wheat crop or if sowing canola into large stubbles.

- Early monitoring is essential to see how effective actions are to allow for re-planning.

Background

Following a GRDC review that identified gaps regarding the impact of stubble retention in southern cropping systems, a five year program was initiated by GRDC in 2014. Ten projects comprising 16 farming systems groups and research organisations which include Birchip Cropping Group (BCG), CSIRO, Central West Farming Systems (CWFS), Eyre Peninsula Agricultural Research Foundation (EPARF), FarmLink Research, Hart Field Site group, Irrigated Cropping Council (ICC), Lower Eyre Agricultural Development Association (LEADA), the MacKillop Farm Management Group (MFMG), Mallee Sustainable Farming (MSF), Riverine Plains, SARDI, Upper North Farming Systems (UNFS), Victorian No-Till Farmers Association (VNTFA) and Yeruga Crop Research are currently involved in exploring the issues that impact on the profitability of retaining stubbles across a range of environments in southern Australia. The aim is to develop regional guidelines and recommendations that assist growers and advisers to consistently retain stubbles profitably.In 2016, grain yields have been high across most of southern and south-eastern Australia, with many cereal crops yielding greater than 5t/ha and often up to 8t/ha, which indicates there will be a residual stubble load of 7.5-12t/ha. This paper examines two main management options to deal with high stubble loads (greater than 5t/ha) in 2017, and incorporates many of the main findings from the stubble initiative to date.

Option 1. How to manage stubble if you plan to retain the stubble at all costs

a. Tine =

- Harvest high (greater than 30cm) and mulch or incorporate.

- Harvest low (less than 20cm), use chopper/power spreader to smash and spread straw evenly across swath at harvest or soon afterwards.

- Stripper fronts/harvest high, good diverse rotation.

Option 2. How to manage stubble if you have a flexible approach to retaining stubble

Harvest big crops high, graze, burn, bale straw as necessary to reduce stubble to amounts that sowing equipment can manage. Focus on reducing stubble in paddocks where the stubble is likely to impact the 2017 crop yield, for example, wheat on wheat paddocks.

It has been well documented that to successfully establish a crop into a full stubble retained system requires an integrated management approach incorporating three main stages of stubble management — pre-harvest, post-harvest/pre-sowing, and finally at sowing (refer to References section, Reference 1, 2, 3, 4, 5, 6). During these periods, a series of questions (some outlined below) will need to be addressed by growers to successfully establish a crop (Reference 4).

- What is my preference for tillage system?

- What is my seeding system?

- What is my row spacing and accuracy of sowing?

- What crop will be planted into the paddock in 2017?

- What is the type of crop residue?

- What is the potential grain yield and estimated amount of crop residue?

- Is the crop lodged or standing at harvest?

- What is the desired harvest speed and harvest height?

- How uniform is the spread of straw from my harvester?

- Should I spread residue or place in a narrow windrow?

- Do I have a weed problem which requires intensive harvest weed seed control (HWSC), chaff carts or chutes?

- Will the stubble be grazed by livestock?

- Am I prepared to process stubble further post-harvest — mulch, incorporate, bale?

- If incorporating stubble, should I add nutrients to speed up the decomposition process?

- What is the risk of stubble-borne disease to the 2017 crop?

- Am I likely to encounter a pest problem in 2017 — mice, slugs, earwigs, weevils, snails?

- What is the erosion risk based upon soil type and topography?

- Do I need to burn or what else can I do?

Remember, there is no perfect stubble management strategy for every year. Crop rotations, weeds, disease, pests, stubble loads, sowing machinery and potential sowing problems will largely dictate how stubble should be managed.

Option 1. How to manage stubble if retaining at all costs

A recent survey was undertaken in the Yorke Peninsula (YP) and Mid North of SA which showed that 82% of growers used tined seeders with the remaining 18% using discs (Yeruga Crop Research). The proportion of growers using either disc or tine seeders would be similar to the YP and Mid North areas, although the percentage using tine seeders would be higher in many areas. In relation to establishing a crop in stubble retained systems, the following issues arose:

- About 21% of growers were totally committed to retaining stubbles at all costs while about 79% would consider burning stubbles if absolutely necessary.

- Herbicide efficacy was extremely important (greater than 80% in both tine and disc).

- Managing weeds (approximately 65% both tine and disc).

- Managing slugs and snails (greater than 50% in tine and disc).

- Efficiency and ease of sowing (82% in tine and 58% in disc).

- More important at seeding:

- Straw length (70% tine).

- Chaff fraction (50% disc).

- Hair pinning (15% tine, 84% disc).

Stubble height

Using a stripper front or harvesting high is the quickest and most efficient method to produce the least amount of residue that needs to be threshed, chopped and spread by the combine. Harvesting high (40-60cm) compared to 15cm increased grain yield and combine efficiency by reducing bulk material going through the header and reduced harvests costs by 37-40% (Table 1). As a general rule, there is a 10% reduction in harvest speed for each 10cm reduction in harvest height (Tables 1 and 2, Reference 4, 5, 8). Slower harvest speed across a farm also exposes more unharvested crop to the risk of weather losses (sprouting, head/pod loss, lodging) during the harvest period, and the cost of this is not accounted for in Table 1.Table 1. Harvesting wheat low or high using a JD9770 combine in 2014 (Reference 7). Ground speed was altered to achieve similar level of rotor losses at both harvest heights. Values are means of three replicates and all differences are significant (P<0.05). Operating costs determined at $600/hr.

