Recent work with spray adjuvants

Author: Chris O’Donnell and Andrew Hewitt | Date: 27 Jul 2017

The University of Queensland

Take home message

Polymeric adjuvants are good spray coarseners.

Adjuvants are defined as any substance that is added to a spray solution that enhances or modifies the action of a pesticide. Adjuvants are often claimed to cause a synergistic effect with the tank mix. Synergy means there is an interaction between two substances that causes a resultant effect that is greater than the sum of the two individual effects from those substances.

An operational notice was issued by the Australian Pesticides and Veterinary medicines Authority (APVMA) in March 2010 that requires new pesticides to be assessed for the potential risk of spray drift. This allows pesticide labels to prescribe mandatory no-spray buffer zones at the time of spray application. The Environmental Protection Agency in the USA implemented similar policy at about the same time. Both agencies are looking at mechanisms by which chemical applicators who use verified Drift Reducing Technologies (DRTs) could access smaller downwind buffer distances (yet to be implemented by the APVMA).

Changing the tank mix with the addition of an adjuvant that coarsens the droplet spectrum is one DRT that has been adopted and there has been a rapid increase in the number of products being brought to market. Many “emulsion” type adjuvants have shown to be good at coarsening the droplet spectra of many different types of hydraulic nozzles but the polymeric adjuvants that are based on guar gum have shown the most success. Earlier polymeric adjuvants suffered adverse shear effects from recirculating pumping that caused the adjuvant to quickly break down and lose its effectiveness. Guar gum is not affected by shear effects but does require careful mixing and sometimes it also requires standing time to become fully hydrated.

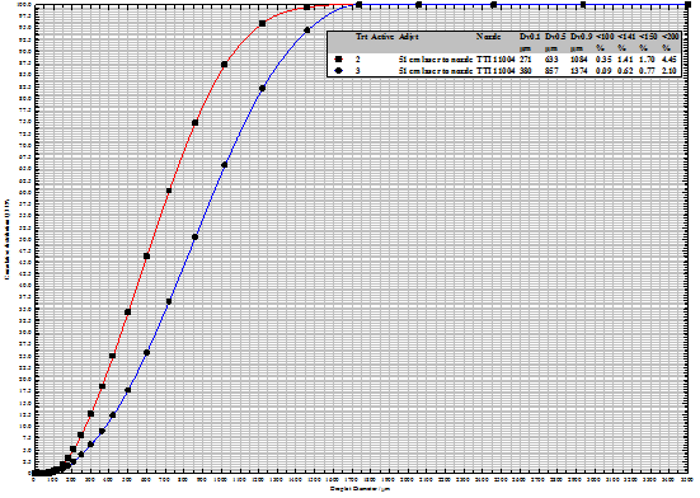

Figure 1. The addition of a polymeric adjuvant “Intact” (blue line) at 0.5% to a standard tank mix (red line) shows that the Dv0.1, Dv0.5 and the Dv0.9 were increased by 40%, 33% and 26%, respectively. The volume percentage below 100 microns was decreased by 74%. This trend has been evident in every one of the several hundred tank mixes that have been tested.

These guar-gum based adjuvants have increased viscosity which can decrease the spray angle of the nozzle. For example, the TTI 11002 nozzle which has a swath width of 180 cm when sprayed from a boom height of 60 cm above the target, has the swath reduced to 125 cm with the addition of 0.5% of polymeric adjuvant “Intact” to the spray tank. Spray booms with nozzles spaced at 50 cm ensure that the spray pattern has a double-overlap at the top of the canopy but this assumes that the full 110 degree angle has been generated. Adjuvants that decrease the spray angle will probably require the nozzle spacing on the boom to be adjusted accordingly in order to ensure that spray operators will still achieve the double-overlap.

Contact details

Chris O’Donnell

The University of Queensland, Gatton, Qld

Ph: 07 5460 1350

Email: c.odonnell@uq.edu.au

Was this page helpful?

YOUR FEEDBACK