Lasers, machine learning, weed recognition and new innovations in weed management

Lasers, machine learning, weed recognition and new innovations in weed management

Author: Guy Coleman (University of Sydney), Caleb Squires (University of Sydney) and Michael Walsh (University of Sydney) | Date: 26 Feb 2020

Take home messages

- Advancements in machine learning, particularly deep learning, are creating opportunities to use non-selective alternative weed control options

- Following a comparison of energy requirements lasers were identified as the most suitable alternative option for further research and development.

Site-specific weed control

The widespread development of herbicide resistance across the northern region and around Australia is driving the need to develop alternative weed management options. The selectivity of several alternatives is linked with their method of application.

Some non-selective alternatives, such as flame weeders may be used inter-row, while commercial broadacre electrical weeders use height to differentiate weeds from crop. Outside of these commercially available implements, most alternatives to herbicides are often more costly, not yet commercialised, lacking research or not sufficiently effective for broadacre cropping.

Machine learning-based weed identification can provide the detection and identification of weeds in the crop using algorithms based on convolutional neural network (CNN) architectures. These can provide the opportunity to use non-selective physical and thermal weed control options for the control of in-crop weeds. Since the demonstration of CNNs as highly accurate for image classification tasks in Krizhevsky et al. (2012), there has been significant advancements such that CNNs may now be used to accurately recognise individual plants, and potentially even the growing points of in-crop weeds. Machine learning-based weed identification enables selectivity on the delivery side of the control. This greatly increases the opportunity to develop previously unviable alternative control options as effective broadacre techniques.

While the opportunities clearly exist, the development of algorithms with consistently high accuracy and precision for use across the grain production region in Australia remains an issue. Recently, companies such as Bilberry (partnering with AgriFac) and now Autoweed are delivering some of the first commercially available camera and CNN-driven site-specific weed control sprayers. Simpler yet highly effective optical-driven camera sprayers such as Weedit® and WeedSeeker® have been in widespread commercial use for the selective control of weeds in fallow throughout the grain growing areas of northern NSW and Qld for many years. Detection-based delivery of herbicide coupled with the ability to differentiate weeds from crop is an important advancement and potentially a weed control game changer when perfected. However, at this stage the level of precision is lower than that needed for delivery of highly targeted alternative control methods.

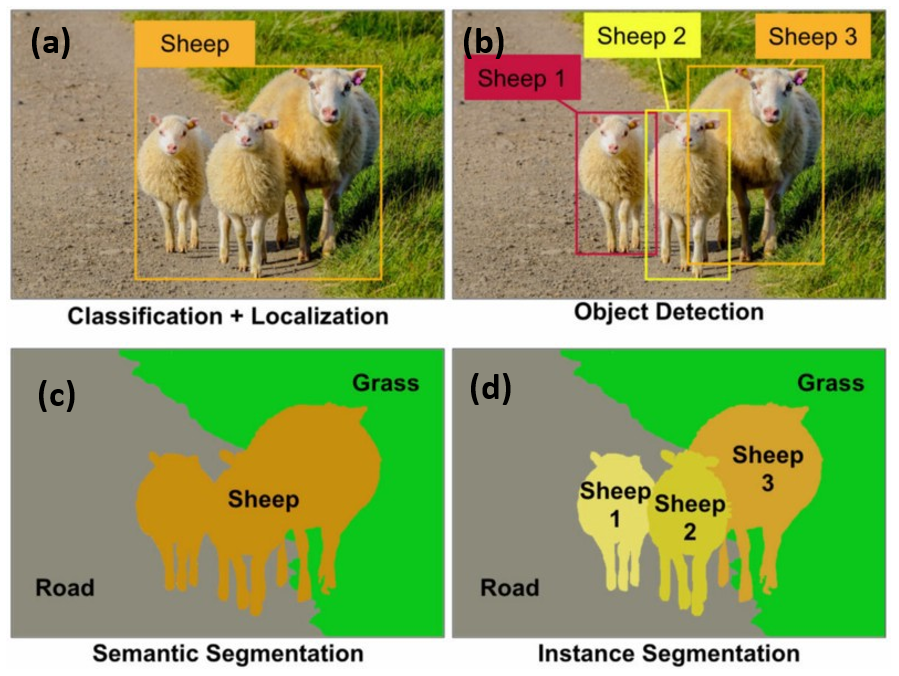

Four different levels of weed detection (and identification) are currently achievable with state-of-the-art algorithms (Figure 1). The lowest granularity is image classification, which takes an image and provides a probability that the object (and others) exists in that image.

