Is our ryegrass really getting harder to kill through our over reliance on glyphosate?

Is our ryegrass really getting harder to kill through our over reliance on glyphosate?

Author: Maurie Street (GOA) and Ben O’Brien (GOA) | Date: 25 Feb 2020

Take home messages

Glyphosate resistance is real and affirmative action needs to be taken now and into the future- BUT:

- The assumption of “herbicide resistant” may be applied too hastily in some cases to herbicide failures

- Many other influences can result in poor herbicide performance. Growers and agronomists need to critically assess any failures to establish true causes

- Populations of weeds suspected to be resistant should be tested to confirm resistance otherwise useful options for control may be overlooked.

Background

Annual ryegrass (ARG) is considered one of the major weeds in the cropping systems of central west NSW and it is commonly resistant to one or more herbicides. It is present on nearly all farms and is never far from mind in any weed control program.

Populations are very commonly resistant to Group A-fops and Group B-sulfonyl urea herbicides (GOA Herbicide resistance surveys web results) with other effective in-crop selective control options becoming limited. However, there are an increasing number of confirmed cases of resistance to glyphosate (Group M). In 2013 and 2014 Grain Orana Alliance (GOA) ran two herbicide resistance surveys in central western NSW which tested 130 non-random or ‘submitted’ samples of ARG. Results of these surveys revealed 26% of the samples tested were resistant to glyphosate. A recent survey undertaken by CSU and funded by the GRDC, testing randomly selected ARG samples from the northern region showed 10% to be resistant to Group M herbicides, a level much higher than many other regions. This paper looks at how our farming practices have evolved to deal with glyphosate resistant ryegrass.

Personal experience of one of the authors, whose agronomy career started in the early 90’s, recalls that ‘in the good old days’ ARG was certainly ever present but glyphosate was very effective with pre sowing knockdown use rates of 500 mL/ha of 450 gai/L product being commonplace, particularly when followed by a full disturbance sowing. Compare this to today, where field rates are seldom below 1500 mL/ha of a 450 gai/L and there is a push to even higher rates still to control the weed spectrum. Furthermore, there is an increase in the use of double knocking, more use of pre-emergent residual herbicides, re-introduction of cultivation, the use of crop topping and the adoption of harvest weed seed management techniques such as chaff lining or windrow burning all in the attempt to manage herbicide resistant weeds – including ARG. Arguably the control of ARG has become more complex and it is more difficult to kill in a farming system that relies heavily on herbicides, particularly glyphosate.

Given the resistance survey results and the increasing efforts in our weed control systems to control ARG, it is not unreasonable for growers or advisers to automatically assume resistance in populations that are not well controlled by glyphosate. However this assumption of resistance is not always confirmed by testing of the population.

Where growers are wanting to control or slow the development of resistance in ARG, alternate knockdown options are very limited. As a result, GOA was asked to investigate alternate herbicides or options to improve the herbicide control of problematic ARG populations ahead of seeding winter crops and established a number of trials over the past three years.

Some of the results are not unexpected but we did find some encouraging and surprising outcomes. Full details can be found on the GOA website. http://www.grainorana.com.au

What did we do?

Growers and advisers were asked to identify paddocks with problematic populations of ARG. In all cases the sites put forward were strongly suspected as resistant to glyphosate with previous cases of poor control.

GOA then employed two different trial protocols at each site:

- Investigate options to improve glyphosate control of seedling ARG through product rate, formulation and adjuvant packages

- Investigating various alternate herbicide options to glyphosate to control seedling ARG.

What did we find?

Resistant ryegrass populations

From 2017 to 2019 GOA established trials on seven separate populations of ARG.

Sites were selected prior to sowing, following rainfall, where there were good populations of emerged ARG. At the time most sites selected were at least strongly suspected as being resistant to glyphosate due to poor and unreliable control in previous seasons, although many had never had this confirmed by testing.

Clearly from the plant populations present, often greater than 200 plants/m2, ARG has been problematic to control in the past allowing the seed bank to grow.

Once the trial site was selected, live ARG samples were collected and sent to Plant Science Consulting for herbicide resistance testing using their Quick Test Service (details of the methodology of the Quick Test can be found at www.plantscienceconsulting.com.au).

The results were surprising. Of the seven populations strongly suspected and being managed as resistant to glyphosate, only two were confirmed as resistant by testing. One had only low level of survival of 10% and survivors demonstrated moderate resistance (RR), the other sample had slightly higher resistance of 20% but only a weak resistance (R) rating. Furthermore, this level of resistance was only evident at rates much lower (500 mL/ha & 750 mL/ha Roundup® CT) than field rates typically applied in present day (>1500 mL/ha) with none detected at higher rates.

