From soil throw to bentleg tine seeding research

Author: James Barr, Jack Desbiolles and John Fielke | Date: 13 Aug 2015

Take home messages

- Soil disturbance caused by tine openers can affect the success of no-till seeding operations, influencing issues such as furrow moisture loss, weed seed germination, seeding depth variability across seed rows, crop safety and pre-emergent herbicide efficacy.

- Research shows that low rake angles increase soil layer mixing and deeper soil delving effects while slightly reducing furrow backfill. A bevel edge at the leading face increases furrow size and reduces lateral soil throw.

- Bent leg openers combined with bevel edge features can mostly cancel soil throw and maximise furrow backfill. They offer an unprecedented ability for high speed, low soil throw no-till tine seeders.

Background

Tine seeders are recognised for their greater soil disturbance at seeding, relative to disc seeders. Aspects of soil disturbance at seeding include furrow size and depth as well as the extent of soil movement or soil throw. The lateral soil throw (i.e. the sideways movement of soil pushed out of the furrow) is a particularly important parameter to consider in a no-till seeding context. A limited amount of lateral soil throw at seeding is typically desired to mechanically incorporate soil applied herbicides. However, excessive soil throw limits the furrow backfill, reducing soil cover over the seed, and creates interactions (ridging) between adjacent seed rows, resulting in additional soil cover which increases seeding depth and potentially induces crop damage from herbicides.

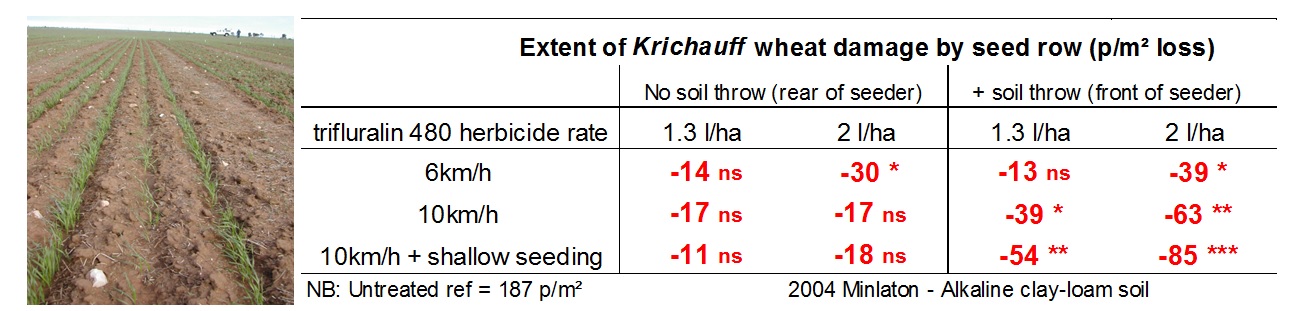

On the issue of managing crop safety, Figure 1 highlights the plant losses to trifluralin damage influenced by rate/ha, furrow ridging, seeding speed and seeding depth, with 20% losses common with uncontrolled soil throw and up to 45% losses measured in the worst case. The extent of seed row interactions (ridging) for a given tine seeder is influenced by the row spacing and the operating speed of the tine seeder. In practice, this limits the adoption of narrow row spacing to increase crop competition with weeds and reduces the machinery work rate at the critical time of seeding. An aspect overlooked in the soil disturbance issues at seeding is the role of furrow opener design features, and how they influence the mechanics of soil movement.

Controlling soil movement with opener design

Recent research (Solhjou et al, 2012, 2013) conducted at the University of South Australia measured the three-dimensional soil movements induced by various furrow opener geometries using small clod-like PVC tracers. These tracers were prepositioned within the prepared soil in a known reference grid pattern and soil movement was calculated by recording the 3D positions of each displaced tracer, simulating 10 mm size soil clods. The experiments were carried out in a remoulded sandy-loam soil bin environment at eight km/h.

Figure 1. Visual crop damage from trifluralin due to soil throw (left) and associated seedling losses by seed row, influenced by rate, speed and shallow seed placement (right) (Source: Desbiolles 2004).

The main findings were:

- All straight openers have an ability to clear the top soil layer out of the furrow centre section, which is a desirable feature with pre-emergent herbicides. This finding explains the reduced weed control along the seed row often found in practice with herbicides incorporated by sowing, as well as the greater seedling vigour observed with tine seeding systems (relative to discs) in Rhizoctonia infested soils, where inoculum is concentrated in the top 2-3 cm soil depth layer.

- Low rake angles promote soil layer mixing, and the delving of deeper soil into the upper soil layers. This makes them useful for sowing into a drying profile where moist soil can be brought up into the seed zone for assisting seed germination.

- High rake angles create slightly narrower furrows at depth with minimal soil layer mixing.

- A chamfered face leading edge reduces both forward and lateral soil throw as well as the surface soil clearing ability, but increases the furrow size and the furrow width at depth. A single-sided chamfer creates an asymmetrical furrow shape.

