Infield spectrometer and NIR on your phone

Author: Dr William Palmer (Rapid Phenotyping) & Matt Gardner (AMPS Research) | Date: 26 Feb 2019

Take home messages

High-throughput screening is a recent innovation which allows testing of soil, liquid, plant and grain samples to happen quickly. A sample is scanned, with the resulting spectral signature sent to the machine learning platform, and then decoded for the quantitative or qualitative variables of interest that the user specifies for that sample.

Using this technology, a handheld device has been developed which allows high-throughput analysis of a large range of chemical components in crops, liquids, soil and grain. This technology has the capacity to completely change the decision-making process on farms by providing increased data and accessibility to chemical testing in real time for a large range of variables, including nutrients such as nitrogen potassium, phosphorous, moisture, pH and many other variables.

This will improve farming practices by allowing greater knowledge of key quality and production indicators.

High-throughput screening

A hand-held platform has been developed to provide instant measurement of a range of chemical traits of commodities, or in broader terms any solid or liquid. Within the agriculture industry this has significance throughout the cropping/farming cycle from measuring soil nutrients, plant nutrient uptake and then protein, moisture or oil content of the grain. It can also be used to track supply chain of the commodity, with implications around confirming the provenance of the food being consumed.

This paper outlines the research and development that has made this platform possible and what are the next steps for use on the farm.

How it works

A handheld device has been developed which uses near infrared (NIR) and other spectral techniques for compositional analysis of a sample. When a sample is scanned, a spectral signature or molecular fingerprint is taken. This signature or fingerprint contains the information about chemical bonds within the sample. When light reflects or passes through a sample it is altered depending on what wavelengths are absorbed or reflected by the material in question. It is this difference that is then recorded by the detector providing information about what the chemical make-up of the material being scanned is, ie. wet soil will return a different spectrum to that of dry soil as the water will absorb some of the infrared light being applied to the sample.

To decode this spectrum, data is transferred to the cloud via a phone application and decoded for the quantitative or qualitative variables of interest that the user specifies for that sample.

To analyse a chemical trait of interest the computer must first be taught what to look for in the spectrum signature. To do this, around 500 samples are analysed using traditional ‘wet chemistry’ methods, like what is done at gold standard labs.

An ensemble of algorithms and artificial intelligence techniques are then applied to teach the computer how to decode the relevant information contained within the spectrum, eliminating the need to conduct further ‘wet chemistry testing’. The analytical system called ‘Hone Prophecy’™ has been developed to decode these spectral signatures for a range of chemical compounds.

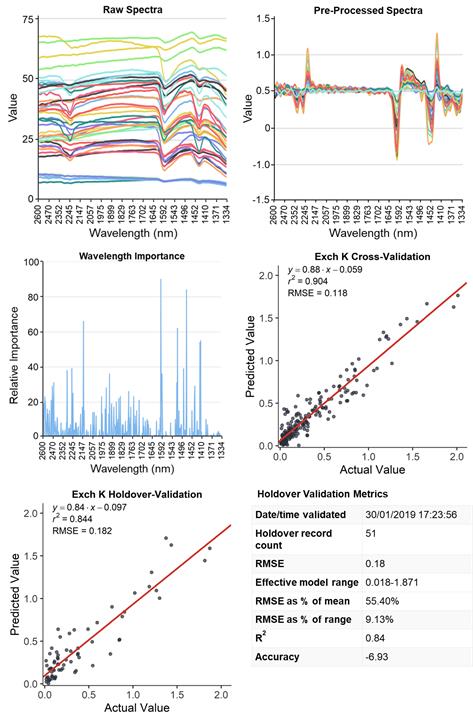

Below is a representation of exchangeable K and the artificial intelligence processing that happens in the background to deliver the results in real-time.

Figure 1. A representation of exchangeable K and the artificial intelligence processing that happens in the background to deliver the results in real-time

Once the algorithm for that variable of interest has been generated it is loaded into the platform and can predict the relative abundance of that chemometric trait. From one spectrum many variables of interest can be measured using this technique. The platform runs through a phone application and can be used on farm in real-time on compatible devices.

Hone is developing two devices for agricultural industries, RapidLab and RapidLab+.

Figure 2. An example of the RapidLab+ product

Both devices use multispectral technology to maximise the number of compounds that can be analysed in the field. RapidLab has been designed to perform a ‘whole of farm’ analysis tool including grain, soil and in-plant testing for key traits. To compliment this, RapidLab+ is designed to incorporate the ability to test liquids using differing spectral sources.

Testing takes less than a minute for key metrics such as nitrogen, potassium, phosphorous, moisture, pH and many other variables.

Benefits to agriculture

The opportunities and benefits for this technology in agriculture will vary significantly depending on the sector and end user.

It is not necessarily what can be measured that is the exciting part to this technology, it is rather the versatility of what can be measured and scanned by one device, lower cost of measurements compared to ‘wet chemistry’ and the speed at which the results/data are returned to the user and the ease of platform use.

These traits logically lead to; improved decision-making process, improved data legacy and improved production efficiency.

Decision making process

Ultimately, this technology will enable faster, more informed decisions to be made reliably on a time frame that is currently unavailable. Soil and plant analysis typically take 1-10 days from sample collection to receiving the results, depending on the test required. Using a field portable handheld device with this technology enables real-time decisions or diagnosis to be made for soil, plant, water and grain samples.

The greatest impact to growers from this type of technology will be the ability to track changes in plants or soils chemical composition over time. Early detection of these changes may be used to inform agronomic decisions at the critical stages of a plants growth and development leading to greater crop productivity.

Once appropriate calibrations are in place, it is envisaged that this technology would become a valuable tool for the adviser/grower and become a key tool in regular use.

Improved data legacy

Given the ease of use and range of things that can be measured, it is expected that more testing will occur, and more data will be produced. This could allow changes in the soil, water and plants to be more accurately tracked through time. Each farm would essentially have a greater data legacy that would enable interrogation and comparison of data between paddocks, seasons, farms and crops. As an example, if say Magnesium was found to be important for increased photosynthesis then a model can be developed and all samples previously scanned, even years ago, can be analysed without having to rescan the sample.

Improved production efficiency

Ultimately the technology has the potential to accelerate the transition of the Australian and global agriculture sector to the era of precision agriculture and improve production efficiency. Increased data and accessibility to testing will improve farming practices by allowing greater knowledge of key quality and production indicators and thus better prediction of farming outcomes. It would allow us to more easily connect the dots between what is available in the soil, what the plant has accessed and what is removed in the harvested product. Greater knowledge of this process can only lead to greater efficiency with inputs.

Furthermore, greater knowledge of the end product/commodity may give the capacity to extract more value. If a detailed analysis of grain, well beyond moisture, protein and oil content, could easily and reliably be produced then commodities could be marketed in a completely different way. This would already have immediate application in closed loop trading systems.

Conclusion

This technology has the capacity to change the way we farm daily. In particular, it is the versatility of what can be measured, the speed at which results are returned and to the ease of use. This will essentially improve the efficiency of production through the capacity to make more informed decision in an unprecedented time frame.

Contact details

Dr William Palmer

Mb: 0401 201 619

Email: william@rapidphenotyping.com

Was this page helpful?

YOUR FEEDBACK