Getting the most out of a centre pivot or a linear move system

Author: Dennis Watson (Agriculture Victoria) | Date: 26 Jul 2018

Take home messages

- Ensure the system is designed right at the start.

- Ensure the system can apply the right amount of water.

- Understand the changing costs of running the system, compared to the value of the crop.

- Ensure the machine is working as it is meant to and as you thought it would.

Ensure the system is designed right at the start

Determine the required system capacity for what you want; factoring in climate and the type of crops that will be grown. Match flow rates and delivery pipe diameter to minimise friction loss and pumping cost. Ensure the pump and motor are matched to the job at hand. The larger the centre pivot or linear move the cheaper the capital cost per hectare. However, for a centre pivot system ensure the soil infiltration rate at the extremities can handle the instantaneous application rate of the system. For larger centre pivots, question if an end gun is worth it and whether it can apply enough water.

Ensure the system can apply the right amount of water

The design system capacity required can be calculated using the following equation:

Application rate = Evapotranspiration rate (ETo) x Crop Coefficient ÷ efficiency of system.

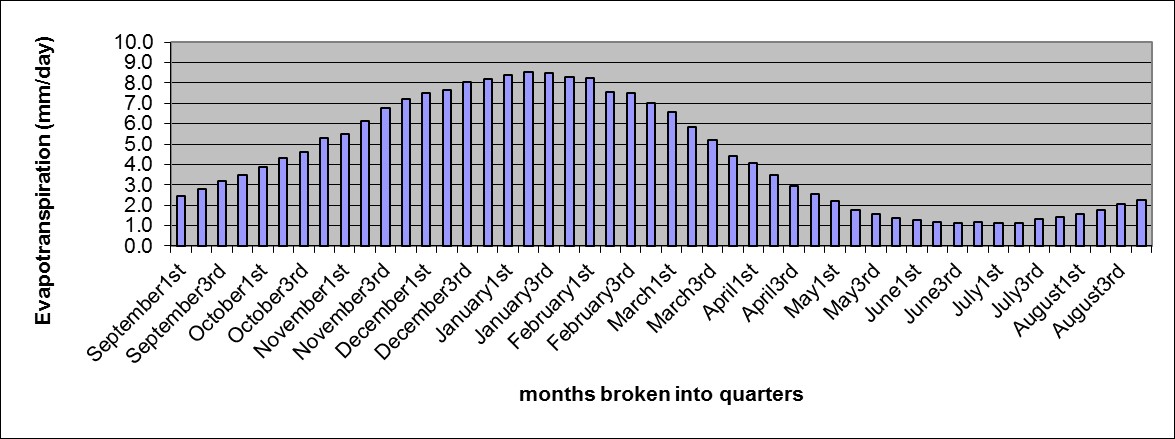

Using the ETo from Figure 1, a healthy, large maize crop grown over January may require a daily application rate of 11.3mm/day (8.5 mm/day x 1.2 ÷ 0.9).

Figure 1. Average daily evapotranspiration (mm/day) over the year in Echuca.

Irrigating on night and/or weekend rate electricity is quite common but it will limit watering to 91 hours a week or an average of 13 hours a day. Using the above example, the design system capacity would have to be capable of applying 21mm/day to cover not irrigating during the day. Building a system to deliver this desired application rate will require a higher capital cost.