| Harvest height | Efficiency (ha/h) | Speed (km/hr) | Fuel (l/ha) | Yield (t/ha) | Cost $t/ha | Cost $/ton |

|---|---|---|---|---|---|---|

| 60cm | 9.5 | 10.6 | 5.4 | 2.19 | $63.2 | $28.7 |

| 15cm | 5.7 | 6.2 | 9.6 | 2.05 | $105.3 | $50.1 |

| % Change to 15cm | -41% | -42% | +78% | -6% | +40% | +57% |

However, there are some negatives to retaining tall wheat stubble, with several groups in the initiative finding that wheat sown into taller wheat stubble (45cm compared with 15cm) received less radiation and were exposed to cooler temperatures. This can reduce early growth and significantly reduce tiller numbers. In a Riverine Plains experiment in 2014, there was a significant reduction in grain yield (4.98t/ha compared with 5.66t/ha with least signficant difference (lsd) at P<0.05 = 0.45t/ha) in tall compared to short stubble. In 2015, the group found no difference in grain yield. In 2016, significantly less tillers were found in several trials in tall stubble, however in all of these trials, this did not result in any difference in grain yield.

Table 2. Harvesting wheat low or high using a Case 8230 combine with a 13m front in 2015 (Reference 7). Ground speed was altered to achieve similar level of rotor losses at both harvest heights. Operating costs determined at $600/hr.

| Harvest height | Efficiency (ha/h) | Speed (km/hr) | Fuel (l/ha) | Harvest efficiency (t/hr) | Grain Yield (t/ha) | Cost $/ha | Cost $/ton |

|---|---|---|---|---|---|---|---|

| 40cm | 12.0 | 8.5 | 6.6 | 45 | 3.8 | $50.0 | $13.5 |

| 15cm | 7.5 | 6.0 | 10.6 | 30 | 3.9 | $80.0 | $20.2 |

| % Change to 15cm | -38% | -29% | +61% | -33% | ns | +37% | +33% |

(ns = no significant difference).

In 2016, like many previous years, herbicide resistant weeds, especially annual ryegrass (ARG) continue to be a problem. HWSC which includes narrow windrow burning, chaff carts, chaff lining, direct baling, and mechanical weed seed destruction is an essential component of integrated management to keep weed populations at low levels and thus slow the evolution and spread of herbicide resistance. HWSC requires crops to be harvested low in order for weed seeds to be captured in the chaff fraction from the combine, and if practiced provides an additional reason to harvest low. The prototype Integrated Harrington Seed Destructor (iHSD) was tested in Temora, NSW in December 2015, Inverleigh in December 2015 and Furner, SA in January 2016 at a constant speed of 4km/hr to compare the efficiency and cost with non-weed seed destruction methods (Table 3). The three large scale field trials in both states are being monitored for changes in ARG populations before and after sowing between 2015 and 2018.

Table 3. A Case 9120 harvesting wheat conventionally at 30cm, harvesting at 15cm for baling or narrow windrow burning and harvesting at 15cm with a prototype iHSD at Furner, SA in 2016 (data supplied by GRDC project SFS00032).

| Harvest height | Grain yield (t/ha) | Speed (km/hr) | Engine Load (%) | Fuel (l/ha) | Fuel efficiency (l/hr) | |

|---|---|---|---|---|---|---|

| Conventional Harvest - Burn | 30cm | 4.7 | 3.8 | 59.8 | 14.3 | 52.7 |

| Windrow Bale/burn | 15cm | 4.6 | 4.0 | 65.5 | 16.4 | 59.5 |

| iHSD | 15cm | 4.6 | 4.0 | 88.7 | 22.7 | 87.7 |

| Isd @ P<0.05) | ns | ns | 2.26 | 1.36 | 2.18 | |

| % Change to 15cm | +9% | +11% | +11% | |||

| % Change to iHSD | +33% | +37% | +40% |

In 2016, there has been less opportunity to harvest cereal crops very high in many areas due to lodged or leaning crops and variable head heights. Cereal crops such as Compass barley often lodged badly, resulting in the need to harvest very low.

Mulch and incorporate

Lightly incorporating the stubble into the surface soil using a disc chain or disc machine (for example, Speed tiller, Grizzly, Amazone Cattross, Vaderstad Topdown or Lemken Heliodor) soon after harvest while the stubble is higher in nutritional value is another option for growers wanting to maintain all of their stubble, especially where a tine seeder is the primary sowing implement, or where lime and stubble needs to be incorporated into the soil in a disc-seeding system. On the lighter sandier soils in SA, the recommendation would be to delay incorporation until 3-4 weeks before seeding as these soils are more prone to wind and water erosion. Mulching and incorporation require soil moisture, warm soil temperature, soil/stubble contact and nutrients to convert a carbon rich feed source into the humus fraction. Early mulching and incorporation allows time for the stubble to decompose and immobilise nitrogen (N) well before sowing, reducing the likelihood of reduced N availability.

