Improving nitrogen fertiliser use efficiency in wheat using mid-row banding

Author: Graeme A. Sandral, Ehsan Tavakkoli, Felicity Harris, Eric Koetz (NSW Department of Primary Industries, Wagga Wagga Agricultural Institute) Simon Diffey (Apex Biometry) John Angus CSIRO Agriculture and Food, EH Graham Centre Charles Sturt University) | Date: 13 Feb 2018

Take home message:

- Mid-row banding (MRB) of urea at sowing provided a higher yield and profit response than all other N application methods other than incorporated by sowing (IBS).

- Nitrogen requirements based on targeting 13% protein ranged from 51 to 58kg N/t/ha for all methods of N application and were lowest for MRB (51kg N/t/ha).

- Urea incorporated by sowing (IBS) was more efficient than deep placement (DP) of urea and urea spread at early stem elongation (DC31).

Introduction

Fertiliser costs represent 20% to 25% of variable costs for growing grain crops. This proportion is likely to increase with the continued decline of soil organic matter and corresponding reduction in annual soil mineralisation of nitrogen (N) (e.g. Angus and Grace 2017). In approximate terms, the N mineralisation potential in cropping soils is declining by 50% every 25 to 30 years. Soil mineralisation of N is not enough to meet crop demand, consequently N fertiliser is typically applied to wheat at sowing, stem elongation and occasionally at booting. The in-crop efficiencies of fertiliser N retrieval vary greatly, with approximately 44% in above-ground plant parts, 34% in soil and 22% not recovered, which is presumably lost (Angus and Grace 2017). Increases in the efficiency with which wheat extracts fertiliser N from the soil can result in substantial fertiliser savings.

In this study four methods of N supply to wheat were compared that included; (i) surface broadcast and incorporated by sowing (IBS), (ii) mid-row banding (MRB) at sowing (8cm deep) between every second row, (iii) deep placement (DP) at sowing under each wheat row (16cm), and (iv) broadcasting at stem elongation (BSE). Results of grain yield and protein response, estimated N use efficiency (e.g. N offtake and apparent proportion of fertiliser recovery) and returns on investment for each method and rate of N application are reported.

Background

The approach to this research was based on some previously established knowledge on N loss pathways. A brief discussion of the N loss pathways and their relation to methods of N application used in this study (MRB, DP, IBS and BSE) are provided below.

Nitrogen volatilisation

When applying urea IBS or BSE, the urea can be dissolved on and in residual stubble where it’s converted to ammonia (NH3) as the stubble has urease activity (approximately 1830mg urea/kg/ha) and a high pH (e.g. approximately pH=8 for wheat straw) which favours N volatilisation (e.g. McInnes et al 1985a, b). Urea washed into the soil can also be converted to ammonia and volatilised, although in southern NSW this is limited by low soil pH (note: volatilisation losses are often greatest with high pH, high temperature and drying conditions).

When comparing volatilisation from IBS and BSE, the partial burial of urea with IBS application will likely reduce losses, while the warmer autumn temperatures act to increase potential losses. Any N buried below eight centimetres is considered safe from volatilisation (Rochette et al., 2014). As the urea moves into the soil it is converted to nitrate (e.g. urea → ammonia → ammonium → nitrite → nitrate). The ammonia form is toxic to plants and therefore it’s the other forms listed that are taken up by plants, although most is taken up as nitrate some as ammonium and very little as nitrite.

The best strategies for avoiding volatilisation losses from urea include (i) burial at or below eight centimetres either as part of the sowing operation; including options such as MRB or in-crop MRB at DC31, (ii) broadcasting on a slightly acid (pH < 6.5) soil surface during winter in front of likely rainfall (BSE) and (iii) ensuring any liming applications are well mixed in the 0cm to 10cm layer as lime stratified in the 0cm to 2cm layer can substantially increase soil pH in this section of soil and increase likely volatilisation losses.

Nitrogen immobilisation

Stubble residues from the previous season are broken down by microbial activity that consume nitrogen and carbon. To grow bacteria, about 12 units of carbon (C) are consumed to one unit of N while wheat straw contains about 80 to 120 units of C for every unit of N. Consequently the bacteria utilise soil N to break down the stubble residue.

