A flexible approach to managing stubble profitably in the Riverina and Southwest Slopes of NSW

Author: Tony Swan, John Kirkegaard, Brad Rheinheimer (CSIRO Agriculture), Kellie Jones, Colin Fritsch (FarmLink Research) and James Hunt (CSIRO Agriculture and La Trobe University (current address)). | Date: 03 Aug 2017

Take home messages

- Don’t let stubble compromise the big things (weeds, disease and pest management and timeliness op crop operations).

- Be flexible in your approach to managing stubbIe.

- Pro-actively manage the stubble for your seeding system and deep band nitrogen (N) at sowing.

- Diversify your crop sequence: Add legumes to rotation with double break to reduce N fertiliser inputs, reduce annual ryegrass (ARG) weed seedbank and be more profitable.

- Options to reduce stubble load include mulching, incorporation + nutrients, baling and grazing.

- If stubbles are too thick to sow through, consider strategic late burn, especially before 2nd wheat crop or if sowing canola into large stubbles. Increase of > 0.5t/ha wheat grain yield in 2nd wheat crop following burning.

Background

Previous studies have highlighted potential negative yield impacts of retained stubble in SNSW (Kirkegaard 1995; Scott et al. 2013), but strict no-till advocates recommend retaining all of the stubble to enhance water capture and storage, ‘soil health’ and crop yields. Over past decades, farmers and scientists have continued to examine a range of methods to flexibly manage stubble to improve profitability. These have included the adoption of minimum till (tine) or zero till (disc) seeding equipment, diversifying management strategies such as changing crop sequences/ nitrogen applications/ herbicide options, adopting various new harvesting options for weed seed control such as the Harrington weed seed destructor/chaff carts or windrow burning, and using techniques such as stubble incorporation, grazing or baling stubble to reduce the stubble load. A late strategic burn can also be incorporated into the mix.

A canola (Brassica napus) crop followed by two wheat (Triticum aestivum) crops (C-W-W) has been a very common crop sequence during the last decade in the no-till farming systems that predominate in southern NSW. As the area comprises 50% of farms with mixed crop livestock enterprises (Kirkegaard et al. 2011), post-harvest residue management by grazing or late burning has been part of the flexible approach to managing stubble. Increasing concern has been raised about the potential negative impacts of these practices on soil health which prompted an experiment to be designed to investigate impacts of stubble burning and grazing on soil conditions and crop growth.

The addition of a break crop such as canola or a pulse legume into the sequence have been shown to be profitable in its own right and an effective management tool for controlling weeds and diseases in stubble retained systems (Swan et al. 2015, Peoples et al. 2016). However, while farmers have found that there are many benefits for retaining stubble, increases in stubble loads in wetter seasons combined with a greater adoption of zero till seeding equipment, can negatively impact on herbicide flexibility, weed control and crop yield.

In this paper, we initially examine what questions farmers and advisors need to ask when managing stubble using a flexible approach and answer some of them by reporting results from the recent stubble management project (GRDC CSP00174). We examine the cost and effectiveness of various harvesting options that have been tested using farm equipment in the Southwest Slopes and Riverina. We report some of the main findings from two field experiments established in the Temora region over the past 4 to 8 years comparing different farming systems. The first experiment compared three management strategies (aggressive, sustainable and conservative) in a full factorial 4 year experiment located at the Temora Agriculture Innovation Centre (TAIC) using a single disc and a tine seeder on yield, gross margin and weed control. The second experiment, a long-term (8 year) field trial examining a canola–wheat-wheat (C-W-W) sequence determined the impact of post-harvest stubble management (heavy grazing, burning, or retaining stubble) on soil mineral N and wheat yield under no-till, controlled traffic cropping with strict summer fallow weed control.

Questions to ask when managing stubble using a flexible approach

It has been well documented that to successfully establish a crop into a full stubble retained system requires an integrated management approach incorporating three main stages of stubble management - pre-harvest, post-harvest/pre-sowing, and finally at sowing (Ref 1,2,3,4,5). During these periods, a series of questions (some outlined below) need to be addressed by farmers to successfully establish a crop.

- What is my preference for tillage system?

- What is my seeding system?

- What is my row spacing and accuracy of sowing?

- What crop will be planted into the paddock next year?

- What is the type of crop residue?

- What is the potential grain yield and estimated amount of crop residue?

- Is the crop lodged or standing at harvest?

- What is the desired harvest speed and harvest height?

- How uniform is the spread of straw from my harvester?

- Should I spread residue or place in a narrow windrow?

- Do I have a weed problem which requires intensive HWSC, chaff carts or chutes for chaff-lining?

- Will the stubble be grazed by livestock?

- Am I prepared to process stubble further post-harvest: mulch, incorporate, bale?

- If incorporating stubble, should I add nutrients to speed up the decomposition process?

- What is the risk of stubble-borne disease in next year’s crop?

- Am I likely to encounter a pest problem next year: mice, slugs, earwigs, weevils, snails?

- What is the erosion risk based upon soil type and topography?

- Do I need to burn or what else can I do?

Prior to harvest, all crops should be assessed to estimate grain yield, potential stubble load and weed issues. As a rule of thumb, the stubble load following harvest will be approximately 1.5 to 2 times the grain yield for wheat and between 2 to 3 times the grain yield for canola (Riverine Plains Stubble management guide No 1 and Stubble management – an integrated approach (2010)). There is no perfect stubble management strategy for every year. Crop rotations, weeds, disease, pests, stubble loads, sowing machinery and potential sowing problems will largely dictate how stubble should be managed.

Methods and materials

Part 1: Harvest stubble management – harvest height

Eight commercial harvesters were tested between 2014 and 2016 on farm scale strips across the west slopes and Riverina to examine the effect of cutting height (15 to 60cm) on harvest efficiency and grain yield. The harvesters included a Case IH 7240, Case IH 8240, John Deere 5680, Case IH 1920, John Deere 9770, Case IH 8230 and New Holland 8090. A prototype Integrated Harrington Seed Destructor (iHSD®) was also tested in Temora, NSW in December 2015, Inverleigh in December 2015 and Furner, SA in January 2016.

