Stubble initiative

Author: Claire Browne and Alison Frischke (BCG) | Date: 15 Mar 2019

Take home messages

- Be flexible in your approach to managing stubble and start stubble management early enough (i.e. at harvest time) so that it does not impact on sowing of subsequent crop.

- Know the limitations of your seeder.

- Don’t let stubble compromise the big things i.e. weeds, diseases, pests and timeliness.

- Diversify your cropping rotation.

- Stubble is not a good source of N for crops.

Background

The ’Stubble Initiative’ was a five-year program of research (2014-2018) initiated by GRDC following a comprehensive gap analysis (Scott et al. 2013) which aimed to provide management guidelines for profitable farming with retained stubble. Farming systems groups (Birchip Cropping Group (BCG), Central West Farming Systems (CWFS), Eyre Peninsula Agricultural Research Foundation (EPARF), FarmLink Research, Hart Field Site group, Irrigated Cropping Council (ICC), Southern Farming Systems (SFS), Lower Eyre Agricultural Development Association (LEADA), MacKillop Farm Management Group (MFMG), Mallee Sustainable Farming (MSF), Riverine Plains, Upper North Farming Systems (UNFS), Yorke Peninsula Alkaline Soils Group (YPASG), Vic No Till Farmers Association Inc (VNTFA), Mid North High Rainfall Zone Group (MNHRZ) and Yeruga Crop Research) worked on locally relevant issues and contributed to co-ordinated research (CSIRO) and extension (SARDI) to develop regional guidelines to maintain profit in stubble retained systems. These guidelines and a range of other detailed extension material have been produced and communicated throughout the ‘Stubble Initiative’ (see reading and reference list for links).

‘How much is too much stubble to handle?’

When do you need to reduce or remove stubble from the paddock to avoid affecting crop production and profitability?

Ideally you want to leave enough stubble after harvest and during the summer fallow to benefit from:

- Groundcover protection from wind and water erosion.

- Better soil moisture retention to help with timely sowing.

- Maintained or improved nutrient retention.

- Same or better soil structure by increasing soil microbial activity.

- Stubble and residual grain for a livestock feed source.

Begin decisions regarding stubble load management before harvest (BCG, 2016a), allowing time to get the header organised and to use the harvesting process to produce stubble with desired characteristics for the following season. Continual monitoring of the stubble over the summer fallow period (BCG, 2016b) is required to determine if the stubble has the same characteristics required prior to seeding as those determined at harvest, due to changes such as rotations, summer rainfall, grazing intensity or weed spectrum.

Harvest (and the harvesting process) is the best time to consider the type of stubble you require and to estimate how much stubble you will have to handle at seeding the following season. Break crops are less likely to cause sowing issues in the Wimmera and Mallee. Canola crops have stems that generally remain upright and crops can generally be sown between them. Legume stubbles break down faster than cereal stubbles because they have a lower carbon (C): nitrogen (N) ratio so generally don’t pose a risk to sowing. For example, lupins have a C:N ratio of 65:1 whereas cereal is 200:1.

Reducing the stubble load however, must be considered if it compromises the crop production and profitability drivers including:

- Poor herbicide efficacy on pre-emergent crop weeds.

- Trash clearance and blockages at sowing – affecting sowing timeliness.

- Poor crop establishment – uneven seeding depth, sowing gaps due to blockages, etc.

As well as potential risks to crop growing conditions:

- Early season N tie-up.

- Stubble borne disease carry-over.

- Habitat for pests such as mice, snails and slugs.

- Increased risk of frost occurring on frost prone areas

Estimation of stubble load

Before harvest, cut 0.5m of crop row to ground level, at five sample points (totaling 2.5m). Cut the heads off, then dry and weigh the samples.

To calculate stubble biomass, use: total weight of dry samples (g)/2.5m x row width (m) = g/m2

Every 100g/m2 equals 1t/ha of dry stubble and crop residue.

After harvest, when straw has been cut and spread, place a quadrat whose sides are the width of the sowing row, centrally over a row, and collect the residue inside at five sample points. Dry and weigh the samples.

