Grower adoption and implementation of strategies to manage soil water repellence in farming systems

Author: Stephen Davies, Paul Blackwell, Craig Scanlan, Breanne Best, Derk Bakker, James Hagan & Kari-Lee Falconer | Date: 27 Mar 2013

Stephen Davies1, Paul Blackwell1, Craig Scanlan2, Breanne Best2, Derk Bakker3, James Hagan1, Kari-Lee Falconer4; WA Department of Agriculture and Food, 1Geraldton; 2Northam; 3Albany; 4Moora

Key Messages

- Growers are tending to adopt a combination of short-term mitigation and long-term amelioration management options for managing water repellent soils both of which can improve crop establishment and productivity.

- Wetting agents, paired row seeding and other mitigation options can improve whole farm income because they are used over the whole seeding program. Amelioration options such as spading or mouldboard ploughing often give greater and longer-lasting yield increases and are profitable but are slow and costly to implement.

Aims

To assess grower practice and intentions in regards to management of soil water repellence and gain an understanding of the major barriers to adoption.

To assess the on-farm implementation of water repellence management strategies, drivers of full adoption and on-farm trial processes and outcomes using grower case studies.

Method

Grower surveys were conducted in 2010-11 as a component of grower group workshops using an interactive presentation format. The electronic ‘KeePad’ survey system was used so that some discussion of the survey findings could be undertaken at the workshops. A key feature of the surveys was an attempt to assess both previously tried water repellence management practices and future intentions. A total of 107 farm businesses were surveyed from the following grower groups:

- Northern Agri Group (NAG) – Binnu, Balla and Northampton; 26 participants

- West Midlands Group (WMG) – Badgingarra, Dandaragan, Moora; 28 participants

- Calingiri LCDC (CLCDC) – Calingiri, Bolgart, New Norcia; 23 participants

- Darkan Farm Management Advisory Service (DFMAS) – Darkan; 30 participants

Grower case studies were conducted with growers who have been actively undertaking assessment and adoption of water repellence management strategies. In all cases the growers have used on-farm trials to assess various options. In many cases the outcomes of these trials were important in the decision making process and in assessing the likely productivity, economic and system benefits of the management options.

Results

Grower Surveys

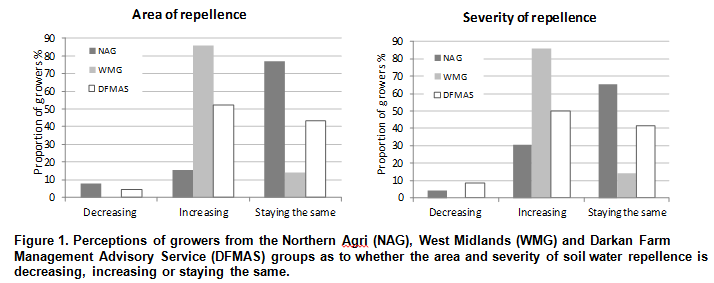

Soil water repellence was ranked the most important soil constraint on their properties by growers (data not shown), although the groups surveyed had nominated repellence as an important issue. Low soil water holding capacity and acidity ranked the next highest and are often found in combination with repellence on poorer sandplain soils. Over 80% of West Midlands Group (WMG) growers and half the Darkan growers believed that both the area and severity of water repellence was increasing on their farms (Fig. 1). Most Northern Agri group growers felt that the expression of water repellence was static, although nearly one-third still believed the severity was increasing.

No detailed time-series soil surveys have been conducted to confirm the perception that water repellence is increasing, however, the expression of the constraint is easier to diagnose than most because of the obvious nature of the impacts on establishment, water infiltration and variable soil wetting. Higher expression of repellence may be result of:

- first opportunity sowing into soil that has marginal soil moisture;

- less soil mixing and stratification of organic matter and plant waxes at the soil surface;

- extensive use of narrow knife points with low soil disturbance;

- a shift from permanent pasture to more cropping.