Part 2: Strategy management experiment – impact on weeds, yield & profitability

The experiment was located on a red chromosol soil with surface pHCaCl2 of 5.0 (0-10 cm) and 4.6 (10-20 cm) and little slope at the Temora Agricultural Innovation Centre (TAIC) 4 km N of the township of Temora in SE NSW (S 34.49°, E 147.51°, 299 m ASL). A fully phased systems experiment was established in 2014 at a site with high levels of group B resistant annual ryegrass ARG (average seedbank of 1864 plants/m2) to compare the yield, profitability and sustainability of three management strategies in a stubble retained no-till (Flexi-Coil tine seeder with Stiletto deep banding & splitting boots) and zero-till (Excel single-disc seeder with Arricks’ wheel) farming system (Table 1). Nitrogen was applied at sowing by deep banding below the seed (tines) or surface applied pre-sowing (disc) at either 20 or 40 kgN/ha (Table 2). Pre-emergent and post emergent grass herbicides were applied to the three management strategies as outlined in Table 3. One of the main differences between the herbicides applied in the disc and tine systems related to trifluralin being used in the tine systems, but not in the disc systems, due to crop safety restrictions. Insecticides and fungicides were applied to treatments at sowing and during the crop development to minimise the effects of disease or insect damage.

The annual ryegrass ARG (Lolium rigidum Gaudin) seedbank was initially measured in March 2014 prior to sowing by taking 40 soil cores, each 58 mm in diameter x 50 mm deep. All plots were then measured in February or March of 2015, 2016 and 2017 by taking 8 cores in each plot to determine the change in ARG seedbank relating to management strategies. The soil was cooled to 4 degrees C for 7 days, then emptied into seedling trays in a glasshouse that were kept wet for the following 3 months. All ARG seedlings emerging were counted fortnightly and removed from each tray before being re-wetted.

Three soil cores (42 mm diameter) were taken in April of each year in each plot to a depth of 1.6 m and segmented for analysis (0.1 segments to 0.2 m depth and 0.2 m segments to 1.6 m depth) with an additional 4 foot cores taken at 0-0.1 m and 0.1-0.2 m depths, with cores bulked according to depths. Soil from each depth increment was analysed for mineral N (NH4 and NO3). Nitrogen was applied to all crops except the legume hay crop at GS31 (cereals) or stem elongation (canola) at different amounts determined by the starting soil mineral nitrogen concentration to attain a predicted yield of 70% of maximum potential as determined by Yield Profit® for each year. Grain yields were measured by plot header harvesting only th4e middle 4 rows and by hand harvesting large areas (> 1.0 m2) of crop and threshing to measure the total dry matter production, harvest index and to estimate the amount of crop residue returned to the plot.

ARG, soil mineral N and grain yield were analysed by ANOVA with “treatment” as (management/sequence) x opener, and “block” as block/plot pair/plot using GenStat 18 software package (VSN International Ltd.). The ARG data often required transformations using either loge or square root to normalise the residuals. Results in the tables are reported following back transformation and significant difference indicated by letters. Significance is assumed at the 95% confidence level and tests of mean separation were made using Fisher’s least significant difference for the 95% confidence level.

Table 1. The crop rotation for each sequence in the three management strategies in a fully phased experiment at TAIC between 2014 and 2017.

Management Strategy | Sequence | Crop | Crop | Crop | Crop |

|---|---|---|---|---|---|

Aggressive | 4 | Wheat 1 (H) | Wheat 2 (H) | Canola RR | Wheat 1 (H) |

Aggressive | 6 | Wheat 2 (H) | Canola RR | Wheat 1 (H) | Wheat 2 (H) |

Aggressive | 10 | Canola RR | Wheat 1 (H) | Wheat 2 (H) | Canola RR |

Sustainable | 1 | Barley | Legume Hay | Canola TT | Wheat (L) |

Sustainable | 3 | Wheat (L) | Barley | Legume Hay | Canola TT |

Sustainable | 7 | Legume Hay | Canola TT | Wheat (L) | Barley |

Sustainable | 9 | Canola TT | Wheat (L) | Barley | Legume Hay |

Conservative | 2 | Wheat 1 (L) | Wheat 2 (L) | Canola TT | Wheat 1 (L) |

Conservative | 5 | Wheat 2 (L) | Canola TT | Wheat 1 (L) | Wheat 2 (L) |

Conservative | 8 | Canola TT | Wheat 1 (L) | Wheat 2 (L) | Canola TT |

Table 2. The planned crop density and seed bed nitrogen quantity/application method at sowing for each crop in the three management strategies for both opener types.

Management Strategy | Crop | Plant density (plants/m2) | Seed bed Tine^ Disc# | N type and application | |

|---|---|---|---|---|---|

Aggressive | Wheat 1 (H) | 150 | 40 | 40 | Urea IBS |

Aggressive | Wheat 2 (H) | 150 | 40 | 40 | Urea IBS |

Aggressive | Canola RR | 40 | 20 | 20 | SOA IBS |

Sustainable | Barley | 120 | 20 | 20 | Urea IBS |

Sustainable | Wheat (L) | 80 | 20 | 20 | Urea IBS |

Sustainable | Legume Hay | 40 | Nil | Nil | Nil |

Sustainable | Canola TT | 40 | 20 | 20 | SOA IBS |

Conservative | Wheat 1 (L) | 80 | 20 | 20 | Urea IBS |

Conservative | Wheat 2 (L) | 80 | 20 | 20 | Urea IBS |

Conservative | Canola TT | 40 | 20 | 20 | SOA IBS |

# Nitrogen spread on soil surface prior to sowing (Disc)

^ Nitrogen deep banded below the seed using stiletto boots (Tine)

Table 3. The herbicides applied at sowing and in-crop to control herbicide resistant annual grasses at TAIC for each management strategy x opener type.

Management strategy | Crop | IBS herbicides x opener Tine Disc | In-crop grass herbicides | |

|---|---|---|---|---|

Aggressive | Wheat 1 (H) | Sakura® + | Sakura + | Atlantis® |

Aggressive | Wheat 2 (H) | Boxer Gold ® | Boxer Gold | Atlantis |

Aggressive | Canola RR | Rustler® + TriflurX® | Rustler | Roundup Ready® |

Sustainable | Barley | Boxer Gold | Boxer Gold | Nil |

Sustainable | Wheat (L) | Sakura + Avadex Xtra | Sakura + Avadex Xtra | Atlantis |

Sustainable | Legume Hay | Nil | Nil | |

Sustainable | Canola TT | Rustler + Gesaprim® + TriflurX | Rustler Gesaprim | Status® + Gesaprim |

Conservative | Wheat 1 (L) | Diuron** + TriflurX | Diuron** | Atlantis |

Conservative | Wheat 2 (L) | Diuron** + TriflurX | Diuron** | Atlantis |

Conservative | Canola TT | Gesaprim + TriflurX | Gesaprim | Status |

** Diuron is not registered for control of annual ryegrass in winter cereals in NSW

Note: When using any of the registered products above check labels and follow label directions.

