Profitable stubble retention systems for the high rainfall zone

Author: Paul Breust and Aaron Vague (Southern Farming Systems) | Date: 23 Feb 2016

Background

The high rainfall zone (HRZ) commonly produces high-yielding crops due to favourable environmental conditions. High yields correspondingly produce high stubble loads. Using the standard harvest index of 40 per cent grain and 60 per cent straw, a crop yielding 8t/ha means 12t/ha straw. In 2013 trials at Inverleigh yields of greater than 10t/ha grain were common.

These high stubble loads can cause several problems for growers in the following year. Seeder blockages impact on plant establishment. Stubble provides ideal habitat for pests to survive, physically intercepts herbicides, increases frost risk (Biddulph et al), carries over diseases, and increases potential for nitrogen tie-up. The GRDC stubble project (BWD00024) aims to test and develop farming systems where retained stubble is managed in the HRZ without a reduction in profitability for the grower.

Retaining stubble has many positive impacts for crop production systems across all rainfall zones. Retained stubble provides excellent ground cover (>2.5t/ha) thus reducing wind and water erosion; increases rainfall infiltration; reduces moisture evaporation (>4.5t/ha); eliminates the need to burn, bale or incorporate; and recycles nutrients back into the soil. Using commercial machinery was the only option to accurately evaluate various stubble retention systems and for these trials we used John Deere single disc opener and Morris Contour tyne and press wheel seeders on 30cm spaces.

Successful stubble retention requires a complex systems approach that considers every aspect of the system and their impact on other parts of the system:

- Harvesting to retain stubble - height, chopper and spreader setup

- Fallow management - weed control, grazing, paddock traffic

- Rotations - weed control, disease management, nitrogen, suitability for establishment in stubble

- Seeding equipment - trash handling, row spacing, inter-row sowing, soil disturbance, fertiliser toxicity

- Establishment and dry matter production - yield, plant density, canopy closure

- Herbicide application - interception, water rates, crop safety, resistance, nozzle selection and spaces

- Weed establishment and control - integrated weed management (IWM), soil disturbance, herbicide contact, crop competition

- Pests - integrated pest management, monitoring, control strategies, rotations

- Yield

- Costs and profit.

Harvesting to retain stubble

Harvesting is a major consideration for a successful HRZ retained stubble system. Several key points have been highlighted by the project work, which are:

- Harvest height should match your seeders capabilities to get through it

- There is a 10 per cent loss of harvest speed for every 10cm you lower the comb height

- Minimise trash that covers soil to reduce blockages and improve pre-emergent efficacy

- Chopper and spreader setup are critical to minimise blockages

- Trash should be spread evenly across the header width

- Reduce traffic on stubble to leave as much standing as possible.

Fallow management

The fallow period allows growers to complete additional operations, if required, to successfully establish the next crop.

- Assess stubble to determine if your seeder will handle it

- Take action to fix any aspects of the stubble that will impede establishment. Such actions include baling, mulching, incorporation, angled sowing and, in severe cases, burning

- Leave stubble standing upright to reduce seeder blockages

- Control weeds and regrowth - reduces biomass, minimises moisture and nitrogen losses

- Grazing can help or hinder stubble retention. When stock eat stubble it reduces biomass. If they lay it over it can increase blockages. It is seasonally dependent.

Seeding equipment

Southern Farming Systems (SFS) has conducted extensive work on seeding equipment performance in relation to stubble retention. These include Seeder Demonstration Day 2015, the Streatham disc versus tyne trial, stubble management comparisons and a stubble management for disc seeders trial at Streatham. Key information thus far from this work is:

- Real time kinematic (RTK) guidance is a critical component to inter-row sowing

- Each seeder has varying capacity to handle retained stubble

- As a rule, discs handle higher loads than tyne and press wheel machines

- Wider tyne spacing across and along the bar will improve stubble handling

- Changing the angle of sowing direction slightly can minimise blockages

- Guidance auto steer on seeder bars will improve inter-row sowing

- Tynes and discs have varying degrees of soil throw and crop safety for pre-emergent herbicides

- Isolation of fertiliser from seed will limit seed burn.

Results thus far

We have collected data on establishment, seed depth, dry matter, Normalised Difference Vegetation Index (NDVI), tiller numbers, head numbers, pest numbers, weed establishment and yield. Some data were not yet available at time of writing.

