Recommendations for deep ripping sandy soils

Author: Brian Dzoma and Kym Zeppel (SARDI Loxton Research Centre), Nigel Wilhelm and Hugh Drum (SARDI Waite Research Precinct) | Date: 11 Feb 2020

Take home messages

- Deep ripping is most effective in deep sandy-textured soils, when the ripper tines go beyond the compacted layer (+60cm). Grain yield increases usually persist for several years on deep sands.

- Based on 2 years of limited data in SA, ripping with narrow (30cm) or wide (60cm) tine spacing resulted in similar grain yield responses, and therefore, wide ripping should be considered as it requires less machinery horsepower and less operational costs.

- A potential downside associated with deep ripping in low rainfall areas is that it increases the risk of crops ‘haying off’ when soil water reserves are rapidly exhausted and the finish to the season is harsh and dry.

Background

Sandy soils dominate the landscape across the low rainfall region of south-eastern Australia and soil compaction mainly caused by heavy machinery is a widespread constraint to root growth. Other constraints that may occur simultaneously on these soils include water repellency and acidity. Compaction inhibits root growth and reduces the storage and supply of water and nutrients, especially from the subsoil. It increases soil bulk density and soil strength, decreases porosity, water infiltration and water holding capacity, and can also adversely affect soil biological activity. In the absence of compaction forces some sandy soils have a natural tendency to form hard layers in the subsurface, thought to be caused by physical and/or chemical cementation processes.

Deep ripping is most effective treatment to loosen compacted subsoils and allow roots to access soil moisture and nutrients at depth. Significant benefits to crop growth from deep ripping are frequently measured on compacted sandy-textured soils, however responses on other soils are often smaller and less frequent (Paterson and Sheppard, 2008). For example, Isbister et al. (2018) reported that responses to deep ripping in Western Australia (WA) were greater in sandy soils (20-37% yield increase) than loamy duplex soils greater than 30cm deep (22%) or shallow duplex soils (4%). For sodic clays and prone to dispersion, ripping is often detrimental to crop growth.

Tine spacing, working depth, shallow leading tines or discs, soil moisture content, timing and soil type all need to be considered to maximise productivity gains and make the process off deep ripping cost effective. Research by the Department Primary Industry and Regional Development (DPIRD), supported by investment from the GRDC, estimates that the costs associated with deep ripping can range from $50-60 per hectare for standard ripping at 50cm spacing to a depth of 30-40cm, and up to $70-90/ha for ripping at narrower spacings and/or a depth of 50-70cm, depending on machinery and soil conditions. Therefore, the challenge that growers face is refining how best to ameliorate compacted soils while keeping costs down, but at the same time maximising and prolonging the benefits. It is important to note that if the soil contains other constraints in, or below the ripping depth such as acidity, poor structure from sodicity or subsoil salinity, the benefits of deep ripping may not be fully realised unless these are also addressed.

This paper summarises the results from replicated trials conducted in different low – medium rainfall cropping regions of Australia to gain insight into how deep ripping is impacting crop performance and how to maximise the benefits on different soil types. Collation of data from these trials will assist in developing guidelines for growers which address key questions around if and why they should be considering deep ripping as a soil amelioration strategy. Once the decision is made to proceed with a ripping program, trial results will also help inform growers of how best to undertake the ripping to achieve sustainable and improved crop yields and sound returns for every dollar invested.

Justification for deep ripping

Research conducted in the 1970s and 80s demonstrated that on deep sands and sandy loams in WA, wheat roots can extract water from depths ranging from 1.4 to 2.5 metres (Hamblin et al. 1982; Hamblin et al. 1988). In moisture limited environments the capacity of roots to extract water and nitrogen from such depths is critical on soil types with relatively low water holding capacity, or where the use of deep subsoil moisture is critical for grain filling. In compacted sandy soils where penetration resistance exceeds 1500kPa, crop root growth is restricted and yield potentials cannot be realised. In these situations, deep ripping can break up that compaction, improve root penetration and ultimately crop performance. Resistance values of 1500-2500kPa are considered moderate, 2500-3500kPa severe and >3500kPa extreme.