Cost was a significant barrier for mouldboard ploughing, rotary spading and claying with wind erosion risk a significant barrier for the deep tillage options. For claying, increased risk of haying off, difficulties with clay incorporation and availability of suitable clay were the main barriers. For wetting agents, cost and inconsistency of results were the principal barriers. Concerns about effectiveness, cost, problems with weed and root disease control and suitability of soils hampered grower adoption of zero-till, full stubble retention systems.

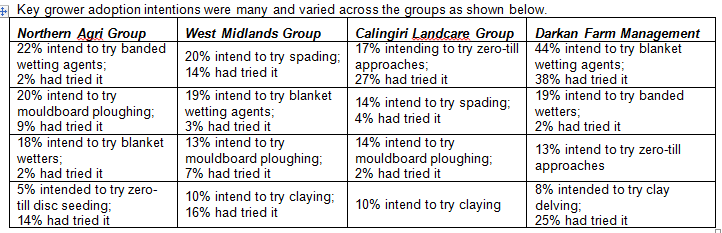

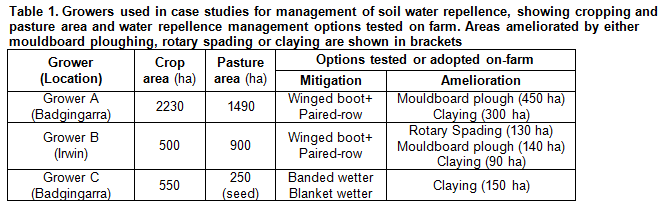

Assessment of grower adoption using case studies indicates that growers often use a combination of strategies for managing water repellence. This generally includes short-term but relatively inexpensive mitigation approaches and long-term gradually implemented amelioration strategies (Table 1). Growers are likely to test and assess strategies before full adoption occurs.

Water repellence is major soil constraint for each of these growers. Soils in both Badgingarra and Irwin typically consist of pale and yellow deep sands, sandy gravels and sandy duplex soils typically with moderate to severe water repellence. More productive soils in these regions, such as the loamy gravels and smaller areas of clay and loam have no or mild water repellence.

Grower Case Studies

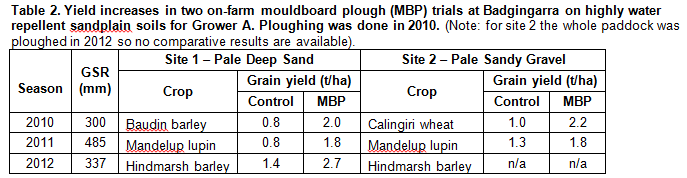

Grower A has undertaken several on-farm trials including a seeder comparison and two mouldboard trials. In 2011 grower A’s knife point seeder was compared with an independent opener drill with a paired row double-shoot winged opener so that seed is placed near the walls of a 4-inch wide furrow. Wheat establishment was doubled using the paired-row seeder in more severely water repellent patches. The overall bulk-harvest yield benefit was 190 kg/ha. While this yield increase is reasonable in a similar comparison on a nearby property the bulk harvest yield improvement was over 500 kg/ha indicating the benefits can in fact be much larger. In 2012 grower A purchased a paired row seeder and used it over his entire cropping program (Table 1) which included 658 ha of wheat, 677 ha barley, 416 ha ‘TT’ canola, 247 ha ‘RR’ canola , 195 ha lupin and 32 ha oats. In 2010 grower A established two large scale on-farm mouldboard plough trials (Table 2) on repellent soil with ploughing resulting in yield increases >1.0 t/ha for wheat and barley and between 0.5-1.0 t/ha for lupins (Table 2). Certainly the measured yield increases were partly a result of overcoming the water repellence by soil inversion and improving crop establishment, At site 1, for example, barely establishment was improved by ~50% (40 more plants/m2) in 2010, lupin establishment increased by 300% (33 more plants/m2) in 2011 and barley establishment by 75% (75 more plants/m2) in 2012. However additional productivity benefits are likely a result of soil loosening (deep ripping effect), improved nutrient access and enhanced crop root growth in the 10-40 cm layer could all contribute to the measured yield improvement.

