NIR sensing and machine learning to rapidly assess crown rot in wheat

NIR sensing and machine learning to rapidly assess crown rot in wheat

Author: Jacob Humpal (USQ Centre for Agricultural Engineering), Cheryl McCarthy (USQ Centre for Agricultural Engineering), Cassandra Percy (USQ Centre for Crop Health) and J. Alex Thomasson (Texas A&M University) | Date: 03 Mar 2020

Take home messages

- Non-destructive sensing enables automated early detection of crown rot that previously could only be detected manually after the appearance of visual symptoms

- Machine learning models enhance classification results over traditional analysis techniques

- Near infrared sensing and machine learning models have potential to be deployed as a handheld or drone-based tool for both paddock-level disease detection and phenotyping

- Embracing new sensing technologies presents opportunities for rapid management decisions and site-specific application of inputs where most profitable.

Background

Wheat crown rot occurs in many arid and semi-arid cropping regions around the globe and can be responsible for up to a 40% yield reduction under conducive conditions. In severe cases crown rot can lead to necrosis of the stem, limiting grain production. Visual symptoms are late in the season with the appearance of white heads and stem browning. The lack of readily discernible visible symptoms causes delays in production decision-making, including input selection and timing, and potentially consumes resources in areas of the crop where productivity will be low. Improvements in disease identification, rapid phenotyping and decision making will help growers remain profitable and operations sustainable.

Currently, crown rot assessment involves physical removal of the plant from the soil followed by removal of the leaf sheaths around the lower internodes and visual colour assessment by trained assessors, for example an agronomist or consultant. This process is time consuming, labour intensive, impractical to perform across a field and prone to variation due to human bias and significant environment/pathogen interactions. A machine vision-based sensing system has potential to be used to objectively and rapidly assess disease incidence and severity with high repeatability.

This project aims to develop an automatic sensing system to identify and quantify crown rot in wheat using near infrared spectral signatures and machine learning techniques. The sensing system has intended application for rapid assessment and phenotyping of crown rot in breeding trials and automatic infield detection of diseased areas of crop on farms. Grower benefits are anticipated to be more rapid access to resistant varieties and enhanced ability for resource-saving decisions based on infield detection of crop disease.

A series of experiments were undertaken in glasshouse and field trials in Southern Queensland from 2018 to 2019 to evaluate the ability of non-invasive near infrared crop sensors and machine learning methods to detect and quantify Fusarium pseudograminearum in bread wheat.

Methods

Glasshouse trials were conducted at QDAF and USQ facilities in Toowoomba, QLD. In 2018 and 2019, five bread wheat genotypes were observed under positive or null inoculation with F. pseudograminearum colonised wheat grain, following the methodology outlined in Percy et al., 2012. Each treatment was replicated 6 times. Pots in the glasshouse trials were configured in randomised block designs and watered to field capacity. The glasshouse temperature was maintained at 20–25 degrees Celsius. Inoculum was applied individually to coleoptiles of each plant at the two-leaf stage.

Two field trials were conducted at the Tosari research station (-27.859964, 151.452766), planted in June of 2018 and 2019. Paired, inoculated and non-inoculated 6 m x 2 m plots were arranged in a strip plot design in a randomised block with three replications. F. pseudograminearum colonised millet inoculum was applied into the furrow above the seed at planting. Six randomly selected plants from each plot were chosen, corresponding to each of the five genotypes in the glasshouse trials.

Measurements were taken using a DLP® NIRscan™ Nano near infrared point sensor (Texas Instruments, USA) with a sensitivity of 900–1700 nm once a week throughout the growing season for nine weeks, from three weeks post inoculation. Technical issues caused data from the week 8 assessment of the first glasshouse trial to be lost. The maximum separation between all other measurement dates was 8 days. Sensor measurements were collected from the centre of the newest emerged tiller, the leaf determined to be centre-most and the youngest flag leaf. Calibration reflectance measurements were gathered from a 10% grey, a 60% grey and a 99% white reference Spectralon® panel.

Observed plants in both sets of trials were pulled at maturity and scored manually at the Centre for Crop Health for the presence and severity of F. pseudograminearum induced crown rot. Linear regression, clustering and neural net machine learning techniques were evaluated for effectiveness in discriminating and quantifying F. pseudograminearum induced crown rot in bread wheat. All analysis and model creation was performed in the Python computing environment (Python version 3.6.8; Python Software Foundation, 2019), using the SciPy ecosystem (Jones & Peterson, 2016) and the Scikit-learn library (Pedregosa et al., 2011).

