The impact of harvest management in chickpeas – desiccation and front of header losses

Author: Richard Daniel, Linda Bailey, Denielle Kilby, Branko Duric, Richard Black and Lawrie Price (Northern Grower Alliance) | Date: 23 Jul 2020

Take home messages

- Generally minor impact from desiccant treatments or application timing on yield or grain quality

- Decisions on harvest management choice should be determined by cost, attitude to Ally® plant back restrictions, weed spectrum present at harvest and speed of desiccation required

- Delayed harvest at low % grain moisture caused more damaged and split grain than desiccant treatment or timing

- Ideally target desiccation at ~85-90% pod maturity and schedule harvest 7 days later to reduce grain quality issues

- Large levels of pod and grain losses were measured at the front of the header in four commercial evaluations (~100-200 kg/ha)

- Losses reduced by ~50-90 kg/ha when harvested with air assist or when brushes were attached to the reel

- Impact from the harvest modifications would have improved returns by $34-67/ha

- In the trials conducted in 2018 and 2019, this represented an additional 5-18% yield.

Background

Northern Grower Alliance have been researching two important aspects of chickpea harvest management during the period 2017-2019.

The first has been to evaluate the impact of desiccant choice and timing on yield and grain quality. The second has focussed on the magnitude of header losses and the impact on yield and economics from changes in harvest approach.

Desiccation evaluation 2017-2019

The area of focus has evolved over the three seasons:

2017 – 5 trials evaluating current and new desiccation tools to assist in refining management programs. Treatments included glyphosate alone, glyphosate + Ally (metsulfuron-methyl), glyphosate + Sharpen® (saflufenacil), Reglone® (diquat), Gramoxone® (paraquat) (refer to label and follow use pattern for chickpeas) and Gramoxone + Sharpen.

2018 - 4 trials continuing the original activity. An additional 3 trials focussed on impact of desiccation timing (application ~3, 2 and 1 week prior to ‘planned’ commercial harvest). In all three timing trials, treatments were also harvested after a 14-day delay. Treatments repeated from 2017.

2019 - 3 trials primarily focussed on the impact of desiccation timing (application at ~70%, 80% and 90% pods at physiological maturity). Harvest was conducted for all timings ~7 days after application. Similar treatments to 2017 and 2018 but replaced Reglone with glyphosate + Ally + Sharpen.

Pod maturity was assessed at each application on a minimum of 10 main branches. Pods were considered mature when a ‘yellow beak’ was starting to extend on the enclosed grains. This stage often corresponded with a purplish tinge appearing on the pod coat.

Key points - desiccation evaluation 2017-2019

Leaf discolouration and leaf drop (visual ratings)

- Treatments increased % leaf discolouration and % leaf drop compared to the untreated but without consistent differences between treatments across sites

- Improvements in % leaf discolouration and % leaf drop compared to the untreated were greatest in 2017 (where high levels of October rainfall encouraged crop regrowth) and generally lowest in 2019 at sites that matured very rapidly under high moisture stress.

- A ‘twist test’ was conducted to assess the % of plants where all stems snapped at harvest. This was done to provide an indication of stem ropiness or harvest readiness

- The most consistent treatments in 2017 and 2018 were the mixture of glyphosate + Ally or Gramoxone 250 + Sharpen. In 2019 there was no significant difference, in any trial, between any treatment and the untreated

- There was a positive dose response to glyphosate in 2017 and 2018 with increased stem snapping from the 1.8 L/ha rate (540 g ai/L formulation).

