What causes and how can we manage grain quality defects in chickpeas

Author: Jenny Wood, NSW DPI | Date: 05 Mar 2019

Take home messages

- Seed defects were estimated (by extrapolation of survey responses across the whole industry) to cost growers up to $242 million for the 2017 chickpea crop.

- To reduce the likelihood of blotch/tiger stripe seed markings in your harvested seed, avoid early sowing of chickpeas in environments where tiger stripe/blotch seed markings are known to occur and avoid sowing blotch/tiger stripe marked seeds as this may increase the risk of marked seeds at harvest.

- To reduce the likelihood of weather damaged, stained and sprouted defective seed (and maximise yield), time harvest (and desiccation, if used) to avoid rainfall on mature/dry crops as much as possible and aim to harvest when seed is at 14% moisture content. This will maximise yield (through maximising seed weight) and minimise both seed loss (pod drop, shattering, cracked seeds) and risk of price penalties from quality loss (cracked seeds, weather damaged, stained and sprouted).

- Ensure combine harvester settings are optimised for every crop to minimise harvest loss, to capture the best quality seed and to remove immature green and small shrivelled seeds.

- Avoid storage of grain when fresh green seeds are present as this increases the likelihood of mould developing during storage. Desiccation prior to harvest will help reduce this potential issue by drying any new green growth at the top of the plants prior to harvest. However, desiccation with glyphosate should not be used on crops that are to be kept for seed, as it reduces seed germination. Only use recommended registered chemicals

- If weather damage occurs, do not retain this seed for planting as it will have lower germination and viability. Always test seed prior to planting.

Background

The Eliminating Grain Defects project was pre-emptive research aimed at protecting the superior quality of Australian chickpeas by increasing our understanding of seed defects to minimise future potential risks to the industry.

The project was triggered by reports that PBA Pistol had very noticeable blotch/tiger striping in the 2013 central Queensland environment. Pre-harvest weather damage leading to seed quality downgrading was also a significant issue for growers in some years. Hence, the project was developed to focus on understanding these two defects aiming to reduce the potential risk through breeding and/or management.

Experimental outline

This 4-year project conducted field trials, controlled experiments and laboratory evaluations to unravel the causes of chickpea seed defects.

Grower survey

An online anonymous grower survey was conducted to capture the scale and impact of chickpea defects at delivery for the 2017 crop. The survey was promoted in social media several times (both facebook and twitter) and was open from February till July 2018. The results were analysed for individual growers and then averaged to gain an overall picture of the scale of defects detected and the impact on growers. Economic analysis was then performed.

73 growers completed the survey, including some very large growers harvesting over 1,000 ha of chickpeas in 2017.

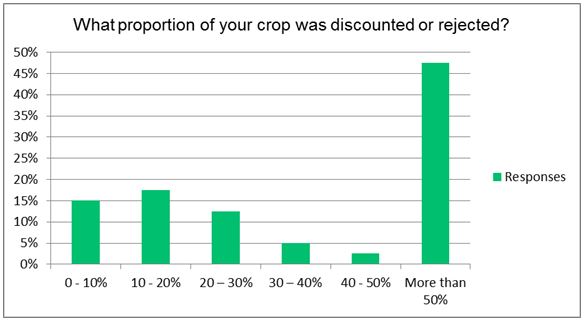

55% of the growers who responded had one or more of their chickpea deliveries discounted or rejected due to defects at the delivery point. Almost half of these had more than 50% of their chickpea crop discounted or rejected.

Figure 1. Grower responses to the proportion of their crop that was discounted or rejected

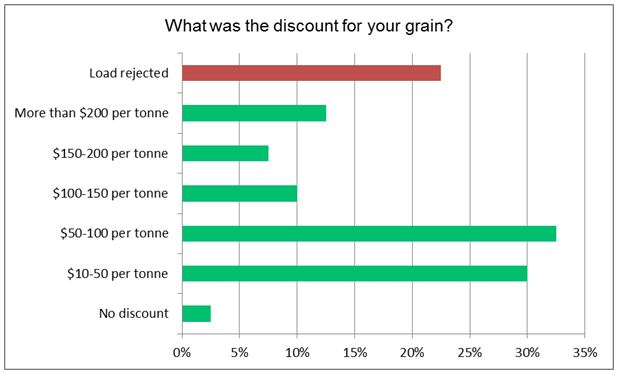

The size of the discount varied widely (Figure 2). Discounts were most often $10 – $100 per tonne (62.5% of responses) and rejections were also high (22.5% of responses).