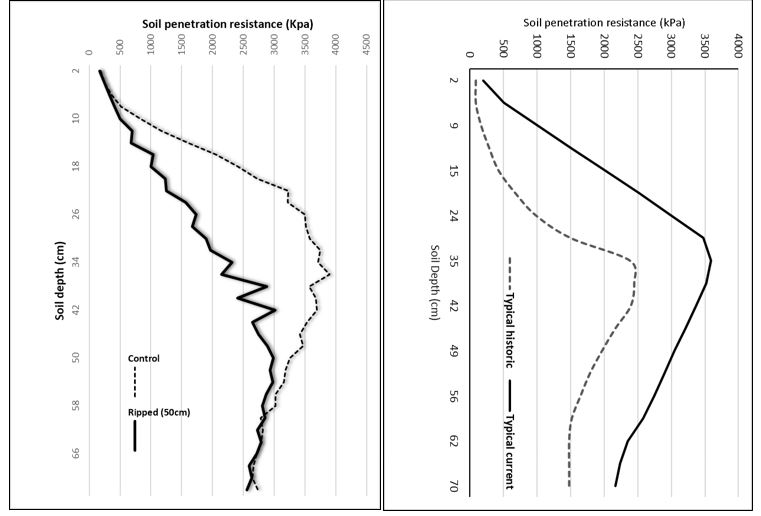

Figure 1. Plots showing penetration resistance for a sandy soil at Loxton, South Australia (SA) (left), and typical historical (1980s) and current soil penetration resistance measures for deep WA sandy soils (right).

During the 1980s, peak soil strength in deep sands and sandy earths typically occurred at depths of 30 to 35cm and reached strengths of 2000 – 2500kPa as shown in Figure 1 (right). Since then, as farms have got larger and machinery sizes and axle loads have increased, the severity of the compaction problem has continued to worsen. Recent soil strength measurements indicate that peak soil strength now occurs at depths as shallow as 20cm, with strengths ranging from 3000 to 3500kPa (Figure 1 left and right). Therefore, when considering shattering soil compaction, deeper ripping past the compacted layer is recommended in order to maximise the benefits.

Crop responses to deep ripping

Reviews of deep ripping trials conducted 20-30 years ago have shown substantial benefits with cereal yield increases of 22 to 37% in the first year (Crabtree 1989; Davies et al. 2006; Jarvis 2000).

In recent experiments conducted in WA (Davies et al., 2017) during 2014 to 2016, ripping increased average wheat yields by 8% for shallow ripping (30 to 40cm), 35% for ripping to depths of 50cm or more, and 53% for deep ripping with topsoil slotting (Table 1). Topsoil slotting is produced when inclusion plates are bolted behind ripping tines with the top of the plate working 100mm below the soil surface, thereby keeping the ripping slot open while allowing topsoil to fall down towards the bottom of the slot.

Table 1. Crop yield responses to deep ripping at different depths and the impact of topsoil slotting (with inclusion plates). Trials conducted in WA during 2014 to 2016 (Davies et al., 2017).

Location, crop | Soil type | GSR (mm) | Control yield (t/ha) | Ripped 30-40cm | Ripped 50-70cm | Ripped 50-70cm + topsoil slotting | |||