Establishment

Table 1: Establishment in SFS disc versus tyne trial 2015. Wheat in 6.68t/ha wheat stubble. No significant difference in establishment for any treatment in middle of seeder or on the wings. 12-tonne roller no significant difference.

| TRT | Establishment Middle | Establishment wing | P=0.5 |

| JD disc, 30cm tall stubble | 128.7/m2 | 144.7/m2 | NS |

| Morris tyne, 15cm stubble | 132.3/m2 | 149.1/m2 | NS |

| TRT | Establishment Middle | Establishment wing | P=0.5 |

| Roll | 134/m2 | 142.2/m2 | NS |

| No roll | 127/m2 | 151.6/m2 | NS |

Table 2: Establishment in SFS disc in stubble management trial 2015. Canola in 6.76t/ha wheat stubble. No significant difference in establishment for any treatment in middle of seeder or on the wings. Two additional trials comparing burn and stubble retention showed no significant difference for establishment, data not reported.

| Plants/m2 wing | Plants/m2 mid | Sig P=0.5 | |

|---|---|---|---|

| JD disc - 30cm high harvest | 31.6 | 35.5 | ns |

| JD disc - 15cm high harvest | 29 | 36.1 | ns |

| JD disc - 30cm high harvest, windrow, bale | 32.5 | 32.63 | na |

Table 3: Seed depth in disc versus tyne trial 2015. Wheat in 6.68t/ha wheat stubble. SFS seeder demo found discs’ 3.2mm less variation than tyned seeders for seed depth.

| Seed depth mm | |||

|---|---|---|---|

| Disc | Tyne | Comment | |

| Average | 21.2 | 26.4 | JD disc better for depth control. |

| Range mm | 17 to 29 | 8 to 42 | JD disc more consistent for depth (parallelograms good too). |

Dry matter (DM)

Table 4: NDVI in SFS disc versus tyne trial 2015. Wheat in 6.68t/ha wheat stubble. Significant positive difference in tyne DM on 5/08/2015.

| TRT | NDVI 5/8/15 | Sig 0.5 |

|---|---|---|

| Disc, 30cm stubble | 0.198 | B |

| Tyne, 15cm stubble | 0.229 | A |

| LSD P=0.05 | 0.018 |

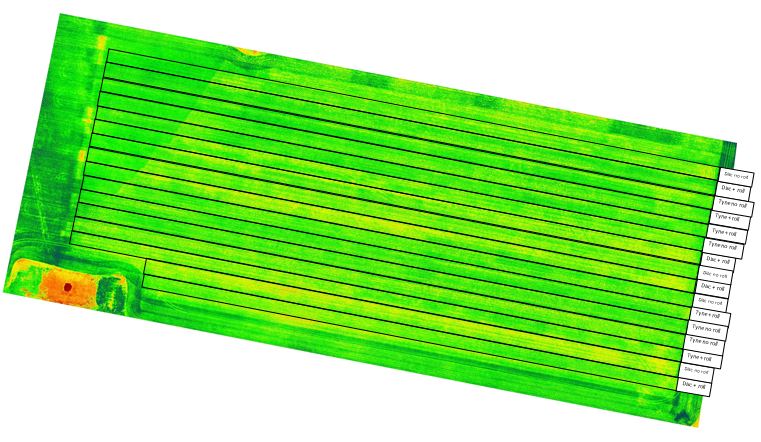

Figure 1: Note the accidental burn line in the top left hand corner of trial. Burning increased NDVI initially by 290kg DM in the burnt area. Disc 125kg/ha less DM than tyne. The presence of stubble will alter NDVI readings so DM may be similar regardless of stubble. Not measured in 2015.

Table 5: Dry matter SFS disc versus tyne trial.

| DM Av/TRT | Sig 0.05 (LSD 0.59) | Av DM | |

|---|---|---|---|

| Disc + roll | 7.27t/ha | ns | Disc 7.22t/ha (LSD 0.88) |

| Disc - roll | 7.17t/ha | ns | Tyne 7.07t/ha (LSD 0.88) |

| Tyne + roll | 6.98t/ha | ns | *Burnt 5.99t/ha |

| Tyne - roll | 7.16t/ha | ns |

n.b.* Burnt area unreplicated.

