Draft requirements of deep ripping with inclusion plates and speed

Author: Glen Riethmuller and Wayne Parker, DPIRD | Date: 25 Feb 2019

Key Messages

- Around 24% extra load is expected on tractors when pulling deep rippers with inclusion plates on sandy loam soils.

- Use of inclusion plates gave an estimated extra fuel cost of $3.7/ha (3.7 L/ha) and work rate was reduced by 24% while initial measurements suggest loosening around 30% more soil volume compared with no inclusion plates.

- These data will be useful for future soil modeling inclusion plate design to reduce the tractor load.

Aims

Growers are concerned that they cannot pull 6 m wide deep rippers with inclusion plates in a controlled traffic farming system as a ripper working at around 400 mm deep can use all available power and traction. Assessing the draft with and without inclusion plates will not only quantify the extra force needed but will provide useful data for future soil movement modeling to help to design a better inclusion plate system.

Method

A field experiment was conducted at Merredin on a yellow sandy loam on 8 September 2017 using a floppy link drawbar dynamometer to measure the force on an Agrowplow deep ripper with and without inclusion plates. Three speeds were used with three replications in a randomised block design. The ripper had four tines with two tines 100 mm shallower and in-line with the deeper tines. Treatments were the deep rear tines with inclusion plates and without inclusion plates working to around 320 mm deep at 4, 6 and 8 km/h along 40 m plots. The inclusion plates were 110 mm wide, 250 mm high and 275 mm long horizontally at the top (Figure 1). The floppy link dynamometer was made at the University of Queensland Gatton Campus using strain gauges and was calibrated on 3 February 2017 at the University of Western Australia using a Baldwin Universal Testing Machine. The draft of the ripper out of the ground (rolling resistance) was 2.5 kN, which was subtracted from the measured draft to give the draft of the four tines alone. The soil strength was measured with a RIMIK CP40II cone penetrometer with ten penetrations per replicate before ripping. The soil bulk density was measured one day after ripping with 55 mm diameter 50 mm long rings hammered into the soil pit wall of the 4 and 8 km/h speeds at five depths in and out of the rip line. The soil moisture content was measured on the bulk density samples by oven drying at 105ºC for 24 hours.

Figure 1. Wayne Parker (left) with the inclusion plates on the rear deep tines (indicated by the solid arrow) and shallow leading tines (SLT) are behind him and (right) without inclusion plates and SLT indicated by the dashed-arrow.

The disturbed soil profile was measured by removing the loosened soil by hand and then using a RIMIK profilemeter.

Results

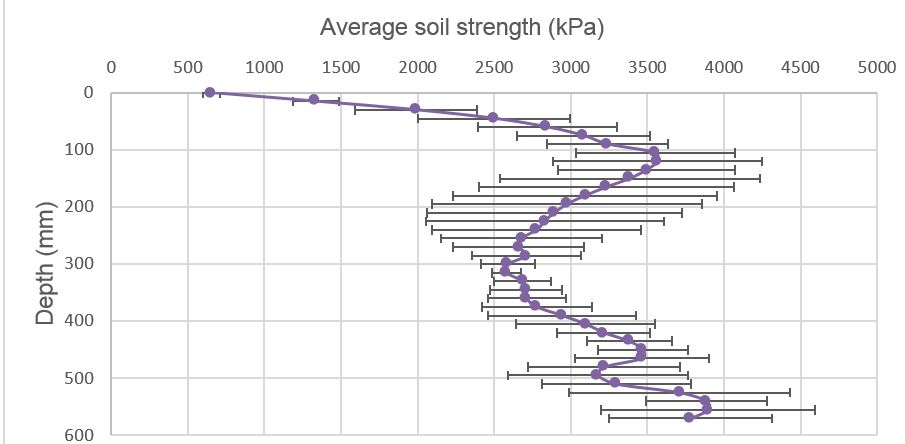

The average bulk density was reduced by around 0.2 Mg/m3 with deep ripping to 40 cm (Table 1). The average soil strength before ripping showed a compacted zone between 5 and 30 cm deep (Figure 2).

Table 1. Soil strength before ripping and moisture and bulk density after ripping.

Treatment/Depth (cm) | Average soil strength (kPa) | Soil moisture (%d.b.) | Bulk density (Mg/m3) |

|---|---|---|---|

0 - 10 no rip | 2240 (960) | 2.64 (0.45) | 1.50 (0.091) |

0 - 10 rip | - | - | |

10 – 20 no rip | 3330 (230) | 5.77 (0.77) | 1.57 (0.102) |

10 – 20 rip | 5.95 (1.26) | 1.42 (0.119) | |

20 – 30 no rip | 2730 (110) | 6.23 (0.74) | 1.60 (0.097) |

20 – 30 rip | 6.26 (1.85) | 1.39 (0.100) | |

30 – 40 no rip | 2730 (120) | 6.18 (0.58) | 1.63 (0.103) |

30 – 40 rip | 6.37 (0.72) | 1.45 (0.094) | |

40 – 50 no rip | 3290 (150) | - | - |

Numbers in brackets are one standard deviation.

Figure 2. Average soil strength with depth before ripping (error bars are 1 standard deviation).