As an estimate, 1000kg/ha of wheat grain produces about 1660kg/ha of stubble. This stubble is made up of approximately 40% to 45% of carbon (747kg/ha assuming 45% carbon) and has approximately 6.2kg N/ha, assuming a 120:1 C:N ratio in wheat stubble. As an estimate, 30% of the stubble is used by microbes for growth while approximately 70% is respired as carbon dioxide. Therefore the microbes would consume 224kg C/ha (30% of 747kg/ha) for growth and at a C:N ratio of 12:1 that would mean they require 18.6kg N/ha of which 6.2kg N/ha is already contained in the stubble. Therefore for every tonne of last year’s grain yield, 12.4kg N/ha (18.6kg N/ha to 6.2kg N/ha) is required to break down last year’s stubble residue.

Where this N is not supplied, the grain yield loss from immobilisation in wheat would be 250kg/ha/t of wheat yield or 250kg/ha/1.66t of residual stubble. With high stubble loads and low C:N rations, N immobilisation can be substantial. For example a 4t/ha wheat crop that was broken down completely over the following year would immobilise an estimated 50kg N/ha or approximately 110kg/ha of urea (note wheat stubble usually takes more than one year to break down in southern NSW).

Strategies to avoid immobilisation of urea include (i) burial below the organic matter rich soil layer, (ii) late stubble burn or (iii) baling of stubble residuals. The latter two strategies result in losses of nutrients from the paddock.

Denitrification of nitrogen

Where soils are limited in oxygen (e.g. > 80% of field capacity), some soil bacteria will use the oxygen molecule in nitrite (NO2-) and nitrate (NO3-), causing the conversion of these forms of N to NO (nitric oxide), N2O (Nitrous oxide) and N2 (Nitrogen gas). Denitrification losses can be avoided by (i) holding N in the ammonium form and/or (ii) putting in place measures that limit waterlogging such as the use of controlled traffic or in more extreme cases raised beds.

Nitrogen leaching

Nitrogen leaching losses can occur where N moves either below the crop rooting depth, or to a depth where the N is not taken up at the same efficiency as N held higher in the soil profile. This may be due to factors such as root length density which decreases with increasing soil depth, particularly in sodic soils. Leaching of N occurs more readily when it is in the nitrate form as it is negatively charged and consequently does not bond to clay particles. Strategies to avoid N leaching include (i) holding N in the ammonium form which is positively charged and is less likely to leach or (ii) applying N at early stem elongation (e.g. DC31).

This study does not measure N losses directly however, differences in N losses combined with different efficiencies of soil N utilisation by wheat are likely to be reflected in grain yield, protein and straw as well as residual soil N levels. At the time of writing this paper only grain yield and protein results were available.

Methods

This experiment was sown at Wagga Wagga Agricultural Institute, NSW on 14 May and included one wheat variety (cv. Beckom), eight N rates and four N application methods with N applied as mono-ammonium phosphate (MAP) and/or urea (Table 1) in a fully randomised complete block design with four replicates. Rainfall for the growing season was 187mm (May to mid-November), stored soil water was 52mm and provides an estimated potential yield of 3.2t/ha (187 + 52 [water in] – 110 [soil evaporation] x 25 [kg gain per mm of water]). Peak grain yield was 3.8t/ha which may have been due to either less soil evaporation than estimated (110mm) or a high conversion efficiency of water to grain or a combination of both factors.

Table 1. Variety, nitrogen rates and nitrogen application methods.

Variety | N rate (kg/ha) | Application method |

|---|---|---|

| Beckom | 0 | Mid-row banding at sowing (May 14) [MRB] |

10 | Spread and incorporated by sowing (May 14) [IBS] | |

35 | Deep placement under each row at sowing[DP] | |

60 | Broadcast at DC31 (July 28) [BSE] |

The soil at the experimental site was a Red Kandosol with a starting mineral N content of 42kg/ha to a depth of 1.5m (May 4). The previous crop was barley which was burnt late, prior to sowing. Soil pH (CaCl2) was 5.8 (0cm to 10cm), 4.7 (10cm to 20cm) and 5.5 (20cm to 30cm) and Colwell P was 57mg phosphorus (P)/kg soil (0cm to 10cm). The experiment was direct sown using deep blade system (DBS) tynes spaced at 240mm. At sowing 100kg MAP (22kg P/ha and 10kg N/ha) was added to all treatments except the nil N treatment which received triple superphosphate at 22kg P/ha to balance all treatments for P.