Dry matter SFS disc versus tyne trial was not significantly different at flowering. Burnt area was visibly more stressed and plant height reduced by 5-6cm, subsequently reducing DM by approximately 1t/ha. Why? Better early growth used more moisture? Less N tie-up? Burning reduced moisture available compared to retained stubble? Less disease pressure? Combination of all?

Table 6: NDVI in SFS disc in stubble management trial 2015.

| TRT | NDVI 29 July 15 | Sig 0.05 | |

|---|---|---|---|

| 30cm stubble | 0.32 | B | CV 11.6197 LSD 0.049 |

| 15cm stubble + roll (low harvest) | 0.36 | AB | |

| Windrowed & baled stubble + roll | 0.40 | A | |

| Roll | 0.37 | A | CV 7.789 LSD 0.026 |

| No roll | 0.34 | B |

NDVI in SFS disc in stubble management trial 2015. Canola in 6.76t/ha wheat stubble. Shorter stubble treatments significantly better for NDVI at this early stage. Rolled treatment significantly more NDVI than nil rolled treatment in canola. No significant difference in DM at flowering but CV of 15 limits conclusiveness of this data.

Weeds

Table 7: Annual ryegrass plants in SFS disc versus tyne trial 2015. Average of 10 x 6m2 paired plots.

| Treatment | ARG/m2 | ARG/Ha |

|---|---|---|

| Morris tyne | 0.15 | 1528 |

| JD disc | 0.01 | 139 |

| ARG/m2 | ARG/Ha | ||||

|---|---|---|---|---|---|

| Seeder | Boss | JD disc | Boss | JD disc | Diff/ha |

| ARG numbers | 1.19 | 0.37 | 11900 | 3700 | 8200 |

Pests

The four trials were monitored for pests at regular intervals. Split plot rolling with a 12m x 12T machine was done in the disc versus tyne and disc in stubble management trials to determine the impact of this treatment on slug numbers. In the disc versus tyne trial, six slug tiles were placed in each plot (16 treatments x six tiles). An early pre-sowing bait was applied in 20m wide strips in three tile locations across all plots. This was followed by a blanket application over the whole trial area after post-sowing. In this trial no slugs were found under any of the tiles in either the pre-sow bait treated areas or the single post-sowing baited areas.

Millipedes were in abundance, but no wheat seedling damage was recorded in this trial. Data from the trial is being examined by Michael Nash SARDI to check correlations between moisture readings and millipede density.

In the stubble management by disc seeder trial, 72 tiles (24 treatments x three reps.) were placed. Three post-sowing applications of bait were applied by the co-operator. Similarly, no slugs were located in this canola crop. Millipedes were again high in numbers, but did not damage canola seedlings. Data is being reviewed by Michael Nash.

Stubble harvest weed seed management trials were also monitored for pests, with no slugs recorded.

Yield

Table 9: Yield and harvester efficiency data; SFS disc versus Tyne trial 2015. Burn area yields average of all treatments. (Disc in stubble management yield not available at time of writing.)

| Yield (t/ha) | ha/hr | L/ha | ||||

|---|---|---|---|---|---|---|

| JD disc, 30cm stubble | 3.7098 | a | 8.431 | a | 5.69 | b |

| Morris tyne, 15cm stubble | 3.1606 | b | 6.619 | b | 7.8 | a |

| LSD P=0.05 | 0.56845 | 0.2073 | 0.99 | |||

| Std | 0.35724 | 0.1303 | 0.622 | |||

| CV | 10.39942 | 1.7314 | 9.228 | |||

| Burnt area | 2.1564 | |||||

| Burn Disc average yield | 2.2161 | |||||

| Burn Tyne average yield | 2.0706 |

Table 10: Yield in rolled versus unrolled treatment SFS disc versus tyne trial 2015.

| Yield T/ha | ||

|---|---|---|

| Rolled treatment (D+T) | 3.5575 | a |

| No rolled treatment (D+T) | 3.3129 | b |

| LSD P=0.05 | 0.20547 | |

| Std | 0.16794 | |

| CV | 4.8889 |

Costs and profit

Table 11: Cost calculations for yield, harvest efficiency and fuel use SFS disc versus tyne trial 2015. (1) Contract sowing @ $45/ha. 12m disc takes 35hrs less time over 1000has at 12km/hr v 12m Tyne at 8km/hr. (2) Red wheat valued at $200/t. (3) 1.98 extra minutes per hectare valued at $6.66/min ($400/hr contract rate). (4) 2.11L/ha less diesel valued at $1.20/L. Financial estimates of cost not yet available.