Part 3: Grazing x stubble management experiment – impact of grazing, burning or retaining stubble on soil nitrogen, crop yield and profitability

The experiment was located on a red chromosol soil with surface pHCaCl2 of 5.0 (0-10 cm) and 4.85 (10-20 cm) and little slope 5 km SSE of the township of Temora in SE NSW (S 34.49°, E 147.51°, 299 m ASL). Treatments were applied in two different phases in adjoining areas of a paddock which had been in lucerne pasture (Medicago sativa) since 2005. In phase 1, lucerne was terminated with herbicide in late spring 2008; in phase 2 it was terminated in late winter 2009. Following lucerne removal, large plots (7.25 x 16 m) were established which allowed all operations to be conducted using controlled traffic. All plots were fenced so they could be individually grazed by sheep. Lime was evenly applied at a rate of 2.5 t/ha across all plots in April 2009.

In both phases, the two grazing treatments (nil graze – NG, stubble graze – SG) were applied in a factorial randomised complete block design with two stubble management treatments (stubble burn – SB, stubble retain – SR) and four replicates. Following harvest in each year (late November-early December), weaner ewes grazed stubbles in the SG treatment (average 2263 sheep.days/ha). The stubble burn treatments were applied in mid to late March of each year.

Crops were sown in mid-late April in all years of the experiment, and both crop phases were kept in a rotation of canola-wheat-wheat (Table 4). All crops in both phases between 2009 and 2016 were inter-row sown using a plot seeder equipped with contemporary no-till seeding equipment consisting of six Flexi-Coil 250 kg break out tines set on 305 mm row spacing and fitted with Agmaster® boots, 12 mm knife points and press wheels. Summer weeds that emerged at the site were controlled with herbicide within 5-10 days of emergence, and all in-crop weeds, disease and pests were controlled with registered pesticides such that they did not affect yield. The same rate of synthetic fertilisers were applied to all treatments determined annually following soil analysis to ensure the treatment with the lowest mineral nitrogen concentration was able to yield to 70% of maximum potential as determined by decision support tool, Yield Prophet® for that year.

Table 4. Crop sequence of Canola (C) – Wheat (W) – Wheat (W) in phase 1 and phase 2 of the experiment following lucerne pasture (P) since 2005. Second wheat crop is shown in bold.

2008 | 2009 | 2010 | 2011 | 2012 | 2013 | 2014 | 2015 | 2016 | |

|---|---|---|---|---|---|---|---|---|---|

Phase 1 | P | W | C | W | W | C | W | W | C |

Phase 2 | P | P | W | C | W | W | C | W | W |

Prior to seeding each year two soil cores (42 mm diameter) were taken per plot to a depth of 1.6 m and segmented for analysis (0.1 segments to 0.2 m depth and 0.2 m segments to 1.6 m depth). Six additional cores were taken for 0-0.1 m and 0.1-0.2 m depths, and cores were bulked according to depths. Soil from each depth increment was analysed for mineral N (NH4 and NO3). Grain yield was measured using a plot header harvesting only the middle four rows of each seeding run to remove edge effects from rows adjacent to tram tracks. Grain yields were also measured by hand harvesting large areas (> 1.0 m2) of crop and threshing to measure the total dry matter production, harvest index and to estimate the amount of crop residue returned to the plot.

Table 5. Monthly and annual rainfall data (mm) from Temora airport 2008-2017

Year | J | F | M | A | M | J | J | A | S | O | N | D | Annual (mm) | GSR (mm) |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

2008 | 43 | 69 | 41 | 26 | 7 | 17 | 48 | 22 | 27 | 24 | 39 | 59 | 423 | 171 |

2009 | 22 | 14 | 16 | 53 | 7 | 58 | 32 | 8 | 24 | 23 | 24 | 44 | 327 | 205 |

2010 | 6 | 109 | 79 | 39 | 41 | 22 | 59 | 63 | 63 | 87 | 105 | 76 | 749 | 374 |

2011 | 62 | 196 | 72 | 17 | 17 | 18 | 25 | 46 | 30 | 48 | 108 | 64 | 702 | 201 |

2012 | 62 | 59 | 24 | 5 | 16 | 18 | 44 | 38 | 15 | 17 | 35 | 30 | 363 | 153 |

2013 | 10 | 40 | 20 | 2 | 52 | 87 | 18 | 25 | 29 | 15 | 47 | 9 | 354 | 228 |

2014 | 21 | 25 | 56 | 70 | 31 | 74 | 5 | 24 | 29 | 17 | 18 | 66 | 436 | 250 |

2015 | 61 | 21 | 3 | 49 | 20 | 51 | 79 | 54 | 10 | 13 | 90 | 29 | 481 | 276 |

2016 | 57 | 9 | 8 | 9 | 90 | 113 | 61 | 71 | 205 | 42 | 5 | 34 | 704 | 591 |

Soil mineral N and grain yield were analysed using mixed linear models with grazing, stubble, rotational position (1st or 2nd wheat crop after canola) and year as fixed effects, and block and phase as random effects in the GenStat 18 software package (VSN International Ltd.). Significance is assumed at the 95% confidence level and tests of mean separation were made using Fisher’s least significant difference for the 95% confidence level, estimated by doubling the average standard error of means.

Monthly, annual and growing season rainfall (April-Oct) at Temora is outlined in Table 5. In 2010, 2011 and 2016, harvest for the canola was delayed until late November early December and wheat until early December, so the November rainfall could be added to GSR in those years.

Results

Part 1: Harvest stubble management – Harvest height

Using a stripper front or harvesting high is the quickest and most efficient method to produce the least amount of residue that needs to be threshed, chopped and spread by the harvester. Harvesting high (40-60 cm) compared to 15 cm increased grain yield and combine efficiency by reducing bulk material going through the harvester and reduced harvests costs by 37 to 40% (Table 6). As a general rule, there is a 10% reduction in harvest speed for each 10 cm reduction in harvest height (Table 6). Slower harvest speed across a farm also exposes more unharvested crop to the risk of weather losses (sprouting, head/pod loss, lodging) during the harvest period, and the cost of this is not accounted for in Table 6.

Table 6. Harvesting wheat low or high using a JD9770 harvester in 2014 (Ref 7). Ground speed was altered to achieve similar level of rotor losses at both harvest heights. Values are means of three replicates STS yield monitor and all differences are significant (P<0.05). Operating costs determined at $600/hr.