To calculate stubble biomass, use: total weight of dry samples (g)/5 x sowing row width (m) x sowing row width (m) = g/m2

Again, every 100g/m2 equals 1t/ha of dry stubble and crop residue.

Estimation of stubble ground cover

It’s recommended that a minimum of 50% (Mallee) (MSF, 2013) to 70% (Wimmera and other areas) ground cover (about 1.0 - 1.5t dry matter/ha) remains on paddocks to prevent wind erosion.

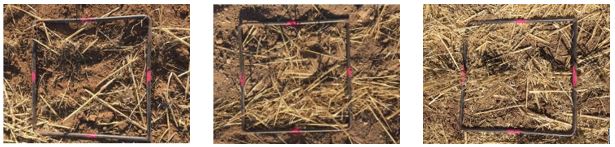

GRDC supported Grain & Graze 3 monitored the ground cover of stubble over summer. Figure 1 shows ground cover for wheat stubble at Birchip (BCG, 2017a).

Figure 1a. 20% ground cover (0.4 t/ha) 1b. 50% ground cover (1 t/ha) 1c. 70% ground cover (1.5 t/ha).

There are also good reference photos of standing, rolled, chained or cultivated stubble for estimating percentage ground cover in Know your Ground Cover – A Guide for Mallee Farmers (MSF, 2013).

The threshold where machinery can start to have trouble handling stubble varies considerably but occurs most commonly from 3 to 4t/ha (GRDC Factsheet, 2011). For some older tined machinery in wet conditions it can be as low as 2.2 t/ha while more modern set-ups and disc seeders can sow into heavy stubbles as of 9t/ha or more (CSU Factsheet, 2011). To establish and successfully grow a crop in these high stubble loads requires strategic planning and will be strongly influenced by seasonal conditions, for example the issues caused by hair-pinning of stubbles in wet conditions.

Many Victorian farmers will graze stubbles soon after harvest to utilise any residual grain. Monitoring of stubbles during grazing to determine when stock should be removed based on groundcover, residual grain and green pick, and stubble orientation (standing vs. lying) is strongly advised.

Once stock are removed, decide whether further stubble reduction is needed. There are occasions when burning will be the most economical solution for trash, weed and disease management. If possible, burning should be avoided due to the loss of groundcover, erosion and moisture conservation reasons, but also public views about air contamination and soil heath. Mulch (slash and leave on surface) or light incorporation of stubble (shallow tillage to increase soil-stubble contact) soon after harvest, achieve the same benefits and avoid the pre-sowing rush to burn once the fire restrictions are lifted. Further discussion about baling, mulching or, as a last resort, burning stubbles safely, can be found on the BCG website (BCG, 2017b).

Stubble management at harvest, sowing and crop establishment

Changing crop harvesting methods

Understanding the financial impact of retaining stubble is necessary across the whole farm; not only the potential benefits to crop and livestock production, but also any costs that may be incurred from managing the retained stubble system. One example is to consider the return on investment (ROI) of using a stripper front to maximise cereal stubble retention (plucks heads only) and potentially save on costs from faster harvest speed and reduced risk of weather losses, compared with a draper front which cuts stubble lower and needs to process more residue through the header before spreading. Initial indications show that wheat and barley can be harvested successfully using a stripper front but harvesting break crops such as faba beans and lentils is still being investigated.

A Machinery Economics Calculator (BCG) has been developed as part of the GRDC supported ‘Stubble Initiative’ project. Using key drivers for profit produced by investments in different harvest methods, the calculator helps quantify changes to the profit drivers, and determines the real ROI of the intended purchase.

