How heat tolerant are our current wheat varieties?

Take home message

Some Australian cultivars are significantly more heat tolerant than others when heat stress is applied at anthesis and grain filling growth stages. Materials identified and developed through this project provide new genetics for heat tolerance that can be used to improve the heat tolerance of current varieties.

Aims

This research compared the heat tolerance of current commercial wheat varieties under elevated day and night temperatures during anthesis (Zadok 60) and grain fill (Zadok 73) growth stages.

Introduction

Extreme heat events may become 85% more frequent and 57% longer in the coming decades due to the increasing impact of climate change (Syktus et al; 2020). Wheat is highly sensitive to extreme heat during anthesis (flowering) and grain fill growth stages. This can have a significant impact on final crop yield and quality. Heat stress at anthesis often affects pollen fertility which reduces the number of kernels produced by each spike. For every one degree rise in the average maximum temperature above the optimum (5°C to 28°C), it is estimated that kernel number decreases by 4% (NSW DPI, 2007). An extreme heat event at grain fill can negatively impact kernel size as it disrupts the translocation of nutrients and the synthesis and deposition of starch.

The most effective way of assessing the performance of a genotype and its range of physiological responses is to screen materials under stressful environmental conditions. Screening methods for heat tolerance often involve single tiered techniques, usually in a glasshouse setting, which can lack relevance to farming environments and does not always represent the most relevant materials. This paper discusses the findings of the second tier of a three-tiered technique developed specifically to screen for heat tolerance (Thistlethwaite et al., 2020). This method evaluates germplasm by combining natural and controlled conditions using in-field controlled environment chambers.

Methods

Twenty-three current commercial bread wheat cultivars and two breeding lines were screened under in-field controlled environment chamber conditions at The University of Sydney Plant Breeding Institute, Narrabri in 2020. Each line was sown in 12 m2 replicated plots. Treatments involved a heated chamber that adjusted its internal conditions to be consistently 4°C above the ambient temperature. Anthesis treatments consisted of an average increased temperature of 30.7°C between 10:00-14:00h and grain fill treatments consisted of an average increased temperature of 15.3°C between 19:00-07:00h. Chamber units were deployed at the same growth stage at the same time of day for each genotype.

The hidden costs associated with a rise in global minimum temperatures, especially late in the season, is the reason a nighttime heat treatment was imposed at grain fill. Different physiological processes occur within a plant during the night compared with during the day. Some varieties could be more efficient at recovering during the night which would then allow them to cope much better when the temperature was high during the day. The physiological basis of this phenomenon remains limited; however, evaluations such as this are a step towards a better understanding of why, rather than how, varieties differ from each other.

In-field controlled environment chambers, designed to fit over a 4 m2 of a plot, were used to increase the maximum ambient temperature for three consecutive days at anthesis and increase the minimum ambient temperature for three consecutive nights during grain fill (Figure 1). Each chamber unit was 2 m x 2 m x 1.5 m (length x width x height) in dimension. Chamber units consisted of a galvanised steel frame covered in clear polycarbonate. HOBOware® weatherproof temperature and humidity data loggers with a temperature measurement range of -40 °C to 70 °C with ±0.2 °C accuracy and a relative humidity (RH) measurement range of 0 to 100% with ±2.5% accuracy was installed in all units and fitted with a radiation shield.

Figure 1. In-field controlled environment chambers in the field at The University of Sydney Plant Breeding Institute, Narrabri 2020.

A positive temperature coefficient (PTC) thermistor with resistance increasing with temperature was installed with output fed to a SPLat HVAC26A AC controller. Each individual chamber was fitted with a domestic reverse cycle air conditioning (AC) unit rated to 3.9 kW heating and 3.6 kW cooling with a maximum full load current of 8.5 amps and ducting ran from the AC unit to the chamber. A 15 kVA 3-phase diesel generator was used to provide in-field power to the chamber units.

Spikes that were deemed to be at the correct stage for treatment were tagged and subsequently harvested to ensure the accuracy of plant growth stage. Yield, yield components and targeted phenological and physiological traits were assessed at key growth stages. Irrigation was applied based on Goanna moisture (capacitance) probe readings to ensure well-watered conditions throughout the season.

Ideally, this evaluation of commercial varieties should be repeated across multiple years and sites due to potential variation in environmental conditions and to allow for the best representation of the germplasm. In previous years, in-field controlled environment chambers were used primarily to assess new heat tolerant material rather than commercial varieties due to the availability of chambers.

