An overview of the Tasmanian poppy industry

Author: Chris Murray | Date: 31 Jul 2014

Take home messages

- TPI want to capture industry growth through security of supply of poppy straw by expanding growth into Victoria.

- In April 2014, the Victorian Government passed legislation that will support the establishment of a controlled commercial poppy industry in Victoria.

- In order to produce a successful poppy crop, attention to detail is essential.

- TPI can demonstrate positive financial returns for poppies grown in Victoria.

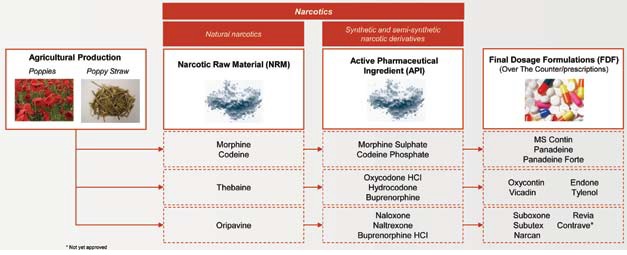

Industry overview – products

Poppy straw is the raw material obtained from the poppy plant, from which the following narcotics are extracted:

- Morphine and Codeine – used in manufacture of pain relief formulations

- Thebaine and Oripavine – used in manufacture of pain relief and anti-abuse formulations

Narcotic Raw Material (NRM) is obtained by extracting narcotics from poppy straw.

Active Pharmaceutical Ingredients (APIs) are synthetic and semi-synthetic narcotics derived from NRMs and are the active ingredients used in Final Dosage Formulation (FDF).

Figure 1. Sources of active ingredients used in Final Dosage Formulation (FDF).

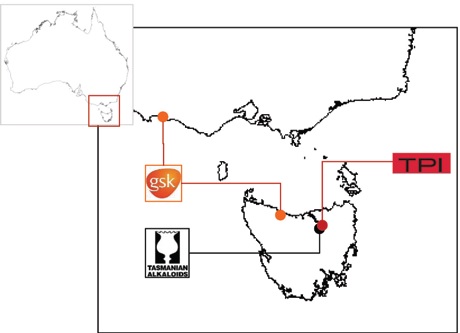

Industry overview – Australia

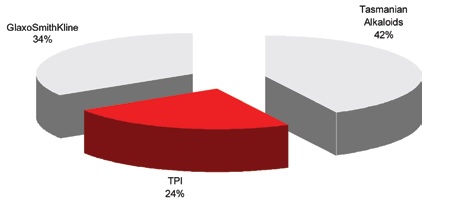

TPI Enterprises Ltd is one of three Australian processors of opium poppies.

Tasmania is the world’s largest producer of NRMs derived from the opium poppy for the Pharma market (approx. 50%).

The poppy industry was introduced to Tasmania in the late 1960s due to:

- Global shortage of morphine; desire for alternate manufacturing regions.

- Beneficial crop cyclicality; fitting well with vegetable and crop rotations.

- Climatic conditions.

- Island state (enhanced security).

Australian companies are industry leaders in production of high-alkaloid yielding poppy varieties and efficient manufacturing processes, driving competitiveness in the global industry.

TPI is a public non-listed company with approximately 150 shareholders and is the only Australian-owned NRM producer.

TPI’s world first and only environmentally friendly extraction and purification process does not emit any harmful toxic solvents to air or water.

Figure 2. Australian industry participants.

Figure 3. Australian industry composition (planted area 2010-11).

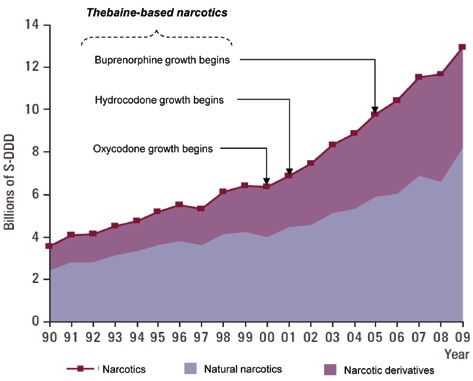

Demands for narcotics

Growth underpinned by traditional use and new products

Demand for narcotics has exhibited steady annual growth in the 20-year period to 2009.

Key drivers include:

- Ageing populations and the increasing incidence and severity of chronic disease.

- New product approvals and alternate narcotic applications (non-pain management).