|---|---|---|---|---|---|---|---|---|---|

Yield (t/ha) | % | Yield (t/ha) | % | Yield (t/ha) | % | ||||

Moora, canola | Loamy sand | 177 | 1.9 | 2.2 | 16 | 2.8 | 47 | 2.9 | 53 |

Wubin, wheat | Deep sand | 228 | 2.1 | 2.7 | 29 | 3.0 | 43 | - | - |

Binnu, wheat | Deep sand | 219 | 0.8 | 0.8 | 0 | 1.4 | 75 | 1.8 | 123 |

Binnu, wheat | Loamy sand | 219 | 2.1 | 2.1 | 0 | 2.8 | 33 | 3.6 | 71 |

Beacon, wheat | Sandy duplex | 240 | 3.8 | 3.9 | 3 | 3.5 | -11 | 4.5 | 15 |

Broomehill, wheat | Sandy duplex | 227 | 1.8 | 2.0 | 11 | 3.0 | 67 | - | - |

Munglinup, wheat | Sandy duplex | 280 | 3.6 | 3.6 | 0 | 3.6 | 0 | 4.2 | 17 |

Meckering, wheat | Sand over gravel | 323 | 2.7 | - | - | 3.4 | 26 | - | - |

Meckering, wheat | Deep sand | 323 | 2.4 | - | - | 3.4 | 46 | - | - |

Meckering, wheat | Sand over gravel | 323 | 2.2 | 2.5 | 15 | 3.0 | 38 | 3 | 38 |

Walkaway, lupin | Deep sand | 219 | 1.2 | - | - | 2.3 | 92 | - | - |

SA Mallee trials

Similar grain yield improvements with deep ripping (+60cm) were previously reported at Waikerie (McBeath et al., 2018). However, intervention to 60cm did not provide any significant yield benefits over a depth of 30cm at several other South Australian (SA) and Victorian (Vic) sites (Moodie et al., 2018; McBeath et al., 2019).

As part of this study five replicated field trials (Table 2) were conducted during the 2018 and 2019 cropping seasons on sandy soils across the SA northern and southern Mallee, and the upper Eyre Peninsula (UEP). Trial 1 (depth x spacing) was set up at Peebinga (2018 and 2019) and at Buckleboo (2019) to investigate the impact of depth of ripping and tine spacing on crop productivity and the longevity of the amelioration benefits.

Trial 2 was set up at Loxton as a crop rotation experiment with three different crop types (wheat, barley and field peas each year), with the aim of assessing which crop types respond best to deep ripping in the 1st, 2nd and 3rd year after amelioration.

Deep ripping treatments were imposed using a straight tine ripper on 11 May and 21 May 2018 at Loxton and Peebinga, respectively and at Buckleboo on 10 April 2019. Penetration resistance readings were taken on 7 August 2018 at both Mallee sites using a Rimik CP40 (II) cone penetrometer to estimate the magnitude and depth of compaction and the impact of the ripping treatments. The depth of compaction layer was measured around 18 – 20cm at Peebinga and Loxton in 2018. To get accurate data, penetration resistance measurements are recommended to be done when the soil moisture is at or near field capacity. Due to the nature of the season with inconsistent low rainfall, no measurements were taken in 2019 at all sites. In-season assessments of crop density, dry matter (DM) production, grain yield and quality were undertaken to understand the effect of ameliorating compaction in typical deep sands of the SA Mallee.

Table 2. Deep ripping locations and treatment details for 2018 and 2019 cropping seasons.

Year | Trial # | Location (crop) | Region | Treatments |

|---|---|---|---|---|

2018 | Trial 1 | Peebinga (barley) | southern Mallee | Depths (0, 20, 40, 60, 70cm) Tine spacings (Narrow = 30cm and wide = 60cm) |

Trial 2 | Loxton (wheat, barley, peas) | northern Mallee | Ripped (50cm) vs compacted (control) Tine spacing 50cm | |

2019 | Trial 1 | Peebinga (wheat) | southern Mallee | Depths (0, 20, 40, 60, 70cm) * Tine spacings (Narrow = 30 cm and wide = 60 cm) |

Buckleboo (barley) | upper EP | |||

Trial 2 | Loxton (wheat, barley, peas) | northern Mallee | Ripped (50cm) vs compacted (control) Tine spacing 50cm |

Growing season rainfall: 2018 Loxton (105mm), Peebinga (116mm); 2019 Loxton (93mm), Peebinga (152mm), Buckleboo (143mm).

With total growing season rainfall (GSR) ranging from only 93 to 152mm, crop growth and productivity were severely limited at all sites. However, visual and positive responses in crop establishment and biomass to ripping were evident throughout the growing season in all trials. No harvestable grain yield was achieved in field peas at the Loxton site for 2018 and 2019 because of severe frost which resulted in pod damage.