In plots receiving MAP, various amounts of urea were added to provide the N rates of 35kg N/ha through to 185kg N/ha. Mean plant density at DC14 was 127 plants/m2 and was similar between treatments. In-crop weed control was undertaken by applying the pre-emergents Sakura® (pyroxasulfone 850g/kg) at 118g/ha and Logran® (triasulfuron 750g/kg) at 35g/ha on May 14 and was incorporated at sowing. Precautionary disease control was implemented, seed was treated with Hombre ® Ultra [Imidacloprid (360g/L) and Tebuconazole (12.5g/L)] at 200mL/100kg and Prosaro® (Prothioconazole 210g/L and Tebuconazole 210g/L) was applied at 300mL/ha at DC 31.

The experiment was harvested on 30 November (hand harvest prior to 100mm of rain) and again on 16 December (header harvest after 100mm of rain) to determine grain yield response to N rate and application method as well as the impact of rainfall on test weight, grain protein and falling numbers. Grain protein and seed quality were estimated using near infrared (NIR) (Foss Infratec 1241 Grain Analyzer) and Seed Imaging (SeedCount SC5000R), respectively.

Nitrogen offtake was estimated by protein (%)/5.7 (conversion constant) x grain yield (t/ha). The proportion of apparent fertiliser N recovery in grain was calculated by (GrainN+N – GrainN-N)/N rate where GrainN+N is the grain yield with fertiliser N, GrainN-N is grain yield with no fertiliser N and N rate is the amount of fertiliser N applied. Economic returns after N costs were determined on 2017 prices (e.g. Junee 11Dec) by multiplying grain yield (t/ha) by $210 for AUH2, AUH2, AGP1 grain grades, $250 for AWP1 grain grade, $265 for H2 grain grade and $280 for H1 grain grade. Pre- and post-rain grain price was only influenced by test weight, protein and falling numbers. Grain discolouration did not impact on price.

Soil mineral N was measured prior to sowing (May 4), early stem elongation (DC31, 29 July) anthesis (DC65, 30 September) and post-harvest (1 December) by coring to 150cm and measuring soil ammonium and nitrate at depths 0cm to 10cm, 10cm to 20cm, 20cm to 30cm, 30cm to 60cm, 60cm to 100cm, 100cm to 150cm and 150cm to 200cm. Only starting soil N results are available at the time of writing this paper.

Results and discussion

Grain yield

Grain yield response to method of N application and N rate were large (Table 2). Grain yields were highest for MRB and IBS when comparing maximum and 95% of maximum grain yield across the four methods of application. However when grain yield was compared at 13% protein, MRB alone provided the highest yield (Table 3). The DP method of N application provided the lowest yields using all three yield comparisons of 100 and 95% of maximum yield and yield at 13% protein while DC31 N application provided yields higher than DP but below that of MRB and IBS (Table 3).

One of the initial hypotheses was that IBS would be the least efficient methods of N application as some of the N applied can volatilise while the remaining N is exposed for longer periods in the nitrate form, leaving it more vulnerable to immobilisation, denitrification and leaching. Consequently the IBS results are somewhat surprising as this method of N application was comparable to MRB, a method of application that buries the N and holds it in the ammonium form for longer making it less vulnerable to loss pathways. It was also anticipated that DP would be amongst the most efficient methods of applying N at sowing.

DP of urea (buried at16cm) into lower subsoil microbial populations was predicted to slow down the N mineralisation process and act as a slow release N supply. It was also surprising to observe DC31 application of N perform below that of MRB and IBS (DC31 had N applied on 28 July prior to 7mm of rainfall). It is speculated that the DC31 application performed poorly as June rainfall of two millimetres was not conducive to surface root development,

N was applied on July 28 and subsequent rainfall in August (approximately 45mm) would have moved the N to approximately 10cm to 20cm based on N movement at half the rate of the wetting front and evapotranspiration. What followed was a dry September (6mm) and once the available soil water was used in the 0cm to 20cm layer the remaining soil N was not accessible. While this is a reasonable explanation it should be said that at this stage there is no evidence to support this explanation (e.g. soil data is still being processed). As a general comment, it is unlikely that immobilisation, denitrification or leaching loss pathways were substantial, as the site had low winter rainfall and the stubble was burnt just prior to sowing.

Grain protein

Grain protein responses were large for both method of N application and N rate. The lowest N rates in each method of application to achieve the H1 grade (13% protein or greater) was 135kg N/ha for DP (14.1%), 135kg N/ha for MRB (13.5%), 160kg N/ha for DC31 (13.5%) and 160kg N/ha for IBS (13.6%). The H2 protein range (10.5 to 12.9% protein) was achieved by all treatments at peak grain yield (Table 2). It was anticipated that IBS would be the method of N application that would be least efficient for improving grain protein and this was supported by the results. However it was also anticipated that DC31 N application would be the most efficient method to improve grain protein, although this was not supported by results (see previous explanation). DP and MRB were the most efficient methods for improving grain protein.