Results

Overall, in-field controlled environment chambers significantly impacted the yield and kernel weight of most lines evaluated when a heat shock was applied at anthesis and during grain fill (Table 1). An average decrease in yield of 14% and kernel weight of 9.7% was observed between control and heated plots when a heat shock was applied during the day at anthesis. When minimum temperatures were increased at night during grain fill, yield and kernel were not as greatly impacted with yield and kernel weight decreases of 4.8% and 5.8% observed, respectively.

Table 1. The impact of heat chambers on yield and kernel weight (TKW) of ten heads selected at anthesis (Zadok 60) and mid-grain fill (Zadok 73) respectively.

Trait | Anthesis Control | Anthesis Treated | Grain Fill Control | Grain Fill Treated | Prob. |

|---|---|---|---|---|---|

Yield of 10 heads (g) | 19.78 a | 16.95 b | 19.28 a | 18.35 c | <0.001 |

TKW of 10 heads (g) | 38.28 a | 34.57 b | 37.86 a | 35.67 b | <0.001 |

Note: means in rows followed by the same letter are not significantly different at P<0.05

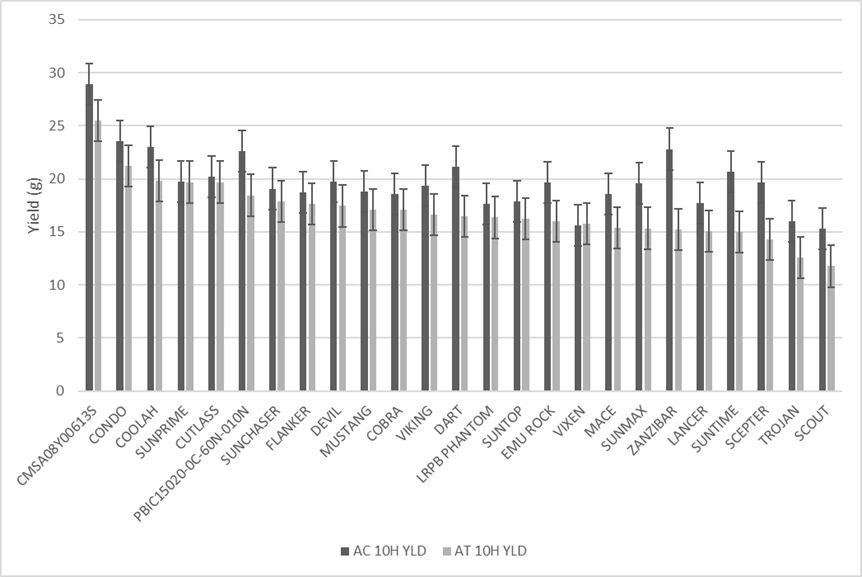

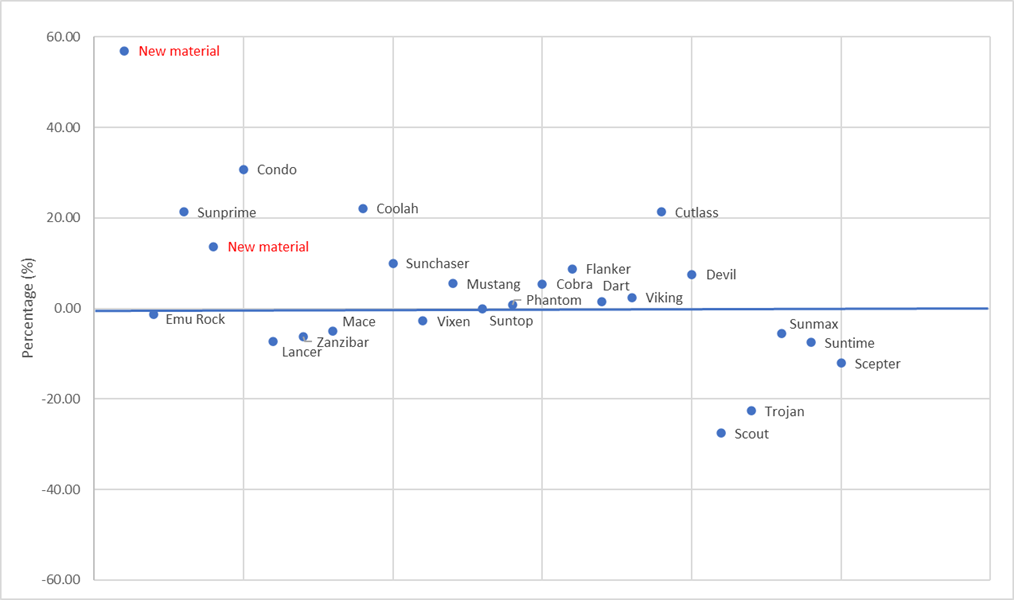

Recent Australian varieties performed well under anthesis heat treatment with the best performing varieties AGT Condo, Coolah, Sunprime and Cutlass combining yield potential and heat tolerance, closely followed by AGT Sunchaser, LRPB Flanker and Intergrain Devil. Varieties such as LRPB Dart, RGT Zanzibar and AGT Scepter showed