Harvest height | Efficiency (ha/h) | Speed (km/hr) | Fuel (l/ha) | Yield (t/ha) | Cost | Cost |

|---|---|---|---|---|---|---|

60cm | 9.5 | 10.6 | 5.4 | 2.19 | $63.2 | $28.7 |

15cm | 5.7 | 6.2 | 9.6 | 2.05 | $105.3 | $50.1 |

% Change to 15cm | -41% | -42% | +78% | -6% | +40% | +57% |

There is substantial evidence indicating wide spread resistance or partial resistance of ARG to a wide range of herbicide groups across south eastern Australia (Broster et al. 2011). Harvest weed seed control (HWSC) which includes narrow windrow burning, chaff carts, chaff lining, direct baling, and mechanical weed seed destruction is an essential component of integrated management to keep weed populations at low levels and thus slow the evolution and spread of herbicide resistance ARG. HWSC requires crops to be harvested low in order for weed seeds to be captured in the chaff fraction from the harvester, and if practiced provides an additional reason to harvest low. The prototype Integrated Harrington Seed Destructor (iHSD) was tested in Temora, NSW in December 2015, Inverleigh in December 2015 and Furner, SA in January 2016 at a constant speed of 4 km/hr to compare the efficiency and cost with non-weed seed destruction methods (Table 7). We found no significant difference in grain yield when harvesting at 15 cm cf 30 cm at 4 km/hr, but there a 9% increase in engine load and 11% reduction in fuel efficiency (Table 7). However, when the weed seed destructor was activated, there was a 33% increase in engine load which resulted in a 40% reduction in the fuel efficiency of the header (Table 7).

Table 7. A Case 9120 harvesting wheat conventionally at 30 cm, harvesting at 15 cm for baling or narrow windrow burning and harvesting at 15 cm with a prototype iHSD at Furner, SA in 2016. (Data supplied by GRDC project SFS00032)

| Harvest height | Grain Yield (t/ha) | Speed (km/hr) | Engine Load (%) | Fuel (L/ha) | Fuel Efficiency (L/hr) |

|---|---|---|---|---|---|---|

Conventional Harvest - Burn | 30cm | 4.7 | 3.8 | 59.8 | 14.3 | 52.7 |

Windrow Bale/burn | 15cm | 4.6 | 4.0 | 65.5 | 16.4 | 59.5 |

iHSD | 15cm | 4.6 | 4.0 | 88.7 | 22.7 | 87.8 |

lsd (P<0.05) | ns | ns | 2.26 | 1.36 | 2.18 | |

% Change to 15 cm |

|

| +9% | +11% | +11% | |

% change to iHSD |

|

| +33% | +37% | +40% | |

Part 2: Results from the strategy management experiment 2014-2017

Stubble load: The cereal stubble load following harvest in 2014 and 2015 ranged between 6.3 and 7.7 t/ha. By April 2016, the cereal stubble /ryegrass DM load that crops were sown into ranged between 7-10 t/ha (Table 8). Following the 2016 decile 9 season with high grain yields, the cereal stubble / ryegrass DM quantity increased in many treatments with a further 8-10 t/ha added to the previous 3 years undecomposed stubble. To ensure all treatments could be established in April 2017, the cereal stubble load was reduced in all treatments to between 4-6 t/ha (total amount of straw at sowing) by baling excess stubble.

Table 8. Stubble type and quantity (t/ha) in April 2016 that crops were sown into at Temora.

Management Strategy | Stubble type & year | Crop 2016 | Disc (t/ha) | Tine (t/ha) |

|---|---|---|---|---|

Aggressive | Wheat 1 (H) | Wheat 2 (H) | 7 | 8 |

Aggressive | Wheat 2 (H) | RR Canola | 9 | 8 |

Conservative | Wheat 1 (L) | Wheat 1 (L) | 7 | 7 |

Conservative | Wheat 2 (L) | TT Canola | 8 | 9 |

Sustainable | Barley | Vetch | 10 | 9 |

The most profitable crop across all management strategies between 2014 and 2016 were canola with an average nett margin of between $694 and $769/ha/year and a profit/cost ratio of between $1.40 (aggressive strategy) to $1.80 (sustainable strategy) for every $1 spent (Table 9a). The highest grain yield was produced by the hybrid RR canola in 2014 and 2015 (2.2 t/ha and 3.1 t/ha respectively), however, this required an increase of 20% in average total costs (Table 9a). The decile 9 season of 2016 (Table 5) resulted in all canola yielding between 2.8 and 3.0 t/ha (Table 11). The introduction of diversity with the sustainable strategy resulted in an average net margin over the three years of $512/ha/year which is higher than in the aggressive strategy ($498/ha/year) and 25% higher than the conservative strategy, with 10% lower cost than the aggressive ($465 cf $517/ha/year) and thus higher profit:cost ratio ($1.12 cf $0.96) (Table 9b). A major difference in the average total costs between the sustainable and either the aggressive or the conservative strategies was the 30-35% saving in nitrogen costs (Table 9b). The vetch hay treatment was profitable in its own right with an average net margin over the three years of $416/ha/yr and a profit:cost ratio of $0.90:$1.00. It also reduced the fertiliser N input for the following and subsequent crops by up to $39/ha/year.

Table 9a. Average net margins (EBIT) and profit:cost ratio averaged across openers at Temora, NSW, 2014-2016

Cropping strategy | Crop type | Average total cost 2014-16 ($/ha/yr) | Average net margin 2014-16 ($/ha/yr) | Average 3yr profit:cost ratio |

|---|---|---|---|---|

Aggressive | Canola RR | $524 | $722 | 1.4 |

Aggressive | Wheat (yr 1) | $525 | $378 | 0.7 |

Aggressive | Wheat (yr 2) | $504 | $394 | 0.8 |

Conservative | Canola TT | $452 | $694 | 1.5 |

Conservative | Wheat (yr 1) | $415 | $289 | 0.7 |

Conservative | Wheat (yr 2) | $419 | $261 | 0.6 |

Sustainable | Vetch (Hay) | $463 | $416 | 0.9 |

Sustainable | Canola TT | $426 | $769 | 1.8 |

Sustainable | Wheat | $492 | $422 | 0.9 |

Sustainable | Barley | $478 | $441 | 1.0 |

Table 9b. Average nitrogen & total costs, net margins and profit:cost ratio for each management strategy combined for opener type

Average N costs ($/ha/yr) | Average total cost | Average net margin | Average 3yr profit: cost | |

|---|---|---|---|---|

Aggressive | $109 | $517 | $498 | $0.96 |

Conservative | $103 | $429 | $415 | $0.95 |

Sustainable | $70 | $465 | $512 | $1.12 |

The barley phase in the sustainable strategy produced the highest yielding cereal crop in all years and were 12% more profitable than the second wheat crop in either the aggressive or conservative strategies (Table 9a), despite record low barley prices in the 2016/17 season. The second wheat grain yield in both the aggressive and conservative strategies were lower (reduction of between 0.3 and 0.7 t/ha) than wheat grain yield following canola (Table 11). Similar results were found in grazing x stubble management experiment (Table 17). There were no significant differences in the net margin of strategies when sown with either the disc or tine openers, except in the conservative strategy when sown with a disc opener. The profit:cost ratio was reduced from $1.14 for every $1 spent to $0.75 (Table 10).