Later research (Solhjou et al, 2014) also investigated a novel furrow opener geometry referred to as bent leg opener (Figure 2 - left), following the initial ‘RT Blade’ bent leg furrow opener development by South African farmer Danie Rossouw in 2004. He adapted the well-known Paraplow subsoiler tine design to fit a smaller scale seeder, aiming to manage soil compaction via deep till sowing with improved backfill at furrow depth and reduced soil throw at speed.

Previous work at the University of South Australia reported by Leonard and Desbiolles (2008) quantified furrow backfill values in the range of 15-97% when measured in tillage test track environment for a wide number of commercial furrow openers operated at 6 and 10 km/h. This study highlighted the need to properly select and operate openers in a no-till context. The furrow backfill parameter (defined as the proportion of furrow volume filled by loose soil tilth) is best when close to its maximum at 100%. With narrow knife openers however, it often does not reflect quality aspects such as a poorly backfilled slot at depth.

Figure 2. Bent leg furrow opener (left) with offset soil disturbance pattern in the field (right).

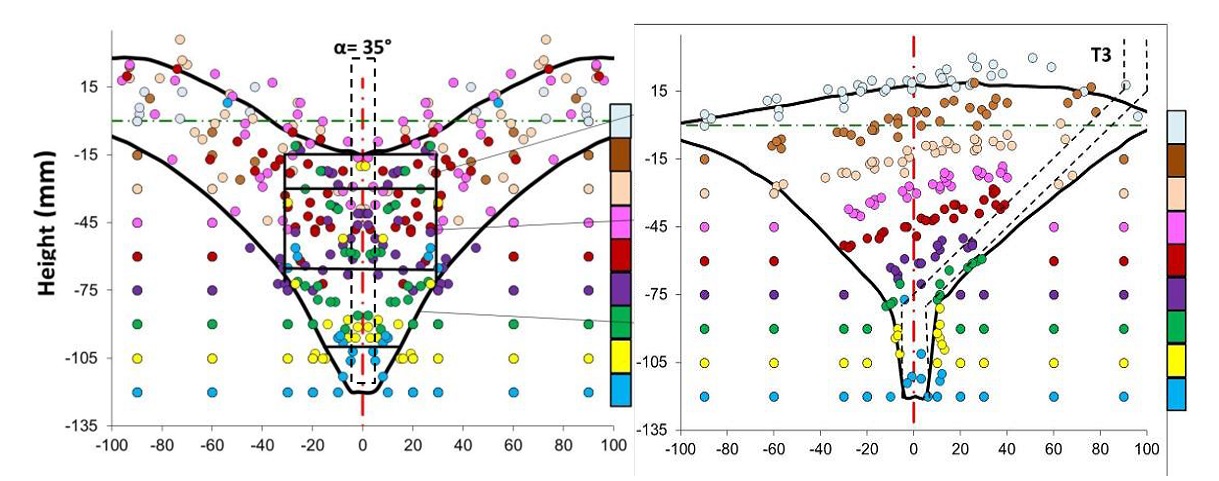

The bentleg design offsets the shank portion of the opener away from the centre of the furrow where the upheaval of soil is greatest (Figure 2 - right). The shank is connected to the loosening foot via a side leg portion. Additionally, the use of a bevel edge is incorporated to maximise the benefits. This results in an opener that can loosen a large furrow size while achieving 100% furrow backfill and virtually cancels lateral soil throw and soil layer mixing. Figure 3 shows a pictorial representation of furrow cross-sections contrasting the ‘bent leg effect’ on soil layer movement to that of a spear point like opener. In practice, scaled-down bent leg openers offer an unprecedented opportunity for high speed, low soil throw no-till tine seeders.

Figure 3. Furrow cross-sections showing furrow boundaries, loose tilth and opener outlines, and PVC soil tracers - coloured by depth layer – displaced from the initial grid layout in the process of furrow loosening: Blunt face, knife opener at 35° rake angle (left); Bevelled edge, bentleg opener (right) (Source: Solhjou et al, 2012, 2014).

