A data-based approach to diagnosing & managing constraint-based yield variability

Author: Stirling Roberton (University of Southern Queensland), John Bennett (University of Southern Queensland) and Craig Lobsey (University of Southern Queensland) | Date: 03 Mar 2020

Take home messages

- Soil sampling is a capital investment, not an operational expense

- We cannot accurately manage multiple constraints using a single set of agronomic soil zones (as opposed to mapping the variation of multiple constraints operating individually or with co-dependence on other constraints)

- It is more beneficial to use soil samples to develop continuous variable-rate soil amelioration maps, not zone maps

- The economically optimum sampling density for soil amelioration is dependent on the inherent variability within a paddock.

Introduction

How many soil samples should be taken within a paddock to provide variable-rate soil amelioration advice? Increasing sampling density will improve the accuracy of the recommendation, however, at some point the cost of taking additional samples will outweigh any economic benefit of an improved recommendation. This body of work aimed to identify the economically optimum sampling density for soil amelioration, taking the amelioration of sodicity as an example. This study also compared the error of blanket-rate application (blanket-rate application is when a single rate is applied across a variable paddock, with the rate often being based on bulked soil sampling) zone-based variable rate and continuous variable rate approaches for amelioration (where error is defined as the estimated cost of under- or over-application of gypsum). (N.B. continuous variable rate maps are not reduced to zones, but instead offer the ability for true precision management, where every 12x12 metre pixel can be managed independently within the paddock). The study investigated the treatment of sodicity to 20 cm and 60 cm depths, with the results for 60 cm treatment presented here. Whilst treatment to 60 cm is not currently possible with commercial equipment (however development in this space is currently occurring), it is crucial to investigate possible yield responses of such treatment to provide an estimated cost-benefit of the equipment investment. Furthermore, the primary focus of this work was to provide indication toward the likely sampling density required for treatment to this depth.

Soil amelioration

Soil amelioration is the process of identifying and alleviating soil constraints (e.g. compaction, salinity, sodicity, acidity and alkalinity). Soil constraints are often highly variable at the sub-paddock scale, and can be interacting or operating independently of each other, meaning their spatial management is extremely difficult without sufficient soil information. Furthermore, amelioration of constraints is expensive, meaning small application errors can be highly economically detrimental, both due to wasted amendment from over-application, and lost yield potential from under-application. Investment in soil amelioration therefore requires significant soil information before making investment decisions.

Method

To identify the economically optimum sampling density for soil amelioration, a 100 ha broadacre site under cereal/pulse rotation was selected. 300 soil cores on a 60x60 m grid were collected (3 cores/ha) and analysed for moisture content, bulk density, texture, pH, electrical conductivity, aggregate stability and exchangeable cations (calcium, magnesium, sodium and potassium) at 0–10 cm, 10–20 cm, 20–40 cm and 40–60 cm depth increments. This equated to directly measured soil properties and an additional nine environmental covariates (i.e. 4x years of yield data, 4x electrical conductivity (ECa) readings from a DUALEM and 1x elevation layer) at each core location. Using this benchmark dataset, the paddock’s ‘true’ amelioration requirements were identified to a treatment depth of 60 cm. In this case, ‘true’ was defined as the level of detail obtained by a potential maximum investment for soil analysis at current sampling costs (i.e. 300 cores in 100 ha).

The economically optimum sampling density was subsequently assessed by simulating gypsum recommendations at sampling densities of 0.1–3 samples per ha and comparing them to the original ‘true’ gypsum requirement maps. This indicated how wrong the gypsum recommendation was (in terms of over- and under-application) at varied sampling densities using either a blanket-rate, zone-based variable-rate or continuous variable-rate approach. The cost of over-application was calculated by multiplying the total over-applied tonnage by the on-farm gypsum price (i.e. $110/t), whereas the cost of under-application was estimated using a site-specific yield model that was developed using the 300 directly measured soil cores and 4 years of yield data. This model was used to estimate the spatial yield response of gypsum application, and subsequently estimate the lost yield potential of under-application. The cost of this under- and over-application error was then compared against the cost of sampling at each density to identify the economically optimum number.