Economic returns

Economic returns after considering N costs, grain protein, falling numbers, screenings, test weight and stained grain pre and post December rainfall (100mm) are shown in Table 2. Pre-December rainfall returns after N costs were highest for MRB and IBS and lower for DP and DC31 (Table 2 and 3). Post December rainfall returns were substantially lower (lower falling numbers and test weights) however, the methods of N application performed in the same order as the pre-December rainfall results. At 13% protein, MRB alone was the highest returning method of application, IBS and DC31 had similar returns and DP the lowest (Table 3).

Table 2. Grain yield (t/ha), grain protein (%), N offtakes (kg/ha), falling numbers (sec) and net return ($/ha) after N costs for the wheat variety Beckom pre and post rainfall (100mm, 2to 8 Dec). Bold indicates the highest value within each N application method.

Treatment | Grain yield (t/ha) | Grain protein (%) | N offtake (kg/ha) | Falling numbers pre-rainfall (sec) | Falling numbers post-rainfall (sec) | Net ($/ha) after N costs pre-rainfall | Net ($/ha) after N costs post-rainfall | Loss ($) due to rain |

|---|---|---|---|---|---|---|---|---|

nil_0 | 1.96 | 7.3 | 25.0 | 354 | 286 | 461.41 | 405.66 | 55.74 |

MRB_10 | 2.41 | 7.7 | 27.8 | 344 | 282 | 555.96 | 464.94 | 91.02 |

MRB_35 | 2.99 | 8.1 | 45.2 | 381 | 252 | 732.30 | 601.49 | 130.82 |

MRB_60 | 3.43 | 9.2 | 59.7 | 411 | 236 | 859.99 | 694.70 | 165.30 |

MRB_85 | 3.71 | 10.6 | 71.3 | 433 | 229 | 939.02 | 744.57 | 194.46 |

MRB_110 | 3.84 | 12.1 | 80.0 | 448 | 228 | 969.40 | 751.10 | 218.30 |

MRB_135 | 3.81 | 13.5 | 85.8 | 456 | 232 | 951.12 | 714.29 | 236.83 |

MRB_160 | 3.63 | 14.5 | 88.7 | 456 | 236 | 884.18 | 634.14 | 250.04 |

MRB_185 | 3.29 | 14.8 | 88.7 | 449 | 239 | 768.59 | 510.65 | 257.94 |

IBS_10 | 2.34 | 7.5 | 27.3 | 354 | 258 | 548.74 | 451.43 | 97.31 |

IBS_35 | 2.94 | 8.4 | 45.4 | 372 | 268 | 718.80 | 585.45 | 133.34 |

IBS_60 | 3.38 | 9.6 | 59.7 | 388 | 266 | 840.25 | 676.75 | 163.50 |

IBS_85 | 3.65 | 10.8 | 70.4 | 405 | 255 | 913.10 | 725.33 | 187.78 |

IBS_110 | 3.75 | 12.0 | 77.4 | 421 | 241 | 937.35 | 731.17 | 206.18 |

IBS_135 | 3.68 | 12.9 | 80.6 | 437 | 229 | 912.99 | 694.28 | 218.71 |

IBS_160 | 3.45 | 13.6 | 80.1 | 453 | 224 | 840.03 | 614.66 | 225.37 |

IBS_185 | 3.04 | 13.8 | 75.9 | 469 | 231 | 718.47 | 492.32 | 226.15 |

DP_10 | 2.41 | 7.1 | 26.5 | 393 | 276 | 609.06 | 523.24 | 85.82 |

DP_35 | 2.82 | 8.0 | 41.9 | 415 | 251 | 689.24 | 568.83 | 120.42 |

DP_60 | 3.13 | 9.4 | 55.2 | 434 | 233 | 754.38 | 602.48 | 151.90 |

DP_85 | 3.34 | 11.0 | 66.3 | 451 | 221 | 804.47 | 624.20 | 180.27 |

DP_110 | 3.46 | 12.7 | 75.2 | 465 | 214 | 839.52 | 633.98 | 205.54 |

DP_135 | 3.48 | 14.1 | 81.9 | 477 | 213 | 859.52 | 631.83 | 227.69 |

DP_160 | 3.40 | 15.0 | 86.4 | 485 | 216 | 864.48 | 617.74 | 246.74 |

DP_185 | 3.22 | 15.1 | 88.7 | 491 | 224 | 854.39 | 591.71 | 262.68 |

DC31_10 | 2.34 | 7.5 | 28.9 | 344 | 272 | 545.95 | 451.39 | 94.56 |

DC31_35 | 2.83 | 8.6 | 43.8 | 375 | 288 | 671.50 | 551.64 | 119.86 |

