The how’s and whys for ripping deep sandy soils of the low rainfall Mallee

The how’s and whys for ripping deep sandy soils of the low rainfall Mallee

Author: Michael Moodie (Frontier Farming Systems), Chris Saunders and Mustafa Ucgul (University of South Australia), and Lynne Macdonald (CSIRO Agriculture & Food). | Date: 25 Feb 2020

Take home messages

- Consistent first-year yield responses to deep ripping have been measured on Victorian Mallee sandy soils, with yield benefits commonly 0.5 to 1.0 t/ha in the first season following deep ripping.

- Yield responses to deep ripping have not been improved through additional inputs of fertiliser or organic matter (OM) on sandy soils in the Victorian Mallee.

- There are opportunities to optimise tine spacing, power requirements and operating costs of ripping and inclusion operations, through improving our understanding of the interaction between soil loosening, shank design and working depth.

Background

Sub-optimal productivity is commonly reported for the deep sands that make up 20 to 30% of the cropping soils in the low rainfall Mallee region of Victoria (Unkovich, 2014). There is evidence of unused soil water, despite an apparent absence of constraints commonly associated with sandy soils (such as non-wetting, soil acidity). Diagnostic studies of local constraints have pointed to low abiotic and biological fertility in the subsoil layers, and to the physical restriction of rooting depth, as the most likely constraints to production on sands in the Victorian Mallee.

There is considerable interest in strategic deep tillage with/without agronomic amendments (fertilisers, organic amendments) aimed at overcoming physical constraints and increasing nutrient supply within the soil profile. Strategic deep tillage includes ripping or deep ploughing (that is; spading, plozza, inversion) to depths of 30cm and more. To explore this further, replicated trials have been established across four sites in the Victorian Mallee; Ouyen (2017), Carwarp (2018), Kooloonong (2019) and Tempy (2019), with further sites to be established in 2020. These trials are part of the research and validation work within the GRDC project; ‘Increasing production on sandy soils in the low-medium rainfall areas of the southern region’ (CSP00203). The trials are a collaboration between Frontier Farming Systems with Mallee Sustainable Farming, CSIRO and UniSA.

Although the benefits of deep ripping in deep sandy soils have been recognised previously, there is a need to understand where ripping can most reliably lead to yield benefits, how benefits can be maximised over multiple season, and which sands are less likely to respond. There are opportunities to optimise machinery set-up and operating parameters (speed, depth, fuel consumption) and to understand how tine design influences constraints within the profile over multiple seasons. Improving this information will help inform grower decision making to better target soil amelioration practices.

Method

Yield response in the Victorian Mallee to deep ripping

Nutrient placement (Ouyen, 2017-19)

The trial had three key factors; the depth of placement (surface band at 7.5cm deep, deep band at 20cm deep and deep ripped band at 30cm deep), the nutrient source (N only or a package of N, P, K, S, Zn, Cu, and Mn) and the frequency of addition (all in 2017, or an annual approach of equivalent total input) supplying 90kg N/ha in total. All plots received an annual baseline addition of 20kg N/ha as di-ammonium phosphate (DAP) at sowing and an early top-dress application of ammonium sulphate.

Organic matter placement (Carwarp, 2018-2019)

This trial compared the impact of physical intervention alone (deep ripping, spading or a combination of the two), to physical intervention combined with incorporation or deep placement of lucerne hay (6t/ha) (Table 1). For incorporation, lucerne hay was surface spread before spading; while for direct subsoil placement the same lucerne material was pelletised and metered at a controlled rate at depth behind the rip tine. Deep ripping operations were completed with a Tilco® ridged shank at 56cm spacing and spading operations were completed with Farmax spader supplied by Groocock Soil Improvement.

Table 1. Treatments included in the organic matter (OM) placement trial at Carwarp, established 2018.

