Soil amelioration in Western Australia

Author: Stephen Davies, Wayne Parker, Paul Blackwell, Bindi Isbister, Giacomo Better, Chris Gazey, and Craig Scanlan (Department of Agriculture and Food, Western Australia) | Date: 07 Feb 2017

Take home messages

- Subsoil compaction has increased in severity and depth in deeper sandplain soil resulting in substantial benefits from deeper ripping with average wheat yield increases of 35%.

- Topsoil slotting behind deep ripping tines can encourage root penetration into the subsoil through providing nutrient and organic matter rich pathways and it is hoped this will improve the longevity of the benefits of deep ripping. Average wheat yield increase has been 53% with topsoil slotting.

- Incorporating soil amendments and overcoming topsoil water repellence may require deeper soil mixing with ploughs or rotary spaders which modify the soil surface.

- Overcoming multiple soil constraints can improve the longevity of benefits and overall returns on investment for up to 10 years at some sites.

Background

The sandplain soils of WA are typically affected by numerous constraints including water repellence, subsoil acidity, subsoil compaction and poor water and nutrient holding capacity (Table 1). Research conducted in the 1970s and 80s demonstrated that on deep sands and sandy earths in WA, wheat roots could extract water from depths ranging from 1.4 to 2.5metres (Hamblin et. al. 1982; Hamblin et. al. 1988; Tennant 1976). The capacity for roots to extract water and nitrogen from such depths is critical on these soil types, which typically have relatively low water holding capacity, and the use of deeper subsoil moisture is critical for grain filling and overall water use (Delroy and Bowden 1986). Sandplain soil constraints can dramatically reduce the final rooting depth and the effective density of roots in the subsoil. Soil amelioration techniques that overcome multiple soil constraints can result in large increases in productivity.

Soil amelioration approaches typically involve either the strategic application of soil amendments, such as lime, dolomite, gypsum, organic matter or clay-rich subsoil, or the use of deep tillage or, often, a combination of the two.

Table 1. Summary of some of the main sandplain soil types in the WA south-west agricultural region, their area and typical constraints.

| Soil type | Typical soil classification | Area in WA | Typical constraints |

|---|---|---|---|

| Pale deep sand | Tenosol | 1.24 | Water repellence, acidity, compaction, water and nutrient holding |

| Yellow deep sand | Tenosol | 1.36 | Water repellence, acidity, compaction, water and nutrient holding |

| Deep sandy earths | Kandosol | 1.55 | Acidity and compaction |

| Deep sandy and duplex sandy gravel | Ferric Tenosol Ferric Kandosol |

1.14 | Water repellence, acidity, water and nutrient holding |

| Shallow sandy duplex | Sodosol Chromosol |

2.27 | Water repellence, subsoil alkalinity, subsoil sodicity, subsoil salinity, boron toxicity, waterlogging and poor subsoil structure |

| Deep sandy duplex | Chromosol Sodosol |

2.42 | Water repellence, acidity, water and nutrient holding, subsoil alkalinity, subsoil salinity, subsoil sodicity and poor subsoil structure |