DC31_60 | 3.21 | 9.7 | 56.4 | 401 | 294 | 768.09 | 623.53 | 144.56 |

DC31_85 | 3.48 | 10.8 | 66.8 | 421 | 293 | 835.72 | 667.04 | 168.68 |

DC31_110 | 3.63 | 11.8 | 74.9 | 436 | 286 | 874.40 | 682.19 | 192.21 |

DC31_135 | 3.68 | 12.7 | 80.6 | 446 | 277 | 884.11 | 668.96 | 215.15 |

DC31_160 | 3.61 | 13.5 | 84.2 | 450 | 266 | 864.86 | 627.37 | 237.50 |

DC31_185 | 3.43 | 14.0 | 85.4 | 448 | 256 | 816.66 | 557.41 | 259.25 |

LSD P=0.05 | 0.10 | 0.45 | 3.72 | 33.8 | 15.7 | 49.48 | 33.58 | - |

Treatment codes: MRB = mid-row banding (between every second row, 8 cm deep), IBS = surface spread then incorporated by sowing, DP = deep placement below every sown row (16 cm), DC31 = surface spread at early stem elongation. Numbers following the underscore (“_”) signify the amount of nitrogen applied (kg N/ha).

Table 3. Grain yield (t/ha), N rate to achieve grain yield (kg N/ha) and returns after N costs ($/ha) for maximum grain yield, 95% of maximum grain yield and grain yield at 13% protein for each of the methods of N application.

N application method | 100% of maximum yield (t/ha) | N rate to achieve 100% of maximum yield (kg N/ha) | Net return ($/ha) after N costs at 100% of maximum yield | 95% of maximum yield (t/ha) | N rate to achieve 95% of maximum yield (kg N/ha) | Net return ($/ha) after N costs at 95% of maximum yield | Yield (t/ha) at 13% protein | N rate to achieve 13% protein | Net return ($/ha) after N costs at 13% protein |

|---|---|---|---|---|---|---|---|---|---|

MRB | 3.84 | 118 | 969 | 3.65 | 78 | 921 | 3.83 | 126 | 963 |

IBS | 3.75 | 113 | 937 | 3.56 | 75 | 890 | 3.67 | 137 | 909 |

DC31 | 3.68 | 132 | 884 | 3.50 | 88 | 843 | 3.66 | 144 | 880 |

DP | 3.48 | 127 | 865 | 3.31 | 80 | 796 | 3.47 | 115 | 844 |

Nitrogen offtake

Nitrogen offtake in grain was used as an estimate of N efficiency for the different N application methods tested (Table 2). These results show that at peak yield each method of N application exported approximately 80kg N/ha. However, when considering a fixed N supply of 110kg N/ha the N offtake was highest for MRB and IBS and lowest for DC31 and DP. These efficiency differences were evident across a range of rates (Table 2).

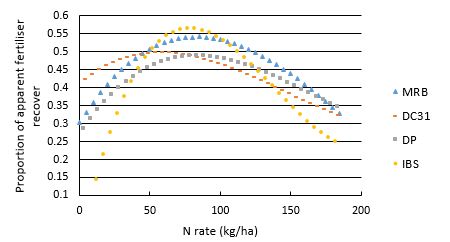

Proportion of apparent fertiliser recovery

The proportion of apparent fertiliser N recovery in grain at 95% of maximum yield (Figure 1) was highest for MRB (0.54) and IBS (0.56) and significantly lower for DP (0.49) and DC31 (0.48).

Figure 1. Apparent fertiliser-N recovery in grain for Beckom in relation to three methods of nitrogen application and nine rates of nitrogen.

Falling numbers

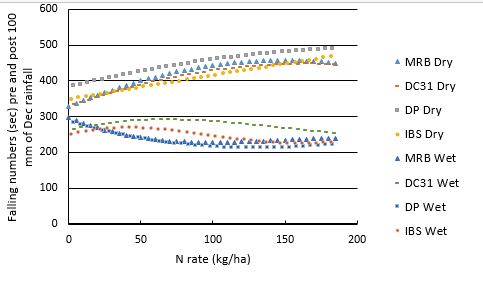

Weather damage as assessed by falling numbers was impacted by the method of N application and N rate (Figure 2). Grain that was not weather damaged had falling numbers above 300sec and these readings increased with increasing N rate. Weather damaged grain had falling numbers below 300sec however the method of N application and N rate determined the extent of the decline in falling number count (Figure 2).

