The production and characterisation of value added pulse flakes

Take home messages

- For pulses to play a role in sustainable and healthy food systems, key constraints through innovations in pulse-based food processing need to be addressed.

- Research into material properties of pulses may reduce costly trial-and-error product development for ready to eat products.

- Current research focus is to quantify how pre-treatment, forming and secondary processes affect flaking performance and product quality of pulse flakes.

Background

Pulses are the mature, edible dry seeds of non-oilseed, legume plants, with significant nutritional, health and environmental benefits(Bhandari, Datta, & Howes, 1997; Rebello, Greenway, & Finley, 2014). Pulses are high in protein, low in fat and glycaemic index (Cuvelier, Storsley, Mollard, Thandapilly, & Ames, 2017) and are great sources of fibre, minerals and B vitamins. Pulse consumption has been shown to protect against certain cancers, high cholesterol, type 2 diabetes and obesity (Hall, Hillen, & Garden Robinson, 2016). Pulse crops add nitrogen (N) to soil keeping soils fertile and are water efficient (FAO, 2017). The significance of pulses was recognised with the Food and Agriculture Organization of the United Nations (FAO UN) declaring 2016 the international year of the pulse (FAO, 2016), promoting the role of pulses in the sustainable supply of healthy food (McDermott & Wyatt, 2017).

Australia is one of the major exporters of pulses (AEGIC, 2016), yet many Australians do not meet the recommended dietary intake of 1-3 serves per week (Broom, 2016). In developed countries, pulses contribute only 1% of the calorie intake and 2.2% of the protein intake (Maredia, 2012). Low consumption of pulses has been attributed to the time and effort required to prepare and deactivate anti-nutritional factors (ANF), which typically involve soaking and boiling for over one hour and the need to modify sensory attributes such as texture and flavour (Revilla, 2015; Roland, Pouvreau, Curran, van de Velde, & de Kok, 2016; Setchell & Radd, 2000; Tyler, Wang, & Han, 2017; Van Der Poel, 1990).

Approximately 60% of Australian pulses are exported for predominantly human consumption, of which 25% of these exports are to India (AEGIC, 2016). The recent 30% tariff imposed on pulse imports to India highlights the need to diversify Australian pulse markets. Developing our domestic pulses processing innovation capability is one way to decrease exposure to the risk of relying on a limited number of large international commodity markets. To improve market stability and growth of Australian grown pulses, such as chickpeas and faba beans, investment in processing innovation is required. Increasing consumption of pulses will offer the key benefits of improved health outcomes, sustainable agricultural practices and economic growth for Australia.

In the past, the per capita consumption of pulses in many areas of the world has been in decline. More recently, a better understanding of the benefits of pulses, and the demand and level of innovation have increased (Table 1).

Table 1. Top innovative pulse markets (Mintel cited by Agriculture and Agri-food Canada).

Innovation Criteria | India | USA | Canada | EU | Australia |

|---|---|---|---|---|---|

Health and wellness claims | 19 | 19 | 14 | 14 | 17 |

Product line diversity | 12 | 11 | 9 | 7 | 6 |

New product | 16 | 15 | 16 | 17 | 19 |

Rating scale | Excellent | Very good | Good | Fair | Low |

While the health benefits of pulse consumption are being used to promote pulse consumption (Table 1), the product line diversity in Australia is still lower than in other countries. India, as the largest producer and consumer of pulses, is the most established pulse market. However, there is scope for improved product line diversity and new product development.

The ’ready to eat’ breakfast foods have a global annual value of more than USD 33 billion annually (Hartman, 2015; NewsRx, 2015). Cereal flakes make up a third of the ready to eat breakfast food market and are processed using many of the pre-conditioning and secondary processes used for other ready to eat foods (Miller, 1994). The use of flaking to add value to pulses is not new with patents for bean flakes being established from the early 1900s, at the same time when corn flakes were developed.

Pulses have very different chemical compositions compared to cereals. Table 2 summarises the range of published carbohydrate and protein contents of selected pulses and cereals on a percentage dry basis. Cereals are very high in starch and also contain glutelin proteins which assist with modification of structure and texture (Table 2). Pulses have significantly more fibre and lysine rich globulin proteins than cereals. These differences contribute to their increased cooking time requirement and impact on their processing properties.

Table 2. Composition comparison of selected pulses and cereals.

Selected pulses | Cereal comparison | |||

|---|---|---|---|---|

Composition % d.b. | Chickpeas | Faba beans | Wheat | Maize |

Total carbohydrate % | 52-71 | 67 | 75-83 | 71-84 |

Starch % | 30-56 | 34-36 | 63-72 | 54-74 |

Total dietary fibre % | 6-25 | 16-29 | 9.9-14.6 | 9-15 |

Protein% | 19-27 | 26-36 | 8-17 | 8-14 |

Major protein type | Mostly globulins | Mostly glutelin and prolamin | ||

Sources: Ambigaipalan et al. (2011); Guillon and Champ (2007); Güzel and Sayar (2012); Haard et al. (1999); Hall et al. (2016); Hejdysz, Kaczmarek, and Rutkowski (2016); Hoover, Hughes, Chung, and Liu (2010); Kouris-Blazos and Belski (2016); Marengo et al. (2016); Rosa-Sibakov et al. (2016); Serna Saldívar (2010).