- Significant global shortage of morphine and emerging pain management markets in developing countries.

- Retreat from non-narcotic pain management alternatives to more traditional narcotics.

Consumption of narcotic derivatives has quadrupled over the same period. Partly driven by thebaine-derivative narcotics including oxycodone, hydrocodone and buprenorphine.

Generally, global stocks of narcotics are targeted to reflect one full year of supply.

Figure 4. Global consumption of narcotics in billions of Defined Daily Doses for Statistical purposes (S-DDD).

Potential land area suitable for poppy production in Tasmania

83% of land identified as suitable for poppy production is ‘land marginally suitable for cropping’.

The area of crop requested for cultivation in Tasmania has grown from 4,900 Ha in 2006 to 36,250 Ha in 2013.

Approximately 73,000Ha (ABS 2009 statistics) is estimated to be annually cropped in Tasmania with the remainder of arable land utilised for pasture and grazing enterprises.

If the recommended crop rotation is used, a total of 3,525 Ha of land in Class 1, 2 and 3 (13,075 Ha) is available for poppy cultivation each year, equating to 9.7% of land required in 2013

Table 1. Area of land cropped in Tasmania.

Elevation | <=300m | <=400m | <=400m |

|---|---|---|---|

Rainfall | <1250mm | <1250mm | No limit |

Class 1 (1 in 3 yr rotation) | 490 ha | 490 ha | 490 ha |

Class 2 (1 in 3 yr rotation) | 1,932 ha | 1,933 ha | 2,587 ha |

Class 3 (1 in 3 yr rotation) | 7,592 ha | 7,798 ha | 9,998 ha |

Class 4 (1 in 3 yr rotation) | 50,245 ha | 50,845 ha | 58,014 ha |

Total | 60,259 ha | 65,066 ha | 71,090 ha |

Class 4 land described as ‘land marginally suitable for cropping. Frequently has severe limitations of both physical and structural nature. Cropping rotations should be restricted to 1 or 2 years in 10.’ (Source: The Tasmanian Institute of Agricultural Research (TIAR) and the Tasmanian Department of Primary Industries, Parks, Water and Environment (DPIPWE) “Potential Land Area suitable for Poppy Production in Tasmania)

A second report written by Macquarie Franklin Water in 2013 for the Tasmanian Department of Primary Industries, Parks, Water and Environment (DPIPWE) and the Poppy Growers Tasmania (PGT) reduced the total available area down to 45,000 Ha (using the same ratio of marginal land).

Why do TPI wish to expand poppy growing to Victoria?

TPI wants to capture industry growth through security of supply of poppy straw.

TPI needs security of supply of input raw material (poppy straw). Customers’ require security of supply of NRMs. TPI’s customer base has increased from 3 in 2011 to 10 in 2013 and supply volume has doubled in the same period.

Insufficient quality land in Tasmania = Reduced crop reliability = Decreasing buffer stocks.

Different regions minimise climatic risks - Weather during growing cycle critical to crop yield.

Growing in Victoria mitigates risks associated with adverse weather events in Tasmania and use of marginal land.

TPI has conducted growing trials at three sites in Victoria.

Determination of project viability and impact of residual herbicides (Treflan)

TPI wishes to grow between 1,500 – 3,000 Ha in 2014.

Factors for consideration:

- Security & licencing requirements.

- Awareness of industry requirements (security, agronomic).

- Understanding risks involved in trial (crop failure, low yield).

Figure 5. Elmore poppy growing trial site.

Figure 6. Rochester poppy growing trial site.

Victorian legislation and regulatory framework

In April 2014, the Victorian Government passed legislation that will support the establishment of a controlled commercial poppy industry in Victoria Source: http://www.parliament.vic.gov.au/static/www.legislation.vic.gov.au-bills.html

The Department of Environment and Primary Industries (DEPI) are responsible for implementing and enforcing the proposed legislative framework.

The Drugs, Poisons and Controlled Substances Amendment Bill 2013 containing the proposed legislative framework was passed in April ’14.

DEPI have defined the Regulations associated with cultivating poppies in Victoria and have prepared “Poppy Fact Sheets” for interested parties; these are available at today’s event.

The Regulations cover licencing requirements for Growers and Processors and address security, management of risks, reporting requirements, NPC’s, signage, fencing & gate specifications etc (refer to DEPI documentation packs).