Despite the dry conditions and poor yields, the trials demonstrated that ameliorating compacted sandy soils in low rainfall environments can lead to substantially improved crop biomass (data not shown) and grain yield in cereals. Deep ripping increased wheat yields by up to 135% for shallow (20-40cm) ripping, and up to 235% for deeper ripping to depths of 50cm or more. Barley grain yield was increased by up to 93% for shallow (20-40cm) ripping, and up to 193% for deeper ripping to depths of 50cm or more (Table 3). Only shallow ripping did not cause large grain yield gains.

Table 3. Deep ripping trials conducted during 2018 and 2019, showing grain yield responses to ripping at varying depths and tine spacings.

Year | Location | Crop | Tine spacing (cm) | Control | Ripped 20cm | Ripped 40cm | Ripped 50cm | Ripped 60 - 70cm | ||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

Yield (t/ha) | Yield (t/ha) | % change | Yield (t/ha) | % change | Yield (t/ha) | % change | Yield (t/ha) | % change | ||||

2018 | Loxton | Wheat | 50 | 0.58 | * | * | * | * | 0.69 | 19 | * | * |

Loxton | Barley | 50 | 0.54 | * | * | * | * | 1.08 | 100 | * | * | |

Peebinga | Barley | 30 | 0.27 | 0.46 | 70 | 0.52 | 93 | * | * | 0.79 | 193 | |

Peebinga | 60 | 0.23 | -15 | 0.43 | 59 | * | * | 0.77 | 185 | |||

2019 | Loxton | Barley | 50 | 0.13 | * | * | * | * | 0.18 | 38 | * | * |

Loxton | Wheat | 50 | 0.22 | * | * | * | * | 0.56 | 155 | * | * | |

Peebinga | Wheat | 30 | 0.2 | * | * | 0.47 | 135 | * | * | 0.67 | 235 | |

Peebinga | 60 | 0.28 | 40 | 0.29 | 45 | * | * | 0.62 | 210 | |||

Buckleboo | Barley | 30 | 2.13 | 2.79 | 31 | 2.88 | 35 | * | * | 3.35 | 57 | |

Buckleboo | 60 | 2.38 | 12 | 3.46 | 62 | * | * | 3.33 | 56 | |||

n.b. *no statistically significant response (i.e. no different to the control).

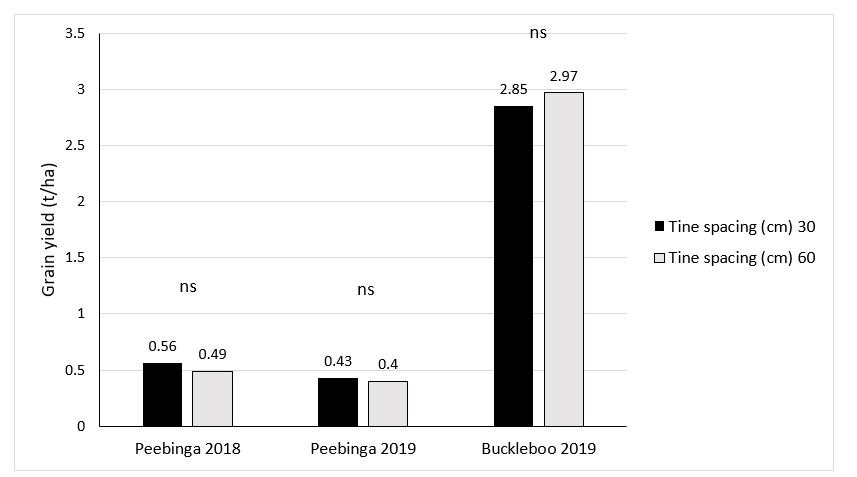

Averaged over all ripping depths, deep ripping with tines spaced at 30cm resulted in a significant increase in early and late shoot DM (data not shown). However, this benefit did not carry through to grain yield (Figure 2). Deep ripping has the potential to promote early biomass growth but in moisture limited environments, one of the greatest potential downsides associated with deep ripping is that it increases the risk of ‘haying off’ when soil water reserves are low and the finish to the season is dry (Davies et al., 2017). In some situations, faster water use and increased vegetative biomass caused by deep ripping can leave inadequate stored soil water for grain filling resulting in ‘haying off’ and reduced yields.