Treatment | Physical disturbance | Depth of disturbance (cm) | OM addition (6t/ha lucerne) | Depth of OM placement (cm) |

|---|---|---|---|---|

Control | Nil | Nil | +/- | Surface |

Spade Deep rip_30 Deep rip_60 Deep rip_30/60 | Rotary spade Deep rip Deep rip Deep rip | 30 30 60 60 | +/- +/- +/- +/- | Surface-30 30 60 30+60 |

Spade + deep rip_60 | Rotary spade + deep rip | 30+60 | +/- | Surface-30 + 60 |

Deep ripping with organic matter inclusion (Tempy, 2019)

The Tempy trial had five treatments (details below) to compare deep ripping only with inclusion plates and OM addition. All deep ripping treatments were implemented to a depth of 50cm with a tine spacing of 56cm. The OM used was a chicken litter compost blend, applied at 5t/ha (Peats Soil & Garden Supplies), in the following treatments;

- control (undisturbed)

- deep ripping (50cm) with rigid shank (Tilco)

- deep ripping (50cm) with inclusion plate (Tilco) operating 150mm below soil surface

- deep ripping (50cm) with inclusion plate (Tilco) plus OM surface applied

- deep ripping (50cm) with OM deep placed behind the ripping shank.

Break crop response to deep ripping and organic matter (Kooloonong, 2019)

The Kooloonong trial was established for each of the break crops tested; lupin, lentil and chickpea. Each trial comprised of four treatments arranged in a factorial design;

- +/- deep ripping (50cm depth with tine spacing of 56cm)

- +/- surface OM application at 5t/ha (chicken litter compost blend Peats Soil & Garden Supplies).

Optimising deep ripping operations

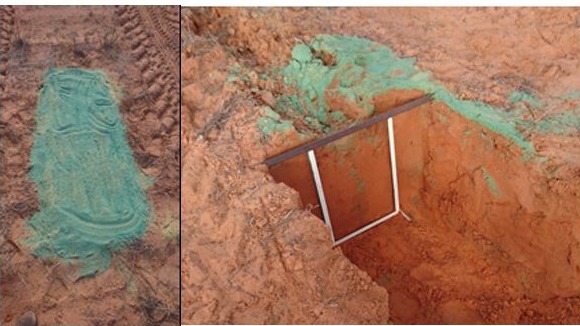

Complementing the agronomic field trials, University of South Australia researchers are using computer simulation and field validation to understand how different set-up and operating parameters affect the performance of deep tillage strategies. Computer simulations have highlighted that forward (driving) speed was likely to have a large impact on the burial performance of commercially available inclusion plates. A range of experimental inclusion plates were manufactured and compared to a standard commercially available plate at two operating speeds in a trial near Caliph, SA Mallee, in June 2019. The soil type was a red sand with 1.6g/cm3 average soil bulk density from 0-400mm and 3% average moisture content over the same depth range. The validation of the surface layer burial was carried out by applying a blue layer of sand to the surface in front of the tine (Figure 1).

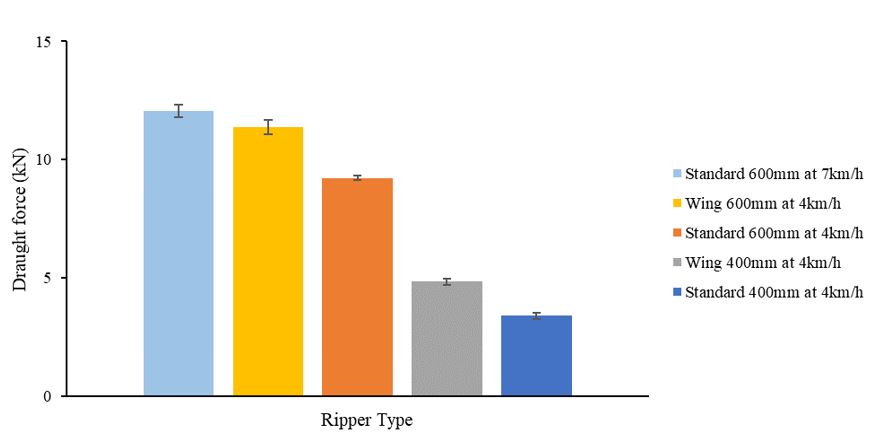

The forces required to pull the standard ripper tine and each of the inclusion plates was also measured. Draught forces were measured using a pull type RIMIK brand pull-meter. The pull-meter was used between two tractors (a draught tractor pulling a free-wheeling, ripper operating tractor) to avoid side and vertical loading, ensuring that the load cell measured pure tension with no side-loading.

Figure 1. Blue sand applied to the surface to validate soil burial behind inclusion plates.