Table 10. Average net margins across all crop types for each crop system by opener type between 2014 and 2016 at Temora, NSW.

Management strategy | Net margins | Net margins | Net margins | Average net margins 2014-16 | profit:cost ratio | |||||

|---|---|---|---|---|---|---|---|---|---|---|

Tine | Disc | Tine | Disc | Tine | Disc | Tine | Disc | Tine | Disc | |

Aggressive | $424 | $422 | $569 | $591 | $533 | $449 | $508 | $487 | $0.98 | $0.94 |

Conservative | $441 | $171 | $540 | $463 | $537 | $336 | $506 | $323 | $1.14 | $0.75 |

Sustainable | $488 | $493 | $520 | $525 | $552 | $495 | $520 | $504 | $1.14 | $1.10 |

Table 11. Effect of management strategy on crop grain yields sown with disc and tine openers at Temora, NSW, 2014-2016

Management strategy | Seq | Crop | Crop | Crop | Grain/DM yield Disc Tine | Grain/DM yield Disc Tine | Grain/DM yield Disc Tine | |||

|---|---|---|---|---|---|---|---|---|---|---|

Aggressive | 4 | Wh 1 (H) | Wh 2 (H) | Can RR | 3.1 | 3.0 | 3.9 | 3.5 | 2.9 | 3.0 |

Aggressive | 6 | Wh 2 (H) | Can RR | Wh 1 (H) | 3.2 | 2.9 | 3.1 | 3.1 | 5.5 | 6.0 |

Aggressive | 10 | Can RR | Wh 1 (H) | Wh 2 (H) | 2.2 | 2.2 | 3.5 | 3.4 | 4.9 | 5.3 |

Sustainable | 1 | Barley | Leg Hay | Can TT | 4.2 | 4.5 | 2.9 | 3.4 | 2.9 | 3.0 |

Sustainable | 3 | Wh (L) | Barley | Leg Hay ((DM | 3.3 | 3.1 | 5.0 | 5.0 | 3.9 | 4.0 |

Sustainable | 7 | Leg Hay | Can TT | Wh (L) | 4.2 | 4.2 | 2.6 | 2.4 | 5.2 | 5.8 |

Sustainable | 9 | Can TT | Wh (L) | Barley | 1.8 | 1.7 | 3.5 | 3.3 | 6.0 | 6.1 |

Conservative | 2 | Wh 1 (L) | Wh 2 (L) | Can TT | 1.9 | 2.5 | 2.8 | 3.0 | 2.8 | 3.0 |

Conservative | 5 | Wh 2 (L) | Can TT | Wh 1 (L) | 1.5 | 2.9 | 2.1 | 2.4 | 2.4 | 4.7 |

Conservative | 8 | Can TT | Wh 1 (L) | Wh 2 (L) | 1.6 | 2.1 | 3.6 | 3.5 | 3.3 | 4.4 |

Effect of management strategy on weeds

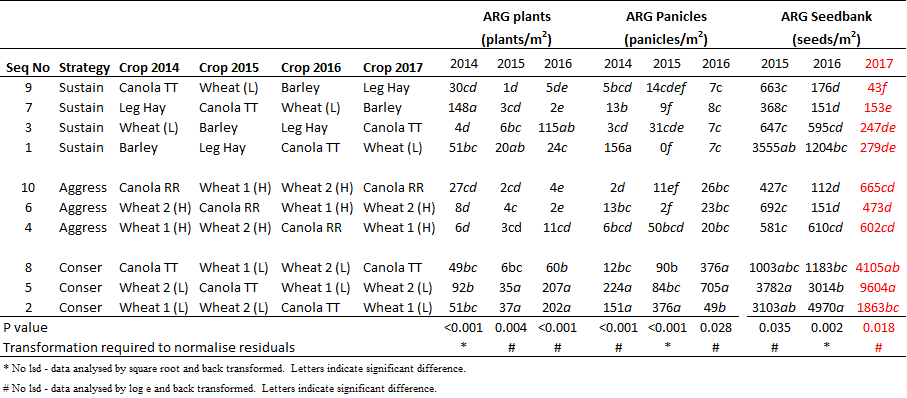

The average annual ryegrass seedbank across the trial area in February 2014 were 1864 plants/m2. Both the aggressive and sustainable management strategies significantly reduced the ARG seedbank to 351 plants/m2 by February 2016, significantly lower than in the conservative strategy (Table 12).

Table 12. Main effect of management strategy on ARG seedbank averaged across disc and tine openers at Temora, NSW, 2014-2017.

Seedbank | Seedbank | Seedbank | |

|---|---|---|---|

Management strategy | seeds/m2 | seeds/m2 | seeds/m2 |

Sustainable | 865b | 449b | 145b |

Aggressive | 556b | 253b | 573b |

Conservative | 2276a | 2830a | 4188a |

P value | 0.003 | <0.001 | <0.001 |

Transformation required | # | * | # |

* No lsd - data analysed by square root and back transformed. Letters indicate significant difference.