In 2012 grower A ploughed a total of 450 ha which was sown to either wheat (180 ha) or barley (270 ha). While control areas were not left in each paddock the paddock yields achieved suggest substantial yield improvements, up to 1 t/ha in some cases. In good gravel soils wheat and barley yields ranged from 4.0-4.8 t/ha while in the poorer sand soils barley yields were 3.1-3.3 t/ha. The grower commented that for some of these paddocks these were the best yields ever achieved.

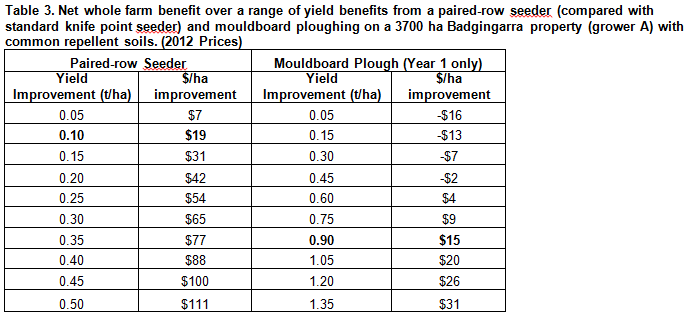

Based on these results the net whole farm benefit (Table 3) for a total arable area of 3700 ha was calculated for both the winged boot + paired row seeder, which was used over the entire cropping program (2230 ha) and for the mouldboard ploughing (450 ha). Mouldboard ploughing was costed by the grower at approximately $150/ha including driver, tractor, plough, levelling and rolling costs.

For net whole farm benefit a conservative estimate of 100 kg/ha yield benefit is used for the paired-row seeder compared with a knife point seeder despite this being the lowest benefit recorded in the 2011 trials. A cereal yield benefit of 900 kg/ha is used for the mouldboard ploughing which is on the low side of the measured trial benefits (Table 2) on this farm. The $ benefit has been calculated using the actual crop makeup on the ploughed areas of barley (270ha) and wheat (180 ha). Using these values it can be seen that the estimated net whole farm benefit was $19/ha for the winged boot + paired-row seeder and $15/ha for mouldboard ploughing in 2012 in the first year only (Table 3). This amounts to an overall additional profit of $77,700 for the new seeder used over the 2230 ha of cropping and $54,000 for the 450 ha of mouldboard ploughing in year 1 only.

Paired-row seeding and mouldboard ploughing combined have had an estimated net benefit of $33/ha over the 3700 arable hectares for grower A in 2012. Many of the paddocks had been cropped continuously for 10 years so reduced herbicide use was a significant additional benefit. The grower intends to continue mouldboard ploughing and using the paired row seeder which is also a good implement for seeding ploughed areas. The grower has undertaken claying in the past and found it does work but the cost is prohibitive and he has found that mouldboard ploughing gives a similar yield response but for only one-fifth of the cost of claying. It is not known how long the benefits of ploughing will last for grower A although significant yield increases have been measured 4 and 5 years after ploughing in some long-term trials.

Grower B seeds with paired row seeding boots which he finds work very well for cereals but less so for lupins. In 2008 grower B at Irwin hosted a DAFWA mouldboard plough trial looking at weed control and productivity responses. After the initial establishment year there was no yield response in 2009 due to rotational differences but ryegrass control was >95%. In 2010 the lupin yield was 960 kg/ha higher and in 2011 the wheat yield was 1.16 t/ha higher for the mouldboard plough treatment (data not shown). In 2012 the site was in pasture. In 2011 grower B rotary spaded 130 ha and in 2012 also further tested mouldboard ploughing over 140 ha. In 2011 spading resulted in a wheat yield increase of 200 kg/ha with additional herbicide savings and in 2012 lupin yield was increased by 600 kg/ha. Mouldboard ploughing increased yield by an average of 400 kg/ha in 2012. The grower noted that the response was greater on yellow sand and less on the pale sand and gravel ridges. Sowing depth was difficult to control on ploughed pale sand in particular, and the resulting poor emergence limited the yield benefit. On the gravel ridges the plough brought up cemented gravel rocks. Given the variable nature of the landscape on this Irwin property and the issues with rocks and sowing depth, grower B is likely to undertake more spading in the future. The grower found that spading left the paddock less rough and was easier to seed into compared to the mouldboard. Lime incorporation is a benefit of spading and the incomplete burial allows more pasture regeneration which is important on this mixed farm.