Commonwealth regulatory changes currently under discussion to allow transport of Victorian grow poppies to Tasmania for processing to NRMs.

Agronomic considerations

In order to produce a successful poppy crop, attention to detail is essential

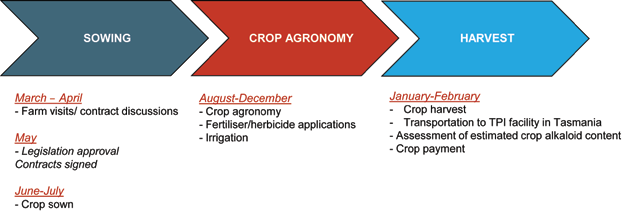

Figure 7. Anticipated poppy growing cycle in Victoria.

In order to produce a successful poppy crop that maximises yield and alkaloid content, a number of agronomic factors need to be considered:

- Seed bed preparation.

- Seed coating/Seeding rate/Sowing time.

- Soil type and pH.

- Nutrient requirements.

- Residual herbicides.

- Weed and disease control.

- Water use and irrigation.

Soils, seed bed preparation and sowing

Soil type and pH, seed bed preparation and seeding rate and depth are critical to successful crop establishment

Seed

Seed coating with fungicides is essential for optimal germination and seedling health; TPI provide seed FOC.

Soil and Ground Preparation

Poppies grow best in at least 200mm of top soil.

Seed beds should be fine with good tilth; avoid compaction.

Free draining soils with an ideal pH of 5.9 – 6.5 (in water).

High balanced soil fertility delivers the best crop results.

Sowing

Plant Density of 70 – 80 plants/m2 or 900 – 1,000g/Ha.

Row Spacing 5-8” (up to 10”); sowing depth of 5mm.

Too high plant densities can lead to increased chance of fungal disease and susceptibility to lodging.

Fertiliser Requirements

Banding or pre-spreading during or prior to sowing.

Boron is a key trace element.

Nitrogen at key growth stages is pivotal to crop performance.

Foliar fertilisers applied to amend deficiencies.

Figure 8. Typical poppy drills.

Herbicides, insecticides and fungicides

It is critical to understand herbicides used in previous cropping as residual activity could impact on the success of the poppy crop.

Insect and Mollusc Pests

Red legged earth mites, lucerne flea and other spring tails, slugs and snails, cut worms are the main insects that cause issues in Tasmania. Common chemicals used include Bifenthrin, Alpha-cypermethrin, Ometheoate, and Clorpyrifos, Metarex and other molluscicides.

Herbicide Regime

A clean seed bed will enhance crop establishment.

Selective herbicides at early growth stages (2 - 8 Leaf) [20-50 days].

TPI FSOs and local agronomists will provide optimal herbicide regimes.

Grower responsibility to apply herbicides at the recommended rates/times.

Weed control is a high priority for the grower as timely weed control is critical to the success of the poppy crop.

Residual Herbicides

TPI’s main concern is Trifuralin as it will affect poppies for 5+ Years after applications.

Other residual chemicals of concern are Atrazine, Chlopyralid, Oxyflurofen and Metsulfuron [6 – 18 months dependent on application rates].

Fungicides Regime

Downy and powdery Mildew are the main concern.

Preventative fungicides are the main defence including Mancozeb, Phos Acid, Metiram + Pyraclostrobin, Mandipropamid; Systemic Fungicide, Ridomil (Mancozeb + Metalaxyl – M)

Irrigation

Application of water is critical to the success of the poppy crop and overhead irrigation systems are preferred

Timing

Application of water at specific growth stages [germination, vegetative growth, hook, flowering] will improve crop performance.

Growing poppies without the assistance of irrigation is considered high risk in low rainfall regions of the state.

Water requirements

The amount of water required is typically 2.5 ML/Ha, however, it is dependent upon soil types, growing season rainfall and evaporation rates.

Irrigation types

Poppies are grown most successfully under pivot or lateral overhead irrigation and travelling gun. Drip tape was successfully demonstrated during TPI’s 2013 trials at Rochester.

Flood irrigation is generally unknown and will be trialled in 2014.

Note: poppies do not like ‘wet feet’.

Harvesting

Effective harvesting of the crop is critical to maximising yield and alkaloid assay

Is your crop ready to harvest?