Results/discussion

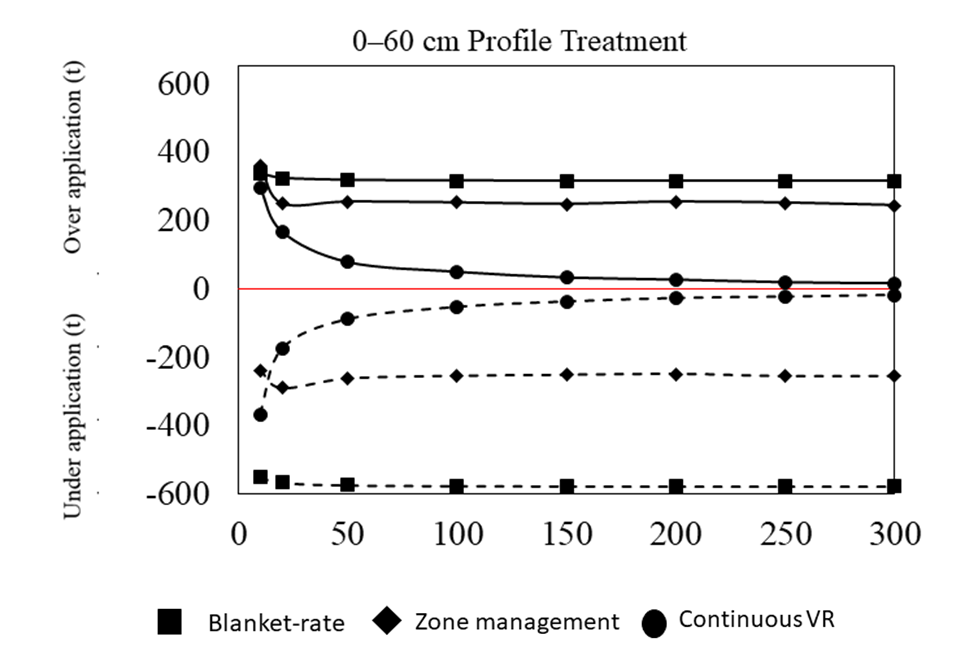

Application error

For each sampling density (i.e. 0.1–3 cores/ha) and each application method (i.e. blanket-rate, zone-based variable-rate and continuous variable-rate), gypsum recommendations were simulated, and their spatial application error assessed. An example of this is presented in Figure 2. The application error at each density was subsequently quantified for the entire paddock and is presented in Figure 1. For 0–60 cm treatment, marginal application improvements can be observed by increasing sampling density for either blanket-rate or zone-based variable-rate methods. Whilst zone-based variable-rate applications provided improved application accuracy over a blanket-rate approach, the continuous variable-rate method was far superior, particularly at sampling densities ≥ 0.2 cores/ha (1 sample per 5 ha). Furthermore, the accuracy of the continuous variable-rate method improved greatly as sampling density increased. However, marginal improvements were observed when sampling density increased above 0.5 cores/ha, indicating that collecting more soil data provided minimal gains in any spatial prediction accuracy.

The predicted spatial yield response due to the application of gypsum was estimated using a site-specific yield model which was developed using the original 300 soil cores and 4 years of yield data.