Research into pulse flakes will improve the scope for pulses as breakfast or snack food, meeting consumer demand for healthy, whole foods, a clean ingredient label with the convenience of shelf stability and reduced cooking time. Knowledge of the adaptation of established cereal flaking processes to pulses will facilitate processor uptake of flaked pulses and release into the ready to eat food market. This project aims to understand the impact of key processing parameters on the quality of flaked pulses.

The project described here is a collaboration between CSU’s Functional Grains Centre, Woods Foods (a family owned pulse processor located in Goondiwindi) and Uncle Toby’s. The aim of this project is to develop technology that will allow Australian pulses to be processed and delivered to domestic and international markets as high value food products. The success of projects such as this will provide Australian pulse growers with more options for marketing their pulses which will result in pulse production becoming a more profitable option.

Materials and methods

Triplicate batches of 8kg Australian desi chickpeas were provided by Woods Foods, processed using the Uncle Toby’s pilot scale plant, applying the following conditions:

- Pretreatment: Dehulled and spilt desi chickpeas heated at 90-98°C for six minutes with one of three steaming times: one, three or five minutes.

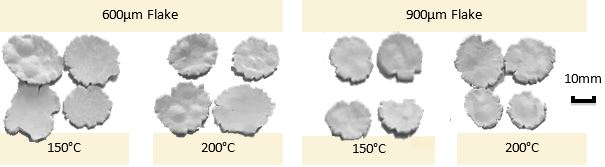

- Forming into flakes: Roller gap set to two different widths.

- Roasting: Roasting and drying with a fluidised bed dryer at 150°C or 200°C.

The resulting flakes were analysed and the following quality parameters assessed:

Size (micrometer), strength (texture analyser), colour (colour meter), degree of starch cooking ((DSC), rapid visco analyser (RVA)), and microstructure (scanning electron microscopy (SEM)).

Results and discussion

It was found that short steaming times and a heating time of six minutes were sufficient to soften the split chickpeas for rolling into flakes (Figure 1).

Figure 1. Desi chickpea flakes produced at two different rolling gaps and different roasting temperatures.

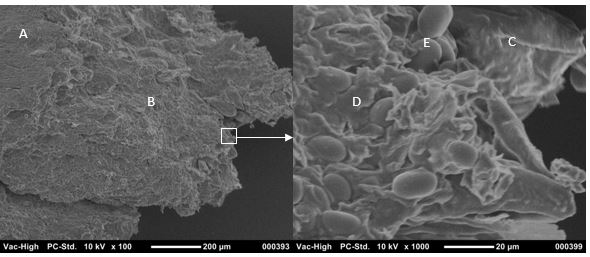

Roasting was able to produce a ’bubbling’ appearance similar to that seen on the surface of pappadams. SEM revealed (Figure 2) an intact cell matrix consisting of fibrous walls, a protein matrix and starch granules. Textural analysis demonstrated that the flakes become weaker with increased processing and are able to take up fluid more rapidly. Thermal and pasting analysis found that an approximately 50% degree of cooking was achieved by this process.

Figure 2. Scanning electron microscope images of chickpea flake. Left: A = surface of flake, B = exposed interior of flake. Right: Magnified image of area within white box. C= cell wall, D = intercellular material (protein), E = starch granule.

Conclusion

Innovation in manufacturing is required for pulses to be part of contemporary western diets. Due to the differences in composition between cereals and pulses, research into the application of common cereal processing methodologies, such as flaking, will enable the development of processes suitable for pulses. Suitable pre-processing parameters that allow for the formation of pulse flakes have been identified. These flakes have maintained significant micro structural features present in unprocessed chickpeas, however, with some significantly different forms and textural properties. Being partially cooked, these products will require less preparation compared to a raw chickpea.

References

Agriculture and Food Market Intelligence

Global Pulse Production and Consumption Trends

International year of the pulses

Australia Export Grains Innovation Centre - Australian Pulses.

Bhandari, B. R., Datta, N., & Howes, T. (1997). Problems Associated With Spray Drying Of Sugar-Rich Foods. Drying Technology, 15(2), 671-684. doi:10.1080/07373939708917253

Cuvelier, K., Storsley, J., Mollard, R., Thandapilly, S. J., & Ames, N. (2017). A Review of the Impact of Whole Pulses on Glycemic Response. Cereal Foods World, 62(2), 53-58. doi:10.1094/CFW-62-2-0053

International Year of Pulses 2016.