Looking at this from the other angle - in these two cases 80%-90% of the plants tested were controlled by glyphosate (at the low rates) and the survivors stunted. If 90% kill rate is deemed acceptable commercial control, even low rates should be achieving close to this on these two populations. If growers are applying higher rates of glyphosate, which likely would be the case, the level of resistance cannot be wholly blamed for failure to control these populations. So, what is responsible for the failure in control?

In the remaining five, confirmed susceptible populations, the poor/unreliable control cannot be explained by resistance, so what caused these failures?

Improving glyphosate performance through product choice, rate or the addition of surfactants or adjuvants

The mechanism of resistance to Group M in ARG is often, but not always, rate responsive. As detailed above, two populations did show resistance at lower label rates of glyphosate, but all those populations could theoretically be controlled at a reasonable level if the rate was increased.

This trait is a weakness in the resistance mechanism that can be exploited by growers and advisers to both manage resistant populations and/or reduce the rate of development of resistance. How effective this may be is related to the type and the level of resistance present in the population at the time of application.

GOA trials aimed to demonstrate a typical dose response to confirm that higher rates are justified for the control of resistant ARG.

The impact of rate on control of ARG is detailed in Table 1. In all but one case there was a positive response to increasing the rate of Roundup® CT and acceptable control was able to be achieved.

Table 1. Percentage control of untreated population of annual ryegrass in response to rate of Roundup® 450 CT.

Year | 2017 | 2018 | 2019 | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Location | Narromine | Parkes | Alectown | Narromine | Alectown | Tichborne | Forbes | ||||||||

Weed size | 3-6 leaf | 3-6 leaf | 3-6 leaf | 3-5 leaf | 3 leaf- 2 tillers | 2-6 leaf | 6 leaf- early tillering | ||||||||

Roundup CT ®L/ha + Wetter TX® | UTC | 0 | E | 0% | J | 0% | H | 0% | A | 0% | F | 0% | B | 0% | A |

0.50 | 99% | BC | 54% | CDE | 54% | C | 56% | ABCDE | |||||||

0.75 | 31% | D | 88% | EFGH | 30% | EGH | 100% | C | 63% | BCD | 60% | C | 89% | EFGH | |

1.00 | 100% | C | 71% | BC | 55% | C | 98% | IJ | |||||||

1.25 | 100% | C | 80% | AB | 67% | C | 100% | J | |||||||

1.50 | 99% | A | 96% | ABCDE | 95% | A | 100% | C | 93% | A | 64% | C | 100% | J | |

Resistance testing | Yes | ND | ND | ND | Yes | ND | ND | ||||||||

Results followed by the same letter only at the same location denotes no significant difference, p= 0.05

Resistance- yes- glyphosate resistance was detected by testing, ND- Glyphosate resistance not detected

UTC – untreated control

The Narromine 2017 and Alectown 2018 sites are confirmed resistant. Alectown was the most difficult of the two to control but plants were largest at this site and moisture deficits were observed at the time of spraying. An acceptable level of control was still achieved with the high rates in both cases.

‘Tichborne 2019’, was not adequately controlled but was confirmed as susceptible. Both Tichborne and the Forbes 2019 sites were noted as very dry, somewhat stressed with warm spraying conditions, yet the one with the largest weed size (Forbes) was controlled readily, the other not.

This situation is an example to illustrate the difficulty growers and advisers face in diagnosing resistance in the field. Both sites were sprayed within one day of the other, the same water source was used as was the spray set up. We were confident in that our spray application was satisfactory so the failure in ARG control observed was thought as confirmation of the assumed resistance. Testing was carried out as a matter of course and it was not until several months later, when the tests results were returned, that the misdiagnosis was exposed.

GOA also looked at two other key aspects; the impact of surfactants or spray adjuvants and the choice of product looking to address the question- “Should growers add additional surfactants or buy a different formulation of glyphosate?”

Commercially available formulations of glyphosate often contain different levels and different types of surfactant to aid in the deposition and absorption of glyphosate to improve control. However additional surfactants are sometimes suggested in certain situations to further improve control - such as controlling ARG in some situations.

The need for additional surfactants is very complex with a range of different glyphosate salts, concentrations and surfactant packages used in current formulations. Salt types respond differently to surfactant packages, in a similar way that some weeds respond differently to particular surfactants (see https://grdc.com.au/resources-and-publications/grdc-update-papers/tab-content/grdc-update-papers/2018/08/factors-to-consider-with-the-use-of-different-glyphosate-formulations). Different formulations have more or less surfactant in their formulations- altering the need for any additional surfactants. Further adding to the complexity of the decision is that the surfactant type and concentration in the glyphosate formulation is generally not made available via the product label, so it is often unclear if surfactant in the formulation is optimised or not. Further, there is often a misunderstanding of what is the optimal type of surfactant that will be most useful for glyphosate, perhaps this is not helped by the many inconsistencies or ambiguity in labels as to the need for (or the benefit of) additional surfactant.