Example

An economic whole-farm case study based on paddock demonstrations across the 2015 and 2016 seasons indicated that the perception of fuel saving and labour saving benefits using a stripper front may be overstated in the Victorian Mallee (Craig and Thamm, 2017). Greater savings on fuel and labour by the stripper front were realised with barley compared with wheat (barley has a higher harvest index). However, the greatest benefit was in higher yielding seasons – which suggests that for the Mallee environment, the ROI for a stripper front will be less compared to a higher yielding environment. The stripper front completed harvest in a shorter time period (two to three days), however again for the Mallee, it was demonstrated that the risk of adverse weather causing sprouting or quality downgrades was unlikely to change with faster harvesting. Several groups in the GRDC ‘Stubble Initiative’ project also found that wheat crops sown into taller stubble (i.e. stubble left following harvest with a stripper front, 45cm compared with 15cm) received less sunlight and were exposed to cooler temperatures, which can reduce early growth and reduce tiller numbers. However, this effect didn’t always result in lower grain yield.

Improving trash clearance and crop establishment

Retention of high stubble loads can cause clumping and machinery blockages at sowing. Stubble can be a physical barrier, reduce soil temperatures, block light and cause uneven seed placement and establishment or sowing gaps. About 1.0 - 1.5t/ha of stubble is needed to prevent wind erosion, and 2.5t/ha of stubble to help soil moisture retention, so some stubble from higher yielding crops can be removed to help sowing conditions, trash flow and subsequent crop establishment and vigour.

A Yeruga Crop Research project (GRDC project: YCR00003) is developing an App to assist growers and consultants to estimate the benefit or cost for different stubble management decisions (Swan et al. 2017). The App will estimate the effect on profit by comparing the cost of stubble treatment operation and value of nutrient loss for practices such as baling, slashing, rolling, using a stripper front, narrow windrow burning or burning a crop to reduce stubble.

Example

To harvest a 2t/ha grain crop that had 3t/ha stubble residue, the total cost of harvesting is $29.76/ha and if 70% of the stubble was burnt, nutrient loss (N, phosphorus (P), potassium (K) and sulphur (S)) would cost $12.65 in N, $1.62 in P, $2.69 in S and $4.17 in K, a total of $21.13/ha. From this calculation, the total harvest and stubble management cost would be $50.89/ha. If the stubble was narrow windrow burned; nutrient removal costs would reduce to $9.05/ha, so total costs would reduce to $38.82/ha. If the stubble was slashed instead, costing $9.50/ha, there would be no nutrient loss, and total costs would be $39.26/ha.

Note: For full stubble retention in exceptional years or irrigated crops, additional costs may be incurred if machinery upgrades are necessary to handle higher stubble loads.

Options to improve trash clearance and crop establishment include:

Tined seeders

- Cut stubble lower (10-15cm) with uniformly spread residue - straw length should be less than half the sowing row spacing; or kept to 65% of the effective tine clearance (the clearance between the ground and the first major obstruction along the shank under the tool bar).

- Slow down and inter-row sow into dry stubble conditions.

- Shank design is best straight, has a round cross sections and is vertical or leaning slightly backwards. Residue guards (round tubes) added to the shank can improve residue flow.

- Tine layout should be spread over 3-4 ranks (at least 50cm apart) to maximise distance between tines and subsequent trash flow (ICARDA Factsheet, 2013).

- Distance between tines should be 1.3-1.5 times residue length (55-60cm) for up to 3.5-4.5t/ha wheat stubbles cut at 35-40cm high, and may require 1.8-2 times residue length for taller, heavier stubble.

- If stubble is cut higher, it will need reducing during the fallow period by either grazing, mulching or incorporating, baling, or as a last resort, burning (BCG, 2017b).

- Coulters can be used to cut straw before the sowing tine pass.

Disc seeders

- Disc seeders can handle taller, larger stubble load (less residue on ground) with uniformly spread residue and have better cutting capacity using a sharp disc opener operating in dry stubble and firm ground.

- Inter-row sowing with precision guidance (2cm) and wider row spacing (30cm) is preferred.

- Avoid hair pinning by disc seeders when soils are wet and stubbles are soft, which pushes stubble into the furrow, causing poor seed-soil contact and furrow closure, and sometimes herbicide damage (herbicide on stubble touches the seed).

- Residue managers clear residue from the path of the disc-seeder.