# No lsd - data analysed by log e and back transformed. Letter indicate significant difference.

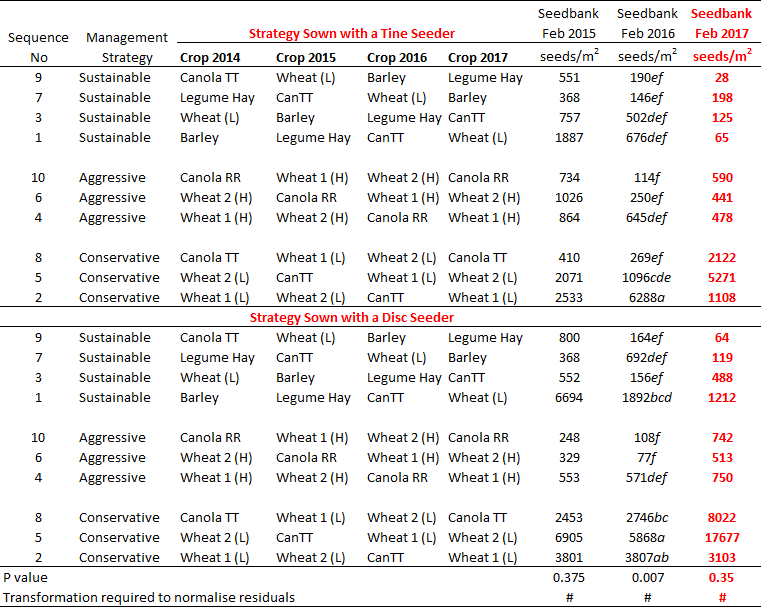

However, following the wet 2016 season with a soft late finish, the sustainable strategy had reduced the ARG seed bank measured in February 2017 by 70% compared to the aggressive strategy, with the conservative strategy increasing ARG seedbank by 600% to above 4000 seeds/m2 (Table 12). There were significant main effects of opener type (disc vs tine) on ARG seedbank populations in 2016 and 2017 with lower ARG seedbank populations in 2016 (650 seeds/m2 in tine cf 1080 seeds/m2 in disc) and 2017 (384 seeds/m2 in tine cf 944 seeds/m2 in disc) (data not shown). When comparing strategy by opener types, there were no significant difference between the aggressive and sustainable strategy x opener type in 2016 but by February 2017, the sustainable strategy sown with a tine seeder had reduced the average ARG seedbank population by 95% to 82 seeds/m2. The aggressive strategy (disc and tine) and sustainable (disc) reduced the ARG seedbank by 75% to an average of 472 seeds/m2 (Table 13). The average ARG seedbank in the conservative strategy increased to 2322 and 7631 seeds/m2 when sown with a tine and disc opener, respectively (Table 13). There was a general increase in ARG seedbank in all wheat crops sown in 2016 in the conservative strategy by a factor of 2 to 10 with a 230% increase in sequence 5 sown with a disc opener compared to a tine opener (17671 cf 5261 seeds/m2, Table 14).

Table 13. Main effect of management strategy x opener type (disc & tine) on ARG seedbank for annual ryegrass at Temora, NSW, 2014-2017.

Management Strategy | Seedbank Feb 2015 | Seedbank Feb 2016 | Seedbank Feb 2017 | |

|---|---|---|---|---|

OPENER | seeds/m2 | seeds/m2 | seeds/m2 | |

Sustainable | Tine | 734cd | 346c | 82 |

Aggressive | Tine | 866c | 300c | 498 |

Conservative | Tine | 1291b | 1840b | 2322 |

Sustainable | Disc | 1020c | 562c | 260 |

Aggressive | Disc | 356d | 207c | 659 |

Conservative | Disc | 4008a | 4045a | 7631 |

P value | <0.001 | 0.023 | 0.345 | |

Transformation | # | * | # |

* No lsd - data analysed by square root and back transformed. Letters indicate significant difference

# No lsd - data analysed by log e and back transformed. Letters indicate significant difference

By February 2017, the competitive 2016 barley crop reduced the ARG to 43 seeds/m2 (Table 15) or to 28 and 64 seeds/m2, respectively sown with a tine or disc opener (Table 14). The double break of the legume hay 2015/canola TT 2016 in the sustainable strategy sown with a tine opener was also very effective at reducing ARG seedbank (Table 14). The canola single break tended to be more effective at reducing ARG seedbank populations when sown with a tine seeder however, the double break in the sustainable strategy was more effective.

The expensive herbicides such as Sakura, Boxer Gold and Rustler provided good early weed control in both the aggressive and conservative strategies as indicated by the low ARG plant numbers in June of each year whereas, there were significantly higher early ARG plant numbers in the conservative strategy (Table 15). There were significant effects of strategy x sequence x opener type with higher ARG plant numbers in the conservative strategy sown with a disc opener compared to a tine opener (Canola TT: 2014 = 99 vs 16, 2015 = 117 vs 10 and 2016 = 452 vs 140 in disc vs tine; data not shown). There were similarly higher plant numbers in the wheat sown with a disc than with a tine seeder. The higher early ARG populations resulted in a greater increase in ARG panicles, especially in the 2nd wheat crop in 2016 (466 panicles/m2 in tine vs 1066 panicles/m2 in disc – data not shown). In contrast, in the sustainable strategy, all sequences by November 2016 had low numbers of ARG panicles and although not significantly lower than the aggressive strategy, had significantly less ARG seedlings in the seedbank in 2017 (Table 15).

Table 14. The effect of management strategy x sequence on ARG seed bank of each year between 2015-17 for disc and tine openers at Temora, NSW, 2014-2017.

Table 15. The effect of management strategy x sequence on ARG plant numbers in June, ARG panicle numbers in November and the ARG seedbank between 2014-17 averaged across disc and tine openers at Temora, NSW, 2014-2017.

Part 3: Results from grazing x stubble management experiment 2009-2016

Grazing is an effective, inexpensive method of reducing stubble while burning removes stubble, assists in reducing disease carryover, reduces certain seedling pests and weed populations. Over the eight years of the experiments, neither burning nor grazing affected yield in the 1st wheat crop after canola (Table 16). However, both heavy grazing and burning increased yield in the second wheat crop after canola and the effects were partly additive (Table 16). Across all years, grazing and burning alone increased yield of the 2nd wheat crop on average by 0.7 t/ha and 0.8 t/ha respectively, but when applied together increased yield by 1.0 t/ha. In three of the four phase years in which the 2nd wheat crop was grown, burning increased yield by between 0.5 and 0.6 t/ha, but in one year (2013) by 1.4 t/ha.

Table 16. Mean grain yield (t/ha) for either 1st or 2nd wheat crop following canola under different grazing and stubble treatments between 2009 and 2016. P-value and LSD are from the three-way interaction between grazing treatment, stubble treatment and rotational position and means followed by the same letters are not significantly different from each other.