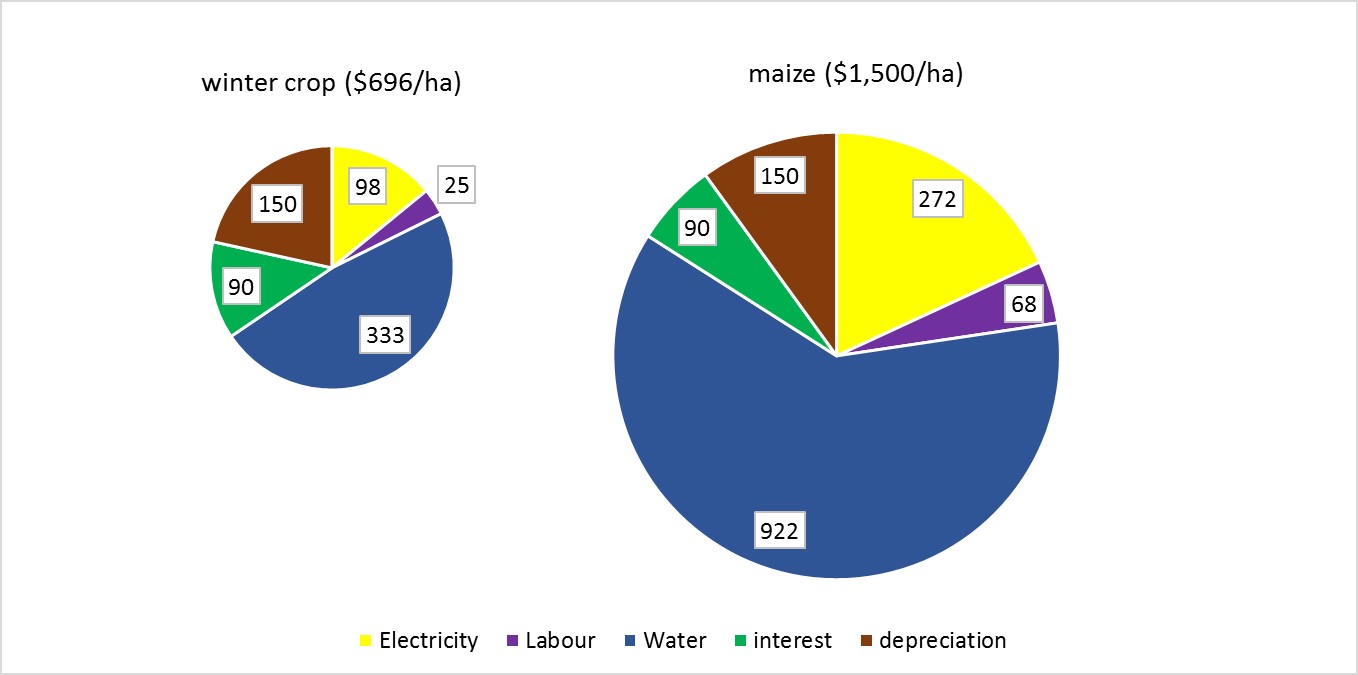

Understand the changing costs of running the system, compared to the value of the crop

The pie charts in Figure 2 show the cost of irrigating a winter crop (left hand side) or maize (right hand side), including electricity, labour, water cost, interest payment and depreciation. Note this does not include the actual crop costs which could be another $100/ha on top of a normal dryland winter crop or $1,200/ha for a maize crop. The water, power and labour demands are higher for the maize crop because it requires more water than the winter crop, however the interest and depreciation cost remain the same.

Figure 2. Typical annual cost breakdown of a 30 ha centre pivot ($/ha) irrigating a winter crop (left hand side) or a maize crop (right hand crop).

Assumptions:

- Maize crop requires 8.3ML/ha

- Winter crop requires 3ML/ha

- Irrigation efficiency with centre pivot of 90%

- Labour $35/hr

- Water $100/ML (temporary market)

- Centre pivot set up cost of $3,000/ha (30ha)

- Interest rate of 6% and the cost of the system is depreciated over 20 years

- Pressure at the pump for centre pivot is 35m head

- Electricity is $0.23/kwatt/hr.

The values in Figure 2 vary for each irrigator. For instance, pumping from a deep bore compared to a river diversion will have a different cost. Some values change throughout the year such as the water price. If the electricity price increased from $0.23/kwatt/hr to $0.30/kwatt/hr the running cost would increase by $30/ha and $85/ha for the wheat and maize crop, respectively.

Ensure the machine is working as it is meant to

Ensure the machine is working properly to maximise yields and keep cost down. Test pressures to make sure they are not too high or too low. Pressures that are too high are simply wasting energy while low pressures will lead to poor water distribution affecting performance.