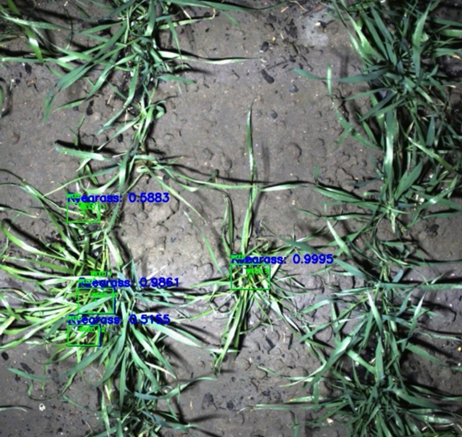

The next level of discrimination is object detection. Object detection algorithms provide information on the number and general location of an object in the image (Figure 1b). Segmentation is the most granular, where every pixel in an image receives a classification (Figure 1c and 1d). Segmentation algorithms provide the level of detection required for delivery of highly targeted alternative control options to individual plants and plant parts, precision beyond the capabilities of current see and spray technology. At the object detection level, the Weed Research Team at the University of Sydney recently demonstrated the capabilities of existing object detection architectures (Figure 2) in differentiating annual ryegrass and wheat. While the demonstration used controlled growing environments and data for algorithm training, a key finding was that a lack of labelled data to train existing algorithms is the main barrier in developing detection algorithms of all four levels.

Figure 2. Initial testing of ryegrass detection in wheat has shown that existing machine learning architectures including You Only Look Once (YOLO) and Single Shot Detectors (SSD) are capable of differentiating ryegrass in wheat under controlled circumstances. This demonstration suggested lack of labelled data is the main barrier to development instead of technological advancement.

Figure 2. Initial testing of ryegrass detection in wheat has shown that existing machine learning architectures including You Only Look Once (YOLO) and Single Shot Detectors (SSD) are capable of differentiating ryegrass in wheat under controlled circumstances. This demonstration suggested lack of labelled data is the main barrier to development instead of technological advancement.

Moving from broadcast to site-specific application shifts the input and cost function of weed control from area-driven to a function of weed density, where the treatment is applied only where it is needed. Importantly, move to site-specificity creates a significant opportunity for cost and input savings, with potential for additional benefits in reduced off target and environmental impacts. It also opens up the possibility of alternative options such as lasers, electrocution and microwaves for practical use in broadacre crop systems.

Based on research comparing the energy consumption of alternative control methods by Coleman et al. (2019), lasers were identified as a potentially viable alternative weed control method. With relatively low power consumption, small size and ease of control, lasers (specifically diode and fibre) were seen as a potentially viable option for weed control. While the method of laser beam generation may differ (be it diode, fibre or CO2 as a few examples), the fundamental control method is through the highly targeted and concentrated delivery of energy in the laser beam. Similar to other thermal methods, this energy heats plant cells to the point of rupture and death, however, rather than moving an implement, tine, microwave, flame or electrode to the weed, lenses and optics are used to direct and focus the beam from a distance. The energy is also highly targeted, with minimal loss in the process of delivery. The beam width, and hence the density of energy in the beam, can also be varied to treat a larger area. These practicalities of lasers, in comparison with the other control options available, made them a good choice for preliminary assessments.

Aims

With research and development occurring in the weed detection and identification space, there is a requirement for the identification and evaluation of alternative weed control options to couple with new detection technology. The aims of this research are two-fold:

- Evaluate the efficacy of lasers for the control of winter and summer weeds

- Identify laser parameters (type, setup and use) required to deliver effective weed control.