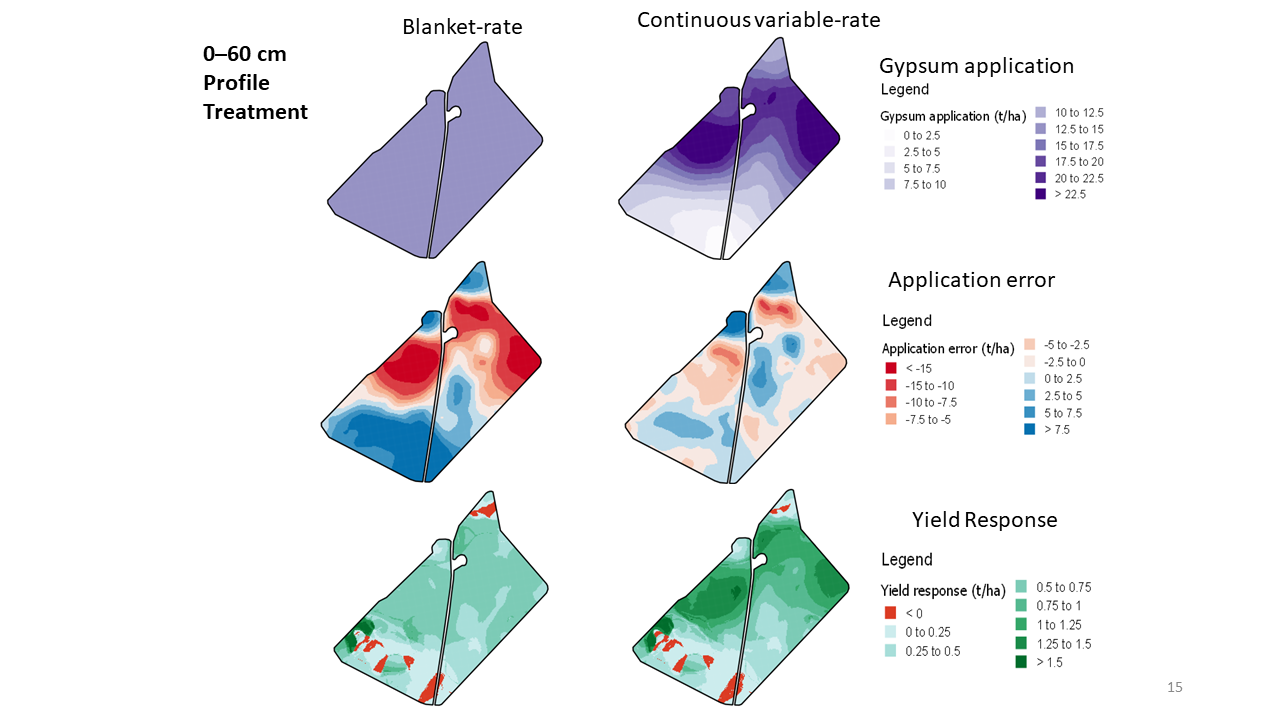

Figure 2. Example of gypsum application based on sampling density of 0.5 cores/ha taking a blanket-rate approach and continuous variable-rate approach for treatment to 60cm. Maps display the resulting gypsum application, the error of that application and the corresponding predicted yield response of the application.

Figure 2. Example of gypsum application based on sampling density of 0.5 cores/ha taking a blanket-rate approach and continuous variable-rate approach for treatment to 60cm. Maps display the resulting gypsum application, the error of that application and the corresponding predicted yield response of the application.