Deeper ripping and topsoil slotting

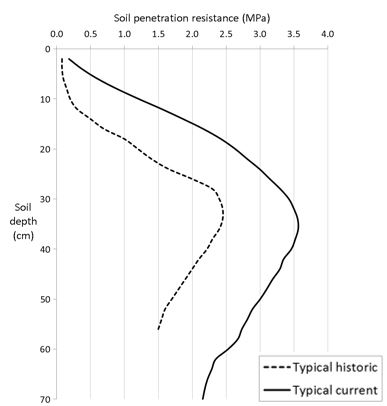

Subsoil compaction is one of the most common and under-diagnosed constraints on deep sandplain soils. As machinery sizes and axle loads have increased the severity of the compaction problem has continued to worsen, with harder and deeper hardpans. Historically peak soil strength typically occurred at depths of 10-25cm and typically reached strengths of 2.5 to 3.0MPa (Hamblin et. al. 1992; Schmidt et. al. 1994). Recent soil strength measurements on deep sands and sandy earths throughout WA indicates that peak soil strength now occurs at depths of 20-50cm, with strengths ranging from 3.0 to 5.1 MPa (Figure 1). The average peak soil strength now exceeds 3.5 MPa which is considered extreme and too hard for cereal root penetration except through existing biopores and soil fractures (Ehlers et. al. 1983). Traditional deep ripping to depths of 30-40cm has been commonly practiced on some of the deeper sands of WA and historically this was adequate to remove most of the hardpan (Figure 1). Reviews of historic deep ripping trials have shown substantial benefits with cereal yield increases of 22-37% in the first year (Crabtree 1989; Davies et al. 2006; Jarvis 2000), but compaction is now deeper and more severe and deeper ripping to 50cm or more is required.

In addition to deeper ripping, another development is to put a soil opener on the back of the deep ripping tine which runs below the soil surface allowing loose sandy topsoil to fall into the ripping furrow (Figure 2 and 3). This results in the formation of vertical seams, or columns, of topsoil in the subsurface soil (Figure 3). The aim of this ‘topsoil slotting’ is to improve root growth into the subsoil by providing a nutrient and organic matter rich pathway through infertile subsoil layers, to overcome the aluminium toxicity associated with subsoil acidity and to improve the longevity of the ripping benefit by stabilising the loosened soil.

Figure 1. Plot showing typical soil penetration resistance measures for deep WA sandplain soils. Graphs are mean values for historic (1980s) and ‘current’ (2005-present) cone penetrometer measurements. Values of 1.5-2.5 MPa are considered moderate compaction, 2.5-3.5 MPa severe compaction and >3.5 MPa extreme compaction.

Figure 2. Soil openers on the back of deep ripping tines. The openers run below the soil surface allowing loose sandy topsoil to be slotted deeper into the profile.

Figure 3. Soil profile in severely repellent pale deep sand showing seams of topsoil (darker soil) incorporated to about 30cm into the subsurface soil from use of soil openers attached to the back of deep ripping tines working at a depth of 40cm. Note how the slotted topsoil provides a ‘root friendly’ pathway through the subsurface soil layer.

In research experiments run over the past three seasons, ripping has increased average wheat yields by 8% for shallow 30-40cm ripping, 35% for deeper ripping to depths of 50cm or more, and 53% for deeper ripping with topsoil slotting (Table 2).

Table 2. Summary of deep ripping trials conducted during 2014-16 showing the crop responses to deep ripping at different depths and the impact of topsoil slotting (inclusion) on crop grain yields.

| Location & crop | Soil type | GSR (mm) | Control yield | Ripped 30-40cm | Ripped 50-70cm | Ripped 50-70cm + topsoil slotting | |||

|---|---|---|---|---|---|---|---|---|---|

| Yield | % | Yield | % | Yield | % | ||||

| Moora, canola | Loamy sand | 177 | 1.9 | 2.2 | 16 | 2.8 | 47 | 2.9 | 53 |

| Wubin, wheat | Deep sand | 228 | 2.1 | 2.7 | 29 | 3.0 | 43 | - | - |

| Binnu, wheat | Deep sand | 219 | 0.8 | 0.8 | 0 | 1.4 | 75 | 1.8 | 123 |

| Binnu, wheat | Loamy sand | 219 | 2.1 | 2.1 | 0 | 2.8 | 33 | 3.6 | 71 |

| Beacon, wheat | Sandy duplex | 240 | 3.8 | 3.9 | 3 | 3.5 | -11 | 4.5 | 15 |

| Broomehill, wheat | Sandy duplex | 227 | 1.8 | 2.0 | 11 | 3.0 | 67 | - | - |

| Munglinup, wheat | Sandy duplex | 280 | 3.6 | 3.6 | 0 | 3.6 | 0 | 4.2 | 17 |

| Meckering, wheat | Sand over gravel | 323 | 2.7 | - | - | 3.4 | 26 | - | - |

| Meckering, wheat | Deep sand | 323 | 2.4 | - | - | 3.4 | 46 | - | - |

| Meckering, wheat | Sand over gravel | 323 | 2.2 | 2.5 | 15 | 3.0 | 38 | 3.0 | 38 |

| Walkaway, lupin | Deep sand | 219 | 1.2 | - | - | 2.3 | 92 | - | - |

Excluding the duplex soils which have more variable responses, the average wheat yield responses on deeper sands and loamy sands are 11% for shallow ripping, 44% for deeper ripping and 78% for deeper ripping with topsoil slotting, although the benefit of topsoil slotting is driven by several large responses and more research data is needed to confirm this benefit.