Stem dry down (physical rating)

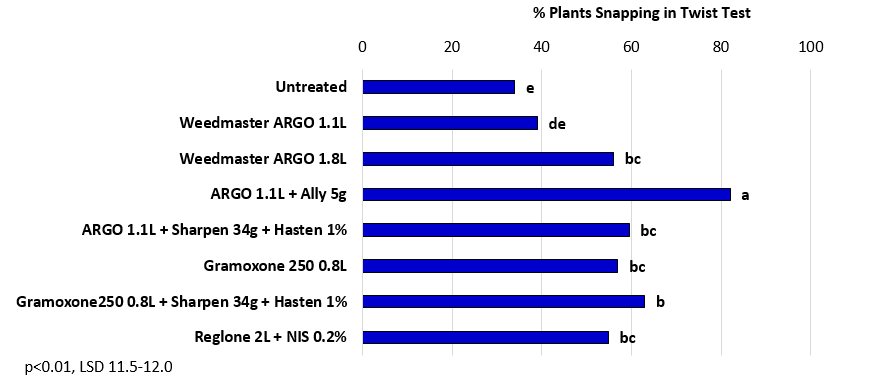

Figure 1. Stem twist test results 10-17 days after application, as an indication of stem dry down. (Mean of 5 trials 2017)

NIS = non-ionic surfactant

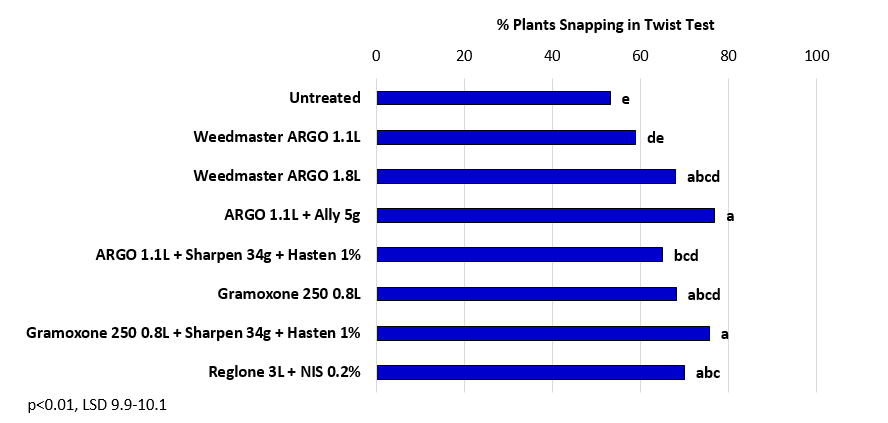

Figure 2. Stem twist test results 7-15 days after application, as indication of stem dry down.

(Mean of 4 trials 2018)

NIS = non-ionic surfactant

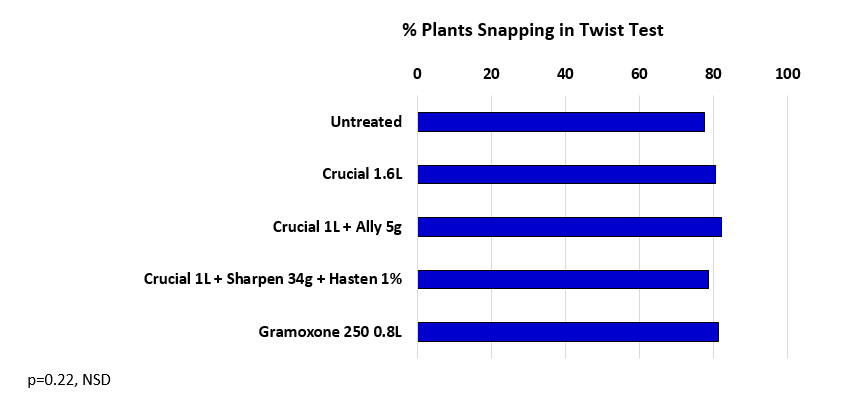

Figure 3. Stem twist test results 6-10 days after application, as indication of stem dry down.

(Mean of 3 trials 2019)

Yield

- In 14 of the 15 trials, there was no significant difference in yield between any treatment and the untreated

- In 2018, there was a significant reduction in yield from Gramoxone 250 at one site where the application was ~4 weeks prior to expected commercial harvest and then harvest was delayed by another 2 weeks. Crop stage at application was only 59% of pods at physiological maturity.