Figure 2. The cost to growers of seed defect discounts and load rejections ($/tonne)

The defects, for which growers were penalised, varied and included mould, stained, poor colour, shrivelled, green and foreign material. Many growers were penalised for more than one of these defects (average of 1.7 defects per grower), the highest was 5 defects.

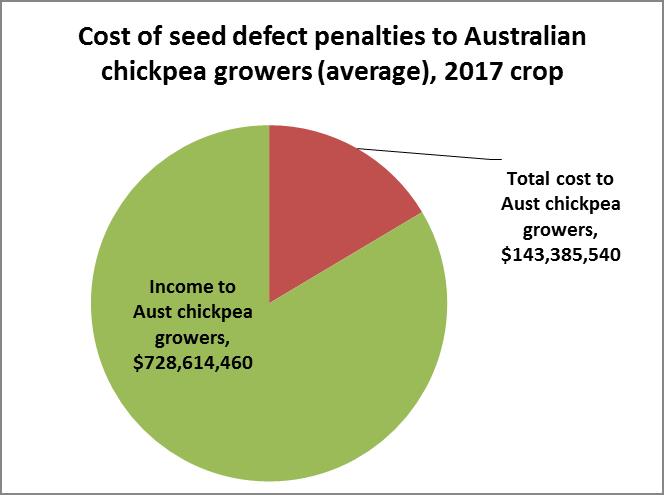

The cost of seed defects to the Australian chickpea industry

Assuming that grower responses to this survey can be extrapolated across the whole Australian chickpea industry, the total cost of chickpea defects to the Australian chickpea growers from the 2017 crop ranged between $44.36 Million to $242.41 Million (average of $143.39 Million).

This equates to 5-28% of the gross value of Australian chickpeas (average of 16%).

The range of the estimate is wide due to the nature of the survey questions. In addition, the number of growers in 2017 was likely higher than the 2015 numbers used in the calculation, so the cost to the industry was probably higher than these figures calculated. Conversely, it is possible that growers with issues were more likely to respond to the survey than growers with no issue and, if so, this may overstate the size of impact.

Notwithstanding, there is much room for improvement in breeding and agronomic practices to restore this 5-28% loss to grower’s pockets. Given the potential scale of these losses, a more targeted annual survey may be warranted in future. The average cost to Australian growers is shown in Figure 3.

Figure 3. Estimated cost of seed defects (average) to Australian chickpea growers, 2017 crop.

(NB: Does not include additional costs such as seed cleaning and delivery delays/costs)

Note that these calculations have only used penalty discounts and do not include the extra costs to growers associated with additional seed cleaning/grading and delivery delays/costs. Comments from growers on these aspects included:

- Grading and cleaning costs in the region of $30-45 per tonne

- Further transport costs in the region of $20-40 per tonne; up to 500 km extra distance for rejected grain

- Harvest stoppages and other delays due to rejected loads, further transport and cleaning. These delays also lead to further risk of defects occurring for any crops not yet harvested, especially if storms occur (causing weather damage) or crops are becoming too dry (leading to pods dropping off plants and shedding of cereals)

It is clear that grain defects are having an impact on grower profitability.

Identification of grain defects

Whilst many growers were penalised for ‘mould’ in the survey, there were reports that seed markings like blotch/tiger stipe and mosaic markings were mistakenly classified as ‘mould’. Evidence of this misclassification was found on Twitter, where chickpeas containing some mosaic seeds were penalised on delivery due to a ‘mould’ misclassification (Figure 4). Mistakes like this at grain receival are costly to growers, as the tolerance for mould is much lower than for poor colour.

Figure 4. Tweet from a well-known grower who had chickpeas penalised after misclassification of mosaic seeds as ‘mould’. The tolerance for mould is much lower than for poor colour

Growers told us in the survey that they wanted:

- to know how to prevent seed defects (and what causes the defects),

- new testing methods at receival sites (fewer visual tests and more measurements), and

- improved training for delivery site staff and better identification of seed defects.