- Many pre-emergent chemicals are not recommended for use with disc seeders. Chemicals that can be incorporated by sowing (IBS) are preferred rather than post sowing pre-emergence (PSPE) chemicals.

- Grazing stubbles or post-harvest cultivation will reduce residue but may affect the ability to inter-row sow depending on the resultant residue characteristics.

Crop rotation

Using crop type in rotations is one way of managing the effects of stubble and successful emergence of different seed sizes. Different crop types provide a less antagonistic stubble to sow into, reducing disease, pest and weed constraints. Break crops are less likely to cause physical sowing issues in the Wimmera and Mallee: canola crops have stems that generally remain upright that can be sown between, while legume stubbles break down faster than cereal stubbles and leave little residue. Planting a larger seeded legume crop after a cereal, followed by a canola crop into the legume stubble is one way to manage seed size and establishment.

Stubbles and herbicide efficacy

There’s no set stubble height or cover amount for herbicide efficacy as it is influenced by stubble load, summer rainfall to decompose stubble, and rain after herbicide application. However, lowering stubble height and loads will assist penetration, as well as chemical application choices.

Options to improve herbicide efficacy include:

- Manage stubbles

- Cut stubbles low (10-15cm) at harvest (http://www.farmlink.com.au/project/maintaining-profitable-farming-systems-with-retained-stubble). Spread evenly for tined seeders.

- Cut hay and silage crops before weed seed set. This has been shown to be most effective in BCG trials to reduce ryegrass seedbank (BCG, 2017b)

- Burn narrow windrows (50-80cm wide) at high temperatures in early autumn (http://www.farmlink.com.au/project/maintaining-profitable-farming-systems-with-retained-stubble). Effectiveness is dependent on the right conditions - to destroy a ryegrass seed the biomass must sustain a burn of 400°C for 20 seconds.

- Use chaff carts (burn residues) or harvest weed seed destruction to manage weed seeds. However weeds must be high enough to enter the header cutter bar, not lower or lodged or it will be less effective (BCG, 2016c).

- If grass weeds are an issue, reduce ground cover to less than 50% (BCG, 2015).

- Use rotations and kill weeds in-season prior to seed set.

- Use burning as a last resort.

Managing early season nitrogen tie-up by stubble

Options to improve plant nutrition include:

- Create a N budget to help track and estimate how much N is needed for a growing crop.

- If soil tests are below 40kg N/ha in the top 60cm, apply 20kg N/ha with the seed or deep banded at sowing to ensure crops get through to the beginning of stem elongation.

- The rule of thumb is that a wheat crop will need 40kg N/ha applied to produce 1t of grain, barley requires 35kg N/ha to produce 1t of grain, and canola needs 80kg/ha of N to produce 1t of grain.

- Allow an additional 5kg N/ha per 1t/ha retained stubble to allow for N tie-up (Kirkegaard et al. 2018).

- Deep-banding N can improve a crop’s N uptake, yield and protein, especially where stubble is retained (Kirkegaard et al. 2018).

- Incorporation of stubble will help to mix nutrients and remove stratification of immobile nutrients at the soil surface but may also increase the N fertiliser requirement of the following crop.

- Grazing of stubbles can increase the mineral N available to crops (Hunt et al. 2012).

- Burning stubbles makes some N available immediately, but you will lose up to 80% of the stubble N content during the burn (Norton and Weaver, 2017).

- Stubble is not a good source of N for crops. Trials at Horsham, Temora and Karoonda found that only 1-6% of the N was recovered by the following two crops.

Stubble borne disease carry-over management

Stubbles can carry over plant diseases from previous crops, which can infect the following crops. The adoption of no-till stubble retained systems has particularly favoured development of yellow leaf spot (YLS), spot form net blotch (SFNB) and crown rot in the Wimmera and Mallee. Other stubble borne diseases include Net form net blotch (NFNB) and Scald in barley.

Options to reduce the impact of stubble borne disease carryover include:

- Use the Predicta®B test to identify diseases and levels and decide how to manage any risks.

- If disease is present, use crop rotation and resistant varieties that do not host the disease.