A range of common surfactants were tested to observe the potential impact on ARG control as well as testing some other formulations/brands of glyphosate (2017 only). This treatment list is rather simplistic, but it was thought that it could help growers’ decisions in their choices to control ARG.

There was no consistent difference in performance of Roundup® CT®, Roundup ULTRA® MAX (a premium, fully loaded product) or a low priced- generic brand if robust rates were used. However, at the lower rates tested, Roundup ULTRA® MAX often performed better than the other two products tested.

The same could generally said regarding surfactants. In general, at robust rates of glyphosate in the large majority of cases tested, there was no advantage to the addition of any of the following: BS1000®, LI700®, Liase®, Wetter TX® or Activator®. At lower glyphosate rates, the addition of these sometimes did improve control, but often not to the levels achieved with higher rates of glyphosate and the response was inconsistent. Put simply, if there is a choice to increase rate or add additional surfactants or additives, in the circumstances tested, the most consistent result was to increase the rate.

What is not always clear is whether the benefits of increasing the glyphosate ‘product’ rate per ha, is due to the increase in active ingredient as opposed to the increase in inbuilt surfactant loading.

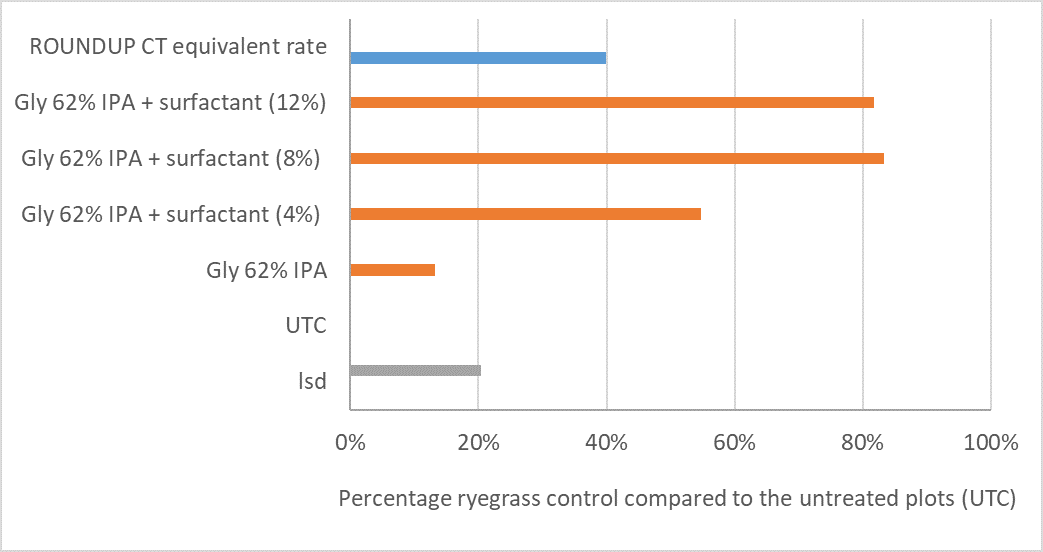

GOA was able to secure a non-commercial formulation of IPA glyphosate at 620g/L (Gly 62% UPA), that had no surfactant added. We trialled adding a surfactant used in some commercial formulations of glyphosate at various rates to reflect a range that may be found in commercial products. It is often suggested that various commercial brands of glyphosate vary largely by the type and rate of co-formulated surfactant used. It has been commonly accepted that surfactant inclusion in most commercial 450gai/L products is 12%. However, some poor quality brands may contain much less than that, with inclusion rates down as low as 4% or nil in some extreme cases.

At Parkes in 2018 control with GLY 62% IPA at a sub optimal rate, improved significantly with increasing rates of surfactant added, confirming that increasing surfactant rates do play a part in improving control. It should be noted that the rate of glyphosate used in this trial was very low and the carrier volume relatively high at 100L/ha. However as discussed above, where commercial glyphosate formulations already have sound rates and types of surfactant included, such as Roundup® CT, additional surfactant may only be warranted where surfactant is diluted at low herbicide rates and/or high-water rates as is demonstrated by this trial.

Figure 1. Impact on ARG control by increasing rates of additional surfactant mixed with a very low dose rate of IPA glyphosate with no surfactant at the relatively high spray carrier volume of 100L/ha (Parkes, 2018).Alternate options to control ARG

Figure 1. Impact on ARG control by increasing rates of additional surfactant mixed with a very low dose rate of IPA glyphosate with no surfactant at the relatively high spray carrier volume of 100L/ha (Parkes, 2018).Alternate options to control ARG

Another option to control a resistant population is to use alternate effective modes of actions. Paraquat or products containing paraquat are often the most logical as they have labelled use patterns, that means growers can use them as a substitute in many knockdown situations or alternatively it can be used as a double knock spray following use of glyphosate or other products.