Rotational position | ||||

|---|---|---|---|---|

Graze treatment | Stubble treatment | 1st wheat | 2nd wheat | |

Nil graze | Retain | 4.58b | 3.93c | |

Stubble graze | Retain | 4.63b | 4.58b | |

Nil graze | Burn | 4.63b | 4.68b | |

Stubble graze | Burn | 4.73ab | 4.89a | |

P-value | 0.007 | |||

LSD (P=0.05) | 0.18 | |||

Grazing stubble increased soil mineral N by 13 kg/ha in the first wheat crop (Table 17) and by 33 kg/ha in the 2nd wheat crop, and there was no interaction between grazing and stubble treatments. Burning stubble had no significant effect on soil mineral N in the 1st wheat crop, but increased soil mineral N by an average of 13 kg/ha in the 2nd wheat crop (Table 17).

Table 17. Mean soil mineral N (kg/ha N) to 1.6 m depth prior to sowing following either 1st or 2nd wheat crops following canola for different grazing and stubble treatments between 2009-2016. P-values and LSDs are for two way interactions between either grazing treatment of stubble treatment and rotational position.

Grazing treatment | Stubble treatment | |||

|---|---|---|---|---|

Rotational position | Nil graze | Stubble graze | Burn | Retain |

1st wheat | 107 | 120 | 110 | 117 |

2nd wheat | 92 | 125 | 115 | 102 |

P-value | 0.031 | 0.035 | ||

LSD (P=0.05) | 13 | 13 | ||

Averaged across both phases for the seven years of this experiment, grazing and then retaining the stubble generated the highest gross income (Table 18). If the grazing was valued assuming one dry sheep equivalent (DSE) consumed 7.6 MJ of energy per day at an agistment rate of $0.4/DSE/week, the grazing value of the stubble was $117/ha/year with an additional increase of $55/ha/year due to higher yields and higher N availability (Total increase = $172/ha yr).

Table 18. Gross income per year averaged across both phases for all years (2010-2016) of the experiment at Temora.

Graze treatment | Stubble treatment | Assuming grazed stubble has no value | Assuming grazed stubble has a value |

|---|---|---|---|

Nil graze | Retain | $1,231 | $1,231 |

Burn | $1,269 | $1,269 | |

Stubble graze | Retain | $1,286 | $1,403 |

Burn | $1,277 | $1,397 |

Discussion

There is no perfect stubble management strategy for every year with crop rotations, weeds, disease, pests, stubble loads, grazing and machinery largely dictating how to manage the stubble successfully. How a farmer answers the questions outlined on page 2 for each paddock and each farm and is able to adapt his/her farming system will influence their ability to handle stubble profitability.

A flexible approach to managing stubble means crops can be harvested high or low depending on the season and situation, stubbles can then be grazed with considerable economic advantage, straw baled and sold, mulched, incorporatedor burnt. The flexible strategy provides a range of options for all farming systems and seeder types to improve profitability while trying to maximize the stubble retained.

We found that using a stripper front or harvesting high is the quickest and most efficient method to harvest grain that produces the least amount of residue at the lowest costs. However, if farmers plan to harvest high but intend to sow with a tine seeder, they may need to determine how they can reduce their stubble load to ensure there are no major problems with the timeliness of sowing the following crop. Large stubble loads potentially create issues for all sowing systems with regards to the type and effectiveness of herbicides that can be applied, the ability of the pesticides to reach the soil surface/ weed or insect, and the effect that the thick stubble load could have on the emerging seedling. Narrow windrow burning has proved very effective in reducing ARG seedlings, but in cereal paddocks with high stubble loads, it may be necessary to incorporate mechanical methods of control such as harvesting low with a HWSD to assist in reducing herbicide resistant ARG seed set, although this will be more expensive and be slower.

One of the negatives we found when sowing wheat into tall wheat stubble (45 cm cf 15 cm) was that seedlings received less radiation and were exposed to cooler temperatures, which often resulted in a reduced early growth and a reduction in tiller number. In our experiments, this didn’t persist to a reduction in grain yield, however, the Riverine Plains Inc grower group found a significant reduction in 2014 in grain yield (4.98 t/ha cf 5.66 t/ha with lsd @ P<0.05 = 0.45 t/ha) in tall compared to short stubble.

In the strategy management experiment, we compared two canola-wheat-wheat sequences against a diversified sequence (canola-wheat-barley-vetch for hay). One was aggressively managed for weed control and to maximize yield which included more crop competition, more expensive herbicides, the inclusion of a hybrid RR canola and higher rates of N at sowing (deep banded in tine opener only) against a conservatively managed sequence with cheaper herbicides, lower crop densities, lower rates of N at sowing and cheaper crop types. The third comparison, a diverse or sustainable cropping strategy allowed each crop to be sown into a less antagonistic stubble i.e. wheat into canola, barley into wheat, vetch into barley and cut for hay followed by, canola sown into low stubble load.

The income from the vetch hay combined with highly effective weed control and the additional N plus water conservation, especially preceding the higher value and risky crops such as canola, were able to make the sustainable strategy a reliable profitable management option for farmers wanting to retain stubble. The double break from the legume hay/canola treatment combined with the crop competition from the barley crop was extremely effective at reducing ARG seedbank to below that of the aggressive canola-wheat-wheat sequence under extremely wet and dry seasonal conditions when sown with a disc or tine opener. The benefit of the double break was most noticeable following the wet season of 2016. With no knockdown applied before the early sowing in 2016, the expensive pre-emergent herbicides sprayed in the aggressive and sustainable strategies such as Sakura®, Boxer Gold® and Rustler® proved extremely effective at controlling the early ARG populations even with high stubble loads (Table 15). However, all pre-emergent herbicides had become ineffective by August 2016 as late ARG plants emerged in the first 3 weeks of August. As crop topping was not possible in this experiment, late control of ARG was left to increased crop competition from barley and/or in combination with the benefits of the legume hay or canola crop in the sustainable tine strategy that resulted in significantly lower (P=0.082) ARG panicles compared to the 1st or 2nd wheat crop in the aggressive strategy (data not shown).In comparison, the conservative management strategy although reasonably profitable especially when sown with a tine opener, was largely ineffective at reducing the ARG seedbank, which significantly increased following the wet 2016 season. The ability to apply trifluralin as a pre-emergent herbicide with a tine opener reduced the ARG seedbank compared to the conservative strategy sown with a disc opener, however, the conservative strategy would not be recommended with either opener type where there is any ARG weed problem.