good yield potential and performed well under controlled conditions but were greatly affected by heat treatment. Intergrain Vixen seemed to be unaffected by heat treatment as the difference between control and treatment yield was negligible. CIMMYT breeding line (CMSA08Y00613S-050Y-050ZTM-050Y-59BMX-010Y-0B) significantly outperformed all current varieties for yield (56% better than AGT Suntop) and kernel weight under control and heat treatments (Figure 3).

(a)

(b)

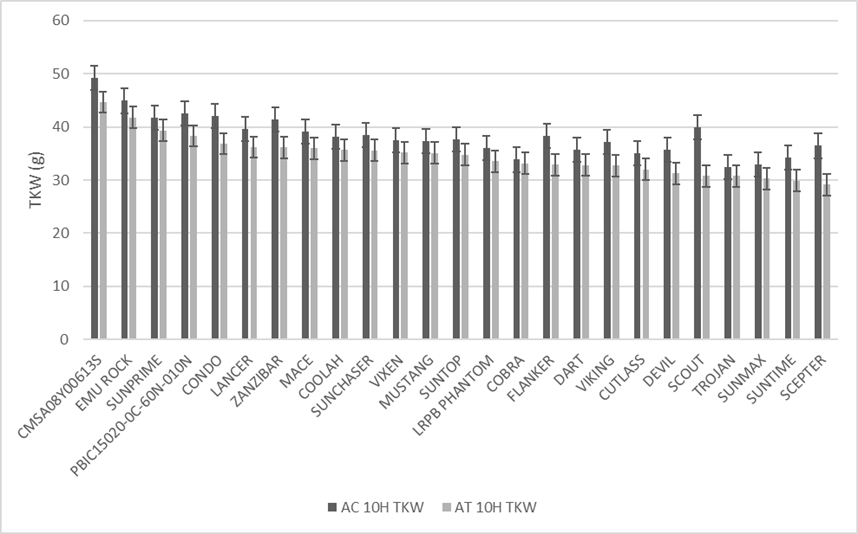

Figure 2. Yield (a) LSD ≤0.05 =3.98 (AC 10H YLD - Anthesis control 10 head yield, AT 10H YLD – Anthesis treatment 10 head yield) and kernel weight (b) LSD ≤0.05 =4.42 (AC 10H TKW - anthesis control 10 head thousand kernel weight, AT 10H TKW - anthesis treatment 10 head thousand kernel weight) of Australian cultivars under elevated day temperatures treatment and associated control at anthesis, Narrabri 2020.

(All the named varieties in the graphs above are protected under the Plant Breeders Rights Act 1994)

Figure 3. Yield of 10 heads for anthesis treatment of current cultivars under elevated day temperature treatment as a percentage (%) of Suntop which is represented by the x-axis (0.00%).

Figure 3. Yield of 10 heads for anthesis treatment of current cultivars under elevated day temperature treatment as a percentage (%) of Suntop which is represented by the x-axis (0.00%).

(All the named varieties in the graphs above are protected under the Plant Breeders Rights Act 1994)