In 2012 grower C grew 275 ha of wheat, 275 ha of canola with the remaining 250 ha used for pasture seed production, consisting of serradella, biserrula and rose clover. He uses banded wetting agent over all his sandy and loamy gravels for both crops and pastures but generally does not use it on his shallower sandy duplex soils as these tend to wet well. Grower C has used banded wetting agents for 4 years to ensure more consistent establishment on his repellent gravels. Banded wetting agents cost about $7-12/ha depending on the products and rates used. He has found the wetting agents to be quite effective particularly if there is rain shortly after they are applied at seeding, but he has found that furrow infill prior to rain can reduce the effectiveness. Grower C has also trialled the use of blanket wetting agents on strongly repellent gravelly patches often on ridges and hill tops in this landscape. While he has noticed some benefit from these and has found that the benefit persists for longer than the banded wetting agents the benefits have not been big enough to warrant the $50/ha cost.

Clay spreading has been carried out on the farm for over 20 years and a total of 150 ha have been clayed so far. Contractors have been used in the past but now grower C does the claying himself so that he can spread clay only on those parts of the paddock that require it. Poor performing deep sand patches that are repellent, prone to blowing and have very low productivity have been targeted first. Grower C has found that sometimes these deep sands can be up to 4 m deep. Some of these patches have been clayed more than once so that clay rates now total 300-500 t/ha and getting adequate incorporation has been difficult. In these very deep sand areas, totalling ~30 ha, Grower C plans to incorporate the existing spread clay by deep ripping and rotary spading then spread a light layer of clay on top to help prevent blow. Generally grower C does not plan to clay his shallow duplex or gravel soils but wind erosion following a fire and subsequent water erosion has reduced the fertility of some of the sandy duplex soils which now look distinctly white. Historically Grower C said these soils have had wheat crops yield up to 5 t/ha but productivity since the erosion damage has been poor so the grower intends to clay these areas in an attempt to stabilise and re-build the fertility of these soils. The clays used on the farm tend to be alkaline with quite high K content. Overall the grower has found that claying has improved the productivity of the deep sands. Wheat grain yields were all in excess of 3t/ha on the clayed deep sands in 2012 soils, which historically, often had crop failures but there was no direct comparison of clayed and unclayed.