When trying to decompose a large quantity of stubble in a short period of time it may be beneficial to add some nutrients to the stubble prior to incorporation. To assist in minimising the amount of fertiliser required to add to the stubble, determining the concentration of the nutrients in the stubble is important. As humus is so nutrient rich and the stubble residues are relatively nutrient poor, only a small proportion of the total carbon in the crop residues can be converted into humus. Dr Clive Kirkby has found that a maximum of 30% of the total carbon from stubble residues could be converted to humus, so recommends setting the humification rate at 20% rather than 30%. In our example (Table 4), the quantity of fertiliser (sulphate of ammonia) that would need to be applied to the 10t/ha residual cereal stubble load where the stubble had a nutrient concentration of 0.7%N, 0.1%P and 0.1%S and the grower wanted a humification rate of 20% would be 33.1kg/ha of N and 7kg/ha of sulphur at an estimated cost of $14.9-/ha for nutrients only (Table 4). In contrast, if a grower was trying to build up the organic carbon concentration in the soil from this stubble residue to the maximum possible amount (30% humification rate), the quantity of nutrients required increases to 45.4kg N/ha, 3.8kg P/ha and 7.6kg S/ha, at a cost of $74.40 for nutrients (Table 5). The nutrients applied are not lost, but should form a source of slow release nutrition to the following crop as humus while avoiding ’nutrient tie-up’ caused by late incorporation of nutrient poor residues. Thus, later inputs could potentially be reduced if costs were of a concern.

Table 4. A snapshot of Dr Clive Kirkby’s stubble nutrient humification calculator to estimate the amount of fertiliser (N:P:S) as sulphate of ammonia (kg/ha) that would need to be applied to a cereal stubble load of 10t/ha with a humification rate of 20% to assist in rapid breakdown of the residual stubble.

| Kirkby's Nutrition Calculator | C | N | P | S | |

|---|---|---|---|---|---|

| Stubble load (kg/ha) | 10000 | ||||

| Humification required (%) | 20 | ||||

| Stubble nutrient concentration (%) | 45.0 | 0.700 | 0.100 | 0.100 | |

| Nutrients already in stubble (kg/ha) | 4500 | 70 | 10 | 10 | |

| Carbon to be humified & nutrients required (kg) | 900 | 77.0 | 9.2 | 11.7 | |

| Carbon remaining (kg) | 3600 | ||||

| Extra nutrients required (kg/ha) | 7.0 | -0.8 | 1.7 | ||

| 1. Fertiliser type and Nutrient concentration (%) | SOA | 21.0 | 24.0 | ||

| 2. Fertiliser type and Nutrient concentration (%) | |||||

| Fertiliser required to supply exact nutrients (kg/ha) | 33 | 7 | |||

| Fertiliser cost ($/ha) | $14.9 | ||||

| Fertiliser and spreading cost ($/ha) | $23.4 | ||||

(Financial support provided by NIEI, EH Graham Centre, CSIRO and GRDC project, DAN00152)

Table 5. A snapshot of Dr Clive Kirkby’s stubble nutrient humification calculator to estimate the amount of fertiliser (N:P:S) as urea and Superphosphate (kg/ha) that would need to be applied to a cereal stubble load of 10t/ha with a humification rate of 30% to assist in more rapid breakdown of the residual stubble.

| Kirkby's Nutrition Calculator | C | N | P | S | |

|---|---|---|---|---|---|

| Stubble load (kg/ha) | 10000 | ||||

| Humification required (%) | 30 | ||||

| Stubble nutrient concentration (%) | 45.0 | 0.700 | 0.100 | 0.100 | |

| Nutrients already in stubble (kg/ha) | 4500 | 70 | 10 | 10 | |

| Carbon to be humified & nutrients required (kg) | 1350 | 115.4 | 13.8 | 17.6 | |

| Carbon remaining (kg) | 3150 | ||||

| Extra nutrients required (kg/ha) | 45.4 | 3.8 | 7.6 | ||

| 1. Fertiliser type and Nutrient concentration (%) | Urea | 46.0 | |||

| 1. Fertiliser type and Nutrient concentration (%) |

Single super | 8.8 | 11.0 | ||

| Fertiliser required to supply exact nutrients (kg/ha) | 99 | 43 | 69 | ||

| Fertiliser cost ($/ha) | $74.4 | ||||

| Fertiliser and spreading cost ($/ha) | $82.9 | ||||

(Financial support provided by NIEI, EH Graham Centre, CSIRO and GRDC project, DAN00152)

In an experiment at Harden, NSW between 2008 and 2011, Dr Kirkby incorporated between 8.7 and 10.6t/ha of cereal or canola stubble without nutrients or with nutrients at a humification rate of 30%. In May 2009, following the incorporation of 8.7t/ha wheat stubble in February 2009, they measured the quantity of wheat stubble that had broken down and found that only 24% of the stubble remained where nutrients had been added, whereas 88% remained where the stubble had been incorporated only (Kirkby et al. 2016). A couple of groups (Riverine Plains, MFMG) have included light incorporation (+/- ) nutrients in their treatment mixes. Although no group specifically examined residue breakdown, they found that the cultivated (+ nutrient) treatment often yielded the same or more than the cultivated (no added nutrient) treatment. In other words, wheat grain at Yarrawonga January 2017 in Cultivate +40kgN/ha = 6.7t/ha compared to Cultivate only = 5.9t/ha, lsd = 0.58).

Diverse cropping sequence

A diverse cropping sequence provides many benefits for growers wanting to retain all their stubble annually. Diversity allows each crop to be sown into a less antagonistic stubble by reducing physical, disease, pest and weed constraints.

