The impact of harvest management in chickpeas

Author: Richard Daniel, Linda Bailey, Denielle Kilby, Branko Duric, Richard Black and Lawrie Price (Northern Grower Alliance) | Date: 26 Feb 2019

Take home messages

- Across 9 trials, there was no impact on yield or grain quality from any registered harvest management option, when applied ~2 weeks prior to anticipated harvest

- All treatments increased leaf discolouration and leaf drop, however the clearest differences were observed in impact on stem dry down

- The most effective treatments for stem dry down were the mixture of Weedmaster® ARGO® + Ally® or the mixture of Gramoxone® 250 + Sharpen WG®

- Decisions on harvest management choice should be determined by cost, attitude to Ally plant back restrictions, weed spectrum present at harvest and speed of desiccation required

- There was no indication that any harvest management treatment increased the level of screenings when assessed with the slotted screen size used for defective grain assessment. However, when crop harvest was delayed by ~14 days, grain moisture was significantly reduced and screenings were increased, even in the untreated plots

- Application of Reglone® or Gramoxone 250 at less mature crop stages (~3 weeks prior to anticipated harvest) resulted in a significant reduction in both yield (~10%) and test weight (2-3kg/hL)

- Large levels of grain losses were measured at the header front in small plot trials (~200 kg/ha) with no indication of any shattering or pod drop prior to harvest

- Large levels of grain losses were also measured at the header front in a commercial case study (~160 kg/ha). These losses were primarily intact pods and losses were reduced by ~50% when harvested with the air front turned on

- Further research into improving harvest management of chickpeas appears warranted.

Background

In recent years, chickpeas have transitioned from being generally considered a rotation option between cereal crops to becoming a ‘pillar’ crop of the northern farming system. Historically, harvest management has fitted around the cereal harvest rather than being specifically driven by maximising the chickpea return. An improved understanding of the impacts of harvest management may enable improved financial returns or avoid significant losses.

NGA are currently involved in two aspects of harvest management evaluation; trials conducted during 2017 and 2018 to help improve the understanding and impact of current crop desiccation tools and in 2018, initial activity to evaluate the impact of desiccation timing and delayed harvest on crop yield, quality and harvest losses.

Chickpea desiccation evaluation 2017

An evaluation of desiccation options was conducted at five sites. Application at each site was when crops were estimated (by the grower or agronomist) to be ~2 weeks prior to harvest. Table 1 shows key details from these trials. NB harvest was delayed at some sites during to rain events after desiccation.

Table 1. Product evaluation trials 2017

Location | Variety | Date of application | Harvest date | Days before harvest |

|---|---|---|---|---|

Warra | PBA Seamer | 10/10/2017 | 14/11/2017 | 35 |

Pittsworth | PBA Seamer | 20/10/2017 | 10/11/2017 | 21 |

Pallamallawa | PBA HatTrick | 18/10/2017 | 1/11/2017 | 14 |

Bellata | PBA Seamer | 3/11/2017 | 16/11/2017 | 13 |

Mullaley | PBA Seamer | 3/11/2017 | 27/11/2017 | 24 |

Chickpea Desiccation evaluation 2018

A second season of product evaluation was conducted in 2018. Application timing was planned for a crop stage with ~85-90% of pods mature. Table 2 shows key details from these trials.

Table 2. Product evaluation trials 2018

Location | Variety | Date of application | Crop stage at application | Harvest date | Days before harvest |

|---|---|---|---|---|---|

Warra | PBA Seamer | 2/11/2018 | 85% pods mature | 16/11/2018 | 14 |

Mt Tyson | PBA HatTrick | 30/11/2018 | 91% pods mature | 11/12/2018 | 11 |

Tulloona 1 | PBA HatTrick | 26/10/2018 | 82% pods mature | 12/11/2018 | 17 |

Tulloona 2 | PBA Seamer | 23/10/2018 | 92% pods mature | 7/11/2018 | 15 |

Trial Results 2017

All treatments improved % leaf discolouration and leaf drop compared to the untreated but generally with only minor differences between treatments.

A ‘twist test’ assessment was conducted to evaluate stem dry down. This assessment was designed in an attempt to provide an objective ‘harvest readiness’ measure. Tested 10 plants/plot. Each plant was evaluated separately using a double twist motion. Data was recorded as the % of plants where stems snapped following the twist test.

Yield, grain moisture and protein were assessed at all sites. Test weight and screenings were evaluated at 3 sites. Screenings were assessed using a 4 mm slotted screen as an indication of % defective grain.

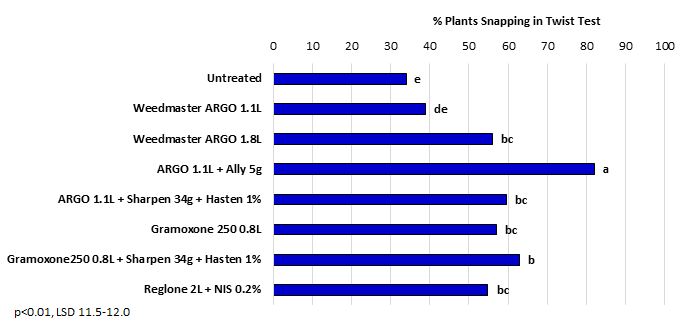

Figure 1 shows the combined analysis from all sites for the twist tests conducted 10-17 days after application.