Harvesting of the capsules occurs after the plant has senesced and dried (moisture < 14%).

Ideally the capsules and approximately 5cm of stem are harvested, hence, an even canopy is important.

It is anticipated that the crop will be ready for harvesting in Victoria between December and January (depending on sowing times).

Figure 9. Stages of late maturity in Papaver Somniferum L.

Figure 10. Harvester types used routinely in Tasmania.

Potential financial returns

TPI offer growers a sowing and harvest contract whereby the grower pays for the sowing and harvest; TPI pays for the delivery of the crop from the paddock to the factory.

The gross margin presented (Table 2) is based on two tonnes dry crop /hectare and a 2.6% alkaloid assay. Note: poppy crops grown on fertile soils by the best growers in Tasmania, typically yield three tonnes/ hectare and assay >3%.

Sowing and harvest will be paid by the farmer.

The input costs include soil testing, all fertiliser, chemical ,water and labour costs.

If a grower commits to a minimum of 25 hectares over the next three years, TPI will offer a $50/ hectare incentive payment.

If a grower commits to a minimum of 50 hectares over the next three years, TPI will offer an incentive of $150/ hectare.

TPI will contribute to the licence application fee, annual administration fee and site inspection fees:

- 10-19 hectares – 33%.

- 20 - 39 hectares – 50%.

- >40 hectares – 100%.

Table 2. Gross margin for poppies grown in Victoria.

Total income | Applications ($) | $3,682 | ||||

|---|---|---|---|---|---|---|

Seed | 0.00 | 0.00 | TPI provides | |||

Sowing | 81.00 | /ha | 81.00 | Grower pays | ||

Fertiliser/Lime | 1 | Lime | 60.00 | /tonne | 180.00 | Depends on pH |

1 | Prespread SSP | 323.00 | /tonne | 64.60 | Depends on P levels in soil | |

1 | 10-17-8 | 778.00 | /tonne | 311.20 | Rate and blend depends on soil test | |

1 | Urea | 662.00 | /tonne | 132.40 | Rate and mix depends on N check test | |

1 | Full soil test | 120.00 | /test | 12.00 | ||

1 | N check | 85.00 | /test | 8.50 | ||

Weeds | 1 | RoundUp 570 | 7.80 | 14.04 | Burn Off | |

1 | Hammer | 295.00 | 8.85 | 2-4 leaf (25-45 days) | ||

1 | Command | 136.00 | 68.00 | 7 days after | ||

1 | Lontrel | 52.00 | 7.80 | 5 days after | ||

1 | Verdict | 100.00 | 15.00 | Prior to emergence | ||

1 | Reglone | 14.50 | 8.70 | Prior to emergence | ||

1 | Deluge 600 | 13.60 | 3.40 | At row cover, and again 7-10 days after | ||

1 | Eclipse | 196.67 | 8.85 | At row cover, and again 7-10 days after | ||

Pests & Disease | 1 | Talstar | 27.80 | 1.11 | ||

1 | Metarex | 9.80 | 78.40 | |||

2 | Pencozeb | 8.15 | 40.75 | |||

2 | Agriphos | 8.30 | 33.20 | |||

1 | Boly 5:3 | 13.50 | 40.50 | Applied with first fungicide | ||

1 | Boron 15 | 5.00 | 10.00 | Applied with second fungicide | ||

0 | Ridomil Gold | 54.00 | 0.00 | Might need to be applied if Mildew pressure heavy | ||

0 | Spray Cal N | 1.74 | 0.00 | |||

Water cost | 5 | Applications | ||||

100 mm | Water use | 75.00 | /ML | 75.00 | ||

Irrigation pump cost | 1.0 ML/ha | 50.00 | /ML | 50.00 | ||

Contract work | ||||||

Cultivation | 3 | 3 passes | 65.00 | /ha | 195.00 | |

Fertiliser Cartage | 40.00 | /tonne | 24.00 | |||

Ground spraying | 8 | Applications | 30.00 | /ha | 240.00 | |

Aerial spray | 0 | Applications | 30.00 | /ha | 0.00 | |

Harvest | 180.00 | /ha | 180.00 | |||

Total variable costs | 1,892.30 | |||||

Gross margin | 1,789.96 | |||||

Total income | 17,899.58 | |||||

Contact details

Chris Murray

Was this page helpful?

YOUR FEEDBACK