Pathways to more grain farming profit by CTF in WA

Author: P Blackwell, J Hagan, S Davies, G Riethmuller, D Bakker, D Hall, Q Knight, J Lemon, S Yokwe & B Isbister | Date: 02 Apr 2013

Key Messages

1. Controlled Traffic Farming (CTF) improves the financial returns from investment in deep tillage.

2. CTF need not be compromised by increasing seeder width for improved seeding capacity.

3. Future risks of very deep compaction in sands from heavier axle loads can be reduced by CTF.

Background

CTF is a system of restricting soil compaction and crop damage to permanent tramlines or wheelways enabling improved crop yields and quality; commonly 10% more yield and less screenings in cereal and more oil in canola (Webb et al. 2004). Compaction and crop damage is especially visual after seeding with tow behind air carts. CTF improves soil health and reduces input costs compared to uncontrolled traffic, especially after deep soil amelioration.

Kingwell and Fuchsbichler (2011) found that “CTF represents a remarkably profitable innovation for farming systems, offering input savings and output increases” but they also noted “Even if more favourable seasons would have occurred, nonetheless the high entry cost would serve as an impediment for some farmers who would incur certain large capital expenses in the hope of receiving uncertain yield benefits”. To turn such a perceived cost barrier into an incentive for wise investment, we need to further assess the benefits of using CTF to improve financial returns from deep tillage (deep ripping, spading or mouldboarding).

The growing dependence on dry seeding in dry autumns and other important seeding windows often sees the prioritisation of seeding capacity (ha/day). Some growers are not adopting, or even disadopting, CTF in preference to using wider seeders for higher seeding capacity. Such wider seeders often do not easily match a CTF system; this may be to the detriment of whole farm profitability. Analysis is needed to find improvements to crop seeding capacity without compromising machinery fit to a CTF system.

Larger capacity equipment with high axle loads enables improved seeding and harvesting capacity to maximise opportunities and improve efficiency. The risks of very deep compaction from these heavier axle loads needs assessment.

Methods

To estimate general benefits, the Kingwell and Fuchsbichler MIDAS model for WA was used with current prices based on 5% grain yield increase from CTF after deep ripping, 2.5% shift to a better grain grade and 10% reduction of inputs and conservative costs for central wheatbelt farms.

To estimate the benefits of CTF for paying off investment in deep tillage we calculated the payoff period required after implementing CTF systems and corresponding investment. This was based on costs of CTF conversion and resulting grain yield increase for a farm cropping 70%, 5% less fuel used and 8.5% p.a. interest.

That analysis was combined with calculated yield increases based on field measurements in 2012. Wheat yield was measured in and between traffic zones of paddocks with yellow sand under normal traffic after previous deep ripping and widths of wheeled zones in normal traffic and those predicted in CTF. Sites were chosen in the Northern Agricultural Region (NAR) as part of a Northern Agricultural Catchment Council and DAFWA CTF extension project “Increasing adoption of reduced cropping traffic in the broadacre industry in WA”.

To calculate the effects of seeder width, seeding speed and loading time on seeding capacity a spreadsheet model was created with realistic values for each of these and innovations from known CTF farms. Deep compaction risks from high axle loads are assessed from previous measurements in the Esperance and Geraldton area and model runs with Yield Prophet to investigate the effect of maximum rooting depth on yield for two contrasting soil types.

Results and Discussion

Analysis of financial benefits from current cropping traffic after deep ripping

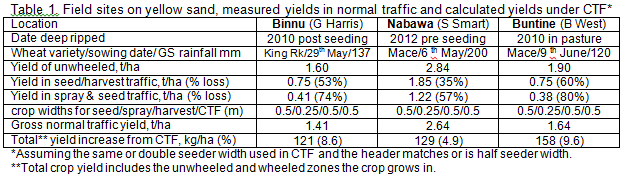

Using the MIDAS model, a farm of greater than 2,000 ha moving to CTF in 2012 was estimated to benefit $36/ha if autosteer is already being used and $45/ha if autosteer has yet to be adopted; based on 5% grain yield increase from CTF. Previous research (Webb et al. 2004) has shown 7-14% total** crop yield increases after deep ripping on yellow sand with CTF in the NAR from paddock-scale trials in 1997-2000. Estimates of total crop yield loss in 2012 from more recent wheel traffic from cropping after deep ripping came from the sites in Table1.

Seeding with discs (Binnu) or normal depth knife points (Buntine) allowed more yield depression by wheeling than seeding using deep working knife points at Nabawa. These calculations are very sensitive to wheeling, tramline and header widths.