Figure 1. Stem twist test results 10-17 days after application, as an indication of stem dry down. (Mean of 5 trials 2017)

NIS = non-ionic surfactant

Trial results 2018

Assessment of leaf discolouration showed similar patterns to 2017, however the magnitude of difference between treatments and the Untreated was reduced. No treatment provided any significant improvement in leaf drop compared to the Untreated. A twist test assessment was again conducted. All trials were harvested with yield and grain quality assessed at all sites.

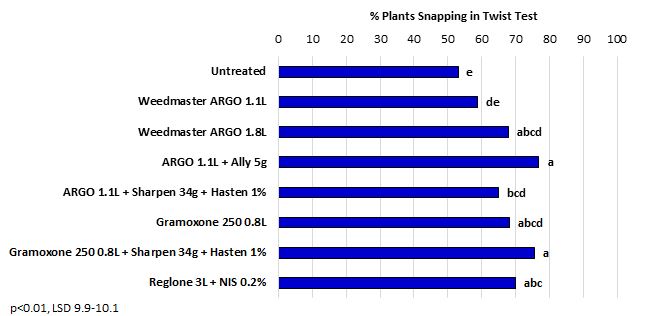

Figure 2 shows the combined analysis from all sites for the twist tests conducted at 7-15 days after application.

Figure 2. Stem twist test results 7-15 days after application, as indication of stem dry down. (Mean of 4 trials 2018)

NIS = non-ionic surfactant

Key Points 2017 and 2018

Leaf discolouration and drop

- All treatments increased % leaf discolouration and % leaf drop but without consistent differences between treatments

- Improvements in % leaf discolouration and % leaf drop compared to the Untreated were greater in 2017, where high levels of October rainfall encouraged crop regrowth.

Stem dry down

- Similar patterns of performance were seen in both seasons, however the differences between treatments were reduced in 2018

- The most effective options for stem dry down were either the mixture of Weedmaster ARGO + Ally or the mixture of Gramoxone 250 + Sharpen

- There was a dose response to glyphosate with increased stem snapping from the 1.8 L/ha rate

- There was no consistent difference between Weedmaster ARGO 1.8L, Gramoxone 250 or Reglone alone, or the mixtures of Sharpen with either Weedmaster ARGO or Gramoxone 250

Yield and grain quality

- There was no significant difference in yield recorded in any of the 9 trials

- There was no significant difference in test weight or % screenings in any of the 9 trials.

- Similar patterns were observed for grain % protein

- There was no significant difference in grain moisture in 8 of the 9 trials. Grain moisture was ~8-10% in Untreated grain in these trials

- However all harvest management treatments reduced grain moisture by ~1% in a 2017 trial where regrowth had been evident and the Untreated grain was ~13% moisture. There was no difference between harvest management treatments in this trial.

Overall

- Harvest management treatments increased both chickpea leaf and stem desiccation but had no impact on crop yield or grain quality. (It should be noted that the use of desiccants is not recommended when the grain is destined for use as seed, as germination % can be affected.)

Desiccation and harvest timing evaluation 2018

Field observations in 2017, suggested significant chickpea yield losses can occur when harvest of ripe crops is delayed. (This was supported by observations from QDPI agronomist Mike Lucy in the early 2000’s). A series of split plot trials were designed to evaluate a combination of desiccant product and application timing combined with harvest timing.

Trials were conducted in commercial crops with desiccation targeted to commence when the crop was ~3 weeks prior to harvest with separate applications at both 2 and 1 week prior to expected harvest. The same treatments were applied with harvest delayed by ~2 weeks. The first application was designed to evaluate the impact from an application where crop maturity was considered ‘immature’. (NB: at Tulloona 2 the first application was delayed and was only ~2 weeks prior to commercial harvest. It was hoped the second timing would be close to current commercial recommendations with a final ‘conservative’ timing.)

Pod maturity was assessed at each application on 10 main branches per plot. Pods were considered mature when a ‘yellow beak’ was starting to extend on the enclosed grains. This stage often corresponded with a purplish tinge appearing on the pod coat. Table 3 shows the key trial details.

Table 3. Desiccation and harvest timing impact 2018

Location | Variety | Dates of application | Crop stages at application | Harvest dates | Days before harvest |

|---|---|---|---|---|---|

Warra | PBA Seamer | 19/10/2018 2/11/2018 9/11/2018 | 52% pods mature 85% pods mature 90% pods mature |

| 28/14/7 42/28/21 |

Tulloona 1 | PBA Seamer | 16/10/2018 26/10/2018 5/11/2018 | 58% pods mature 83% pods mature 88% pods mature |

| 29/17/7 44/33/22 |

Tulloona 2 | PBA HatTrick | 18/10/2018 23/10/2018 30/10/2018 | 82% pods mature 91% pods mature 100% pods mature |

| 20/15/8 33/28/21 |

NB: the Tulloona 2 site was a late replacement and was only ~ 2 weeks prior to harvest at the first application timing. Tulloona 1 and 2 used different varieties than assessed in the product evaluation project.