Results and discussion

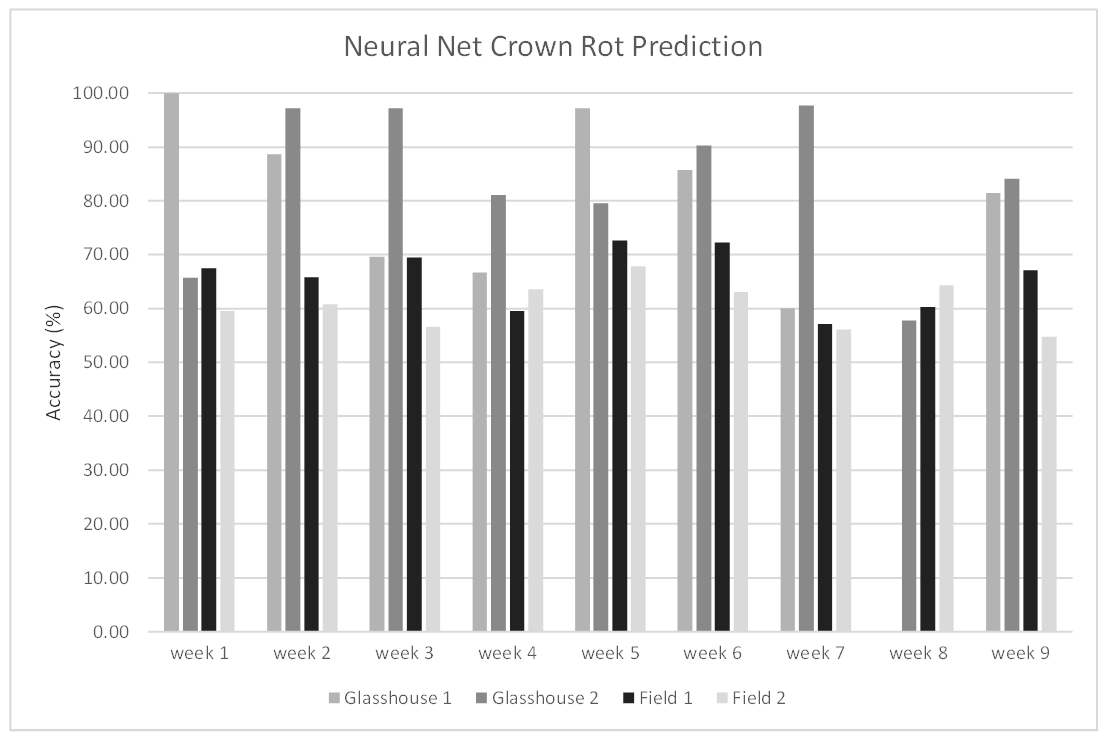

Machine learning models were compared for the ability to accurately discriminate crown rot at different timepoints from inoculation. The results achieve crown rot detection ability with accuracies ranging from 55–100%. The top performing machine learning model was an artificial neural network classifier (ANN), which performed with an accuracy of up to 100.00% under optimal glasshouse conditions (Figure 1). Lower classification accuracies were observed in the field trials and may be due to low levels of disease, particularly in genotypes with some resistance. Further analysis is being completed to determine the impact of low disease levels. Differences between the spectral signatures of inoculated and uninoculated treatments indicate that this sensing approach has potential to be scaled to a camera-based system. Further work is being conducted to establish operational requirements for a remote sensing system, for example on a UAV, which is an important step towards large-scale, automated disease discrimination.

The results of the near infrared-based, machine learning models show detection capability at three weeks post inoculation, allowing time to make production decisions. A near infrared imaging system provides potential for in-crop characterisation on a paddock level automatically and in real-time, where existing characterisation requires manual visual assessment or pre-sowing soil/stubble testing (e.g. PREDICTA®B) which can take days or weeks.

Early detection of crown rot is crucial to optimise operation profits by enabling growers to reduce inputs on affected paddocks and plan future rotations and management strategies. The estimated potential annual yield loss from F. pseudograminearum is 22.2% (Murray & Brennan, 2009), as such early detection allows for the reduction of costly inputs, such as foliar fungicides, foliar nitrogen application, or irrigation in dry seasons.

Additional advantages of near infrared sensing of crown rot exist to plant breeders and researchers providing further potential benefits to growers. Rapid phenotypic assessment of crown rot increases breeding company capacity to screen larger numbers of lines more efficiently, delivering improved germplasm to growers in less time.

Summary

Near infrared technology provides rapid, automated and non-destructive detection of crown rot that previously could only be performed manually through destructive methods by trained assessors. Embracing new non-invasive sensing technologies potentially enables rapid management decisions by reducing labour and time costs of disease detection. Further, near infrared technology potentially maximises profit by optimising input timing and restricting input application to the areas where the highest return on investment can be expected. The adoption of near infrared sensing by plant breeders may provide tools to more rapidly release resistant lines, providing further potential benefits to growers. Near infrared technology has the potential to be deployed as a handheld or drone-based sensor for rapid characterisation of paddock disease levels.

References

Jones, E, Oliphant, T and Peterson, P (2016). SciPy: Open source scientific tools for Python, 2001.

Murray, GM and Brennan, JP (2009). 'Estimating disease losses to the Australian wheat industry', Australasian Plant Pathology, vol. 38, no. 6, pp. 558-70.

Pedregosa, F, Varoquaux, G, Gramfort, A, Michel, V, Thirion, B, Grisel, O, Blondel, M, Prettenhofer, P, Weiss, R & Dubourg, V (2011). 'Scikit-learn: Machine learning in Python', Journal of machine learning research, vol. 12, no. Oct, pp. 2825-30.

Percy, C, Wildermuth, G & Sutherland, M (2012). 'Symptom development proceeds at different rates in susceptible and partially resistant cereal seedlings infected with Fusarium pseudograminearum', Australasian Plant Pathology, vol. 41, no. 6, pp. 621-31.

Python Software Foundation. Python Language Reference, version 3.6.8. Available at http://www.python.org

Acknowledgements

This PhD project has been funded by USQ through a Research Training Program stipend and USQ International Fees Research Scholarship. We would like to thank USQ-Centre for Crop Health in collaboration with the Grains Research Development Council for providing access to crown rot field sites and glasshouse trials.

Contact details

Jacob Humpal

University of Southern Queensland, Centre for Agricultural Engineering

P9 West St, Darling Heights QLD 4350, Australia

Ph: 0455 220 027

Email: jacob.humpal@usq.edu.au

® Registered trademark