Laser weeding

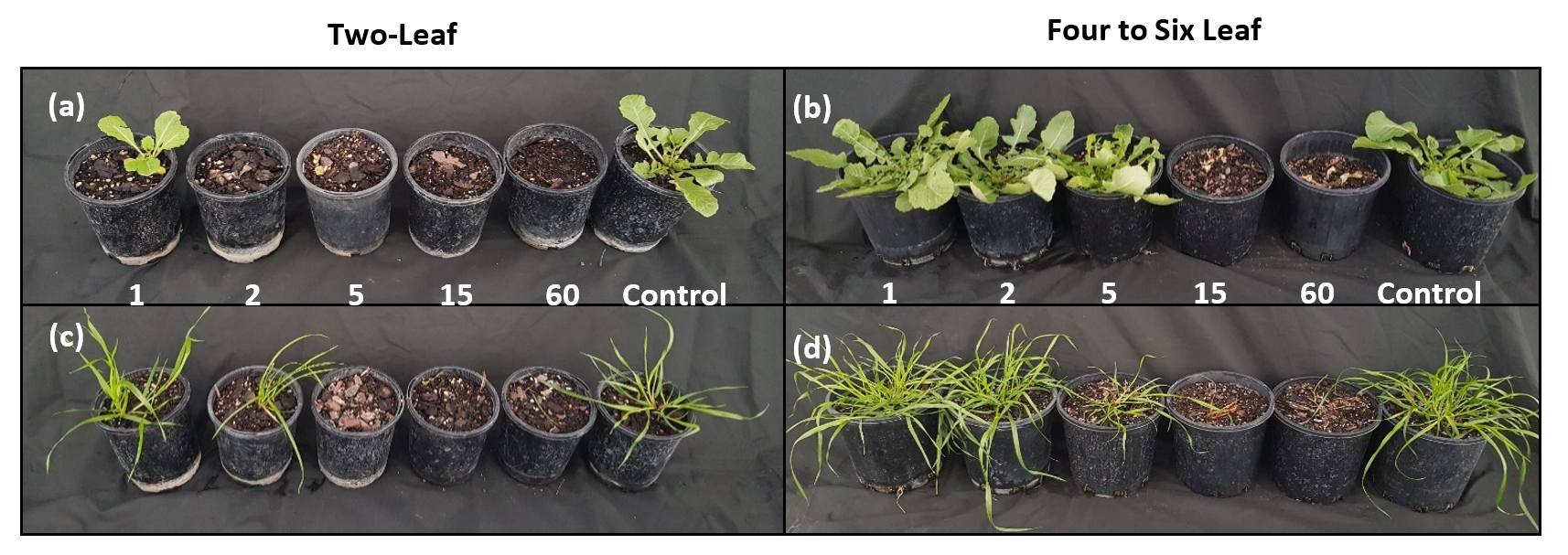

During the 2019 winter season, pot trials on the efficacy of a 25 W, 1064 nm continuous wave diode laser were conducted on representative broadleaf and grass weeds relevant to the northern region, namely turnip weed (Rapistrum rugosum) and annual ryegrass (Lolium rigidum). The trials evaluated the effect of laser treatment duration, laser beam width (spot size), weed species and weed growth stage on weed control efficacy.

Treatment duration

Using a 5 mm diameter spot size, 60 second treatment times provided 100% control of two and six leaf ryegrass and turnip weed plants (Figure 3). In the two-leaf plants, the 2 second treatment provided control of the turnip weed, but did not control the ryegrass. These results suggest the subsoil growing point of many grass species may protect the plant from lower energy laser treatments. While the treatment time is long for a 25 W laser at 5 mm spot size (1.3 J/s mm2), increasing the laser power increases the rate of energy delivery, reducing the treatment time required to deliver an equivalent dose. Where control was not provided, significant reductions were seen in weed biomass in mid-tillering ryegrass.

Laser beam width

While duration of laser treatment changes the total amount of energy delivered, adjusting beam width impacts on the intensity of energy applied to the plant. The intensity of the beam, which is determined by power per unit area or energy density, changes the properties from heating (low intensity) to cutting (high intensity). The 25 W laser was tested with 2, 5 and 10 mm spot widths, providing 8.0, 1.3 and 0.3 J/s mm2 energy intensities. Larger spot sizes reduce the precision required for the targeting and detection system, however, the less intense energy means the treatment duration must be longer or the plant may not heat enough for cell death.