Figure 2. Falling numbers pre and post 100 mm of rainfall over December 2 to 8. Weather damaged readings were all below 300sec.

Test weight

There was no effect of method of N application or N rate on test weight, however there was an impact of December rainfall on test weight with test weight prior to rainfall averaging 81.6kg/hl and after rainfall the average was 74.1kg/hl.

Estimated nitrogen budget

The estimated N required to produce 1t/ha of wheat ranged from 41kg/t/ha to 58kg/t/ha (Table 4). These estimates are within the range provided by Angus (2016) where [grain yield (1t/ha) X protein (11%) X 2.33]/0.5 = Soil N required of 51kg N/ha]. MRB was consistently the most efficient method of N application (Table 4).

Table 4. The estimated nitrogen required (kg N/t/ha) to produce 1t/ha of wheat for 100 and 95% of maximum yield as well as N required for a 1t/ha yield at 13% protein. Assumptions included; the in-crop mineralisation was 28kg N/ha which was estimated by growing season rainfall x organic carbon x 0.15. The pre-sowing soil N content was 42kg N/ha.

N application method | 100% of maximum yield (t/ha) | 95% of maximum yield (t/ha) | Yield (t/ha) at 13% protein |

|---|---|---|---|

MRB | 49 | 41 | 51 |

IBS | 49 | 41 | 56 |

DC31 | 55 | 45 | 58 |

DP | 57 | 45 | 53 |

Mid-row banding in-season

With the advent of precision guidance systems it is also possible to consider MRB of N into established crops as an alternative to topdressing or liquid applications. In situations where variable seasons or other factors dictate a greater proportion of N being applied in‑season, MRB may help to reduce the risk of loss to volatilisation. This could present the opportunity for growers to apply N at a time that better suits their logistics rather than aiming to apply in front of rainfall which can be hard to predict.

GRDC investment in research conducted by Agriculture Victoria during 2016 and 2017 has shown that in-season MRB has the potential to improve nitrogen use efficiency; in particular increasing the proportion of fertiliser recovered by the crop (DAV00143; Wallace et al 2016). The effects on yield and protein have been more variable; in some cases increasing yield and or protein compared to top‑dressed, granular or liquid applications, but in others not.

In considering a move to MRB in‑season, it is important to assess the ability to accurately apply N inter-row at a given row spacing, stubble load and soil moisture level, speed of operation, cost of capital and ongoing operating costs plus unforeseen impacts such as the potential for increased weed germination following inter-row soil disturbance. A link to a summary of results from the 2016 Agriculture Victoria study is provided in the ‘Useful Resources’ section.

Conclusion

Mid-row banding of N resulted in the highest grain yield, while the highest N removal rate and profit were achieved by MRB and IBS. Mid-row banding of N provides growers with an alternative strategy to improve nitrogen use efficiency in wheat by providing improved recovery of N in grain, higher yields and higher grain protein compared with most other N application methods.

Useful resources

a-test-of-nitrogen-fertiliser-use-efficiency-in-wheat-using-mid-row-banding

References

Budgeting crop nitrogen supply better estimation better decisions.

McInnes KJ, Ferguson RB, Kissel DE, Kanemasu ET (1986a) Field measurements of ammonia loss from surface applications of urea solution to bare soil. Agronomy Journal 78:192–196.

McInnes KJ Ferguson RB Kissel DE and Kanemesu ET (1986b) Ammonia loss from applications of urea-ammonium nitrate solution to straw residue. Soil Science Society of America Journal 50:969-974.

Rochette, P. Ammonia volatilization and nitrogen retention: How deep to incorporate urea? Journal Environmental Quality. 42(6):1635-42, 2014.

Acknowledgments

Technical support from the following people was critical to the completion of this study: Russel Pumper, Vince Vanderrijt, Graeme Poile, Daniel Johnson, Aysa Pourvali, Kelly Fiske, Holly Menz, Abrahim Ahaddouz, Chris Leywood and Matt Clarke. This study is not externally funded, consequently the support of NSW DPI is gratefully appreciated.

Contact details

Graeme Sandral

graeme.sandral@dpi.nsw.gov.au

@gsandral

Was this page helpful?

YOUR FEEDBACK