Grain quality (NIR and sievematic)

- Impact on grain quality was generally minor

- Test weight was significantly reduced in 2 trials in 2018 by Gramoxone 250 or Reglone when application occurred ~4 weeks prior to expected harvest. Crop stage at application was ~50-60% of pods at physiological maturity

- There was no significant impact on screenings from any desiccant treatment in 2018 (using a 4mm slotted screen as an indication of defective grain)

- Impact on grain moisture at harvest was minor with no significant difference between desiccant treatments and the Untreated in 12 of 15 trials. All treatments reduced grain moisture by ~1% in a 2017 trial where regrowth was evident and Gramoxone 250 significantly reduced harvest moisture at 2 of the 3 sites in 2019.

Grain grading (visual rating)

- Visual grain assessment on all trials from 2019 showed no significant impact from desiccant treatment or timing on the % green or yellow grain compared to untreated grain harvested at the same time

- In one trial, application of glyphosate alone at 70% of pods at physiological maturity reduced the percentage of mature grain by ~2% and increased the percentage damaged grain by a similar amount. There was no significant impact when glyphosate was applied at 90% pod maturity.

Germination

- Germination tests were conducted on seed samples from application timing trials in 2018 and 2019. Effects were generally minor

- Significant reductions in germination were observed from glyphosate + Ally applied at 58% pod maturity in 1 trial in 2018 and glyphosate + Sharpen + Ally applied at 66% pod maturity in 2019. In both cases, application of the same treatment at later crop stages had no effect

- Reduced germination was observed from all treatments at one site in 2019 when applied at 90% pod maturity where a rain event of ~18mm occurred between application and harvest. There was no consistent impact from treatments on germination from applications at the same site at 70 and 80% pod maturity.

NB The use of desiccants is not recommended when the grain is to be used for seed.

Overall

Differences between desiccant treatments and timing of application were less obvious than originally expected.

- The addition of Ally to glyphosate will generally improve stem dry down compared to other treatments, whilst higher label rates of glyphosate will improve the speed of discolouration and stem dry down.

- Impacts on yield and grain quality were relatively minor, even when application occurred up to 2 or 3 weeks earlier than currently scheduled.

However, in 5 of the 6 trials where harvest timing was also compared, it was clear that the earlier harvest of chickpeas had significantly lower levels of damaged grain. This effect was irrespective of whether the plots had been desiccated or untreated. Although differences in header setup can’t be eliminated, it is likely that the lower levels of damaged or split grain is at least partly due to the higher levels of grain moisture at harvest. NB even the early application treatments had grain moisture lower than 10%, when tested within 24 hours of harvest, in 5 of the 6 trials.

Rather than suggesting that the industry desiccate chickpeas at an earlier maturity stage, this data should provide good confidence that desiccation at 85-90% pod maturity is highly unlikely to have any negative impact on yield or grain quality. When combined with harvest scheduled ~7 days after application, this should allow harvest at slightly higher grain moisture and significantly reduce the amount of damaged or split grain in samples.

Commercial harvest losses 2018-2019

Commercial observations have frequently indicated high levels of harvest grain and pod loss in chickpeas, particularly in crops with reduced biomass that ‘feed’ poorly into the header. This grain loss is different to grain that passes through the header (processing loss) or grain left on plants (harvest height loss). Front of header grain loss is made up of pods and grain that are knocked off by the reel, cut off by the knife but fall outside the header front or thrown out from the header by the drum or belt.

In 2018, data was generated at a site near Gurley where PBA Seamer was harvested with a header fitted with an air front. Replicated strips were established where the only difference was whether the air front was turned on or off during harvest.

Counts were taken of pods or grain on the ground together with the number of grains/pod and grain weight. In 2018, sampling zones were assessed across the harvested width with no pods or grain apparent on the ground prior to harvest. Results in Table 1 are for the pod and grain losses away from the header trail. These are the harvest losses that occurred at the front of the header but exclude any pods that were unharvested but still attached to plants.