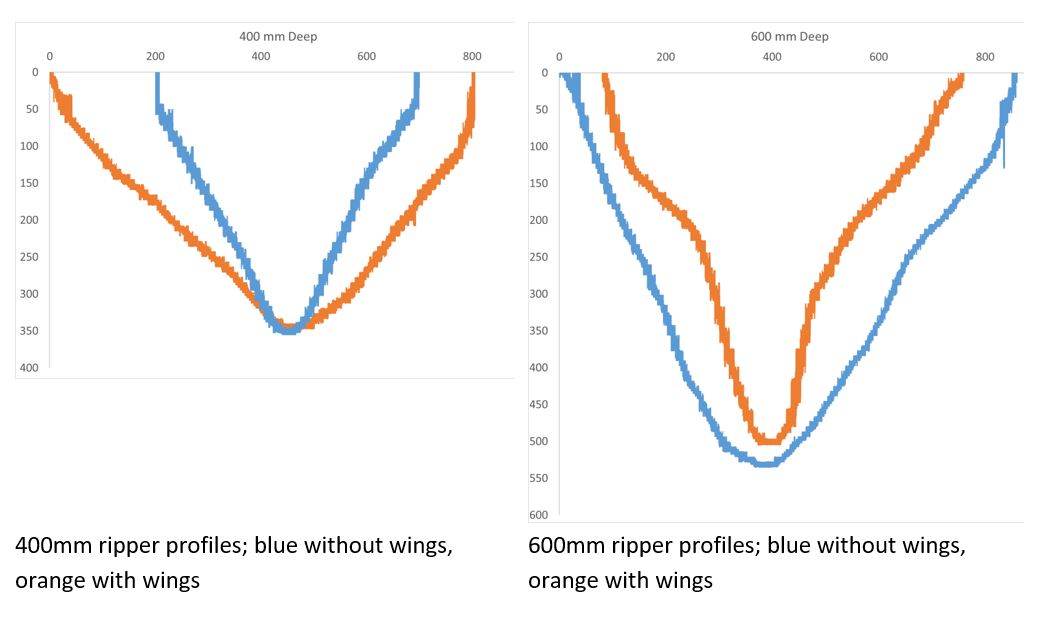

The research also aimed to quantify the impact of shank working depth and design on soil loosening performance in the compacted sandy soils. Tines tested included with and without wings (Figure 2), and measurements included differences in relevant draught forces (RIMIK pull-meter) and in soil disturbance profiles. After ripping operations, face pits were excavated across the direction of travel to visualise and refine the loosened cross-sectional area (Figure 3). Digital image analysis was used to quantify the profile area loosened across different test treatments.

Figure 2. Ripper tine (left) and ripper tine with wings (right).

Figure 3. Excavated pit with a rope defining the boundary of the loosened soil area.

Results and discussion

Yield response in the Victorian Mallee to deep ripping

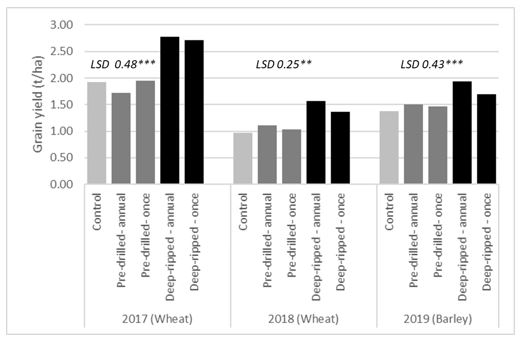

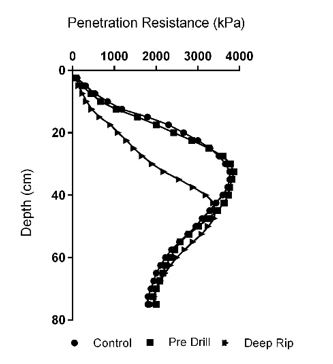

Positive yield benefits were observed across all four trial sites in the first season following deep ripping. At the Ouyen trial (2017, year 1) deep ripping (~30cm) provided a yield benefit of 0.8t/ha over the control and pre-drilling treatments (Figure 4). This result reflected a reduction in penetration resistance under the deep ripped treatments (Figure 5). Pre-drilling (20cm depth) did not reduce the sands penetration resistance, as the narrow tine and knifepoint used had a slotting effect and did not disrupt soil strength like the deep ripping implement (Agroplow deep ripping shank with a wide foot).