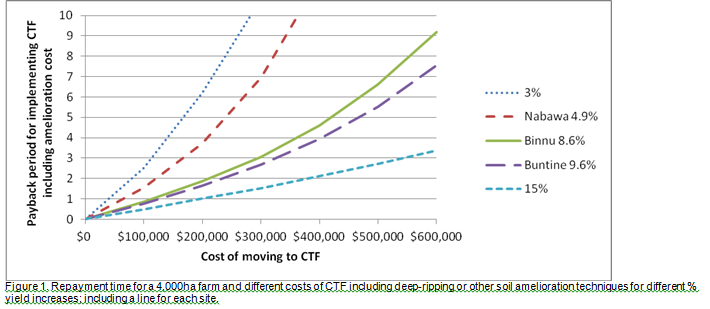

The financial context of these estimated yield benefits from CTF after deep ripping is shown in Fig. 1 by the relationship between the payback period of a whole farm investment in CTF (8.5%pa interest) for different costs of conversion and for a range of yield increases of wheat by the system change. If $200,000 is invested in conversion to CTF and the yield benefit is on average 15% per year the investment could be payed off in about 1 year. Each subsequent season would then profit the business by that 15% yield increase.

Real examples from the field sites show a range from 5–10% calculated yield increase, requiring between 1.5 and 2.5 years to pay back a $200,000 investment in conversion to CTF. While autosteer is assumed to already be in use, previous MIDAS modelling by Kingwell and Fuchsbichler (2011) suggests that improvements in grain quality would double the financial benefit received, thus halving the repayment time calculated in the figure below.

CTF also further reduces the payback period for deep ripping because ripper tines are lifted to leave the permanent tramlines uncultivated, thus resulting in a lower fuel requirement per ha and a lower total investment cost. Spading or mouldboarding do not obviously offer such additional benefits.

Increasing seeding capacity without compromising a CTF system

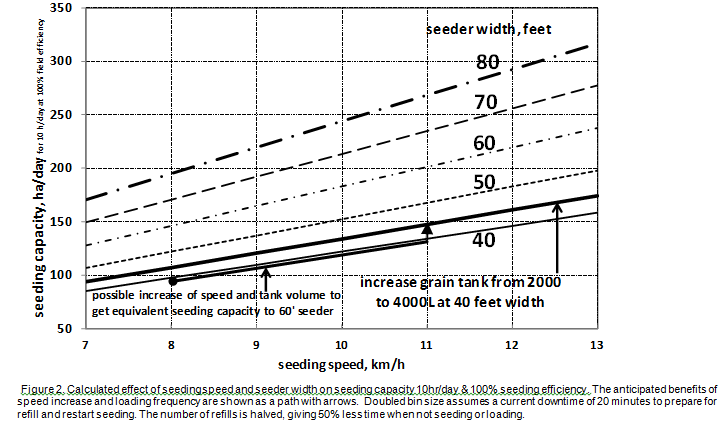

Seeding capacity per day is calculated from seeder width, forward speed and down time for loading and maintenance. Fig. 2 shows the relationship between capacity and speed for seeder widths of 40’ to 80’; zero overlap from autosteer use is assumed. Soil throw and furrow infill usually restricts forward speed to about 7-8 km/h for knife points on 250 mm spacing. Conversion to disc openers or tines at 375 mm spacing with twin row or ribbon sowing boots can enable speeds up to 11-13 km/h. A 40’ (12.19 m) seeder with openers sowing at 11 km/h will cover140 ha/day , compared to 145ha/day with a 60’ seeder at 8 km/h. A further increase of capacity by doubling the volume of the seeding bin with a 40’ seeder at 11 km/h enables a capacity of about 150 ha/day - equivalent to the seeding capacity of a 70’ seeder at 7 km/h.

Thus investment in tine or disc systems which allow greater forward speed and in larger volume air carts can enable improvements to seeding capacity. Such improvements can bring seeding capacity to equivalent or better than using a wider seeder at the same speed and with no improvements to shutdown time. Faster methods of loading the air carts would also add further improvement. Such strategies can enable a CTF system to be maintained and allow improved seeding capacity. A less complex strategy of simple doubling of seeder width to use the same tramlines may provide a better solution in many circumstances.

Risks of very deep compaction from very high axle loads

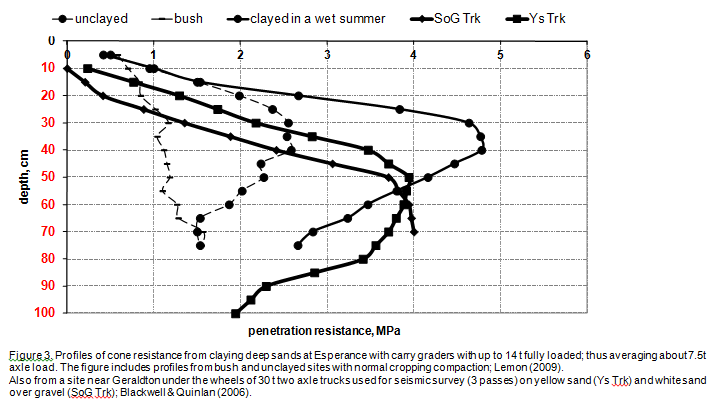

Recent measurements of deep compaction from very heavy equipment on WA agricultural soils are shown in Fig.3 for claying equipment and seismic survey trucks. As axle loading increased the depth of maximum soil strength increased from 40 to about 50-70 cm. The deeper compaction was mainly rectified by 2 winged tines pulled at 70 cm depth by a D4 tracked tractor. The effect of claying in wet conditions is probably less than the seismic trucks because the axle load of the claying grader would cycle between empty and full conditions, while the seismic truck axle load is constant in travel.