A fully phased systems experiment was established in Temora in 2014 at a site with high levels of Group B resistant ARG to examine if a diverse crop rotation (Sustainable - vetch hay-TT canola-wheat-barley) could improve the profitability of stubble retained no-till (Flexi-Coil tine seeder with Stiletto knife points and deep banding and splitting boots) and zero-till (Excel single-disc seeder with Aricks wheel) systems. Three cropping systems (Aggressive, Conservative and Sustainable) were compared with the rotations for each as Aggressive (RR canola-wheat-wheat), Conservative (TT canola-wheat-wheat) and Sustainable (vetch hay-TT canola-wheat-barley). In the cereal crops in the Aggressive and Sustainable systems, new-generation pre-emergent herbicides (Sakura® and Boxer Gold®) were used for grass weed control. In the Conservative system, trifluralin and diuron were used for grass weed control in the tine system, and diuron alone in the disc system.

The introduction of diversity in the Sustainable system has allowed it to achieve a net margin ($512/ha/year) which is higher than in the Aggressive systems ($498/ha/year) and at lower cost ($465 compared with $517/ha/year) and thus higher profit:cost ratio ($1.12 compared with $0.98) (Table 6). The reduced costs in the Sustainable system are driven by lower fertiliser N inputs from the inclusion of vetch hay, which requires no fertiliser N itself and provides residual N for subsequent crops. The barley phase of the Sustainable system has also been more profitable than the second wheat crop in either the Aggressive or Conservative system (Table 6), despite record low barley prices in this 2016/17 season.

Table 6. Average net margins (EBIT) — effect of crop strategy at Temora, NSW between 2014 and 2016.

| Cropping System | Crop Type | Average total cost (2014-16) | Average Net Margin 2014-16 | Average 3yr Profit:Cost ration |

|---|---|---|---|---|

| ($/ha/yr) | ($/ha/yr) | ($/ha/yr) | ||

| Aggressive | Canola RR | $524 | $722 | 1.4 |

| Aggressive | Wheat (yr 1) | $525 | $378 | 0.7 |

| Aggressive | Wheat (yr 2) | $504 | $394 | 0.8 |

| Conservative | Canola TT | $452 | $694 | 1.5 |

| Conservative | Wheat (yr 1) | $415 | $289 | 0.7 |

| Conservative | Wheat (yr 2) | $419 | $261 | 0.6 |

| Sustainable | Vetch (hay) | $463 | $416 | 0.9 |

| Sustainable | Canola TT | $426 | $769 | 1.8 |

| Sustainable | Wheat | $492 | $422 | 0.9 |

| Sustainable | Barley | $478 | $441 | 1.0 |

| System averages | ||||

| Aggressive | $517 | $498 | 0.96 | |

| Conservative | $429 | $415 | 0.95 | |

| Sustainable | $465 | $512 | 1.12 | |

The Riverine Plains group compared a wheat-faba bean-wheat rotation against a wheat-wheat-wheat (+/- burning) and found there was no significant difference in wheat yield following wheat stubble that was retained or burnt (average 3.42t/ha), but there was a 2t/ha increase in wheat yield following faba beans. The wheat stubble also acted as a trellis, assisting to keep the beans off the ground and improve airflow and the higher N concentration following the bean crop combined with the increased decomposition of the wheat stubble resulted in the bean crop ’resetting’ the system and burning was not required. Similar findings have been observed by the Hart Field Site group in relation to lentils, using the wheat stubble as a trellis. Earlier maturing varieties such as Blitz were found to be taller with increasing stubble height (30 and 60cm stubble height compared with 15cm or baled). They also found that the type of stubble was important for the following crop with wheat maintaining its supportive structure better than barley.

Establishing crops with disc and tine seeders

It has been well documented that a disc seeder can handle higher stubble loads in comparison to a tine seeder, have less variability in seeding depth and higher sowing efficiencies than a tined seeder. Over the three year trial at Temora, there has been little difference in the net margin of either the disc or tine openers where ARG was effectively controlled by pre-emergent herbicides in the Aggressive and Sustainable cropping systems. However, in the Conservative system, the combination of trifluralin and diuron was able to achieve a reasonable ARG control in the tine system, but diuron alone was largely ineffective in the disc system, and this has reduced yields and profit in this system (Table 7).

Table 7. Average net margins across all crop types for each crop system by opener type between 2014 and 2016 at Temora, NSW.

| Net Margins 2014 ($/ha) | Net Margins 2015 ($/ha) | Net Margins 2016 ($/ha) | Average Net Margins 2014-2016 ($/ha/yr) | Profit:Cost ratio 2014-2016 | ||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Tine | Disc | Tine | Disc | Tine | Disc | Tine | Disc | Tine | Disc | |

| Aggressive | $424 | $422 | $569 | $591 | $533 | $449 | $508 | $487 | $0.98 | $0.94 |

| Conservative | $441 | $171 | $540 | $463 | $537 | $336 | $506 | $323 | $1.14 | $0.75 |

| Sustainable | $488 | $493 | $520 | $525 | $552 | $495 | $520 | $504 | $1.14 | $1.10 |

Southern Farming Systems have been comparing the advantages of establishing crops with a disc and tined seeder over the past three years. They found that although there was no significant difference in wheat yield at the 95% confidence level (0.5t/ha increase in yield at the 90% confidence level), there were significant improvements in efficiencies in the disc system with quicker sowing, quicker harvesting (harvest high) and fuel savings in 2015 (Table 8). It must be remembered that both types of seeders have advantages and disadvantages in different circumstances and the main aim is to establish seed reliably in a wide range of sowing conditions.