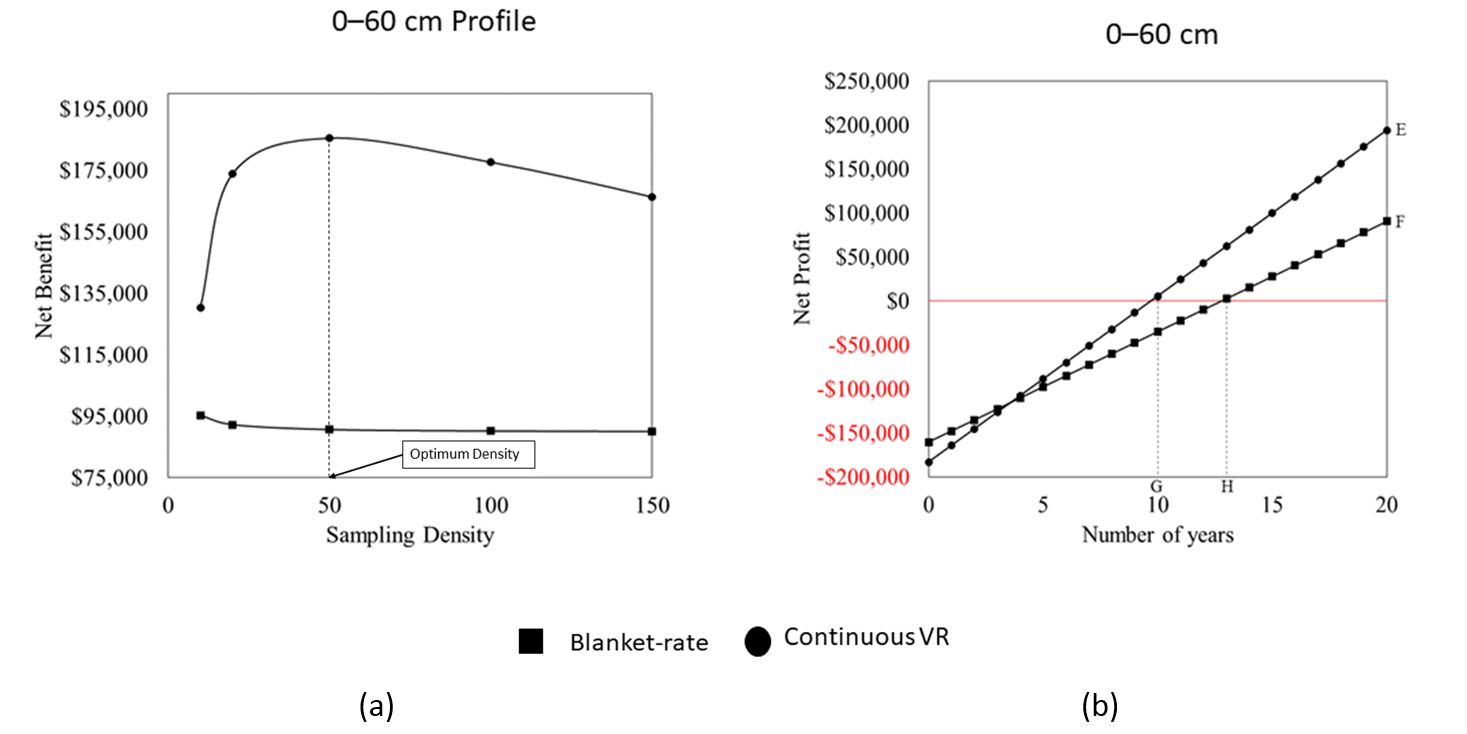

Return on investment

The economically optimum sampling density for the investigated site was identified by assessing the cost-benefit of each simulated gypsum application, both using a blanket-rate approach and continuous variable-rate approach. This was achieved by totalling the predicted annual yield benefit for each simulated gypsum application associated with varied sampling densities over a twenty-year period and comparing against the cost of sampling and amendment (Figure 3a). It can be observed that as sampling density increases to 50 (i.e. 0.5 cores/ha), the largest net benefit of the application can be achieved. At sampling densities below this, the cost of application error exceeds that of the cost of sampling, and at sampling densities above this, the cost of sampling outweighs any benefit of a spatially improved recommendation.

The return on investment of the gypsum application for sodicity amelioration using a continuous-variable rate approach at a sampling density of 0.5 cores/ha was also estimated and is presented in Figure 3b. Whilst at year 0, the cost of taking a continuous variable rate approach was increased, due to an increased sampling requirement, the estimated cost-recovery period of sodicity amelioration was reduced to 10 years, as opposed to 13 years for a blanket-rate approach. Furthermore, the net benefit of the continuous variable-rate approach was estimated to be approximately $100k over the blanket-rate approach, for treatment to 60 cm on this 100ha site over a time period of 20 years.

Conclusion

This work estimated the economically optimum sampling density to be approximately 0.5 samples/ha (50 in a 100 ha paddock) for the treatment of sodicity to 60 cm. However, the economically optimum sampling density for any given paddock is site-specific and is dependent on soil formation factors and the inherent variability of that paddock. Therefore, a thorough understanding of the pedology, local geomorphology and underlying geology needs to be linked to these digital soil mapping techniques. Future work aims to integrate this information with other field variability layers to inform the optimum sampling density at an unvisited site. Current work is also investigating the feasibility of gypsum application below surface soil layers, and this should be a consideration for further refinement of optimum sampling densities.

Soil amelioration and the sampling required to undertake it, is a capital investment within the farming business. Cost-recovery of these investments need to be included in medium-long term strategic business development plans.

Acknowledgements

The research undertaken as part of this project is made possible by the significant contributions of growers through both trial cooperation and the support of the GRDC, the author would like to thank them for their continued support.

Contact details

Stirling Roberton

Centre for Sustainable Agricultural Systems,

University of Southern Queensland

West St, Toowoomba, Queensland, 4350

Ph: 0417 138 503

Email: Stirling.Roberton@usq.edu.au

GRDC Project Code: GRS11002,

Was this page helpful?

YOUR FEEDBACK