- Control the green bridge that can host stubble borne diseases, particularly grasses for cereals.

- Timely sowing and adequate nutrition for early crop vigour.

- Monitoring and timely fungicide applications for some diseases.

- Graze stubble with livestock to reduce loads and trample residues for faster breakdown.

- Mulch or lightly incorporate stubble into soil to allow breakdown of disease before sowing (needs moisture).

- Use burning as a last resort.

Pest management in stubbles

Increased stubble retention, reduced cultivation and more intensive cropping has created a more favourable habitat and quantity of feed for pests to survive and multiply; particularly mice and snails, and in wetter seasons; slugs, millipedes, earwigs, slaters and weevils.

Options to improve pest management include:

- Bait for mice and snail control.

- Graze stubble with livestock to reduce food sources and trample residues for habitat breakdown. Anecdotally, in 2017 mouse populations were considerably smaller where stubbles had been grazed across the Wimmera and Mallee, compared to where stubbles remained ungrazed.

- Control summer weeds and crop volunteers that provide food and habitat.

- Mulch or lightly incorporate stubble to remove habitat and food sources. Cultivation will disturb burrows.

- Use burning as a last resort.

(Source: BCG, 2018)

Making stubble management decisions

Use information within this paper to help decide when reducing or removing stubble will benefit your crop production system, from reducing potential negative effects of stubble on plant establishment, production and profitability. There is no magical stubble amount that suits all situations and solves all problems. Every farm is different and the need for stubble management will depend on how much and what type of stubble, whether you manage livestock and need to deal with trampled residues, type of harvest equipment and whether sowing with tyne or disc systems, and what weed, disease or pest threats are posed.

Conclusions

- Be flexible in your approach to managing stubble and start stubble management early enough (i.e. at harvest time) so that it does not impact on sowing of subsequent crop.

- Know the limitations of your seeder.

- Don’t let stubble compromise the big things i.e. weeds, diseases, pests and timeliness.

- Diversify your cropping rotation.

- Stubble is not a good source of N for crops.

Useful resources and references

5 farm business analysis - investment in harvest machinery for stubble retained systems

Monitoring Stubbles during the fallow period

Weed management in stubble retained systems in the Wimmera and Mallee

Keeping livestock productive on crop stubbles

Tools to Manage Stubble During Fallow in the Wimmera and Mallee

Pest Management in Retained Stubble Systems

Stubble management Factsheet, 2011.

Kirkegaard et al. (2018). The effects of stubble on nitrogen tie up and supply. GRDC Grains Research Updates in Adelaide, Wagga Wagga and Bendigo

Kirkegaard et al. (2019). Ten key lessons from the stubble initiative every agronomist should know, GRDC Grains Reserach Update in Adelaide

Swan et al. (2017). Maintaining profitable farming systems with retained stubble across various rainfall environments in SA, Victoria and central and southern NSW. GRDC Updates in Adelaide, Wagga Wagga and Bendigo

Acknowledgements

The research undertaken as part of this project is made possible by the significant contributions of numerous growers and grower groups (BCG, CWFS, EPARF, FarmLink Research, Hart Field Site group, ICC, SFS, LEADA, MFMG, MSF, Riverine Plains, UNFS, YPASG, VNTFA, MNHRZ, Yeruga Crop Research) through both trial cooperation, and the support of the GRDC. CSIRO (research component) and SARDI (extension) are also acknowledged. The author thanks all those participants who provided the material presented on their behalf, and their efforts to develop regional guidelines to maintain profit in stubble retained systems.

Contact details

Claire Browne

BCG 73 Cumming Avenue Birchip Vic 3483

(03) 5292 2787 or 0429 922 780

claire@bcg.org.au

@BrownyBCG

GRDC Project Code: BWD00024, CSP00186, CSP00174, EPF00001, MSF00003, YCR00003, MFM00006, CWF00018, CWF00020, RPI00009, LEA00002, UNF00002, SFS00032, DAS00160, DAS00119,

Was this page helpful?

YOUR FEEDBACK