Following the single ripping event at Ouyen (2017), significant yield benefits were observed for two subsequent seasons, but not in the third season, providing a cumulative benefit of 1.5t/ha. Where ripping was repeat applied on an annual basis, positive yield responses were observed in all three seasons (Figure 4), with cumulative benefit over the control of 2t/ha.

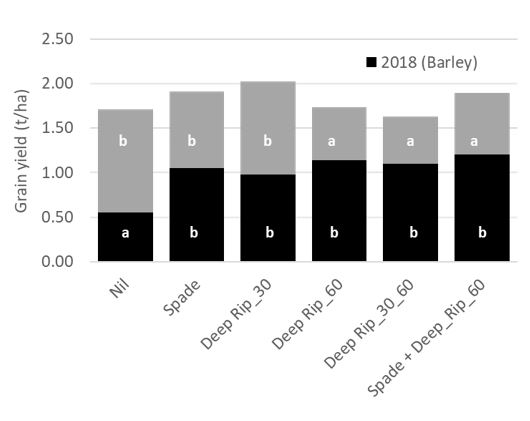

In the first year of the Carwarp trial, mechanical disturbance to 30cm by rotary spading or deep ripping resulted in additional grain yield of 0.5t/ha compared to the unmodified control yield of 0.55t/ha (Figure 6). Deeper ripping to 60cm did not provide a significant yield increase over working to a depth of 30cm only. These responses were observed under very low growing season rainfall, with only 75mm of rain received post sowing. Another drought was encountered in 2019 with similar low rainfall during the growing season and very little rainfall over the summer fallow. Consequently, a negative yield effect of 0.5-0.6t/ha was observed in treatments where deep ripping was conducted to 60cm in the previous season. The mechanism of this result is not clear and is still being explored.

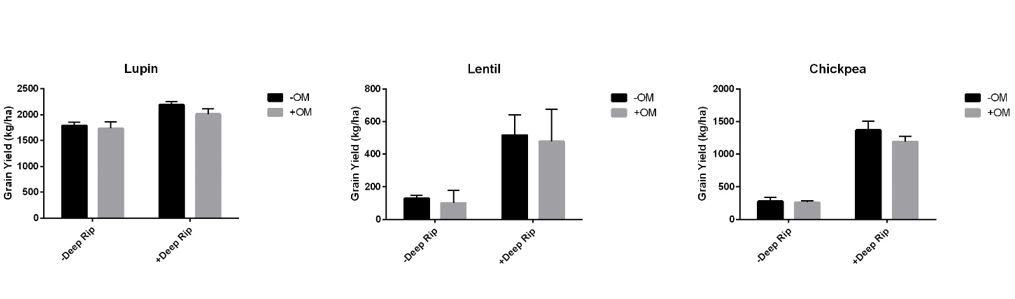

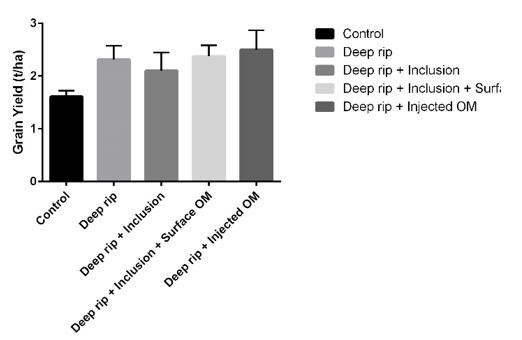

In 2019, new sites were established at Kooloonong (Figure 7) and Tempy (Figure 8) demonstrating yield gains across several crop types. Comparing grain legumes at Kooloonong, deep ripping significantly increased the yield of lupin, lentil and chickpea by 0.4, 0.4 and 1.0 t/ha respectively. At Tempy, deep ripping provided a 0.7t/ha increase in barley yield over the control, however adding inclusion plates did not provide any advantage over deep ripping with a ridged shank tine.