There can be benefits from topsoil slotting with shallow (30-40cm) deep ripping. At Meckering, WA in 2016 shallow ripping of pale sand over gravel increased wheat grain yield by 11% (320 kg/ha) over the control with the addition of topsoil slotting increasing the yield by 26% (560 kg/ha — data not shown). It is hoped that topsoil slotting will improve the longevity of the deep ripping benefit and research is continuing to investigate this.

Controlled traffic will maximise the longevity of the benefits from deep ripping. For many deep sandplain soils, deep ripped areas can remain soft for at least 4 to 5 years in controlled traffic situations. For those soils that undergo some natural re-compaction through settling and cementation processes the inclusion of organic matter through topsoil slotting is likely to help prevent this and maintain the rip lines in a soft condition in a controlled traffic scenario. Controlled traffic will ultimately result in a much improved return on investment through increased longevity of the deep ripping benefit and a reduced need to repeat the deep ripping with its associated cost.

Situations where deeper ripping may not work

Deep sandy-textured soils are more responsive to deep ripping than finer-textured soils (Paterson and Sheppard 2008; Farre et. al. 2008). On duplex soils deeper ripping may only be effective when the clay B-horizon is hospitable for root growth, although topsoil slotting has resulted in good success on duplex soil with sodic B-horizons (Blackwell et. al. 2016). In drier environments deep ripping may promote early biomass growth but with the risk of haying off with a warm and dry finish to the season (Farre et. al. 2008). Finally deep ripping typically does not drastically change or mix the soil surface — though this can depend on the type of ripper used. While this can often be an advantage it also means that deep ripping can have limited long-term benefits on topsoil water repellence.

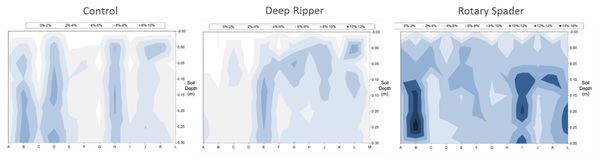

Soil moisture profiles to 30cm on a soil pit face were assessed (Figure 4) on severely repellent pale deep sand following 50mm of rain which fell over four days, 21 to 24 May 2016. Higher moisture levels are shown by darker shading and in the untreated control, moisture infiltration followed the typical pattern for repellent soils with clear preferential flow paths, large areas of ‘dry patch’ (Figure 4) and evidence of bypass flow. In the deep ripped treatment there was little improvement in moisture infiltration and evenness of wetting, with preferential flow paths and areas of ‘dry patch’ evident. Rotary spading however did modify the soil surface condition and generate a more even water infiltration, reduced dry patches and higher water retention in the 15 to 30cm layer associated with the topsoil organic matter buried by the spades (Figure 2). In the case of strongly repellent sandplain soils ripping alone may be inadequate to overcome the soil water repellence constraint and deeper soil mixing or inversion, application of soil wetters or addition of soil amendments such as clay-rich subsoil may be required.

Figure 4. Volumetric soil moisture (%) profiles on soil pit faces for severely repellent pale deep sand following 50mm of rain over four days at Irwin, WA. Pits were 140cm wide and 30cm deep. Darker shading is indicative of higher soil moisture content.

Deep soil mixing and inversion

One-off strategic deep ploughing or rotary spading is being used to overcome water repellence (Davies et. al. 2012; Roper et al. 2015) and to mix nutrients, organic matter and soil amendments into the subsoil and bury herbicide resistant weed seeds. This strategic tillage is followed by an immediate resumption of minimum or no-till cropping practices. Strategic deep ploughing tends to take one of two forms:- Deep soil mixing, typically with rotary spaders or large offset disc ploughs.

- Soil inversion using mouldboard, square or modified one-way disc ploughs.