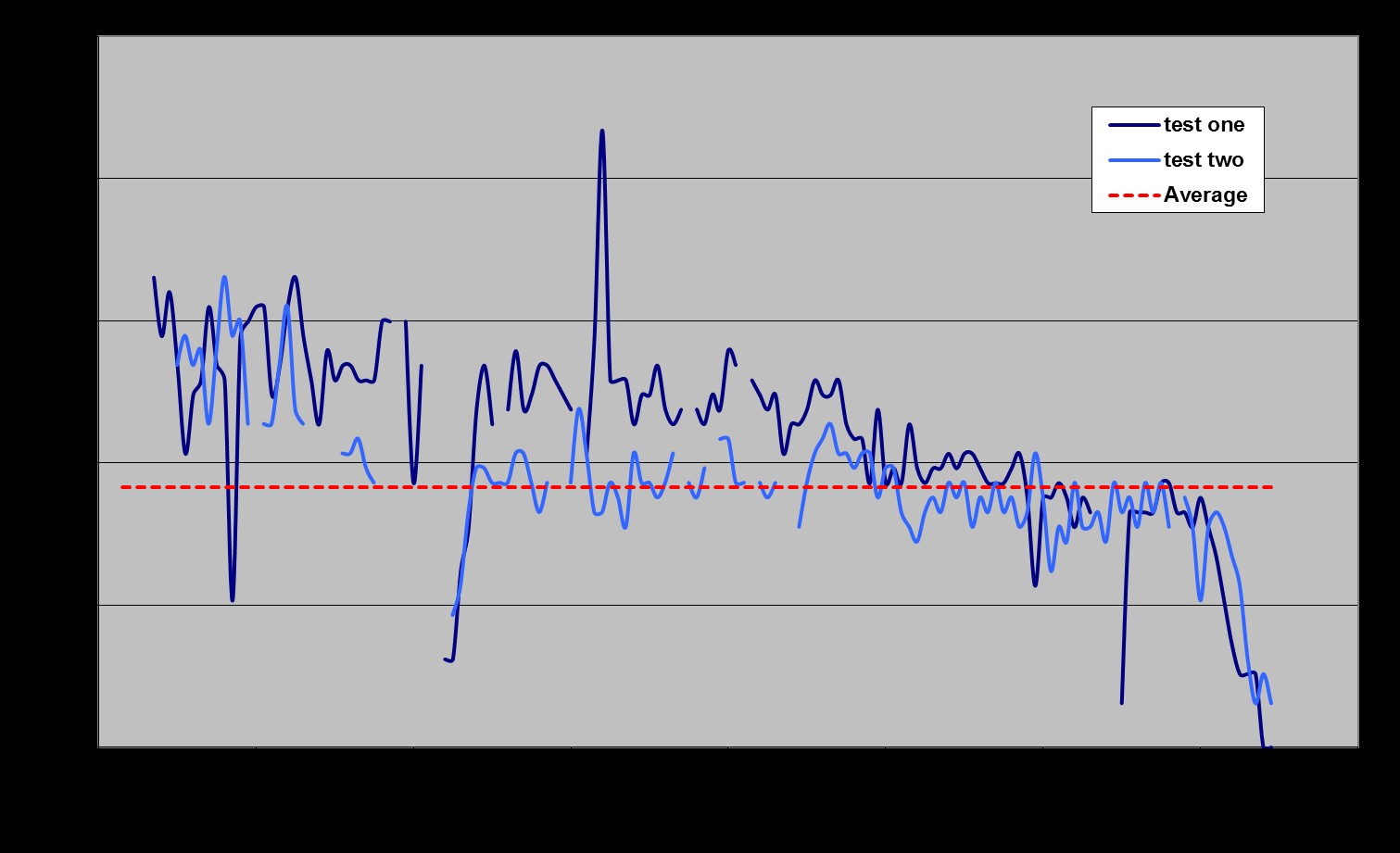

Undertake uniformity tests to check correct and even application. The results of a uniformity check can be seen in Figure 3. This centre pivot was set to apply 12mm, however a uniformity check indicated it was only applying 9.2mm with a poor coefficient of uniformity (CU) of 80%. The pressure at the end of the pivot was 7PSI while it should have been 20PSI; 5PSI above the regulated pressure.

Figure 3. Example of a poor performing centre pivot with a coefficient uniformity of 80% applying 9.2mm (despite being set to apply 12mm).

A poor CU can have one of two consequences or a combination of the two:

- Extra water is applied to compensate for the poor CU, resulting in higher pumping and water cost or

- Insufficient watering occurs incurring a yield penalty.

Extra water applied to a wheat crop to compensate for a CU of 80% compared to 90% will increase the cost by an extra $54/ha for a winter crop and $152/ha for a maize crop.

Contact details

Dennis Watson

Agriculture Victoria- Rutherglen

02 60 304 567

dennis.watson@ecodev.vic.gov.au

Was this page helpful?

YOUR FEEDBACK