Table 8. Cost calculations for sowing efficiency, harvest efficiency and fuel usage in a SFS disc versus tine trial in Victorian HRZ in 2015.

| Sowing | Harvest time | Fuel Usage | |

|---|---|---|---|

| Disc v tine | 4.8km/hr faster* | 1.81 ha/hr faster# | 2.11 L/ha## |

| Value of difference | $210 | +$13.23 | $2.53 |

| (* contract sowing at $45/hr, # increased speed at harvest $400/hr, # fuel @ $1.20L) | |||

Deep banding versus surface applied N at sowing

One mechanism by which large amounts of retained cereal stubble can reduce yields in subsequent crops is through immobilisation of N. Banding N fertiliser either at sowing using a deep-, side- or mid-row banders or in-crop using mid-row banders is a way of separating fertiliser N from high carbon stubble that microbes use as an energy source when immobilising N. In 2016, an experiment was established at Temora on 5.1t/ha of retained wheat stubble where 122kg/ha N as urea was either banded beside and below wheat seed using Stiletto splitting boots, or spread on the soil surface before sowing with the same boots. Starting soil mineral N concentration was 58kg/ha N (0-150cm) and no additional N was applied. By Z30 more N had been taken up by the plant where the N was deep banded (4.3% compared with 3.8%), a pattern which continued with greater plant dry matter (DM)and N uptake at anthesis and higher grain yield (Table 9). However, there was no significant interaction with the presence/absence of stubble, indicating that banding N may improve N use efficiency in all systems (with or without stubble).

Table 9. Wheat (Lancer) emergence, DM, %N in the tissue, N uptake and grain yield where 122kgN/ha was applied at sowing either below the seed using stiletto points or on the surface pre-sowing into either 5.1t/ha of wheat stubble or where stubble was removed at Temora in 2016.

| Pre-sowing Nitrogen Application | Emergence | G530 | G530 | G530 | Anthesis | Anthesis | Grain Yield |

|---|---|---|---|---|---|---|---|

| Plant Dry Matter | Plant nitrogen | Nitrogen uptake | Plant Dry Matter | Nitrogen uptake | |||

| Plants/m2 | (t/ha) | (%N) | (kgN/ha) | (t/ha) | (kgN/ha) | (t/ha) | |

| Deep Surface |

132 137 |

1.4 1.4 |

4.3 3.8 |

60.0 51.6 |

9.2 7.9 |

136.4 102.5 |

5.2 4.1 |

| P value (interaction) Isd (P<0.05) |

0.257 ns |

0.570 ns |

0.016 0.394 |

0.074 ns (9.58) |

<0.001 0.3 |

0.007 17.0 |

0.001 0.43 |

Option 2. How to manage stubble if you have a flexible approach to retaining stubble

There are many reasons why a flexible approach to retaining stubble may be required as there is no perfect stubble management strategy for every year. Crop rotations, weeds, disease, pests, stubble loads, sowing machinery and potential sowing problems will largely dictate how stubble is managed.

A flexible approach to manage stubble means crops can be harvested high or low depending on the season and situation, stubbles can then be grazed with considerable economic advantage, or straw baled and sold, or burnt.

Grazing

For mixed growers, the option to graze the stubble soon after harvest can be quite profitable. In a long term no-till controlled traffic grazing experiment in Temora between 2010-2015 with crop rotation of canola-wheat-wheat, four treatments were compared including a full stubble retention system (nil graze, stubble retain) and a post-harvest grazing of the stubble (stubble graze, stubble retain). Each of these was split to accommodate a late burn pre-sowing (nil graze, stubble burn and stubble graze, stubble burn) (Table 10). All plots were inter-row sown with deep knife points and machinery operations conducted using controlled traffic. Stubble grazed plots were grazed within 2-3 weeks of harvest at approx 300 DSE/ha for five days ensuring greater than 3t/ha remained for soil protection and water retention. All plots were sown, fertilised and kept weed free such that weeds, disease and nutrients did not limit yield. Over seven years, the experiment has shown that there is a $44/ha increase in gross income where sheep were used to graze the stubbles compared to nil grazing if no grazing value was assumed. This increase was related to higher yields and grain quality in subsequent crops driven by greater N availability in the grazed stubble. There was a $159/ha increase if a grazing value for the stubble was assumed (see GRDC paper 2015 Hunt et al. for details).

Table 10. Gross income per year averaged across two phases where stubble was either grazed post-harvest or not, and either burnt just before sowing or retained between 2010 and 2015 at Temora, NSW.

| Gaze treatment | Stubble treatment | Gross income ($/ha/yr) | |

|---|---|---|---|

| Assuming grazed stubble has no value | Assuming grazed stubble has value as per methods | ||

| Nil graze | Retain | $1,153 | $1,153 |

| Burn | $1,179 | $1,179 | |

| Stubble graze | Retain | $1,197 | $1,312 |

| Burn | $1,193 | $1,307 | |

One of the negatives of using a less diverse rotation (canola-wheat-wheat) in a full stubble retained system is that there can be a significant reduction in the grain yield in the second wheat crop (Table 11). This difference is presumably due to lower N availability due to immobilisation in the retained stubble treatment (as establishment was good and weeds, pests and disease were controlled). Similar results were observed in a crop systems experiment where wheat (first wheat) was either sown into canola stubble or into 7.2t/ha wheat stubble (second wheat) in April 2016.