Rotary spaders are effective at burying some topsoil and lifting seams of subsoil to the surface (Figure 5). In repellent soils these seams act as preferred pathways for water entry and this improves the overall wetting of the soil profile and can substantially improve crop establishment (Figure 5). Overall, rotary spaders tend to bury about two-thirds of the topsoil in the 10-25cm layer. Wheat grain yield increases in response to rotary spading are on average 600kg/ha in the first year and around 300kg/ha in subsequent years (Table 3), although the responses on severely repellent soils can be much greater. Current trials indicate that the benefit from rotary spading can last at least 4 to 5 years — depending on soil type. In WA, soils are typically deep ripped prior to spading as this increases the working depth of the spader, reduces wear and tear, and removes rocks and stumps from the profile reducing the risk of damage. Spaders are costly to use, in part due to a relatively slow work rate and high maintenance costs.

Figure 5. Soil profile showing mixing and burial of water repellent topsoil into the subsurface layers by a rotary spader (left image) and improvement in wheat establishment (right image) from rotary spading (left) compared to an untreated area (right) on severely repellent deep yellow sand.

Complete soil inversion is the most extreme form of deep soil tillage as it buries the topsoil in a distinct layer below a layer of subsoil. This buried layer of relatively concentrated organic matter and nutrients greatly promotes root growth and proliferation at 15-35cm, and unlike the topsoil, is not subject to such rapid and frequent drying cycles throughout the growing season. The subsoil brought to the surface is typically low in organic matter, lower in fertility and in WA is typically more acidic than the original topsoil. Depending on the soil type the subsoil surface can have higher clay content. This can be an advantage in preventing a recurrence of water repellence but can also create problems due to surface crusting and higher evaporative losses as a result of increased water holding at the soil surface.

In repellent soils the inverted subsoil brought to the surface is wettable and so water tends to infiltrate evenly from the soil surface which can substantially improve crop establishment. On severely repellent soil the yield responses to soil inversion can be large and sustained over many years. On severely repellent pale deep sand at Badgingarra one-off mouldboard ploughing in 2010 has increased the yield of each crop by 1.0t/ha or more for the six seasons the site has been measured (data not shown). On average the wheat yield response to soil inversion is about 500kg/ha in the first year, with 400kg/ha in subsequent years (Table 3). In many of the trials and on-farm demonstrations the benefits from the inversion seem to be long lasting, with measured benefits for five or more years. Burial of topsoil can have similar effects as burying compost or manure encouraging more-dense crop root proliferation at depth. In repellent deep sand at Badgingarra, 70% of the roots were found in the top 10cm of the control soil while with soil inversion 70% of the roots could be found in the 10 to 30cm part of the profile. Buried topsoil is less subject to frequent wetting and drying cycles compared to topsoil at the surface and the associated organic matter can have an important role in holding water and nutrients in the root zone.

Other tools suitable for soil inversion include square ploughs and modified one-way disc ploughs. Chamberlain and Shearer one-way disc ploughs are being used by a number of growers in WA as a means of inverting the soil much more cheaply given the low capital cost required to purchase and modify a second-hand one-way plough. The one-way ploughs are modified by removing every second disc, which is important because it allows sufficient space between the discs for the soil to fully turn over. With every disc in place the soil will just be thrown up onto the jump-arm and back off the neighbouring disc and fall down in a mix. The growers also fit bigger, scalloped discs, typically 28-30inches diameter to engage the subsoil and bury repellent topsoil (Figure 6). Shearer ploughs are heavy but on the Chamberlain ploughs growers often add extra weight to improve soil penetration and working depth which is further aided by having fewer and larger discs. The ploughs tend to be used partly closed up rather than fully open to achieve a degree of bulldozing which allows the soil to roll up and through the disc and be turned over. Another advantage of one-way ploughs is they can be used on gravel soils provided there is not too much cemented gravel rock or boulders. Crop responses to modified one-way ploughing have been similar or better than other soil inversion tools, with an average of 900kg/ha yield increase (Table 4), although this is only for four comparisons over the past two seasons to date.

Figure 6. A modified one-way disc plough being used to invert water repellent sandy gravel (left image) and the soil inversion achieved using a modified one-way plough on repellent pale yellow deep sand (right image) near Badgingarra WA, 2015.