While deep ripping has provided clear benefits across these four trial sites, the addition of inputs such as OM or additional fertiliser is yet to show consistent and/or economic benefits. Improving inputs over and above good agronomic practice through, subsoil placement (30cm or deeper) of nitrogen or a broader nutrient package (P, K, S, Zn, Mn, Cu) did not provide a yield benefit at Ouyen. A sister trial at Ouyen, looking at the incorporation of organic inputs with rotary spading, has shown a positive response to the addition of chicken litter and compost (Moodie et al. 2019). However, this effect was unable to be replicated with similar organic inputs at the Tempy and Kooloonong sites in 2019. Lucerne hay was used as an organic source at Carwarp with no positive yield impacts observed across the first two, albeit very dry, years of the trial.

Figure 4. Grain yield (t/ha) response at Ouyen to pre-drilling or deep ripping implemented prior to sowing in (once) or in each season (annual). Only the control treatments are presented which all had equivalent rates and placement of nutrient.

Figure 5. Penetration resistance (kPa) measured at the Ouyen site in 2017 for the control, pre-drill and deep rip treatments.

Figure 6. Grain yield (t/ha) response at the Carwarp site to deep ripping and spading treatments without organic matter (OM) addition over two seasons (2018 and 2019).

Figure 7. Grain yield of lupin, lentil and chickpea at Kooloonong in 2019 in response to deep ripping and organic matter (OM) addition. Error bars are standard error of mean (SEM).

Figure 8. Grain yield of barley in response to treatments implemented at Tempy in 2019. Error bars are standard error of mean (SEM).

Optimising deep ripping operations

There is considerable interest in ripper modification through fitting inclusion plates to the back of the ripping shank. Inclusion plates aim to improve subsurface fertility by creating a void behind the ripping shank, which topsoil, surface residues, and surface spread amendments fall into.