Figure 2. Mean cereal grain yield (t/ha) on 30cm and 60cm tine spacing at Peebinga and Buckleboo

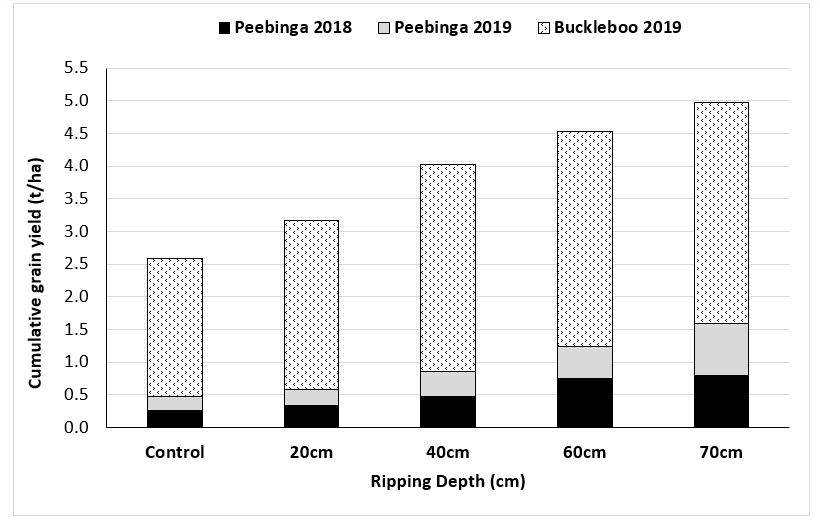

There was a consistent trend of increasing grain yield with increasing ripping depth across all sites in the two years of conducting these trials (Figure 3). But the cumulative grain yields over the two seasons showed that the deepest ripping treatment (70cm) achieved the highest yield. This is attributed to increased plant root growth, and increased access to nutrients and water down the soil profile. Similar results of improved grain yields with deeper ripping have generally been reported by several authors (Davies et al., 2017; Isbister et al., 2018; McBeath et al., 2018; McBeath et al., 2019; Moodie et al., 2018). However, it is important to note that the highest yielding treatment does not necessarily translate to the most profitable and most sustainable tillage strategy. In addition, the optimum depth of ripping will depend upon the depth of the compaction. For example, there is point in ripping to 70cm if the compacted layer is only between 20 and 30cm.

Figure 3. Cumulative cereal grain yield (t/ha) at Peebinga (2018, 2019) and Buckleboo (2019).

Economics of deep ripping

Economics are an important factor when evaluating whether an amelioration strategy should be implemented on farm or not. Soil amelioration is often costly, so it is necessary to have significant and long-term benefits to achieve a good return on investment. Physical interventions like deep ripping have the potential to improve crop productivity in compacted sandy soils, but there is a risk of low returns in low rainfall seasons. Our results from two years of conducting ripping depth x tine spacing trials are showing that better returns are achieved when deep ripping is achieved below 60cm (Table 4). If a narrow tine spacing is being considered, then going deeper than 60cm may not give the best economical return in the first year because the yield gain and extra income may not outweigh the extra cost of ripping further down the soil profile. However, the two years of data from Peebinga showed that by ripping down to 70cm, the marginal benefits in the second year (2019) improved by more than 100%, compared to shallow ripping. There is no evidence from our data of a drop off in yield in the second year after ripping, which implies that the benefits of deep ripping could extend into the third year and beyond, improving the economic returns even more.

Table 4. Summary of marginal economic benefits from deep ripping at Peebinga (2018, 2019) and Buckleboo (2019).