Table 3. Summary of deep tillage methods, suitable soil types and typical wheat yield responses based on WA research.

| Deep tillage implement | Working depth (cm) | Estimated cost ($/ha) | Mechanism | Suitable soil types | Typical wheat yield response (t/ha) | Longevity of benefit (years) | Main constraints addressed | |

|---|---|---|---|---|---|---|---|---|

| Year 1 | Year 2 | |||||||

| Standard ripping | 30-40 | $50-60 | Deep working tines break out hard pans, minimal soil mixing. | Deep sands, loamy sands and deep sandy duplex | 0.2-0.5 | 0.1-0.3 | 3+ (> with CTF) | Compaction |

| Very deep ripping | 50-70 | $80-90 | 0.6* | ? | 3? | Compaction | ||

| Very deep ripping with topsoil slotting | 30-70 | $90-100 | Openers behind ripper tines allow topsoil to fall into the profile. | 1.0* | ? | 5+ | Compaction, subsoil acidity, deep nutrition | |

| Rotary spader | 30-35 | $150-200 | Rotating spades bury about 70% of the topsoil and lift seams of subsoil to the surface. |

Deep sands, loamy sands and deep sandy duplex |

0.6 | 0.3 | 5-7 | Subsoil acidity, water repellence, deep nutrition, compaction, resistant weeds |

| Offset disc plough (deep working) | 35-45 | $50-60 | Large scalloped offset discs mix soil to working depth. Deep ripping prior to offsets can increase working depth and mixing efficacy. |

Deep sands, loamy sands, deep sandy duplex, sandy gravels |

0.5* | ? | ? | |

| Mouldboard plough | 35-40 | $100-150/ha | Skimmers and plough boards invert soil into furrows – very effective burial of topsoil. |

Deep sands, loamy sands, deep sandy duplex, sandy gravels, loamy gravels |

0.5 | 0.4 |

5-10+ | Water repellence, resistant weeds, deep nutrition, compaction, subsoil acidity |

| Square plough | 30-40 | $80-100/ha | Plough boards invert soil into furrows. |

|||||

| Modified one-way disc plough | 35-40 | $60-80/ha | Every second disc removed and large (28in plus) discs fitted. Inverts the soil, typically on an angle from the surface. |

0.9* | ? | 5+10? | ||

*Based on very limited data sets.

Potential problems and issues with strategic deep soil mixing and inversion include an acute short-term wind erosion risk until a cover-crop is re-established on the site, destruction of the continuity of existing biopores and root channels, re-compaction and deep wheel ruts, surface crusting (depending on clay content of subsoil), seeding too deep, and increased risk of pre-emergent herbicide damage. On soils with low fertility the benefits of strategic deep tillage can be short lived.

Long-term benefits from ameliorating multiple constraints

Soil amelioration is slow and costly, so it is necessary to have long-term benefits to achieve a good return on the investment. One of the longest continuous running replicated plot experiments was established in 2007 on deep yellow sandy earth, in a cropping paddock near Mingenew, WA. The site had subsoil acidity, mild water repellence and a large weed burden consisting mainly of wild radish and ryegrass. One-off soil inversion was achieved using a 3-furrow Kvernerland mouldboard plough (MBP) inverting at a depth of 25 to 30cm. High quality limesand was applied to selected treatments at a rate of 2t/ha. Treatments applied in 2007 included mouldboard ploughing or liming on their own or in combination. The site was sown to a cover crop of barley in 2007. In 2008 the site was sown to canola using a coneseeder. From 2009 to 2014 the site has been sown across using the grower’s seeder. In 2007, the first season, the Stirling barley cover crop was sown late, 28 July, so yields were low with the untreated control yielding 680kg/ha. Despite the low yields mouldboard ploughing had 20% higher yield at 807kg/ha. In 2008 canola was sown across the site using a coneseeder but sinkage on the mouldboard plots substantially reduced establishment and yields were slightly reduced. Since then there have been substantial yield responses in each of the cereal years with yield increases due to ploughing ranging from 300-600kg/ha (Table 4).