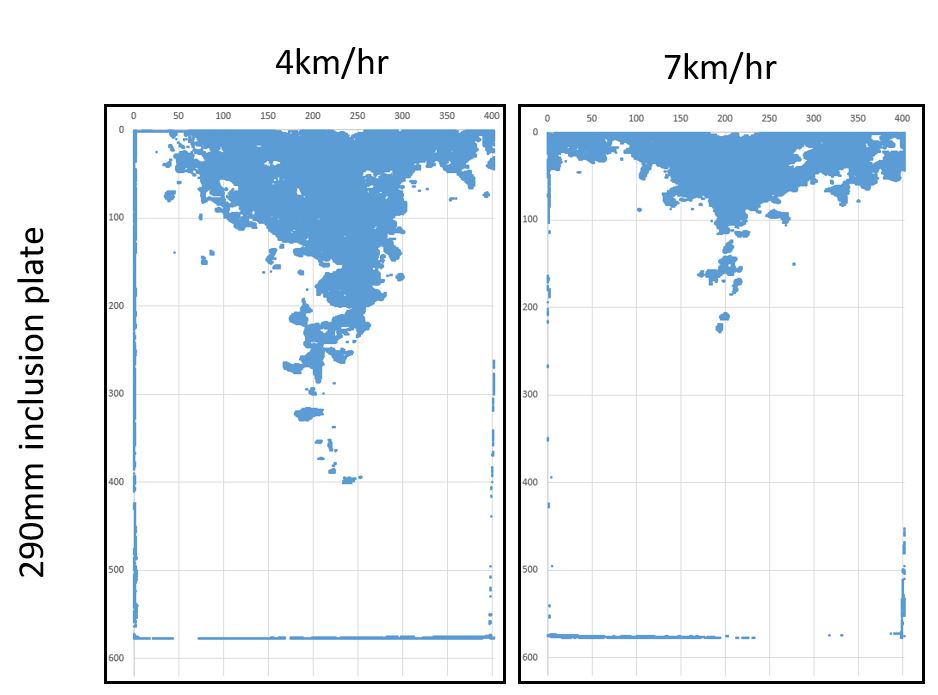

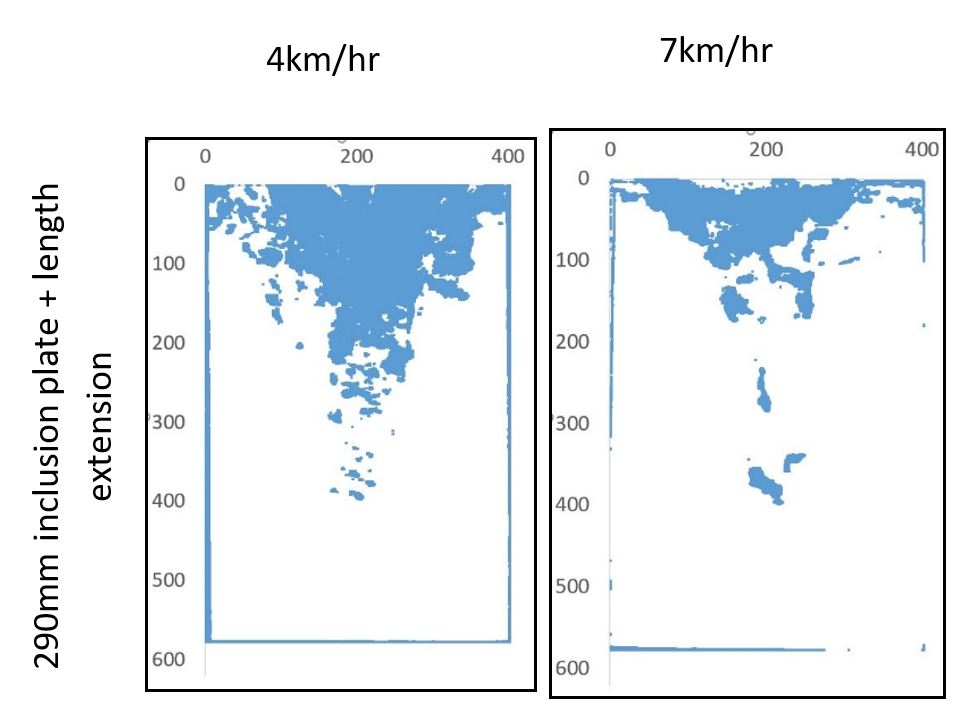

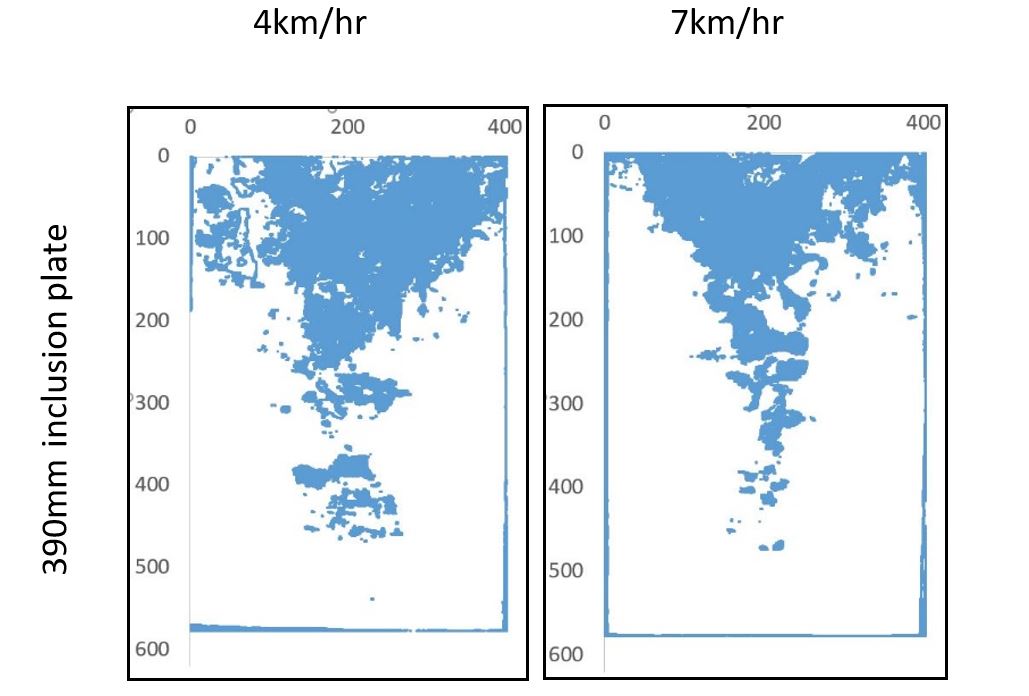

Incorporation of surface material behind a standard (280mm) commercial inclusion plate is greatly affected by speed of operation, where higher speeds lead to lower burial (Figure 9). Modification of inclusion plates, such as increasing the length of the side wall (plus 150mm), can lead to improved burial at higher speed operation ( such as 7km/hr), as demonstrated comparing Figures 9 and 10. Further modification to the plate (390mm high and 650mm long) improved depth and quantity of included surface layer (Figure 11).