Paraquat was both tested as a single pass options as well as a double knock treatment with results similar to Borger & Hashem (2007) and Newman & Adam (2004). Where paraquat was used as a double knock, control was improved substantially. When used as a single pass option, results were more variable but useful control was still often achieved.

Alternate options investigated included some Group A, K + J, H or G herbicides as either a standalone or a spike to aid in the knockdown of ARG.

Whilst all of the evaluated products are currently unregistered for use in this situation, the results confirmed they were generally not effective in controlling ARG.

The Group A herbicides, in particular the Fops- were all but ineffective, but this is not surprising given the resistance status of most ARG populations. The DIMs in many cases did not achieve commercially acceptable control when applied alone but when mixed with Roundup® CT, control was better but generally no better than glyphosate applied alone.

The Group K+J, H and G herbicides were applied with Roundup® CT and showed little advantage over that of Roundup® CT alone. In all cases better control could be achieved with higher rates of glyphosate.

In Summary

The presumption of glyphosate resistance in five of seven sites, has shown to be incorrect. It is not doubted that the populations have proved problematic with previous applications, but it could be said in most, if not all cases the poor control was not the result of resistance alone.

Of greater concern, is that if failure was not due to resistance, why was control so poor? There are many possible reasons such as poor spray water quality, incorrect spray timing, inappropriate sprayer set up delivering less than optimal spray droplet size and/or water rates, products with sub-optimal surfactant loadings, plant or environmental stresses. All these issues can result in poor control, and in the event of herbicide failures, all aspects of the application should be reviewed or investigated - including Stress; Timing; Application and Rate (STAR).

Furthermore, the results of these trials highlight the value of herbicide resistance tests in the event of a failure. Tests would have revealed that in all seven paddocks, glyphosate was still effective albeit at a higher rate for some.

A clear outcome from these trials is for growers to move to higher rates within label guidelines if not already doing so. Higher rates are a sound way to maximise control whether resistance is present or not and may be more effective than any investment in additional surfactants. It must be noted that the decision to add adjuvants to improve water quality, for example using Liase for hard water, should also be addressed.

Indeed, this view is pointed out by Boutsalis et al. (2015), increasing glyphosate rates may also contribute to more effective control by “… counteracting poor application, improving control of older plants, stressed plants or overcoming reduced efficacy caused by using poor quality water or treating plants covered by dust. Higher label rates can also improve glyphosate activity on plants exposed to higher temperatures that can arise in early autumn or late spring”.

In reply to the title question- is ryegrass getting harder to kill? I think we could say that controlling ryegrass has become more complex. In many cases glyphosate resistance is most definitely present, and this is harder to deal with. But it has been demonstrated that resistance is not the only thing making it harder to control.

The most important take home is to review spray failures. The first and arguably easiest ‘failure parameter’ to eliminate is resistance, so get it tested. That way you know what you are dealing with and what will work and what won’t work in subsequent management sprays. Simply assuming resistance may see useful options overlooked and a failure to identify and address the real cause of any spray failures.

References

Boutsalis P, Gill G and Preston P (2015). Optimising the impact of glyphosate. GRDC Grains Research Update paper.

Borger, C., & Hashem, A. (2007). Evaluating the double knockdown technique: sequence, application interval, and annual ryegrass growth stage. Crop & Pasture Science, 58(3), 265-271.

GOA herbicide resistance surveys web results. Retrieved from: http://www.grainorana.com.au/documents?download=36

McNamara E (2017) Ryegrass resistance continues to spread. GRDC media release.

Newman, P and Adam G (2004). Double knock down, one day between knocks. Retrieved from: https://ahri.uwa.edu.au/wp-content/uploads/2015/04/PNewman-doubleknock-cropupdates-04-.pdf

www.plantscienceconsulting.com.au

Somervaille A (2018). Factors to consider with the use of different glyphosate formulations and getting it right with the use of adjuvants. GRDC Grains Research Update paper.

Acknowledgements

The research undertaken as part of this project is made possible by the significant contributions of growers through both trial cooperation and the support of the GRDC, the author would like to thank them for their continued support.

Contact details

Maurie Street and Ben O’Brien

Grain Orana Alliance

PO Box 2880

Dubbo NSW 2830

Ph: 0400 066 201

Email: maurie.street@grainorana.com.au

Email: ben.obrien@grainorana.com.au

® Registered trademark

GRDC Project Code: GOA00002,