High speed openers

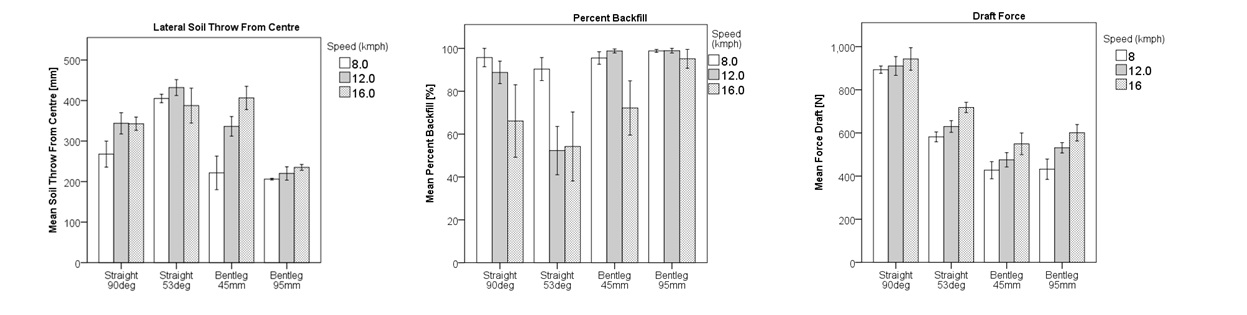

A field trial was conducted in a clay-loam soil at Roseworthy in Sept 2014 to validate the findings in a field situation (reflecting here a condition of dry-sowing) and investigate the potential for higher speed seeding. A selection of straight and bentleg openers was tested, measuring draft, vertical and side forces, lateral soil throw, as well as furrow backfill at eight, 12, and 16 km/h and at 120 mm operating depth. Selected results are highlighted in Figure 4. The two straight openers used encompassed the range of rake angles displayed in commercial narrow knife points, and the two bentleg openers featured a bevelled edge and differed in their shank offset values (45 and 95 mm). The lateral soil throw quoted represents the minimum row spacing for limited interactions between two adjacent furrows (i.e. 10% of furrow area subject to some soil throw at that distance).

Both bentleg openers reduced soil throw compared to the blunt face straight openers at eight km/h. At the higher speeds, the 95 mm offset bentleg opener retained its very low soil throw benefits, while the 45 mm offset bentleg design showed a sensitivity to speed, reaching similar levels of soil throw to the 53° rake angle straight opener at 16 km/h. Under the dry soil conditions, the vertical knife opener significantly reduced the extent of soil throw compared with the 53° rake angle opener.

The furrow backfill data show the ability of the 95 mm offset bentleg opener to maintain maximum furrow backfill regardless of speed. In comparison, the straight openers, from a comparative baseline of eight km/h, significantly emptied the furrows with faster speed, reaching values in the range of 50-60%. The strongest ‘furrow-emptying’ feature of straight openers was observed with the 53° rake angle opener. The 45 mm offset bentleg achieved significantly lower backfill at 16 km/h only.

Overall, the 90 mm offset bentleg design was able to maintain its baseline lateral soil throw at twice the sowing speed while maintaining 100% furrow backfill.

Figure 4. Selected field data for four furrow opener geometries (blunt face, straight openers at 90° and 53° rake angle, chamfered bentleg openers with 45 and 95mm offset) at three operating speeds (8, 12, 16 km/h).

The draft force measurements showed the following:

- The vertical knife opener required approximately 50% more pull than the 53° rake angle opener, demonstrating the known beneficial effect of low rake angle on draft. This was also approximately twice that of the bentleg openers, which were able to minimise the pulling requirement due to their 45° rake angle leading foot.

- Under the dry conditions, the draft requirement increased with speed for all openers, with the least effect measured with the vertical knife opener.

Conclusions

The field data acquired to date confirm the large potential benefits of bentleg opener designs, both in controlling soil throw (and associated crop safety) and in minimising draft forces, compared with existing knife and spear point style technologies. Bentleg openers thus represent a new opportunity for optimising the performance of tine seeders and in particular enabling high speed sowing operations, on the par with disc seeders. Further, the soil handling features of the bentleg opener may achieve specific benefits of low weed seed germination, which need to be validated in dedicated field studies.

The work also demonstrated the need for dedicated research to optimise the bentleg opener design, as there are opportunities for further scaling down the design (but not the properties) of this innovative opener (currently sized to operate at 120 mm depth), to suit shallow soils and further minimise power requirements. Current postgraduate studies will seek to further validate (and optimise via modelling) the bentleg opener concept and recommend solutions for the design of an integrated seeding system. Seeding system solutions for commercial adoption of this technology currently include a split system such as ‘bentleg tine + following disc unit’, an approach which was initially used in South Africa for evaluating the RT blade prototype, and also used in limited South Australian trials to date. The benefits of a scaled-down and integrated seeding system would broaden the scope for widespread adoption of this technology.

References:

- Desbiolles, J (2004). Operating knife point systems for least trifluralin damage.2004 Results Book of the YP Alkaline Soils Group.

- Leonard E and J Desbiolles (2008). Points of difference. in "The Essential Guide to Conservation Agriculture - Moving beyond adoption" 2008 SANTFA publication, p27-29.

- Solhjou A, J Fielke and J Desbiolles (2012). Soil translocation by narrow openers with various rake angles. Biosystems Engineering 112: 65-73.

- Solhjou A, J Desbiolles and J Fielke (2013). Soil translocation by narrow openers with various blade face geometries. Biosystems Engineering 114, pp.259-266.

- Solhjou AA, JM Fielke, JMA Desbiolles and C Saunders (2014). Soil translocation by narrow openers with various bent leg geometries. Biosystems Engineering 127: 41-49.

Acknowledgements:

Funding from the GRDC, SAGIT and the University of South Australia for previous and on-going seeding system research is gratefully acknowledged.

Contact details

James Barr

Office J208, Mawson Lakes Campus, University of South Australia

0417823623

james.barr@unisa.edu.au

@JamesBarr_

Was this page helpful?

YOUR FEEDBACK