Trial results

Assessment of leaf discolouration and leaf drop were conducted, however the main focus was impact on yield from varied desiccant application timings and the impact from harvest delay. Consistent small plot header settings were attempted but environmental and other conditions varied between harvest dates.

Application timing

- Desiccant applications ~prior to the industry standard recommendation of <15% green pods present in chickpeas with Gramoxone 250 or Reglone significantly reduced test weight (by ~2-3 kg/hL) and grain yield by ~10% (~120 kg/ha)

- However, there was no impact on % protein, % moisture or % screening from any product

Harvest timing

- Inconsistent results were observed on the impact of harvest timing on yield:

- A significant reduction in yield was measured at Tulloona 1 (by 28% or ~300 kg/ha) when harvest was delayed by 15 days

- No difference at Tulloona 2

- A significant increase was measured at Warra (by 13% or ~130 kg/ha) when harvest was delayed by 14 days. NB High levels of harvest losses occurred at this site, particularly from the first harvest.

- Grain moisture was significantly lower at the delayed harvest timing when analysed over all trials

- There was a significant increase in % screenings (increased from 7 to 11%) at the delayed harvest timing in all individual trials, with no significant product impact.

Harvest losses

An assessment of harvest loss was conducted at all sites. Pre-inspection showed there was no shattering loss of grain or pod drop prior to either harvest. Individual grain, pods and splits were counted together with the number of grain/pod and grain weight.

Two types of harvest loss were assessed. ‘header front’ losses were pods or grain that did NOT physically get into the header for processing and were found where the crop had been harvested but before any losses from the back of the header.

Losses were also assessed directly behind the header. These losses were the combination of any header front loss plus the ‘header processing’ loss. The difference between the two was the amount of grain that was lost over the sieves. This loss is largely determined by the header set-up.

Small plot headers were used in all trials. Increased header processing losses are likely compared to commercial headers, however header front losses would generally be considered low due to operation speed and the ability to harvest at very low heights.

- There was no evidence of any pod drop or shattering loss prior to either harvest timing

- Header front losses (grain or pods ‘lost’ at the front of the header) averaged ~100 grains/m2 (~200 kg/ha)

- In these 3 trials, the header front losses represented an extra ~15-20% of harvested yield

Commercial harvest loss evaluation 2018

Commercial observations and comments indicated that high levels of header front loss of grain and pods were also being experienced, particularly in crops with reduced height or yield potential. Commercial scale data was generated at one site where an air front was in operation on a crop of PBA Seamer.

Replicated areas were assessed where the only difference was whether the air front was operating or turned off. Individual grain, pods and splits were counted together with the number of grain/pod and grain weight. Harvest monitor estimates indicated the yield ranged from ~0.5 to 1.0 t/ha.

- When the air front was turned OFF, header front losses were ~160 kg/ha (~$135/ha). This was the equivalent of ~15-30% of the harvested yield

- When the air front was turned OFF, ~90% of the header front losses were intact pods (~145 kg/ha)

- When the air front was turned ON, the header front losses were reduced by ~80-90 kg/ha (saving ~$70-75/ha)

- Header front losses were ~85% of the total grain losses i.e.: the header processing losses were ~25 kg/ha

Conclusions

The comparison of registered harvest management options in chickpeas has shown no impact from any option on crop yield or grain quality when products are applied at currently recommended crop maturity stages.

However, application on less mature crops, particularly with desiccants such as diquat or paraquat, are likely to reduce yield with grain test weight also impacted in these trials. There was however no indication that desiccation treatments were having an impact on screening levels.

The clearest difference in product performance was observed in the stem dry down ‘twist test’ where the addition of Ally to glyphosate or Sharpen to paraquat resulted in the largest % of plants with dry stems. These treatments may provide a benefit in situations where stem dry down is of concern and likely to cause harvest difficulties.

The level of header front grain losses is of concern and warrants more detailed evaluation than conducted in this initial activity. Although these losses may have been more evident in 2018 due to lower yielding and possibly poorer feeding crops, a better understanding of header management appears warranted. In the commercial case study, a benefit of $70-75/ha was achieved by the use of an air front.

Acknowledgements

The research undertaken as part of this project is made possible by the significant contributions of growers through both trial cooperation and the support of the GRDC, the author would like to thank them for their continued support.

NGA would particularly like to acknowledge the assistance from a large number of trial co-operators during this series of trials: Wade Bidstrup, Graham Butler, Jack Williamson, Sam Chaffey, Glen Kendall, Mark Cotter, Drew Penberthy and Ross Durham.

Contact details

Richard Daniel

Northern Grower Alliance

Ph: 07 4639 5344

Email: richard.daniel@nga.org.au

Varieties displaying this symbol beside them are protected under the Plant Breeders Rights Act 1994

® Registered Trademark

GRDC code: NGA00004 - GRDC Grower Solutions for northern NSW and southern Qld

GRDC Project Code: NGA00004,

Was this page helpful?

YOUR FEEDBACK