Table 11. Grain yield of wheat and canola sown using deep knife points in two phases between 2009 and 2016 where stubble was either retained or burnt (pre-sowing) at an experiment in Temora, NSW.

| Phase | Stubble Treatment | Grain yield 2009 - 2016 | |||||||

|---|---|---|---|---|---|---|---|---|---|

| 2009 | 2010 | 2011 | 2012 | 2013 (frost) | 2014 | 2015 | 2016 | ||

| 1 | Retain | 1.7 | 4.2 | 4.6 | 4.4 | 0.7 | 3.8 | 4.1 | 3.2 |

| 1 | Burn | 1.7 | 4.0 | 4.6 | 5.0 | 1.0 | 3.8 | 4.6 | 3.2 |

| 2 | Retain | 6.3 | 3.4 | 4.5 | 2.0 | 2.0 | 5.5 | 5.2 | |

| 2 | Burn | 6.2 | 3.5 | 4.8 | 3.4 | 2.0 | 5.3 | 5.7 | |

Note: shaded boxes indicate canola crop.

The wheat was deep banded with 40kgN/ha at sowing in both treatments to assist in supplying N to the crop, however, there was a 0.6-0.8t/ha reduction in wheat yield in the second wheat crop (Table 12). Many growers in the south west slopes also observed decreases in the grain yield of their second consecutive wheat crop compared to wheat sown after canola in 2016 in stubble retained systems.

Table 12. Wheat grain yield in crop following canola (wheat yr 1) compared to second wheat crop at crop systems experiment at Temora, NSW between 2014-2016 in disc and tines x systems.

| Cropping system | Crop | 2016 Disc | 2016 Tine |

|---|---|---|---|

| Aggressive | Wheat (yr 1) | 5.5 | 6.0 |

| Aggressive | Wheat (yr 2) | 4.9 | 5.3 |

| P value = <0.001 | Lsd (P<0.05) | 0.54 | |

Computer applications (Apps) for stubble management

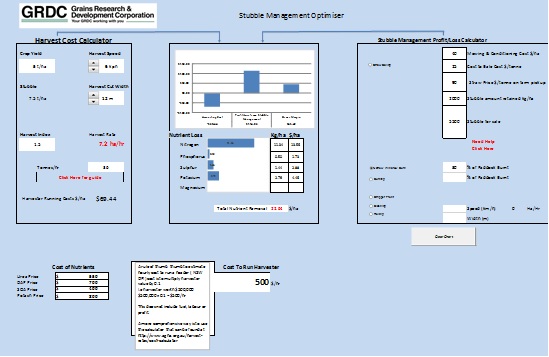

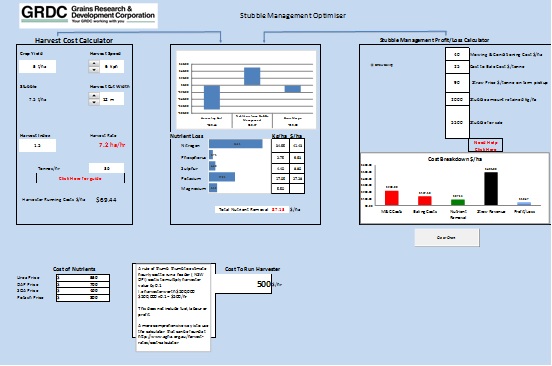

The GRDC Project YCR00003, led by Yeruga Crop Research is finalising a computer/smart phone application (App) which may be of great benefit to growers and consultants. It provides a quick and efficient method to indicate what the benefit or cost could be for different stubble management decisions such as narrow windrow burning, burning or baling a crop to reduce stubble. A couple of examples are highlighted in the following section for narrow windrow burning (Figure 1) and baling (Figure 2) the stubble from a 5t/ha wheat grain crop.

For more information, contact Yeruga Crop Research. The tool was developed by Stefan Schmitt in conjunction with Bill Long, Mick Faulkner, Jeff Braun and Trent Potter.

Figure 1. The estimated effect on profit from harvesting a 5t/ha wheat yield with 7.5t/ha stubble load remaining that is narrow windrow burnt valuing the loss of nutrients.

Narrow windrow burning (NWB) has been practised for several years now and has proven to be an effective tool in reducing weed seeds. One advantage of NWB compared to entire paddock burn is the reduction in nutrients lost from the stubble residue.

The stubble management optimiser indicates that approximately $22.60/ha is lost from the paddock if NWB compared to approximately $76/ha if the entire paddock is burnt (Figure 1). One constraint with narrow windrow burning as AHRI indicated would be the increased risk if the wheat grain yield was greater than 2.5t/ha (> 4t/ha stubble residue). In 2014/15, NWB was successfully undertaken in wheat crops between 3-3.75t/ha with an estimated stubble load of 4.5-6t/ha in the Riverina, NSW (Grassroots Agronomy 2014). Due to the high stubble loads in 2016/17, narrow windrow burning may be restricted to canola stubbles and other lower DM crops. It must be acknowledged that a wet cool autumn can severely reduce the efficiency of burns leading to weed strips in the paddock.

Figure 2. The estimated effect on profit from harvesting a 5t/ha wheat yield with 5.5t/ha of the remaining 7.5t/ha stubble load being baled and sold (valuing the loss of nutrients).

Baling — In many areas across southern Australia, a significant area of stubble has been baled in the 2016/17 season. Baling allows the grower to harvest high and efficiently (use stripper front if possible), and reduce the stubble load in the paddock to minimise problems at sowing. One of the negatives of baling stubble is the loss of nutrients from the paddock. The stubble management optimiser shows the grower the cost to make hay including the cost of nutrient loss (Figure 2).

