Seed quality – strategies to ensure good establishment in 2019

Author: Philip Burrill, DAF Qld | Date: 26 Feb 2019

Take home message

- Planting seed is the most valuable grain stored on farm. Each month check storages for pests and monitor grain temperatures

- Clearly identify / number each silo and keep up-to-date storage records

- Keep seed varieties pure. Clean out silos, augers and trucks to prevent contaminating seed with other varieties that have different maturities and disease resistant levels

- A cone-based silo, with aeration cooling, that is sealable when a fumigation is required, is the ideal farm seed storage. Locate silos in the shade or paint white to reduce seed temperatures

- Warm grain temperatures and higher seed moisture contents in storage are major causes of poor seed germination and vigour. Invest effort into achieving effective aeration cooling

- To minimise pest damage, apply a registered grain protectant treatment to seed at harvest time. When sieving and probe traps detect pests, fumigate with phosphine in a sealable silo.

The most valuable grain – planting seed

Planting seed is the most valuable grain you will ever store on farm. The consequences of allowing seed to deteriorate while in storage can be very costly. Poor crop establishment usually leads to reduced yield potential and problems with more in-crop weeds.

At times complete crop planting failures occur due to the use of seed that had low germination and vigour. Poor storage conditions such as warm grain temperatures, higher grain moisture content and damage by storage insects (weevils) can have a major impact on seed quality.

In dry times, the more common practice of planting deeper into soil moisture makes it critical we do our best to look after seed vigour quality during storage.

If possible, avoid keeping seed that has suffered weather damage prior to harvest, as seed viability falls more rapidly during its time in storage. Always test seed for germination and vigour well before planting time. Also check seed prior to harvest for the presence of smut / bunt diseases.

Seed storage silos and equipment

For bulk seed storage, aim to use a cone-based silo that is easy to clean / wash out, has aeration cooling fans fitted and is sealable so effective fumigations can be carried out when required.

Seed storages and equipment to maintain seed quality

- Clearly number each silo and keep up-to-date storage records of where each variety is stored. Also record monthly insect and temperature checks, etc. A blackboard painted section on the silo base is also helpful

- Bright reflective silo walls, or painted white walls will help reduce grain temperatures in the silo

- Locate seed silos in the shade if possible. e.g. south / east side of larger silos or sheds

- Aeration cooling is important. Operate fans using a good quality aeration auto-controller for best results

- Silo roof venting - a removable ‘chinaman’s hat’ vent fitted to the silo top fill point can provide effective venting for a silo while seed is stored under aeration cooling

- Good quality silo seals and design for effective fumigations when required. Silo should meet the AS2628 sealing standard when purchased new

- Silo hygiene – easy to clean or wash out the inside of silo to reduce contaminating a seed line with other grains or varieties. This also reduces carry over of insect pests in grain residues

- Have ladders on silos to provide access to the top of silos to take samples for seed quality testing, using a probe to measure grain temperature, checking for insects with probe traps, and undertaking fumigation activities

- Grain protectant treatments for storage pests or fungicide seed treatments – use spray equipment and augers that are easy to calibrate for accurate dosage and provide uniform coverage on seed

- Detecting insect pests – use an insect sieve, insect probe traps, a grain temperature probe, plus a storage note book or iPad to keep monthly records of pests found, seed treatments, etc

Figure 1. Seed silos fitted with aeration cooling and designed as sealable for fumigations

Managing pests and maintaining seed quality

Fumigations and use of grain protectant insecticides are only two of the five key tools used to maintain planting seed quality and achieve reliable insect pest control. Combining the five practices outlined below forms the foundation for successful seed storage.

Top five practices for successful seed storage

- Aeration: Correctly designed and managed, it provides cool grain temperatures and uniform grain moisture conditions. Aeration reduces storage problems such as moulds and insect pests, plus helps maintain seed quality, germination and vigour.

- Hygiene: A good standard of storage hygiene is crucial in keeping storage pest numbers to a minimum. Good hygiene for silos, augers and trucks reduces the risk of seed contamination.

- Monitoring: To prevent serious damage, undertake monthly checking of seed in storage for insect pests (sieving / trapping) as well as checking grain quality and temperature. Keep monthly storage records, including any grain treatments applied.

- Fumigation: In Australia, only fumigant gases (e.g. phosphine) are registered to deal with live insect pest infestations in stored grain. To achieve effective fumigations the storage/silo must be sealable – gas-tight to hold the gas concentration for the required time. Note – phosphine fumigations, used according to the label, does not damage seed germination.

- Grain protectants: Grain protectant insecticide sprays provide another line of defence against storage pests. Prior to storage, treat cereal grain planting seed held on farm with a registered grain protectant. Use according to label directions.

