Seeding systems and pre emergence herbicides

Author: Sam Kleemann(1), Jack Desbiolles(2), Gurjeet Gill(1) & Chris Preston(1) | Date: 27 Feb 2015

1School of Agriculture, Food & Wine, University of Adelaide

2Agricultural Machinery Group, Barbara Hardy Institute, University of South Australia

Take home messages

- Keeping the weed seeds on the soil surface will improve control by pre-emergence herbicides, so minimise soil disturbance.

- Pre-emergent herbicides can cause crop damage. Separation of the product from crop seed is essential, this is more easily achieved in knife-point & press wheel seeding systems but considerably more difficult with low soil disturbance discs.

- Choose the right herbicide for the job – not all pre-emergent herbicides behave the same so follow label recommendations closely. Be mindful that volatile herbicides like trifluralin and triallate (Avadex® Xtra) require some incorporation to limit herbicide losses from volatilisation and sunlight degradation.

Background

Pre-emergent herbicides play an important role in cropping systems by providing broad-spectrum residual weed control. Applied to the soil they can provide effective early weed control, often controlling multiple germinations to reduce early weed competition with crops.

Because of their diverse chemistry, pre-emergent herbicides are represented across several different mode-of-action groups, from inhibitors of microtubulin assembly (Group D, trifluralin) to very long chain fatty acid synthesis (Group K, Sakura®).

At present growers in south eastern Australia are relying heavily on pre-emergent herbicides because of widespread resistance to Group A (fop & dim) and B selective herbicides. However, their widespread use can also be attributed to their relative low cost and mixing compatibility with non-selective herbicides like glyphosate and Spray.Seed® thus often allowing a single timely application prior to sowing.

Maximising weed control with pre-emergent herbicides and minimising crop damage requires an understanding of how various products interact with the crop, the distribution of weeds seeds in the seedbank; soil type, surface residues, rainfall and seeding system. Herbicide behaviour can vary greatly between sites and seasons and factors such as water-solubility, binding affinity, volatility, sunlight degradation, weed uptake and site of action (i.e. root, shoot or both), longevity of herbicide persistence can all influence herbicide behaviour (Table 1).

Influence of different seeding systems on pre-emergent herbicides

Over the last two decades seeding equipment used by the growers has changed considerably to enable greater stubble retention and more uniform seed placement, whilst creating minimal soil surface disturbance. As a consequence growers have now widely adopted knife-point and press wheel seeders, and more recently there has been some adoption of disc seeders.

Table 1. Water-solubility and binding of some common pre-emergence herbicides

|

Herbicide |

Trade name® |

Solubility (mg L-1)* |

Binding KOC (mL g-1)** |

Safety margin for wheat in adverse conditions |

||

|

Trifluralin |

TriflurX® |

0.22 |

Very low |

15,800 |

Very high |

Very low |

|

Pendimethalin |

Stomp® |

0.33 |

Very low |

17,500 |

Very high |

Low |

|

Triallate |

Avadex Xtra |

4.1 |

Low |

3000 |

High |

Low |

|

S-metolachlor |

Dual® Gold |

480 |

High |

200 |

Medium |

Low |

|

Prosulfocarb |

Boxer® Gold*** |

13 |

Low |

2000 |

High |

Medium |

|

Pyroxasulfone |

Sakura |

3.9 |

Low |

223 |

Medium |

Medium-high |

*at 20 C & neutral pH; ** in typical neutral soils; ***Boxer Gold also contains S-metolachlor

The behaviour of pre-emergent herbicides from both a crop safety and weed control perspective can vary considerably depending on the seeding equipment used and the level and type of soil disturbance it creates.

Given that most pre-emergent herbicides are non-selective, herbicide safety at sowing is often obtained by creating ‘positional selectivity’, that is the physical separation between crop seed and herbicide. Achieving this separation involves the seeding system displacing and throwing herbicide treated soil into the inter-row to create a clean slot from which crop seed can safely germinate. This objective is more easily achieved by tined seeding systems fitted with knife-points which can more aggressively engage the soil than low disturbance discs.

Seed bed conditions, including soil type, soil moisture, soil compaction, row spacing, seeding depth and sowing speed can also influence the ability of seeding system to create adequate herbicide separation from crop seed and provide crop safety.