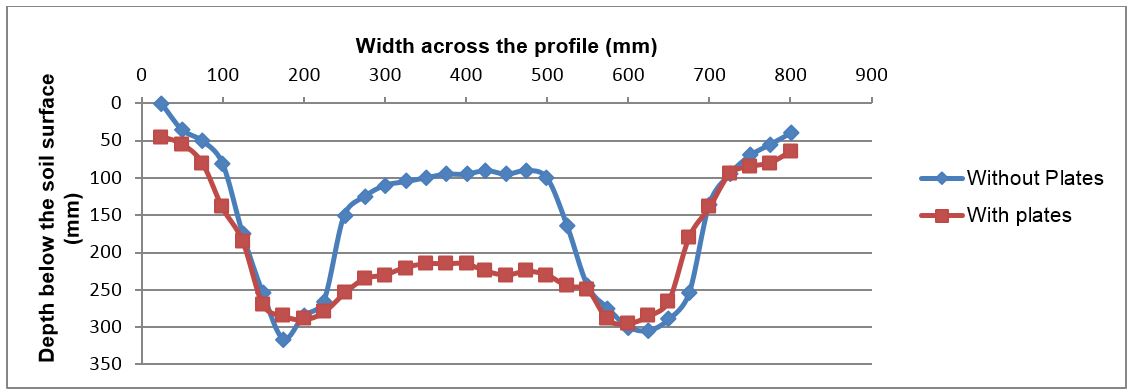

After ripping, the disturbed soil profile was measured in the centre of one plot each from the with and without inclusion plates treatments at 8 km/h. The loose soil was carefully moved away by hand which showed the inclusion plates broke out 32% more soil, particularly between the tines than without the plates (Figures 3 and 4).

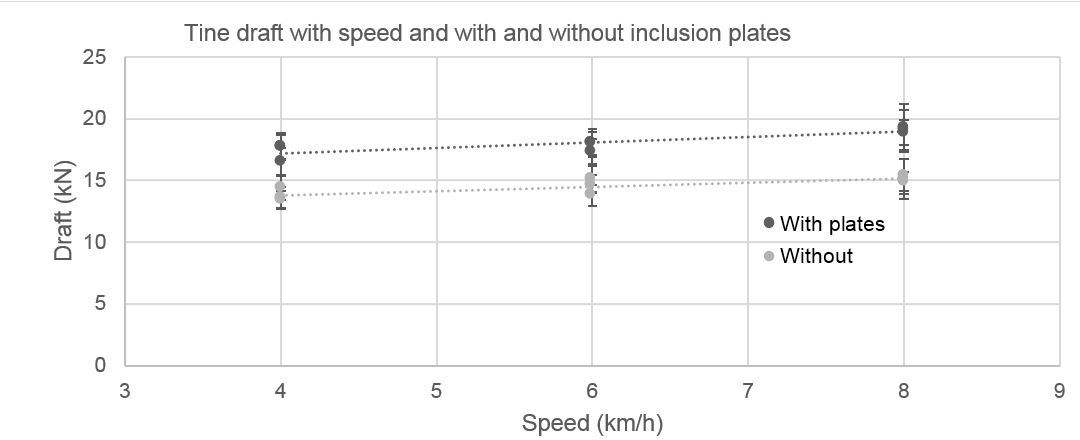

The draft increased with increasing speed and the inclusion plates added around 24% to the draft at each speed (Figure 5).

A regression using Genstat of draft with speed and plates gave both speed and plates highly significant (p<0.001) with the following equation:

Draft (kN) = 12.2 + 0.38 x Speed (km/h) + 3.6 x Plates (0 for no plates and 1 for plates)

% variance accounted for (adjusted r2) = 94.6

To estimate fuel use, the following equation was used (Riethmuller 1988):

PTO power (kW) = Draft (kN)/m * speed (km/h) x width (m)/(TE * 0.96 *3.6),

where Tractive Efficiency (TE) was assumed to be 0.76 for firm soil (ASAE which uses the average 0 – 15 cm soil strength) and the TN6050 tractor used had an estimated efficiency of around 3.2 kWh/L from the Nebraska Tractor Test reports (ref).

At 8 km/h this gave an estimated fuel use of 18.9 L/ha with plates and 15.2 L/ha without plates.

Figure 3. Profilemeter without inclusion plates (left) and with inclusion plates (right) at 8 km/h.

Figure 4. Disturbed soil profile after ripping from one plot with and without inclusion plates.

Figure 5. Adjusted tine draft (less ripper rolling resistance) with speed and plates (error bars are 1 standard deviation).

Conclusion

The addition of an inclusion plate increased the draft of the deep ripper tines by around 24% with an associated increase in fuel use by 24%. This means that work rate would be reduced unless a larger tractor was used. Growers would be concerned about this level of increased fuel use and the economics would have to be evaluated for return on investment.

Future work is needed to examine the design of inclusion plates to maintain effectiveness while limiting the draft increase. Discrete element soil movement modelling would be ideal for this work and engineering students at universities may be ideally placed to help with this work.

Acknowledgments

The authors would like to thank the staff of the Merredin Research Station for assisting with the site.

Reference

Riethmuller, G.P. (1988). Draft requirements of tillage equipment in the Western Australian wheatbelt. Conference on Agricultural Engineering of the Institution of Engineers, Australia, Hawkesbury Agricultural College, NSW 25-29 September, 1988, pp 137-141.

ASAE Standard D497.7 MAR2011(R2015). Agricultural machinery management data.

GRDC Project Number: DAW00243

GRDC Project Code: DAW00243,

Was this page helpful?

YOUR FEEDBACK