In relation to the forces required to pull these inclusion plates, adding an inclusion plate always led to an increase in draught force to pull the ripper. Increased draught forces were in the order of 40%, but the improved burial inclusion plates only increased the draught force an additional 12% and 15% at 4km/h and 7km/h respectively. Increasing draught forces will also increase power and fuel requirements associated with the operation.

Figure 9. Topsoil inclusion using a standard 290mm high inclusion plate at 4km/h and 7km/h.

Figure 10. Topsoil inclusion using a 290mm inclusion plate with 150mm length extension at 4km/h and 7km/h.

Figure 11. Topsoil inclusion using a 390mm inclusion plate with 150mm length extension at 4km/h and 7km/h.

Ripping shank design and working depth will influence profile loosening impact, power requirements, and the cost of ripping. Adding an experimental wing to the ripping shank increased loosening areas by about 49% to 53% when operating depth was 400mm and 600mm respectively (Figure 12). Increasing working depth from 400 mm to 600 mm increased the area of loosened soil by about 70% (Figure 12). Considering power and cost implications, working at 600mm depth, the wing addition increased loosening by ~50%, but the draught force increased by only 24% (Figure 13). Improving our understanding of the interaction between soil loosening, shank design, and working depth will help optimise tine spacing, power requirements and operating costs.

Figure 12. Comparing ripper loosened area, with and without the addition of wings.

Figure 13. Draught force of ripper tines, with and without wings

Conclusion

The primary constraints to crop water-use in deep sandy soils of the Victorian Mallee appear to include physical barriers to root growth and nutrient supply in the subsoil layers. Acidity, strong repellence, and subsoil toxicity are not primary constraints at the focus research sites in this project. Provided there is reliable subsoil moisture, ripping to a depth beneath hard compacted layers provides a good starting place for growers aiming to improve under-performance. Deep ripping provides more consistent yield responses compared to combined approaches, looking to physically ameliorate and boost profile fertility through incorporation of high N organic amendments. Growers should consider the depth of the constraint and choose a ripper which can work into, and under, compacted and consolidated layers. Deeper ripping operations, requiring greater draught, are more costly and do not necessarily lead to higher yield benefits. Use of inclusion plates for burial of surface material have not provided consistent yield benefits above ripping alone, and significantly increase draught and operation costs. There are opportunities to optimise tine spacing, power requirements and operating costs of ripping and inclusion operations through improving our understanding of the interaction between soil loosening, shank design, and working depth.

Acknowledgements

This research is a collaborative project between the GRDC, CSIRO, the University of South Australia, the SA state government through Primary Industries and Regions SA, Mallee Sustainable Farming Inc, AgGrow Agronomy and Trengove Consulting. The research undertaken as part of this project is made possible by the significant contributions of growers through both trial cooperation and the support of the GRDC, the author would like to thank them for their continued support.

UniSA also acknowledge GRDC / DAFWA project (DAW00243) for supporting the computer simulations and Tilco Engineering for supplying modified inclusion plates.

Useful resources

Think strategically before ripping into sandy soils_GRDC

Advice to match design of inclusion plates to soil type for optimum effect_GROUNDCOVER

References

Moodie M, Macdonald L, Correll R (2019) Deep ripping: an effective first step to lift productivity on deep sands in the Victorian Mallee? In ‘Cells to Satellites’. (Ed J. Pratley). Proceedings of the 19th Australian Society of Agronomy Conference,25-29 August 2019, Wagga Wagga, NSW, Australia © 2019. (Agronomy Australia Proceedings).

Unkovich M (2014) A review of the potential constraints to crop production on sandy soils in low rainfall south-eastern Australia and priorities for research. A technical report for the Grains Research and Development Corporation, Mallee Sustainable Farming, Mildura, VIC.

Contact details

Michael Moodie

Frontier Farming Systems

7B Byrne Court, Mildura VIC 3500

0448 612 892

michael@frontierfarming.com.au

@Moodie_ag

Chris Saunders

Agricultual Machinery Research & Design (AMRDC)

School of Engineering, Mawson Lakes Campus, University of South Australia

08 8302 3664

chris.saunders@unisa.edu.au

@AgEngUniSA

GRDC Project Code: CSP00203,