Knife-points & press wheels

The no-till, knife-point press wheel has seen the revival in old products like trifluralin and triallate (Avadex), because controlled soil throw under these systems often provides adequate separation between the germinating crop seed and treated soil to provide sufficient crop safety. This has enabled the use of higher herbicide rates than previously with conventional full cut seeding systems. In addition, volatile pre-emergence herbicides such as trifluralin and triallate require mechanical incorporation via soil throw at seeding to reduce losses from sunlight degradation and volatilisation.

Issues surrounding crop safety under knife-points can sometimes arise from the use of herbicides with high water solubility, which can move into the furrow after heavy rainfall events soon after seeding. Under some situations, herbicide treated soil can be displaced across adjacent rows because of excessive sowing speeds or inappropriate machine setups. When determining an appropriate speed for sowing, consideration should not only be given to row spacing but also to seed bed conditions because soil throw behaviour can vary considerably depending on the soils moisture status (wet vs. dry). In addition be mindful to knockdown/desiccate weeds prior to sowing, this will help to avoid large weeds from wrapping around the tine, preventing excessive soil throw and widening of the furrow. Melons are often a culprit of this, leaving a large furrow void of herbicide, from which weed escapes will be more common.

Good weed control can be achieved under these low soil disturbance systems because weed seeds are mostly present on the soil surface, which maximises their exposure to concentrated band of herbicide. This was particularly evident in the early days of trifluralin use under knife-points where ideal soil throw and concentration of weed seedbank on the soil surface resulted in exceptional improvement in weed control compared to previous conventional full cut incorporation (from 50 to >90% control).

Disc seeders (triple vs. single)

Many no-till farmers have now adopted disc-based zero-till cropping. Disc seeders enable growers under higher stubble loads to either maintain or even narrow their crop row spacing (5"). With low disturbance disc seeders, reliable separation of seed from pre-emergent herbicides can be difficult and may result in crop damage. Consequently no pre-emergent herbicide labels currently provide specific advice or recommendations for their use with disc seeders, with the TriflurX label specifically stating that it is not to be used with disc opening systems. The situation is complicated by the large number of disc seeders available to growers, which can differ enormously in their level of soil disturbance (pers. comm. J Desbiolles).

Disc seeder setups can vary greatly in the angle of disc entry into the soil, disc arrangement (triple vs. single), size, shape and width, seed placement, closing plate or wheel, depth gauge and press wheel size and shape. Their operation can also vary depending on soil type, soil moisture, soil compaction, residue conditions, row spacing, seeding depth and sowing speed. All these factors combined can influence the level and type of soil throw they generate, and importantly the risk of herbicide damage.

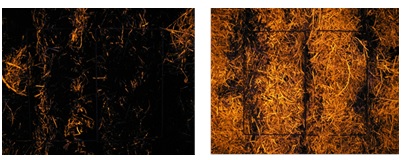

Triple discs – influence of coulters

Recent research by the University of Adelaide and University of South Australia has shown that pre-emergent herbicides were consistently safer under triple disc (i.e. KHart, Bertini) than single disc systems (JD90 series, NDF 650 series). In triple discs, the engagement of rippled coulters (Figure 1) with soil can provide adequate soil throw and herbicide displacement, which often leads to similar crop safety and establishment as tined seeders fitted with knife-points. The role of coulter induced soil throw in crop safety was clearly illustrated in field trials by using coulter skids. Herbicide damage from pre-emergence herbicides was significantly increased when coulter skids were fitted to Bertini coulters to minimise soil throw. These skids are ‘soil throw controllers’ designed to limit the amount of soil movement out of the furrow by preventing soil from riding up the coulter and thus keeping herbicide treated soil within or close to the furrow, thus increasing herbicide damage.

Figure 1. Soil surface disturbance created by KHart triple disc with rippled Yetter coulter (80%; left) compared with JD 90 series single disc (<35%; right). Percentage soil surface disturbance (%) was determined by using fluorescent pigment Blaze-Orange & digitial image analysis software.

Leading coulters can also limit potential for stubble hairpinning where the disc opener rolls over the residue rather than cutting through it. Hairpinning often results in poor seed placement, placing the germinating seed in direct contact with herbicide treated residue and soil.

Single discs – Influence of disc design, sowing speed & depth of sowing

Disc seeding system design and setup can also influence pre-emergent herbicide behaviour. For example, greater soil throw by the seed banding boot deflector of the DayBreak Duodec disc seeding system significantly improved crop safety as compared to other single disc configurations investigated.