Figure 4. Brushes attached to the header reel Bellata 2019

In 2019 three sites were evaluated with sampling away from the header trail to identify the pods or grain losses at the front of the header. Again there was no indication of pod or grain loss prior to harvest. Two of the sites had air assist fitted to the header that could be simply turned on or off. The third site evaluated lengths of brushes attached to the reel (Figure 1).

Table 1. Impact on chickpea yield losses from air assist or reel brushes

Location and year | Variety and yield | Header set-up | Yield losses on ground | Reduced grain losses kg/ha and ($/ha) | ||

|---|---|---|---|---|---|---|

Pods/m2 | Grain/m2 | Total kg/ha | ||||

Gurley 2018 | PBA Seamer ~0.62 t/ha | Air assist OFF | 55 a | 10 | 164 a | 89 kg/ha ($67/ha) |

Air assist ON | 22 b | 8 | 76 b | |||

Wee Waa 2019 | PBA Monarch ~1.0 t/ha | Air assist OFF | 33 a | 5 | 115 a | 45 kg/ha ($34/ha) |

Air assist ON | 21 b | 3 | 70 b | |||

Bongeen 2019 | PBA HatTrick ~0.45 t/ha | Air assist OFF | 38 a | 1 | 123 a | 80 kg/ha ($60/ha) |

Air assist ON | 14 b | 0 | 43 b | |||

Bellata 2019 | PBA HatTrick ~0.40 t/ha | Reel brushes OFF | 62 a | 11 | 217 a | 63 kg/ha ($47/ha) |

Reel brushes ON | 43 b | 9 | 154 b | |||

Letters of significance show significant differences within each site (2 sample T test, p=0.05)

Economic impact calculated on a $750/t grain price

All results in Table 1 are for sampling away from the header trail. This shows the yield losses occurring at the header front. Assessment of grains/pod and grain weight was conducted to calculate total grain loss.

Key points – commercial harvest losses 2018-2019

- The majority of grain losses were as whole pods rather than individual grains

- At all four sites between ~100 and 200 kg/ha of grain was lost at the front of the header using a conventional setup

- Use of air assist or brushes attached to the reel significantly reduced the losses of whole pods and the total grain loss, at all sites

- There was no significant difference in losses of individual grains

- The mean reduction in grain loss was 70 kg/ha (range 45 to 89 kg/ha)

- The mean reduction in grain loss was $52/ha (range $34 to $67/ha)

- The reduction in losses would have been equivalent to an extra 5-18% crop yield.

Overall

All four trials highlighted the amount of chickpea grain and income that can be lost at the front of the header at harvest. The impact of air assist or even the simple approach of attaching brushes to the reel provided benefits of ~$50/ha. However some caution is needed as both 2018 and 2019 were low yielding seasons with yields varying between 0.4 and 1.0 t/ha. The benefits of simple header adaptations may be more substantial in lower yielding years or where crop biomass or planting configuration is likely to result in poor levels of ‘feeding in’ of harvested material.

Further evaluation is warranted under more normal conditions to provide growers with realistic indications of the benefits of changes in chickpea harvest management.

Acknowledgements

The research undertaken as part of this project is made possible by the significant contributions of growers through both trial cooperation and the support of the GRDC, the author would like to thank them for their continued support.

NGA would particularly like to acknowledge the assistance from a large number of trial co-operators during this series of trials: Wade Bidstrup, Graham Butler, Jack Williamson, Sam Chaffey, Glen Kendall, Mark Cotter, Drew Penberthy, Nigel Melbourne, Ash Butler and Ross Durham.

Contact details

Richard Daniel

Northern Grower Alliance

Ph: 07 4639 5344

richard.daniel@nga.org.au

Varieties displaying this symbol beside them are protected under the Plant Breeders Rights Act 1994

® Registered Trademark

GRDC Project Code: NGA00004,

Was this page helpful?

YOUR FEEDBACK