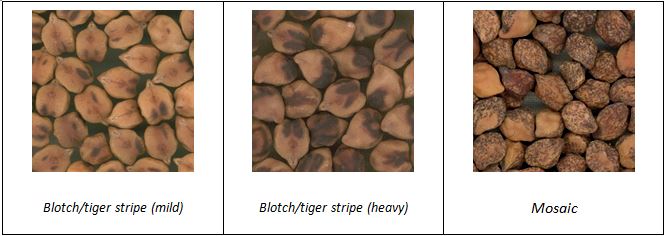

So, what exactly do seed markings look like? Images of the two main seed markings are shown in Figure 5.

Figure 5. Seed marking types examined in this project: blotch/tiger stripe and mosaic markings

These seed markings are not related to disease, mould or shrivelled seeds. There is no mark on the underlying cotyledons and the mark only affects the seed coat.

The 2018/19 Australian Pulse Trading Standards state that “tiger striping” is not classified as defective, however they can look similar to diseased or damaged seeds. In addition, they do detract from the clean and uniform appearance preferred by our export customers, so may be discriminated against in the market.

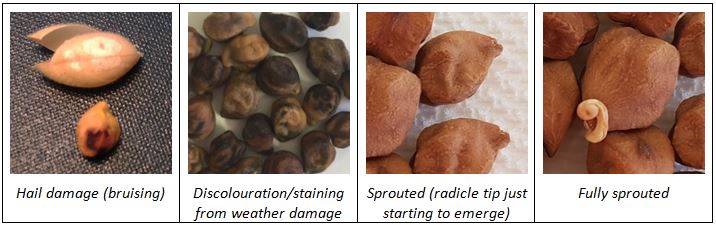

Mosaic markings are classified as defective, but generally occur at a lower percentage within most harvested crops. Images of weather damage are shown in Figures 6 and 7.

Figure 6. Weather damage seed defects are classified as defective: Hail damage, discolouration/staining and sprouting.

Weather damaged seed will also be more prone to cracked seed coats and splitting of seed during harvest and subsequent handling.

Split seeds not only reduce yield but are also classified as defective in the 2018/19 Australian Pulse Trading Standards.

Figure 7. Cracked seed coats and split seeds are more likely to result from weather damaged grain

Summary of results – blotch/tiger stripe seed markings

- The blotch/tiger stripe seed marking defect is under strong genetic control. PBA Pistol and Sonali were found to be the most susceptible varieties. The worst sample evaluated during the 4 years had 47% of its seeds affected, however <10% is more typical

- The blotch/tiger stripe seed markings can begin to appear on seeds when they are large and green just prior to physiological maturity. Surprisingly, one marked seed and one unmarked seed can reside within a single pod

- Planting seeds with blotch/tiger stripe seed markings is likely to result in an increased proportion of blotch/tiger striped seeds in the subsequent harvest, possibly due to an epigenetic effect. So, it is recommended that marked seeds are not kept for sowing

- It was difficult to determine the exact environmental factors involved in the expression of the blotch/tiger stripe seed markings due to the complex nature of the environment over many different sites, sowing dates and seasons. However,

- The defect does appear to be more prevalent and severe in the northern regions compared to southern Australia; we hypothesise due to increased UV priming of biochemical pathways during plant growth

- There is evidence from several different trials suggesting that moisture (rainfall or irrigation) with cooler days during grain filling could promote the defect

- Further research would be required to confirm these new theories

- In most, but not all sowing date trials, susceptible genotypes expressed higher levels of blotch/tiger stripe markings when sown earlier, than at later sowing dates. Hence, avoiding early sowing dates may minimise the risk of blotch/tiger stripe incidence and severity

- This type of seed marking is a good candidate for molecular marker development. A robust molecular marker will allow the PBA chickpea program to screen breeding material at an early generation stage (where manual seed defect evaluation would be ineffective due to the small amount of seed available).

Summary of results – mosaic seed markings

- Mosaic markings, whilst are often visually more obvious than some other seed defects, occur at a low percentage (<4% of seeds affected) within most harvested crops

- These markings are under more environmental influence, while still being more prevalent in some genotypes than others. There are large G x E interactions.

- Sowing mosaic seeds led to:

- Increased mosaic defect in harvested grain from a susceptible breeding line in all 3 years, but not for PBA Pistol or Howzat

- Higher percentages of blotch/tiger stripe marked seeds in harvested grain in 2 of the 3 years for PBA Pistol, Howzat and the susceptible breeding line

- Further research is required to confirm whether the blotch/tiger stripe defect and the mosaic defect are independent or genetically related defects, as we have evidence from different experimental paths suggesting both theories.