| Sowing | Yield | Harvest time | Fuel use | ||

|---|---|---|---|---|---|

| Variation disc versus tyne | 4.8ha/hr(1) | 0.5492t/ha(2) | 1.812ha/hr(3) | 2.11L/ha(4) | Totals |

| $ value of differences/ha | 2.10 | 109.84 | 13.23 | 2.53 | 127.70 |

| $ value of differences/1000ha | 2100 | 109840 | 13230 | 2530 | 127,700 |

Discussion

The results of work done in 2015 must be reviewed carefully and should be considered as one year’s data from one set of seasonal conditions.

‘Normal’ HRZ conditions of long wet winter months and water logging could drastically alter results. Stubble retention may prove less profitable due to a number of factors in ‘normal’ seasons. However, it is encouraging that all trials established with no significant differences. It is also encouraging that no yield penalties were evidenced. Experience in other HRZ zones of Australia have shown similar results. (CSIRO, FarmLink Research results WUE project 2008-2013, FarmLink disc versus tyne demonstration Junee, GrassRoots Agronomy).

It appears adopting stubble retention in the HRZ is a viable option and many growers have developed systems-based approaches that maintain profitability at similar levels to traditional methods. Growers are leading the development of individually-tailored systems based on their equipment and resources. There have been significant technological gains made with RTK guidance, boom spray setup, harvest spreaders, seeder design and fertiliser management in recent years, and this is ongoing.

Traditional methods of burning, baling, mulching or incorporating stubble are additional operations not required in stubble retention. Harvesting at 15cm significantly reduces harvest efficiency and has potential to cause damage to harvesters from rocks that are common throughout the Western District. Harvesting at 15cm also increases trash placed onto the soil surface and can then increase potential for seeder blockages and inhibit pre-emergent herbicide efficacy. May stripper fronts might improve this aspect further?

There are many things to consider in order to successfully implement a stubble retention system, but early indications are that with careful management it can be as profitable via reducing costs and increasing efficiency of harvest and sowing operations.

Retaining stubble has been shown in many cases to reliably establish crops earlier as a result of increased availability of seed bed moisture being a key factor in achieving yield potentials.

Conversely, there are many potential problems that can accompany stubble retention. Fertiliser toxicity, interception of herbicides, herbicide crop safety, reduced early growth, nitrogen management, increases in pest and disease levels are all areas of concern. Many have been and continue to be addressed by early adopters. Potential adopters will need to consider each one carefully and implement a system that minimises these risks.

Adopting a stubble retention system will require attention to detail and some growers may find it easier to continue to manage a traditional stubble burning or removal program. Mixed farms with a pasture phase will increase complexity. Restrictions on burning will require growers to change from their traditional practices and the additional cost incurred in stubble removal will influence how they approach this in the future. Data from across Australia has shown stubble retention is a viable option in the HRZ and this GRDC-funded work will better equip growers to evaluate all of the options available to them.

Acknowledgements

Myles Read, Scott Blurton, John and Stewart Hamilton, Noel, Tim and Simon Barr, Craig Drum (Gorst Rural), Ben Dumesny (Premier Ag), Neil Vallance, Troy Missen, Tim Pilkington (Compass Agribusiness), Greg and Kirrily Condon (Grassroots Agronomy), Michael Nash SARDI, Andrew Whitlock and Brendan Torpy (Precision Agriculture).

Funding for this work was provided through the GRDC Project BWD00024 and their support is gratefully acknowledged.

References and additional information

Southern Farming Systems YouTube Channel

Ground Cover 111 article Close eye on research lifts WUE and saves the sheep

Southern Farming Systems website

The Stubble Project: Victoria and Tasmania

Grassroots Ag Disc Seeding in Southern NSW

Ground Cover 109 Supplement Stubble lifts frost severity

Contact details

Paul Breust

Aaron Vague

GRDC Project Code: BWD00024,

Was this page helpful?

YOUR FEEDBACK