Deep banding of N was incorporated into the management strategy (tine only) of this experiment. The amount of applied N at sowing captured by wheat crops has been found to increase when deep banded below the seed in the presence or absence of stubble (Kirkegaard et al. 2017). Although the rates of N deep banded were 122 kgN/ha, similar results from 2017 have been observed with rates at 100 kgN/ha. Similar benefits are expected to have occurred in the cereal and canola crops sown with the tine opener in the management experiment as N was deep banded at sowing. The application of early N applied to the soil surface pre sowing with a disc opener may have resulted in slower early growth. There is the potential for mid-row banding technology to be used with disc openers to apply N deep below the seed at sowing.

With careful planning and diverse management, burning can be kept for those occassions where the system needs to be reset which can result in farmers retaining stubble for another series of years. A late burn, conducted wisely just prior to sowing to minimise the time the soil is exposed is one option farmers may need to consider when dealing with large stubble loads. Grazing and burning canola stubbles had no effect on the yield of the 1st wheat crop following canola, but grazing or burning the stubble of the first wheat crop increased yield substantially in the 2nd wheat crop. Whilst this difference could logically be attributed to various biotic mechanisms such as disease, no treatment differences were recorded within the very low level of stubble-borne diseases (yellow leaf spot, crown rot, Zymoseptoria tritici) that were present at the site in some years. It thus appears more likely that N dynamics are principally responsible for the observed differences in yield.

Grazing and burning stubbles increased soil mineral N accumulation during the summer fallow to a much greater extent in the 2nd wheat crop compared to the 1st wheat crop presumably due to both higher amounts and higher C:N ratio of wheat stubble compared to canola stubble which would lead to more N immobilisation (Hunt et al. 2016). The average increase in mineral N due to grazing in the 2nd wheat treatment was 33 kg/ha N. Hunt et al. (2016) suggested that grazing either removed C from the system or neutralised C with potential immobilising power of 52 kg/ha N. Under the no till surface-retained residue management practiced at this site, immobilisation would presumably occur over several years as residues slowly decompose. The greater effect of grazing stubble on mineral N compared to burning stubble in this experiment is likely due to differences in the timing of the two treatments with respect to soil measurement. The grazing treatment was applied immediately after harvest, giving 4 to 5 to months between removal of stubble by grazing and measurement of soil N. In contrast, the burn treatment was applied only ~1 month before measurement of soil mineral N, giving less time for differences in N immobilisation to act before the pre-sowing soil N tests. Both treatments influenced grain yield as they both would have presumably altered in-season net N mineralisation. The results suggest that where disease is absent or controlled and good crop establishment achieved, N immobilisation by wheat residue can significantly reduce crop yield in subsequent wheat crops.

Beyond the effects of N dynamics on grain yield, burning stubble also reduced frost-induced sterility of the 2nd wheat crop from 59 to 30% following severe frosts of -2.6oC, -1.8oC and -3.6oC (screen temperatures) that occurred on the 15, 16 and 18 October in 2013. In that year, grazing increased the yield of the 2nd wheat crop by 1.0 t/ha, burning by 1.4 t/ha and combined by 1.6 t/ha. However, no differences in frost-induced sterility were measured in any other year of the experiment.

It must be recognised that some of the negatives to burning include loss of nutrients (amount depends on temperature), increased regulation and potential losses of soil from erosion. Increasing restrictive regulations are being implemented that also make burning more difficult in the future. In some shires, a single burn requires 6 people, 2 fire control units (1 with 5000L and the other with 500L) and you are not able to leave the paddock until NO smoke is detected.

Conclusion

It is extremely important for farmers NOT to compromise managing weeds, disease, pests or being able to sow their crop in a timely manner due to excessive stubble loads. Farmers need to be pro-active in managing their stubble which should have commenced before harvest and continued until sowing to ensure their stubble management will suit their seeding system. It has been shown that by diversifying a crop rotation (increasing the number of pulse crops and barley), deep banding nitrogen, managing pests and diseases, managing stubble by baling or grazing that it is easier to manage stubble without the need to burn. A diversified sustainable management strategy incorporating a double break crop offers a profitable farming system with reduced nitrogen costs that is effective at controlling weeds. Farmers can also retain their stubble in most years even when establishing crops with a tine opener. However, if the stubble load remains too large or the potential weed/disease/pest burden remains too high, then a one off strategic late burn can be used to “re-set” the system.

We suggested that growers wishing to retain all stubble should avoid growing wheat after wheat, that residue loads are reduced by grazing and/or burning where wheat is to be grown following wheat, or supplementary N fertiliser is applied to offset that immobilised by the residue. Grazing wheat stubbles can increase the yield of subsequent wheat crops due to less immobilisation and greater availability of mineral N to subsequent wheat crops. Burning wheat stubble residues also increased yield of subsequent wheat crops, but did not increase pre-sowing soil mineral N to the same extent as grazing, possibly due to later timing. However, both treatments presumably influenced in-crop N availability and thereby crop yield. Burning wheat stubble can also reduce frost damage in subsequent wheat crops and increase yield accordingly in frosty seasons.

References

GRDC Managing Stubble Booklet, May 2012

Mallee Sustainable Farming Inc: Stubble Management – A guide for Mallee farmers (2013)

Riverine plains Stubble management guideline No 1 . “Managing stubble at harvest improves sowing success” –. GRDC project RPI00009 - Maintaining profitable farming systems with retained stubble in Riverina Plains region.

Stubble management – an integrated approach (2010): EH Graham Centre for Agricultural innovation

Broster et al. (2011) Herbicide resistance levels in annual ryegrass (Lolium rigidum Gaud.) in southern New South Wales. Plant Protection Quarterly 26 (!) 22-28.

Hunt et al. (2015) The effect of grazing and burning stubbles on grain yield and quality in no-till and zero-till controlled traffic farming systems in SNSW. GRDC Updates Adelaide and Wagga.

Kirkegaard et al. (2017) Opportunities and challenges for continuous cropping systems. GRDC updates in Adelaide, Wagga Wagga and Bendigo.

Peoples et al. (2016) Profitable break crop management guide. “Profitable Break Crop management Guide”

Swan et al., (2015) Profitable crop sequences to reduce ryegrass seed bank where herbicide resistant ryegrass is a major constraint to the sustainability of cropping systems. Proc.17th ASA Conference Hobart.

Contact details

Tony Swan

Business Address: CSIRO Agriculture and Food, GPO Box 1700, Canberra ACT 2601

Mb: 0428 145 085

Email: tony.swan@csiro.au

® Registered trademark

GRDC Project Code: CSP00174,

Was this page helpful?

YOUR FEEDBACK