Summary of results – weather damaged crops

Delaying harvest can cause major losses, such as:

- Loss of grain yield through;

- Losses due to pod drop (abscission); more likely when plants become too dry and brittle or suffer from weather damage

- Losses due to pod splitting (dehiscent pods and shattering) where seeds fall to the ground (Figure 4)

- Losses due to increased seed coat cracking and seed splitting

- Lower grain weight due to excessive moisture loss

- Reduction in grain weight occurs in weather damaged grain due to enzymes breaking down seed components to provide energy for sprouting.

- Loss of quality including;

- Reduction in grain weight and increased brittleness of the seeds as enzymes degrade storage components for energy

- Higher percentage of split seeds – classified as defective

- Visually sprouted seeds – classified as defective

- Darkening/staining of seeds, especially where pods were in contact with soil due to lodging or where pod splitting has allowed water entry – classified as defective

- Hail damaged seeds – classified as defective

Up to 44% yield loss was recorded in our harvest delay trials, and this does not consider the additional financial impact of defective seeds reducing price/tonne or possible load rejections at delivery.

Even a single rain event on a mature and dry chickpea crop has the ability to reduce seed weight by a small but significant amount, the financial impact being magnified over large areas.

Summary of results – weather damaged seeds

- Germination rate and vigour of planting seed is reduced by weathering; visually sprouted seeds are not viable. Do not retain weather damaged seed for planting

- Even mildly weather damaged seeds (those where sprouting is not yet visible) have altered quality, functionality and food processing characteristics compared to “sound” seeds

- Objective methods were developed to detect levels of deleterious weather damage in pulse seeds. These now need to be validated in a wider range of varieties and environments.

How to maximise yield and reduce the likelihood of weather damaged, stained and sprouted defective seed

- Time harvest (and desiccation, if used) to avoid rainfall on mature/dry crops as much as possible

- Harvest when seed is at 14% moisture content. This will maximise yield and minimise both seed loss and risk of price penalties from quality loss

- Ensure you optimise your combine harvester settings for every individual crop to capture the best quality seed and to remove defective material (such as immature green seeds, small shrivelled seeds and split seeds). Test it in the crop and adjust. This simple step can negate the need for seed cleaning prior to delivery

- Avoid harvesting when fresh green seeds are present, as this increases the likelihood of mould developing during storage. Desiccation prior to harvest will help reduce this potential issue by drying any new green growth prior to harvest. However, desiccation using glyphosate is not recommended for crops that are to be kept for seed, as glyphosate treatments may reduce seed germination.

- If weather damage occurs, do not retain this seed for planting as it will have lower germination and viability. Always test seed prior to planting.

Acknowledgements

The research undertaken as part of this project is made possible by the significant contributions of growers through both trial cooperation and the support of the GRDC and NSW DPI. The author would like to thank them for their continued support.

This GRDC project was a large collaborative effort and the author would like to thank all of those involved;

- NSW DPI (Catherine Keir, Narelle Egan, Julie Miller, Rebecca Miller, Nerida Coleman, Steven Harden, Fiona Scott, Bruce Haigh, Andrew Verrell, Michael Nowland, Matthew Grinter, Sean Bithell, Amy Treblico, Kevin Moore, Gail Chiplin, Leigh Jenkins, Kristy Hobson and her breeding team)

- SARDI (Victor Sadras, Lachlan Lake)

- QDAF (Douglas Sands, Penny Borger, Peter Aguis)

- University of New England (Richard Flavel, Matthew Tighe, Calista McLachlan)

- University of Southern Queensland (Anke Martin, Mark Sutherland and Kiruba Arun Chinnappa)

- University of Western Sydney (William Price, Timothy Stait-Gardner)

- Adelaide University (Tim Sutton, Yongle Li)

- Pulse Breeding Australia (PBA; many collaborators for providing samples)

- National Variety Trial (NVT; many collaborators for providing samples)

- Australian chickpea growers for providing samples and completing the grower survey

Thank you to Georgina Pengilley (NSW DPI) for reviewing this paper prior to submission.

Contact details

Dr Jenny Wood

NSW Department of Primary Industries

Tamworth Agricultural Institute, 4 Marsden Park Rd, Calala, NSW 2340

Ph: 02 6763 1157

Email: jenny.wood@dpi.nsw.gov.au

Varieties displaying this symbol beside them are protected under the Plant Breeders Rights Act 1994

GRDC Project Code: DAN00196,

Was this page helpful?

YOUR FEEDBACK