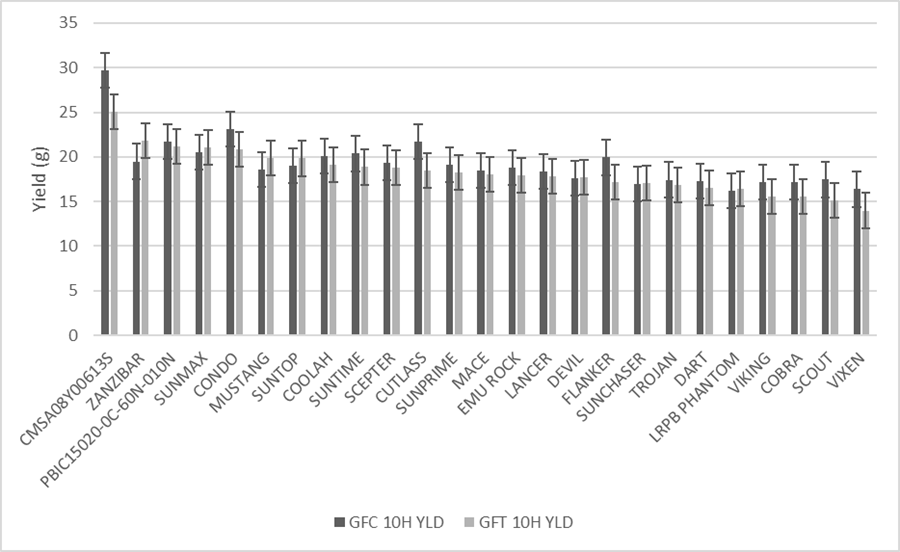

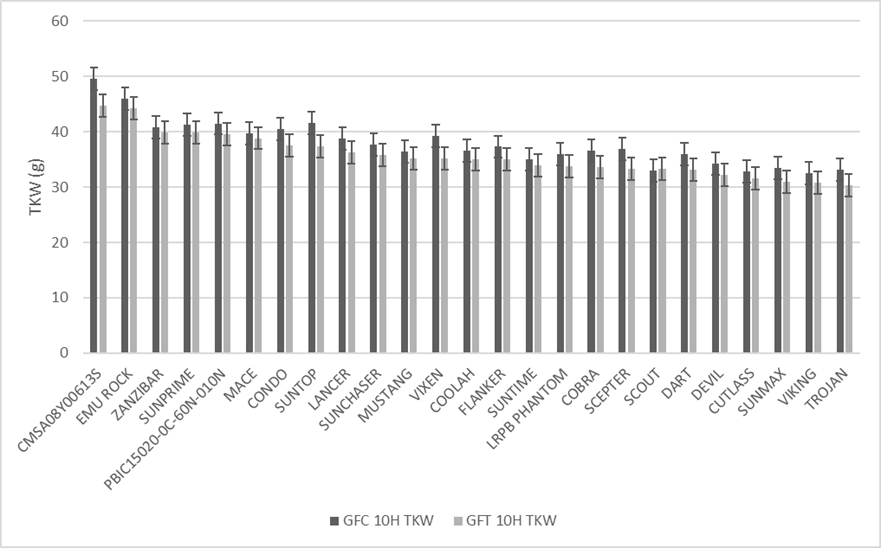

This was closely followed by AGT Suntop, Coolah, Suntime and Scepter (Figure 4). In some cases, as with RGT Zanzibar, AGT Sunmax and Suntop and LRPB Mustang, the heat treatment slightly outperformed the control. The varieties that were the most stable between treatments included Intergrain Devil, AGT Sunchaser and LRPB Phantom although they didn’t have as high a yield potential. CIMMYT breeding line (CMSA08Y00613S-050Y-050ZTM-050Y-59BMX-010Y-0B) surpassed all current varieties for kernel weight.

(a)

(b)

Figure 4. Yield (a) LSD ≤0.05 = 3.57 (GFC 10H YLD – grain fill control 10 head yield, GFT 10H YLD – grain fill treatment 10 head yield) and kernel weight (b) LSD ≤0.05 = 3.81 (GFC 10H TKW – grain fill control 10 head thousand kernel weight, GFT 10H TKW – grain fill treatment 10 head thousand kernel weight) of Australian cultivars under elevated minimum ambient temperatures treatment and associated control at grain fill, Narrabri 2020.

(All the named varieties in the graphs above are protected under the Plant Breeders Rights Act 1994)

Conclusion

Current and emerging Australian cultivars have a good degree of heat tolerance, however there is still more that can be achieved. This research identified and developed new sources of heat tolerance that can be used by wheat breeders to improve yield in our increasingly variable climate.

References

Jozef Syktus, Nathan Toombs, David Ahrens, Kenneth Koon-Ho Wong, Ramona Dalla Pozza, Heatwaves intensification in Australia: A consistent trajectory across past, present and future, Science of The Total Environment, Volume 742, 2020.

NSWDPI, 2007. Wheat Growth and Development. In: White, J., Edwards, J. (Eds.), p. 93.

Rebecca. J. Thistlethwaite, Daniel. K.Y. Tan, Anowarul. I. Bokshi, Smi Ullah, Richard. M. Trethowan, A phenotyping strategy for evaluating the high-temperature tolerance of wheat, Field Crops Research, Volume 255, 2020, 107905, ISSN 0378-4290.

Acknowledgements

The authors acknowledge the funding support of the GRDC, the University of Sydney and Agriculture Victoria, and the in-kind contributions of Intergrain and AGT.

Contact details

Rebecca Thistlethwaite

University of Sydney

Ph: 0403 525 345

Email: rebecca.thistlethwaite@sydney.edu.au

Varieties displaying this symbol beside them are protected under the Plant Breeders Rights Act 1994.

® Registered trademark

GRDC Project Code: US00081,

Was this page helpful?

YOUR FEEDBACK