Pests

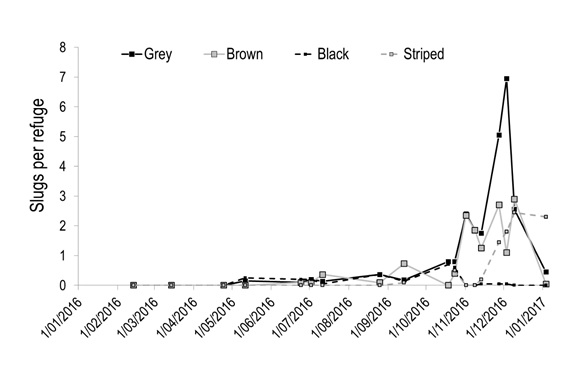

Invertebrate and vertebrate pests will potentially be a major problem in 2017, and may in some cases provide justification for strategic burning and tillage. Snails, slugs, mice and other insect numbers are currently being monitored and the cool wet spring has provided excellent conditions for increased numbers. The large stubble loads and plentiful grain on the ground from shedding and harvest losses are providing an excellent environment for breeding, so this needs to be factored into the equation if retaining stubble in 2017. Monitor mice numbers after harvest and bait as required.

Figure 3. The change in population of four slug species between May 2016 and January 2017 at one site in south west Victoria (GRDC slug ecology project DAS00160).

The wet cool spring in the Victorian HRZ has resulted in an increase in the population of slugs and earwigs pre-harvest. The populations of slugs (Figure 3) and earwigs are expected to pose a greater threat to establishing crops in 2017 (Figure 3). Plan to roll then bait at sowing for slugs, monitoring problem areas and keep baiting if using cheap bran based baits. More information on slug and snail baits may be found here.

Snails

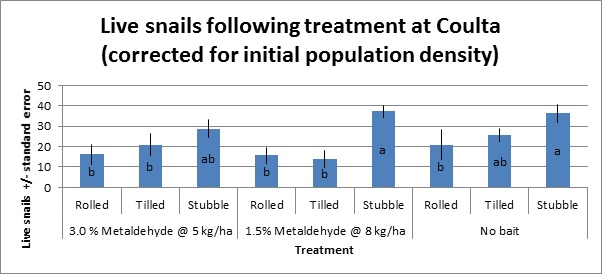

A field trial on the Lower Eyre Peninsula (LEP), SA demonstrated the benefits of using mechanical snail control methods over retaining tall standing stubble — either light tillage or heavy (ribbed) rolling — in conjunction with a baiting strategy (Figure 4). Carried out under optimal conditions (late February, 35°C + and low humidity), the mechanical treatments proved effective to reduce snail numbers initially, whilst also appearing to improve the accessibility of baits applied in March.

Figure 4. Mechanical treatment by baiting experiment in canola stubble at Coulta, Lower Eyre Peninsula, SA.

This project demonstrated a number of key points for the coming growing season. Mechanical rolling, light tillage or cabling in the right conditions (hot and dry) is an effective action which can reduce the breeding population before a crop is present when there is less time pressure from other tasks (Figure 4). Baiting efficacy after this mechanical strategy is likely to be improved, as snails will find the baits easier in a rolled/tilled surface, rather than where tall stubbles remain, providing ’bridges’ for snails over and around baits.

Baiting should not be applied during the same hot, dry conditions as cultural controls. Baiting should commence during moist, cool conditions. The same field trial incorporated time lapse video and micro weather station monitoring to monitor snail activity and found high levels of night time activity where RH went above 85-90%, and feeding during wet periods in early March.

The key with all management strategies is to try to reduce the breeding population prior to reproduction. This research showed snails feeding and increasing sexual maturity during March with egg laying taking place 21 April — prior to the break of season and seeding. Baiting at seeding may be too late where snails have already laid eggs.

For further information: Summer snail activity and control Issue

It is also important to consider using insecticide seed treatments in canola and legumes to suppress or control early seedling pests including earwigs, slaters, aphids, millipedes and earthmites (always adhere to label guidelines).

Herbicide efficiency in retained/burnt stubble systems

Two separate experiements were set up in the EP and LEP to compare the effectiveness of pre-emergent herbicides in stubble retained systems compared with burnt stubble in 2015. In both experiments, cereal crops were harvested low with straw spread evenly across the swath and either retained or burnt late pre-sowing. Standing stubble was also compared at one experiment. Residual stubble load was between 5 to 6.9t/ha. In both experiments there was no significant difference in the effectiveness of Sakura®, Avadex Xtra®, or Boxer Gold® on the emergence of ryegrass post sowing where the spraying water application rates was 100L/ha or higher. An important finding was that a spray water volume of 100L/ha was required to improve the effectivness of the herbicides, but this must be put in context with spray quality and nozzle type (Table 13).

Table 13. The reduction in ryegrass populations with increasing water rate in the LEP in 2015.

| Watre Rate (L/ha) | Reduction in ryegrass numbers compared to control (%) |

|---|---|

| 50 | 52a |

| 100 | 73b |

| 150 | 75b |

The wet season in 2016 throughout much of south-eastern Australia resulted in growers not being able to manage weeds to their normal high standard. The combination of high annual weed populations in large cereal stubble residues may mean that growers may need to consider burning problem paddocks in 2017 to reduce weed populations and improve herbicide effectiveness where stubble loads and ground cover percentage are high. The higher the percentage of ground covered by residue, the higher the percentage of herbicide captured by the stubble (Shaner 2013).