Tine spacing (30cm) | Tine spacing (60cm) | ||||||||

|---|---|---|---|---|---|---|---|---|---|

Depth (cm) | 20 | 40 | 60 | 70 | 20 | 40 | 60 | 70 | |

Estimated cost ($/ha)* | 40 | 60 | 90 | 100 | 30 | 50 | 70 | 80 | |

Peebinga 2018 | Yield change from control (t/ha) | 0.19 | 0.25 | 0.56 | 0.48 | -0.04 | 0.16 | 0.42 | 0.57 |

Value of extra yield ($/ha) | 42 | 55 | 123 | 106 | -9 | 35 | 92 | 125 | |

Marginal benefit ($/ha) | 2 | -5 | 33 | 6 | -39 | -15 | 22 | 45 | |

Peebinga 2019** | Yield change from control (t/ha) | 0 | 0.27 | 0.3 | 0.62 | 0.08 | 0.09 | 0.26 | 0.57 |

Value of extra yield ($/ha) | 0 | 78 | 87 | 180 | 23 | 26 | 75 | 165 | |

Marginal benefit ($/ha) | 0 | 78 | 87 | 180 | 23 | 26 | 75 | 165 | |

Buckleboo 2019 | Yield change from control (t/ha) | 0.58 | 0.67 | 1.34 | 0.94 | 0.17 | 1.25 | 0.82 | 1.42 |

Value of extra yield ($/ha) | 145 | 168 | 335 | 235 | 43 | 313 | 205 | 355 | |

Marginal benefit ($/ha) | 105 | 108 | 245 | 135 | 13 | 263 | 135 | 275 | |

*Estimated cost of deep ripping extrapolated from Davies et al., 2017.

**Cost of deep ripping has only been factored in once in 2018, and therefore, the value of extra yield in 2019 is the same as the marginal benefit in 2019 because there is no cost associated with ripping.

Assumptions. Price of wheat @ $250/t (2018), $290/t (2019), and barley @ $220/t (2018), $250/t (2019) (Source: AWB Daily Contract Prices, Mallee and and South East SA, Jan 2020, AWB Daily Contract Prices, SA, Jan 2020)

Tackling more than just one constraint

Our experiments have focused only on the physical intervention of deep ripping to ameliorate subsoil compaction, however, other research has acknowledged that tackling more than one constraint is better in the long run to improve and sustain crop yields, particularly on sands in medium to low rainfall environments. Trials in the WA wheatbelt have found deep ripping combined with topsoil slotting with inclusion plates can increase yields from sandy soils by more than deep ripping alone. The aim of this topsoil slotting is to improve root growth into the subsoil by providing a nutrient and organic matter rich pathway through infertile subsoil layers, to overcome aluminium toxicity associated with subsoil acidity and to improve the longevity of the ripping benefit. At Meckering WA in 2016, shallow ripping of pale sand over gravel increased wheat grain yield by 11% (320kg/ha), while the addition of topsoil slotting increased the yield by 26% (560kg/ha) over the control (Davies et al. 2017). It is likely that the organic rich topsoil will help prevent re-compaction, and research is continuing to investigate if topsoil slotting will improve the longevity of the benefits of deep ripping.

Ripped soil can be very soft and susceptible trafficking issues for field operations. To maximise the benefits of deep ripping and minimise risks of re-compaction, adopting a controlled traffic farming (CTF) system should be considered. CTF is system built on permanent wheel tracks where the crop zone and traffic lanes for seeding, spraying and harvest are permanently separated. For many deep sandplain soils, deep ripped areas can remain soft for at least four to five years in controlled traffic systems (Davies et al., 2017), and the benefits of deep ripping can be maximised (Wilhelm et al., 2018).

Other research activities are investigating alternative methods to overcome a range of soil constraints including acidity and water repellency to further improve grain yield with cost effective soil modification and ameliorants (Masters and Davenport 2015, McBeath et al. 2018). Common modifications and ameliorants being investigated include delving and spading, and incorporating gypsum, lime, clay, fertilisers or organic matter. However, with all of these soil amelioration strategies it is important to take into consider practices to minimise the risk of wind erosion, especially on sandy soils with low amounts of stubble cover.

Conclusions

Slow and restricted crop root growth caused by subsoil compaction can often reduce uptake of water and nutrients and poor growth, yields and profits, while increasing the risk of erosion Soil amelioration using strategic deep ripping is costly and time consuming and multiple constraints may occur variably within a paddock, so careful diagnosis of compaction is critical to targeting the right practice in the right location.