Closing the seed slot/furrow and achieving adequate seeding depth were also critical to avoiding herbicide damage from pre-emergent herbicides. This is particularly important for water-soluble herbicides that are more likely to wash into and concentrate in an open seed furrow after rainfall. Disc seeders are often operated at fast travel speeds (i.e. in a 2007 disc seeder survey, 50% of SA farmers operated between 11-13 kph, with some up to 16 kph), but higher speeds can reduce the uniformity of seed placement. Shallow seed placement can increase the risk of herbicide damage in situations where the pre-emergent herbicide has not been effectively removed from the furrow by the seeding disc. In our trials, increasing the sowing depth reduced herbicide damage when a double shoot version of NDF 650 single disc seeding system was used, which created greater soil disturbance and achieved deeper sowing depth. Such disc configurations are likely to increase herbicide removal from the furrow and increase the separation between the herbicide and germinating seed.

In addition fitting air diffusers, which slow the rate of seed delivery to the boot, and use of seed tabs to firm soil around the seed, help reduce seed bounce and poor seed placement associated with fast operating speeds, and can promote greater crop safety.

Single discs – Influence of closing furrow wheels & residue managers

There has been considerable speculation amongst growers and advisors that some closing furrow wheels contribute significantly to herbicide damage by dragging herbicide treated soil from the furrow side wall into the seed slot. However, trial results showed that there was little or no effect of closing furrow wheel design on herbicide damage, but the furrow needs to be properly closed. In some single disc treatments, where the furrow-slot was deliberately left open, herbicide damage caused near complete crop failure. In the field this situation can occur with excessive bouncing of the closing wheel at speed, particularly with solid cast wheels. However, some growers have overcome this issue by fitting spoke wheels (i.e. Thompson closing wheel) which tend to bounce less whilst crumbling the furrow side wall. Growers have also reported that closing the seed slot is made more difficult when weeds are present at sowing, suggesting their root systems bind the surface soil to reduce the amount of friable soil that can be pressed back into the furrow.

Use of residue managers fitted in front of single disc openers were shown to significantly improve crop safety. The managers appear to sweep both herbicide treated stubble and soil ahead of the disc opener thereby limiting the interaction between the disc blade &/or closing furrow wheel, resulting in greater crop safety. However, the ability of residue managers to operate under certain residue situations (i.e. tall stripper front residue) can be compromised and careful consideration is needed at harvest to ensure the residue is suitable for handling at sowing.

Similar to the knife-point & press wheel system, research has shown that weeds seeds accumulate on or near the soil surface in disc opening systems. As a consequence most weed seeds germinate in close proximity to a concentrated herbicide band that can result in consistently greater weed control, in addition to hastening natural seed mortality.

Our trials have shown that some herbicides and rates of herbicides were better suited to disc systems than others. Inadequate soil throw and poor incorporation of trifluralin with single disc systems often causes crop damage and poor weed control, and can result in massive weed seed set and hence the label specifically recommends against using disc opening systems. Such large build-up in weed seed bank would be expected to have serious effects on productivity of subsequent crops grown in the rotation. Therefore careful consideration should be given to choosing the right herbicide for the job, and remember not all herbicides behave the same so follow the label recommendations closely.

Acknowledgements

The research undertaken as part of this project is made possible by the significant contributions of growers through both trial cooperation and the support of the GRDC, the authors would like to thank them for their continued support. The collaboration of many disc seeder and accessory suppliers in loaning a range of seeding systems is also gratefully acknowledged. We also wish to thank Dean Thiele from the University of South Australia for his assistance in trial preparation and implementation and Malinee Thongmee for providing technical support.

Contact details

Sam Kleemann

University of Adelaide

School of Ag, Food & Wine, Waite Campus, PMB 1, Glen Osmond, SA, 5064

Ph: 0418 256 475

Email: samuel.kleemann@adelaide.edu.au

Jack Desbiolles

University of South Australia

UniSA, Mawson Lakes Campus, Mawson Lakes, SA, 5095

Ph: 0419 752 295

Email: jack desbiolles@unisa.edu.au

® Registered trademark

GRDC Project Code: UA00113; UA00134,

Was this page helpful?

YOUR FEEDBACK