Burning

Burning is an effective, inexpensive method of removing stubble, assisting in reducing disease carryover, reducing certain seedling pests and weed populations and if using a flexible management approach should be considered in strategic situations. With careful planning and diverse management, burning can be kept for those occassions where the system needs to be reset which can result in growers retaining stubble for another series of years. A late burn, conducted wisely just prior to sowing to minimise the time the soil is exposed is one option growers may need to consider in 2017. In a long term experiment at Harden in NSW, burning late just prior to sowing is still producing some of the highest grain yields after 28 years of continuous cropping, which would indicate that a single strategic burn to re-set the sequence may do little damage. In general, late burning resulted in the largest yield benefits in wetter years, and had little impact in other years. Across a number of trials in the Riverine Plains, Victorian HRZ and those conducted by the MacKillop Farm Management group, the comparision between burning or stubble retain treatments has resulted in variable results. More often than not, there was no significant difference in grain yield between the burn and stubble retain treatment in 2014-15. However, in some years, the burn treatment has resulted in good early crop vigour, more early biomass and the crop has become moisture stressed with reduced grain yield where there has been an early end to the season with a hot and dry spring.

Some negatives to burning include loss of nutrients (amount depends on temperature), increased regulation and potential losses of soil from erosion. Increasing restrictive regulations are being implemented that also make burning more difficult in the future. In some shires, a single burn requires six people, two fire control units (one with 5,000L and the other with 500L) and you are not able to leave the paddock until no smoke is detected.

Conclusion

This paper has outlined many of the overall findings from the ’Stubble Initiative’ project to date and incorporated these into a series of regional guidelines to assist growers to deal with the high stubble loads from the 2016/17 harvest.

It is extremely important for growers to not compromise managing weeds, disease or being able to sow their crop in 2017 due to excessive stubble loads. Growers need to be pro-active in managing their stubble which should have commenced before harvest and continued until sowing in 2017 to ensure their stubble management will suit their seeding system. It has been shown that by diversifying a crop rotation (increasing the number of pulse crops and barley), deep banding N, managing pests and diseases, managing stubble by mulching, baling, grazing and if sowing with a timed seeder, sowing at 15-19 degrees from the previous direction, that it is easier to manage stubble without the need to burn. However, if the stubble load remains too large or the potential weed/disease/pest burden remains too high, then a one off strategic late burn can be used to ’re-set’ the system. In a year where stubble residue loads are greater than ever before experienced, it is also important that as new techniques are tried, to keep monitoring the results early to see how effective the actions have been.

References

- GRDC Stubble Management Fact Sheet, March 2011: Strategies to manage winter crop stubbles without reaching for the matches

- GRDC Managing Stubble Booklet, May 2012:

- Mallee Sustainable Farming Inc: Stubble Management – A guide for Mallee farmers (2013)

- Farmlink Guideline No 3. ’What sort of stubble? It all begins at harvest’. GRDC Project 000174 - Maintaining profitable farming systems with retained stubble in NSW SW slopes and Riverina.

- Riverine Plains Stubble management guideline No 1. ’Managing stubble at harvest improves sowing success’. GRDC project RPI00009 - Maintaining profitable farming systems with retained stubble in Riverina Plains region.

- Stubble management – an integrated approach (2010): EH Graham Centre for Agricultural innovation.

- Farmlink Guideline No 4. ’Contractors and stubble. Engaging contractors with equipment suitable for stubble retention’. GRDC Project 000174 - Maintaining profitable farming systems with retained stubble in NSW SW slopes and Riverina.

- Efficacy of harvest weed seed control techniques in Southern Victorian HRZ – Southern Farming Systems.

- Grassroots Agronomy and GRDC extension notes. ’Narrow windrow burning in southern NSW … the good the bad and the ugly’.

- Hunt J, Swan T, Pratt T, Rheinheimer B, Goward L, Jones K, Kirkegaard J (2015). The effect of grazing and burning stubbles on grain yield and quality in no-till and zero-till controlled traffic farming systems in SNSW. GRDC Updates Adelaide and Wagga.

- Kirkby C A. Richardson A E, Wade L J, Conyers M, Kirkegaard J A (2016). Inorganic nutrient increase humification efficiency and C-sequestration in an annually cropped soil. PLOS ONE DOI: 10.1371/journal.pone.0153698 May 4, 2016.

- Shaner, D (2013). Interactions of herbicides with crop residue. GRDC Adviser Update, Goondiwindi.

Acknowledgements

The research undertaken as part of this project is made possible by the significant contributions of growers through both trial cooperation and the support of the GRDC — the author would like to thank them for their continued support.

I would like to acknowledge all the collaborating scientists, technicians, staff, growers and consultants from all of the organisations and groups who have contributed significantly in terms of their time and research capability to each farming systems group to ensure the project in their region is producing the highest quality of work. To keep the list of co-authors to one cricket team only one person from each group was included as authors.

Contact details

Tony Swan

CSIRO

Clunies Ross St, Acton 2601

0428145085

GRDC Project Code: CSP00174, EPF00001, BWD00024, YCR00003, MFM00006, CWF00018, RPI00009, LEA00002 plus collaboration with SFS00032 and DAS00160,

Was this page helpful?

YOUR FEEDBACK