Trial results

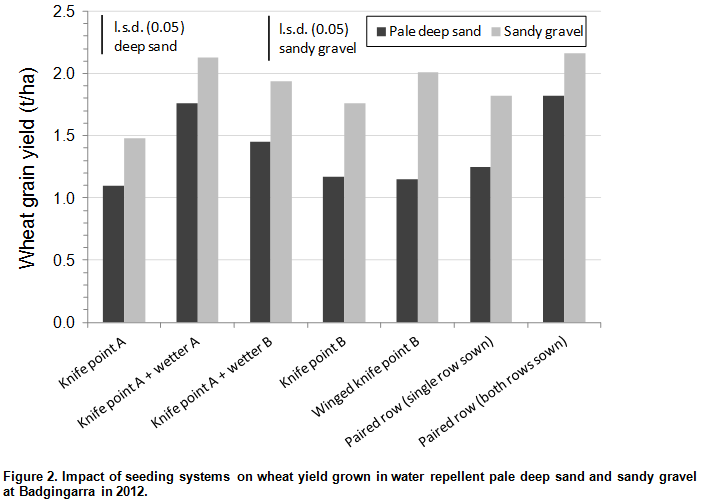

For these growers the use of banded wetting agents with knife points or winged paired row seeding systems seem to offer advantages over standard knife point systems on repellent soils. In a furrow sowing wheat trial at Badgingarra in 2012 both banded wetting agents and a paired row seeding boot had significant yield increases over knife points alone (Fig. 2). Early sowing into highly variable and marginal soil moisture conditions, with dry soil over some moisture, resulted in partial crop emergence with the majority emerging 3 weeks later following a >20 mm rainfall event. The wetting agent improved crop emergence over knife points alone with this subsequent germination suggesting it had remained active for the 3 week dry period. Total establishment was increased using banded wetting agents by 48% (18 plants/m2), on average, in the pale deep sand and by 36% (15 plants/m2) in sandy gravel (data not shown). On average the wetting agents increased the yield over knife points by 46% (507 kg/ha) on the pale sand and 35% (523 kg/ha) on the sandy gravel. Paired-row seeding, with both rows sown, increased yield by 88% (965 kg/ha) on the pale deep sand and 43% (650 kg/ha) on the sandy gravel. The paired-row (both rows sown) treatment increased overall crop establishment by 66% (25 plants/m2) in the sandy gravel and by 31% (13 plants/m2) on the deep sand (data not shown). Winged points gave a 33% yield increase (500 kg/ha) on the sandy gravel but showed no yield benefit on the deep sand (Fig. 2).

On the sandy gravel soil the knife point control had screenings of 3% and the used of banded wetting agent and winged paired-row seeding decreased this to 2.5% (data not shown) with smaller but still significant declines in screenings for these treatments on the deep sand. Grass weed ratings indicated that the banded wetting agent treatments had less weed numbers than the knife point control on both soil types while the paired row (both rows sown) treatment had less on the deep sand soil (data not shown). Weed seed counts indicated that all treatments had large reductions in ryegrass seed set on the sandy gravel soil but only the banded wetting agents reduced brome grass seed set on the sandy gravel. There was no effect of treatment on grass weed seed set on the pale deep sand (data not shown).

Early seeding in marginal moisture conditions resulted in greater benefits from the banded wetting agent and paired row systems in this trial compared with what growers typically experience, although all treatments had staggered and patchy emergence. Typically in these medium-higher rainfall areas growers may leave seeding these repellent soils until later in the program when they have had more opportunity to wet up. However for growers with large areas of water repellent soils it is in the first opportunity sowing into dry or marginal soil moisture conditions where improved furrow sowing is likely to show bigger benefits, as was the case with this trial. In banded wetting agent trials conducted by WMG with the support of GRDC and SACOA yield responses to banded wetting agent ranged from 0-32% (data not shown). In situations where seeding was carried out in wet soil or there was significant rain after shortly after seeding the impact of the wetting agents was minimal. For example, a banded wetting agent demo near Badgingarra received 40 mm of rain after sowing so the whole site wet up well irrespective of treatment. While some differences were observed in timing of emergence, wheat yields at the site were 5 t/ha+ so the 3% (170 kg/ha) increase in yield with banded wetting agent was not significant but would have paid for the wetting agent.

Conclusion

In these surveys and case studies, growers are interested in utilising both short-term, relatively inexpensive mitigation approaches as well as the more costly longer-term amelioration approaches for managing water repellence. From our assessment this is a productive and financially successful approach. The capacity of growers, often in conjunction with groups, researchers and consultants to assess these options on-farm is effective in determining which options best suit their soils, landscapes and farming systems. More research is needed to confirm the best furrow sowing methods on repellent sands but banded wetting agents and paired row sowing look promising.

Key words

Soil water repellence, adoption, furrow sowing, spading, mouldboard, claying, wetting agents

Acknowledgments

We want to express our sincere thanks to the growers of the West Midlands, Northern Agri, Calingiri LCDC, Darkan Farm Management Advisory Service and Mingenew-Irwin grower groups especially the case study growers. Thanks to WMG, particularly David Gartner, Anne Wilkins and the host-growers for ‘Irrigator’ banded wetting agent trials, supported by GRDC, SACOA and DAFWA. This work is funded by DAFWA and GRDC through the “Delivering agronomic strategies for water repellent soils in WA” research project.

GRDC Project No.: DAW00204

Paper reviewed by: Rob Grima (DAFWA Geraldton); Bill Bowden

Was this page helpful?

YOUR FEEDBACK