In 2014 ryegrass biomass was measured in each treatment, as visual differences in ryegrass density across the treatments were evident. Ryegrass shoot biomass was highest in the untreated control at just over 500kg/ha (data not shown). Mouldboard ploughing on its own had 36% lower ryegrass biomass but the impact of surface liming was even greater with a 54% reduction in ryegrass biomass. The combination of mouldboard ploughing with lime further reduced ryegrass biomass by up to 75% (data not shown). In 2015 a substantial but small lupin yield response was measured, the first time a yield response for the break crop had been measured. In 2016, the 10th season after the treatments were applied the combination of mouldboard ploughing and liming increased wheat yield by 400kg/ha (Table 4).

Table 4. Crop type, growing season rainfall (GSR), yield changes and additional income benefits for 2007 to 2015 seasons following soil amelioration with a combination of mouldboard ploughing (MBP) and lime applied once only in 2007. (n.m. = not measured).

| Year | GSR (mm) Apr-Oct | Crop type | Crop price $/t | MBP yield response t/ha over NIL | Lime t/ha over MBP | MBP $/ha Benefit | Lime $/ha Benefit |

|---|---|---|---|---|---|---|---|

| 2007 | 233 | Barley | 220 | 0.1 | 0 | 22 | 0 |

| 2008 | 313 | Canola | 625 | -0.1 | 0 | -63 | 0 |

| 2009 | 384 | Wheat | 250 | 0.6 | 0 | 150 | 0 |

| 2010 | 257 | Lupin | 200 | 0 | n.m. | 0 | n.m. |

| 2011 | 361 | Wheat | 310 | 0.4 | n.m. | 124 | n.m. |

| 2012 | 313 | Lupin | 250 | -0.1 | n.m. | -25 | n.m. |

| 2013 | 350 | Wheat | 330 | 0.3 | 0.2 | 99 | 66 |

| 2014 | 226 | Barley | 260 | 0.4 | 0.6 | 104 | 156 |

| 2015 | 216 | Lupin | 330 | 0.1 | 0.1 | 33 | 33 |

| 2016 | 436 | Wheat | 230 | 0.1 | 0.3 | 28 | 58 |

| Total $ returns | 472 | 313 |

Additional income benefits from the treatments have been determined over the course of the experiment using September grain prices for each growing season (Table 4). This has not taken into account the cost of the amelioration treatments which is estimated at $150/ha for mouldboard ploughing and $50/ha for application of lime at 2t/ha. Returns over the nine seasons of the experiment have more than covered these costs with returns from liming providing an additional $313/ha over the past four seasons (Table 4). Overall the combined additional income generated from the combination of both soil inversion and liming has been $785/ha over the course of the experiment. Soil amelioration that addresses multiple constraints is more likely to have long term productivity and agronomic benefits. In many soil amelioration experiments the yield responses over the first two seasons have covered the cost of the amelioration treatments, with any subsequent yield gains being additional profit.

Conclusion

Soil amelioration using strategic deep tillage or claying is costly and slow to implement which means it can typically only be implemented over relatively small areas in a given year. Given this, it is often important that cheap short-term mitigation options (Davies et al. 2012; Roper et al. 2015) are also implemented over large areas in combination with soil amelioration, as this can often give substantial whole-farm returns (Blackwell et. al. 2014). In WA, soil amelioration has resulted in the biggest benefits when it has been used strategically to help overcome a suite of soil and agronomic constraints, compounding the benefits associated with the investment. Evidence is building that the benefits of soil amelioration can be long-lasting with deep tillage approaches showing benefits for five or more years and be highly profitable. The new approach of incorporating topsoil seams behind deep ripping tines appears to be a particularly good option for deeper sandplain soils (Blackwell et. al. 2016), provided they are not severely repellent or have other constraints which may require deep topsoil burial or mixing. Ongoing research will determine the long-term benefits of this approach.

Useful resources

AGRIC Soil constraints: water repellence

AGRIC Soil constraints: soil compaction

AGRIC Soil constraints: soil acidity

GRDC: Non-wetting soils

References

Blackwell P, Hagan J, Davies S, Bakker D, Hall D, Roper M, Ward P and Mathews A (2014) Smart no-till furrow sowing to optimise whole-farm profit on non-wetting soil. WA Agribusiness Crop Update, 24-25 February 2014, Perth WA, DAFWA and GRDC.