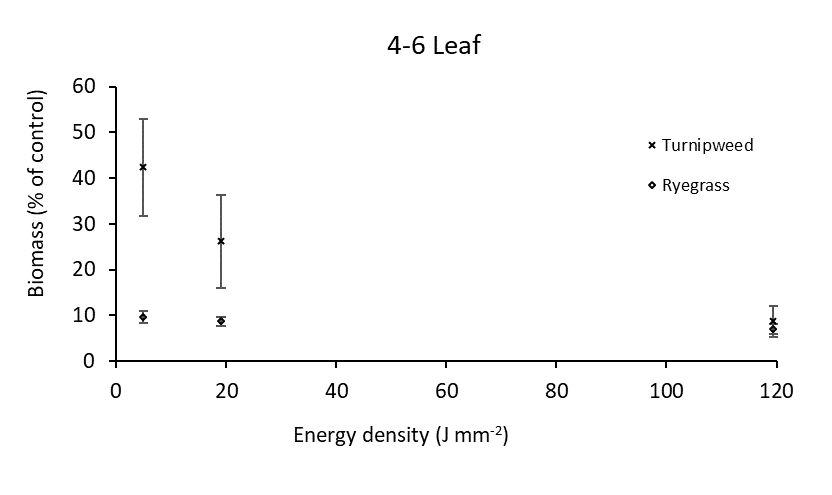

At the two-leaf stage, there was a high level of control across all spot sizes for both turnip weed and ryegrass. At the four to six-leaf stage (Figure 4), the biomass reduction of turnip weed increased with increasing energy density (smaller beam width or higher intensity). Ryegrass was not significantly impacted. Using equivalent energy densities, it is estimated a laser of at least 400 W would be required to control four to six leaf stage weeds (including annual ryegrass) under 1 second treatment at a 5 mm beam width.

Future research on lasers will continue to evaluate the temperature thresholds required for control the growing point. A larger laser is expected to be used to assess the impact of the rate of energy delivery on control efficacy. Summer weeds will be tested in March 2020.

Figure 4. Comparing the impact of energy density (spot size) on plant growth behaviour as a percentage of the biomass of the control. Weeds were treated for 15 seconds using the 25W, 1064 nm diode laser.

Figure 4. Comparing the impact of energy density (spot size) on plant growth behaviour as a percentage of the biomass of the control. Weeds were treated for 15 seconds using the 25W, 1064 nm diode laser.

Conclusion

Weed recognition through machine learning has the potential to enable alternative physical and thermal weed management options not previously considered relevant in broadacre agriculture. When applied on a site-specific basis, the energy costs of thermal control technologies such as lasers and electrocution are significantly reduced. Furthermore, lasers are showing promise as a highly targeted method for control of up to eight-leaf growth stage weeds. Yet even with such opportunity, the delivery of these technologies relies on highly accurate, precise and repeatable weed detection. Training state-of-the-art machine learning algorithms requires significant quantities of labelled image data obtained in diverse field conditions. Thus, a high-quality database of labelled images which reflects the diversity in Australian weeds, crops, and conditions is a pre-requisite and limiting factor for development of accurate weed recognition algorithms.

Concurrent with the development of detection capability, investigation of alternative weed control methods should be completed to determine relevancy and other optimal parameters for use. Initial research has shown that the potential for lasers is high due to the ability to flexibly deliver highly targeted energy, with positive results in both ryegrass and turnip weed.

Acknowledgements

The research undertaken as part of this project is made possible by the significant contributions of growers through both trial cooperation and the support of the GRDC, the author would like to thank them for their continued support.

The authors would like to thank the project collaborators at the Australian Centre for Field Robotics (ACFR) and the Sydney Astrophotonics and Instrumentation Library (SAIL) who supported the laser weeding trials.

References

Coleman GRY, Stead A, Rigter MP, Xu Z, Johnson D, Brooker GM, Sukkarieh S and Walsh MJ (2019) Using energy requirements to compare the suitability of alternative methods for broadcast and site-specific weed control. Weed Technol 33:633–650

Krizhevsky A, Sutskever I and Hinton GE (2012) Imagenet classification with deep convolutional neural networks. Adv Neural Inf Process Syst:1097–1105

Llewellyn R, Ronning D, Clarke M, Mayfield A, Walker S, Ouzman J, Llewellyn R and Mayfield A (2016) Impact of weeds in Australian grain production: the cost of weeds to Australian grain growers and the adoption of weed management and tillage practices. CSIRO, Australia.

Contact details

Guy Coleman

University of Sydney

Ph: 02 8627 7157

Email: guy.coleman@sydney.edu.au

GRDC Project Code: UOS1703-002RTX,