Warning: Grain protectant notes do not apply to the grains industry in Western Australia where their use is restricted. In all cases, product labels are to be used to determine correct use patterns.

Figure 2. Rice weevil Sitophilus oryzae, a serious pest of stored seed

Figure 3. A probe trap and insect sieve used for regular grain inspections

Figure 3. A probe trap and insect sieve used for regular grain inspections

Seed storage – cool and dry

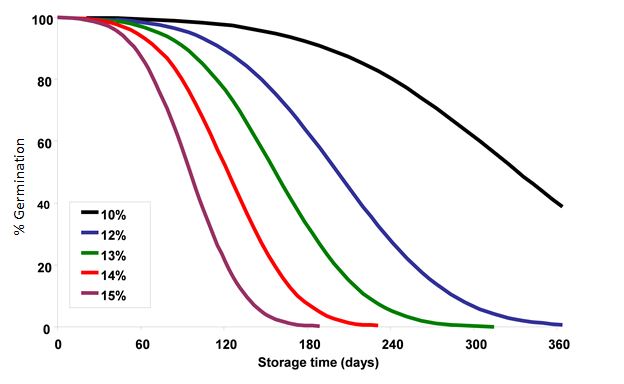

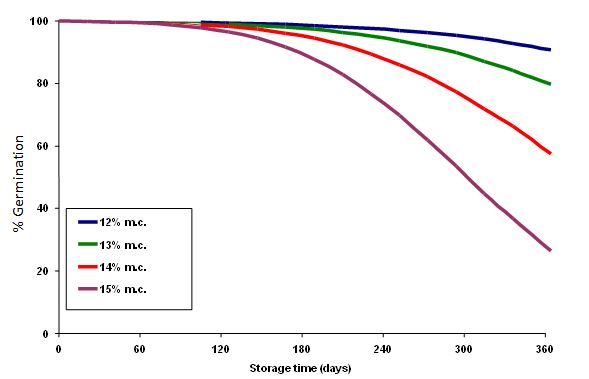

Figures 4 and 5 below show the impact of storage temperatures (30°C and20°C) and grain moisture content (10, 12, 13, 14, 15% m.c.) over time on the germination viability of wheat seed.

Figure 4. Influence of moisture contents (10 to 15%) on percentage germination of wheat stored at 30°C (Source CSIRO – SGRL)

Figure 5. Influence of moisture content (12 to 15%) on percentage germination of wheat stored at 20°C (Source CSIRO – SGRL)

Additional seed management strategies

Cool grain temperatures in storage and low moisture content seed are two critical factors for maintaining good seed germination and vigour quality. Aeration cooling systems play an important role.

Aeration research trials have shown it is feasible and that we should aim to achieve grain temperatures under 23 degrees Celsius in summer and less than 15 degrees in winter.

To monitor seed / grain temperatures in storage, use a hand held temperature probe, or fixed cables inside silos such as OPI™ grain cables, see here . Be aware that some cables with sensors measuring both temperature and relative humidity may suffer damage to the relative humidity sensor following a phosphine fumigation. Phosphine gas is corrosive and will damage exposed electrical components.

A typical phosphine fumigation to kill all storage pests, needs to achieve a minimum of 200 ppm phosphine gas concentration for at least 10 days. This will only be achieved in a well-sealed silo.

Planting seed held on farm should in most cases be treated with an insecticide ‘grain protectant’ at harvest time (not WA) to reduce storage pest insect problems. e.g. Conserve Plus™ with Reldan™.

For smut and bunt disease control, seek good advice on what fungicides to treatyour planting seeds with. Some fungicides can shorten seedling coleoptile length. Spend time with your contract seed grader and understand exactly what they are doing with your planting seed. Only treat seed you will plant, as you cannot sell fungicide treated planting seed to any grain markets.

Further information

GRDC Fact Sheet – Saving weather damaged grain for seed

GRDC booklet – Aerating stored grain – Cooling or drying for quality control

Kondinin Research report: Planting seed treatments – armour against insects and diseases

Dow™ AgroSciences - Conserve Plus™ Grain Protector

BAYER CropScience - K-Obiol® EC Combi

Acknowledgements

The authors acknowledge the RD&E support from GRDC. The authors would also like to thank DAF’s Postharvest research team members, GRDC’s national grain storage extension team, along with valued support from growers and industry collaborators.

Contact details

Philip Burrill

Department of Agriculture and Fisheries, AgriScience Qld.

Hermitage research facility, 604 Yangan road, Warwick Qld. 4370

Mb: 0427 696 500

Email: philip.burrill@daf.qld.gov.au

® Registered trademark

TM Trademark

GRDC code: PRB00001

GRDC Project Code: PRB00001,

Was this page helpful?

YOUR FEEDBACK