Blackwell P, Isbister B, Riethmuller G, Barrett-Lennard E, Hall D, Lemon J, Hagan J, Ward P (2016) Deeper ripping and topsoil slotting to overcome subsoil compaction and other constraints more economically: way to go! 2016 GRDC Grains Research Updates, 29-30 February, Perth WA.

Crabtree W (1989) Cereal grain yield responses to deep ripping on duplex soils. Australian Journal of Experimental Agriculture 29: 691-694.

Davies SL, Gazey C, Gilkes RJ, Evans DJ, Liaghati T (2006) What lies beneath? – understanding constraints to productivity below the soil surface. 2006 Regional Crop Updates, Geraldton, Department of Agriculture and Food, Western Australia.

Davies S, Blackwell P, Bakker D, Scanlan C, Roper M, Ward P (2012) Developing and assessing agronomic strategies for water repellent soils. WA Agribusiness Crop Updates, 28-29 February 2012, Perth, W, DAFWA and GRDC.

Delroy and Bowden W (1986) Effect of deep ripping, the previous crop, and applied nitrogen on the growth and yield of a wheat crop. Australian Journal of Experimental Agriculture 26: 469-479.

Ehlers W, Kopke U, Hesse F and Bohm W (1983) Penetration resistance and root growth of oats in tilled and untilled loess soil. Soil and Tillage Research 3: 261-275.

Farre I, Bowden W, Davies S (2008) To rip or not to rip. When does it pay? WA Agribusiness Crop Updates, 13-14 February 2008, Perth, WA, DAFWA and GRDC.

Hamblin A, Tennant D and Cochrane H (1982) Tillage and the growth of a wheat crop in a loamy sand. Australian Journal of Agricultural Research 33: 887-897.

Hamblin A, Richards Q and Blake J (1988) Crop growth across a toposequence controlled by depth of sand over clay. Australian Journal of Soils Research 26: 623-635.

Jarvis RJ (2000) Deep tillage. In ‘The Wheat Book: Principles and Practice’. Eds. WK Anderson and JR Garlinge. pp. 185-187. Agriculture Western Australia, Bulletin 4443.

Paterson C, Sheppard W (2008) Soil compaction trials 2006-2008. In 'Eyre Peninsula Farming Systems 2008 Summary'. Eds. N Scholz, A Cook, A Frischke, N Wilehlelm, M Bennet, C Paterson, D Brace and L Guerin. pp. 159-162. (South Australian Research and Development Institute: Minnipa)

Roper MM, Davies SL, Blackwell PS, Hall DJM, Bakker DM, Jongepier R, Ward PR (2015) Management options for water repellent soils in Australian dryland agriculture. Soils Research 53: 786-806.

Schmidt C, Belford R and Tennant D (1994) Effect of different direct drilling and conventional sowing techniques on soil strength, root growth and grain yield of wheat on sandplain soils in Western Australia. Australian Journal of Agricultural Research 45: 547-564.

Tennant D (1976) Wheat root penetration and total available water on a range of soil types. Australian Journal of Experimental Agriculture and Animal Husbandry 16: 570-577.

Acknowledgements

This research is a collaborative project between the GRDC and the DAFWA through the following GRDC ‘Soil Constraints West’ projects: DAW00244 – Water repellence; DAW00243 – Soil compaction; DAW00242 – Subsoil constraints; DAW00236 – Soil acidity. The research undertaken as part of this project is made possible by the significant contributions of growers through both trial cooperation and the support of the GRDC, the author would like to thank them for their continued support.

The authors would also like to acknowledge the support of all the growers, grower groups, agricultural industry, agronomists and consultants who have supported this research.

Contact details

Stephen Davies

Department of Agriculture and Food, Western Australia

08 9956 8515; 0408 439 497

stephen.davies@agric.wa.gov.au

GRDC Project Code: DAW00244; DAW00243; DAW00242; DAW00236,

Was this page helpful?

YOUR FEEDBACK