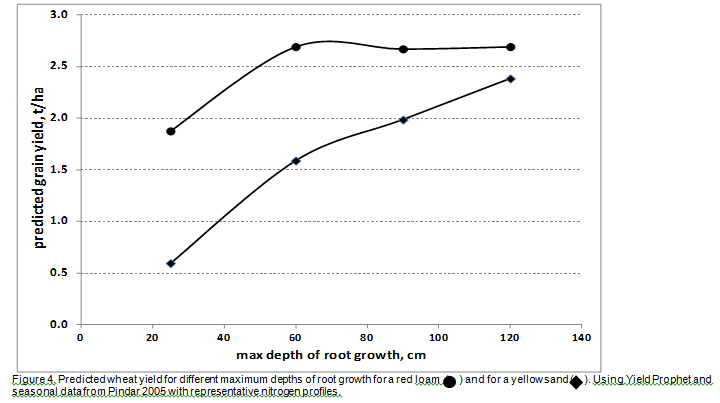

Some recent chaser bin models have 20 t axle loads when fully laden, heavier than the seismic survey trucks considered above., All types of cropping equipment are increasing in capacity (and hence higher axle loads) to improve seeding efficiency. Such changes seem to increase the risk of deeper and more severe compaction of deep sands. Estimated severe restrictions on crop yields from more deeply compacted sands (Fig. 4) emphasise the risks. If root growth was limited to 60cm depth in the sand yield would be about 1t/ha less than for root growth to 1.2m in a season such as 2005. The yield on loam would not be restricted as much by the same depth of root growth limitation in the same kind of season.

N and K requirements may also increase if root growth is slowed and cannot keep up with leaching nutrients. Sands provide a valuable proportion of grain production in drier seasons, thus conversion to CTF should minimise the risk of the benefits of such soils being compromised by very deep compaction.

Current measurements of cone resistance in paddocks under long term CTF in the NAR have shown deep ripping effects persisting for at least 7 years under CTF.

Other benefits and challenges to CTF

Other benefits of CTF (Webb et al. 2004) include reduced greenhouse gas emissions and better opportunities for useful agronomic methods such as sowing between or next to previous crop rows.

Current problems and challenges to CTF of most importance include poor redistribution of nutrients by uneven straw spreading behind headers more than 9m wide and keeping the same position of burned windrows. Deep rutting of tramlines is also a problem in higher rainfall areas and heavier soils. Innovative solutions to many such problems are developing.

Conclusion

- CTF can increase return on investment into deep ripping, spading or inversion ploughing. A $200,000 cost of conversion may be paid off in at least 2 years if CTF provides yield increases of about 9%. Estimated grain yield increases range from about 5-10% in this paper and compare well to measured increases of about 7-13% for wheat in previous field experiments.

- Improved seeding capacity is possible without compromising a CTF system. Seeding capacity of a 12m wide seeder can be increased to equivalent to an 18m seeder by increases in speed and air cart capacity.

- Future risks of very deep compaction of sands can be minimised by conversion to CTF. Axle loads of about 15t on wet soil can induce root restricting cone resistance as deep as about 500mm. Such very deep compaction may be very expensive to rectify in deep sands which need easy crop root access to depth for conservation of their yield potential.

References

Blackwell P and Quinlan R 2006. Soil and crop effects of seismic survey and ameliorative deep ripping and rolling; Report to ARC Energy Ltd; DAFWA

Kingwell R and Fuchsbichler A (2011) The whole-farm benefits of controlled traffic farming: an Australian appraisal. vol. 104, issue 7, pages 513-521.

Webb B, Blackwell P, Riethmuller G, Lemon J, 2004. Tramline Farming Systems: Technical Manual. State of Western Australia. DAFWA.www.agric.wa.gov.au/objtwr/imported_assets/content/lwe/land/cult/bulletin4607

Lemon J, 2009 Compaction in ‘Managing south coast sandplain soils to yield potential’. DAFWA bulletin 4773.

CONCLUSION

- CTF can increase return on investment into deep ripping, spading or inversion ploughing.

- Improved seeding capacity is possible without compromising a CTF system.

- Future risks of very deep compaction of sands can be minimised by conversion to CTF.

KEW WORDS

Controlled Traffic Farming, deep tillage, seeding capacity, deep compaction

ACKNOWLEDGMENTS

Brad West (Buntine), Simon Smart (Nabawa), Graham Harris (Binnu) and Brady Green (Nabawa)

Caring for our Country Project No. OC13-00083: ‘Increasing adoption of reduced cropping traffic.’

Paper reviewed by: Jaron Leask and Craig Scanlan

GRDC Project Code: OC13-00083,

Was this page helpful?

YOUR FEEDBACK