Our trials in the dry 2018 and 2019 seasons have shown that ameliorating compacted sandy soils in low rainfall environments of SA often improves crop biomass and grain yield significantly. Ripping with narrow tine spacing (30cm) or wide tine spacing (60cm) gave similar outcomes in terms of grain yield responses, therefore wider tine spacings of 50-60cm which require less fuel and machinery horsepower should be considered.

Ongoing research is showing that deep ripping alone may not be the ultimate strategy to improving soil productivity and crop performance. Where water repellency, acidity, other constraints occur in conjunction with compaction, other practices could improve the longevity of benefits and overall returns on investment.

Acknowledgements

The research undertaken as part of this project is made possible by the significant contributions of growers (Gum-Peebinga, Schaefer-Loxton, Baldock-Buckleboo) through both trial cooperation and the support of the GRDC, the author would like to thank them for their continued support. SAGI for statistical analysis and support.

References

Crabtree W (1989). Cereal grain yield responses to deep ripping on duplex soils. Australian Journal of Experimental Agriculture 29: 691-694.

Davies SL, Gazey C, Gilkes RJ, Evans DJ, Liaghati T (2006). What lies beneath? – understanding constraints to productivity below the soil surface. 2006 Regional Crop Updates, Geraldton, Department of Agriculture and Food, Western Australia.

Davies S, Parker W, Blackwell P, Isbister B, Better G, Gazey C, and Scanlan C (2017). Soil amelioration in Western Australia. (Department of Agriculture and Food, Western Australia) | Date: 07 Feb 2017.

Hamblin A, Tennant D and Cochrane H (1982). Tillage and the growth of a wheat crop in a loamy sand. Australian Journal of Agricultural Research 33: 887-897.

Hamblin A, Richards Q and Blake J (1988). Crop growth across a toposequence controlled by depth of sand over clay. Australian Journal of Soils Research 26: 623-635.

Isbister B, Blackwell P and Hagan J (2018). The changing options for soil compaction management. GRDC Grains Research Update. GRDC Project Number: DAW243.

Jarvis RJ (2000). Deep tillage. In ‘The Wheat Book: Principles and Practice’. Eds. WK Anderson and JR Garlinge. pp. 185-187. Agriculture Western Australia, Bulletin 4443.

Masters B and Davenport D (2015). Overcoming subsoil constraints to increase soil carbon on Eyre Peninsula soils. In 'Eyre Peninsula Farming Systems 2015 Summary'. Eds. B Dzoma. Pp 205 – 208. (South Australian Research and Development Institute: Minnipa).

McBeath T, Macdonald L, Desbiolles J, Llewellyn R, Moodie M, Davoren B, Shoobridge W (2018). Options to Manage Underperforming Mallee Sands- SA Mallee Trials. - Options to Manage Underperforming Mallee Sands - SA Mallee Trials

McBeath T, Macdonald L, Llewellyn R, Gupta V, Desbiolles J, Moodie M, Trengove S and Sheriff S (2019). Getting the edge on improving crop productivity on Southern sandy soils. Perth GRDC Updates.

Moodie M, Macdonald L, Correll R (2018). “Ripping” results from Mallee Sandy Soils trials.Ripping Results from Mallee Sandy Soils Trials

Paterson C, Sheppard W (2008). Soil compaction trials 2006-2008. In 'Eyre Peninsula Farming Systems 2008 Summary'. Eds. N Scholz, A Cook, A Frischke, N Wilhelm, M Bennet, C Paterson, D Brace and L Guerin. pp. 159-162. (South Australian Research and Development Institute: Minnipa).

Wilhelm N, Fisher P, Bluett C and Mitchell R (2018). Trafficking a heavy Minnipa soil does not hurt crop production but beware on deep sands. In 'Eyre Peninsula Farming Systems 2018 Summary'. Eds. B Masters: pp 108 – 110 (South Australian Research and Development Institute: Minnipa).

Contact details

Bernard Brian Dzoma

Research Agronomist

SARDI

Loxton Research Centre.

1801 Bookpurnong Road, Loxton, SA 5333

0455 071 032

brian.dzoma@sa.gov.au

GRDC Project Code: DAS00169-BA,

Was this page helpful?

YOUR FEEDBACK