The future of food and agriculture: Trends and challenges

Guillon, F., & Champ, M. M. J. (2007). Carbohydrate fractions of legumes: uses in human nutrition and potential for health. British Journal of Nutrition, 88(S3), 293-306. doi:10.1079/BJN2002720

Güzel, D., & Sayar, S. (2012). Effect of cooking methods on selected physicochemical and nutritional properties of barlotto bean, chickpea, faba bean, and white kidney bean. Journal of Food Science and Technology, 49(1), 89-95. doi:10.1007/s13197-011-0260-0

Major chemical components of cereal grains fermented cereals.

Hall, C., Hillen, C., & Garden Robinson, J. (2016). Composition, Nutritional Value, and Health Benefits of Pulses. Cereal Chemistry, 94(1), 11-31. doi:10.1094/CCHEM-03-16-0069-FI

Hartman, L. R. (2015, Jul 29, 2015). <Breakfast Food Trends- Easy-to-Eat in the Morning.pdf>. Food Processing.

Hejdysz, M., Kaczmarek, S. A., & Rutkowski, A. (2016). Extrusion cooking improves the metabolisable energy of faba beans and the amino acid digestibility in broilers. Animal Feed Science and Technology, 212, 100-111. doi:10.1016/j.anifeedsci.2015.12.008

Composition, molecular structure, properties, and modification of pulse starches.

Kouris-Blazos, A., & Belski, R. (2016). Health benefits of legumes and pulses with a focus on Australian sweet lupins. Asia Pacific Journal of Clinical Nutrition, 25(1), 1-17. doi:10.6133/apjcn.2016.25.1.23

Maredia, M. (2012). The Potential of Pulses to Achieve ‘Feed the Future’ Food and Nutritional Security Goals. Global Pulse Production and Consumption Trends: . Global Pulse Researchers Meeting, Rwanda, Feb 13‐19, 2012: Department of Agricultural, Food and Resource Economics, Michigan State University.

Marengo, M., Carpen, A., Bonomi, F., Casiraghi, M. C., Meroni, E., Quaglia, L., Iametti, S., Pagani, M.A.,. Marti, A. (2016). Macromolecular and Micronutrient Profiles of Sprouted Chickpeas to Be Used for Integrating Cereal-Based Food. Cereal Chemistry, 94(1), 82-88. doi:10.1094/CCHEM-04-16-0108-FI

McDermott, J., & Wyatt, A. J. (2017). The role of pulses in sustainable and healthy food systems. Annals of the New York Academy of Sciences, 1392(1), 30-42. doi:10.1111/nyas.13319

Miller, R. C. (1994). Breakfast cereal extrusion technology. In N. D. Frame (Ed.), The Technology of extrusion cooking (pp. 73-109). London, New York: Blackie Academic & Professional.

NewsRx. (2015). Persistence Market Research - Breakfast Cereals Market: Hot Cereals to Reach US$43.2 Billion by 2019 (19458177).

Rebello, C. J., Greenway, F. L., & Finley, J. W. (2014). A review of the nutritional value of legumes and their effects on obesity and its related co-morbidities. Obesity Reviews, 15(5), 392-407. doi:10.1111/obr.12144

Revilla, I. (2015). Impact of Thermal Processing on Faba Bean (Vicia faba) Composition Processing and Impact on Active Components in Food (pp. 337-343). San Diego: Academic Press.

Roland, W. S. U., Pouvreau, L., Curran, J., van de Velde, F., & de Kok, P. M. T. (2016). Flavor Aspects of Pulse Ingredients. Cereal Chemistry, 94(1), 58-65. doi:10.1094/CCHEM-06-16-0161-FI

Serna Saldívar, S. R. O. (2010). Cereal grains: properties, processing, and nutritional attributes. Boca Raton, Fla.: CRC Press/Taylor & Francis.

Setchell, K., & Radd, S. (2000). Soy and other legumes: 'Bean' around a long time but are they the 'superfoods' of the millennium and what are the safety issues for their constituent phytoestrogens? Asia Pacific Journal of Clinical Nutrition, 9, S13-S22.

Tyler, R., Wang, N., & Han, J. (2017). Composition, Nutritional Value, Functionality, Processing, and Novel Food Uses of Pulses and Pulse Ingredients. Cereal Chemistry, 94(1), 1-1. doi:10.1094/CCHEM-12-16-0500-R

Van Der Poel, A. F. B. (1990). Effect of processing on antinutritional factors and protein nutritional value of dry beans (Phaseolus vulgaris L.). A review. Animal Feed Science and Technology, 29(3-4), 179-208. doi:10.1016/0377-8401(90)90027-6

Acknowledgements

Australian Research Council – Industrial Transformation Training Centre (ITTC) Scholarship.

Supervisors – Dr Asgar Farahnaky, Professor Chris Blanchard, Professor John Mawson.

Industry Partner – Woods Foods.

Pilot plant – Cereal Partners Worldwide.

NSW DPI – Cereal Laboratory.

Contact details

Stephen Cork

NaLSH, Charles Sturt University

agga Wagga NSW 2650

0456396757

scork@csu.edu.au

Was this page helpful?

YOUR FEEDBACK