The agronomic value of precision planting technologies with winter grain crops

The agronomic value of precision planting technologies with winter grain crops

Take home messages

- Precision planting improved the uniformity of crop stands and often allowed reductions in plant density without loss of yield.

- Potential benefits will be greatest in crops with high seed input costs.

- Grain yield responses to precision planting have been variable in project trials to date and suggests adoption of the technology may not be warranted based on crop yield response alone.

- Growers using precision planting in winter crops have often struggled because of lack of technical support and have reported variable benefits, but they have provided recommendations for adoption of the technology and field operation.

- Precise and smart seeding technology is evolving rapidly with air-seeder based transitional options becoming available, which may allow a more practical and cost-effective pathway to greater planting precision.

Background

Precision planting technologies are designed to place seed at a consistent depth and interplant distance within a row to promote uniform emergence and to minimise interplant competition. The ability to precisely locate a single seed in the seeding row is referred to as singulation. Precision planters first appeared in the post-war era as a technology to improve yield in maize and they have been used extensively since then in a wide range of summer crops where expensive and high vigour hybrid seeds are planted at relatively low plant populations. The ideal case is to have every seed planted producing a productive plant and, by reducing interplant competition, to have uniform growth of plants within the stand to maximise yield per plant.

Currently most commercial precision planters use disc seeding systems with a vacuum or positive pressure seed singulation system located on each seed row which allows accurate placement of individual seeds within the row. This technology is well-known to summer crop growers in the northern region, but it is in its infancy in the southern and western regions.

The recent interest in using precision planting technology with winter crops, especially in hybrid canola, has been prompted in part by a desire to reduce the costs of using hybrid seeds and has been spurred on by reports that even placement of seeds improves yields at low plant densities, which would allow significant reductions in seeding rates. For example, field trials in Canada (Yang et al. 2014) reported yields with equally spaced canola plants up to 20% and 32% higher compared to uneven spacing at low and high yielding sites, respectively. More recent work in Western Australia (WA) in canola and lupin have indicated that even spacing, to minimise interplant competition, may allow a reduction of sowing rates below current recommended rates, with predicted savings of $24/ha in seed of hybrid canola (Harries et al. 2019).

While these results are encouraging, there has been no systematic assessment of the value of precision planting technology in winter crop production for small grain crops in Australia. The aim of the current project is to assess the value of precision planting in canola and numerous pulse crops in the southern and western regions. The project has three main components:

(i) A paddock survey of establishment in a number of crops in 2018 and 2019 in the southern and western regions to assess the variation in seedling emergence and seedling depth and to examine what factors may contribute to this variation;

(ii) a series of small-scale and large-scale trials comparing conventional sowing (either a cone seeder or an air-seeder) with precision planting; and,

(iii) a qualitative survey of current users of precision planters for winter grain crops.

This paper focusses on the results of the field trials and the experiences of growers using precision planters. The results of the crop survey have been reported previously (McDonald et al. 2020).

Method

A series of small plot trials was conducted between 2018 and 2020 using a purpose-built 6-row seeder that could sow seeds as a conventional cone seeder or as a precision planter. The precision planting units used in Victoria (Vic) and South Australia (SA) were commercial row units supplied by Spot-on-Ag, in Boort, Vic (Table 4). The trial at Merredin in 2019 used a small plot seeder operated by WA DPIRD with the capacity for singulation as well as conventional sowing. Both plot seeders used disc seeding systems, except in 2018 when cone seeding could only be done with a tyned seeding system. Details of the trials are given in Table 1.

Table 1. Details of the small plot trials conducted between 2018 and 2020.

Year and site | Crops | |

|---|---|---|

2018, 2019 Birchip Hart | Canola Lentil | Seeding method (Conventional, Precision) Plant density (6) Row spacing (23cm, 30cm) |

2019 Roseworthy | Canola Faba bean | Seeding method (Conventional, Precision) Plant density (5) Seeding method (Conventional, Precision) Seed treatment (Graded, Ungraded) Plant density (10, 20 seeds /m2) |

2019 Merredin | Lupin Canola | Seeding method (Conventional, Precision) Plant density (4) |

2020 Horsham | Canola Faba bean | Seeding method (Conventional, Precision) Plant density (4) Seeding method (Conventional, Precision) Row spacing (23cm, 46cm) Plant density (4) |

2020 Hart | Canola Chickpea Wheat | Seeder type (Conventional, Precision) Plant density (4) |

Large scale trials were also conducted with canola and faba bean near Skipton in western Victoria using a Väderstad airseeder (Seedhawk model in 2018; Rapid model in 2019) and a Väderstad precision planter (Tempo). Each trial compared the responses to row spacing (25cm versus 50cm) and sowing rate (recommended versus half-recommended) and were sown in plots 150m long.

In all trials, seedling emergence at five weeks after seeding, interplant distance at seedling emergence, normalised difference vegetation index (NDVI), biomass production at flowering or peak biomass, grain yield and yield components were measured. All trials were replicated and randomised and were designed either as split plot or as complete factorial trials with between four and six replicates. The uniformity of seed placement within the rows was assessed by the coefficient of variation (CV) of the interplant distance.

Survey of growers using precision planters

Growers who have been using precision planters with winter grain crops were surveyed. Twenty-one growers were identified in New South Wales (NSW), Vic, SA, Tasmania (Tas) and WA and thirteen interviews were conducted either by phone or face-to-face, guided by a questionnaire. The aims of this qualitative survey were to document the reasons for adopting precision planting, record what growers considered to be the benefits of precision planters over conventional air-seeders, and to record their experiences with adopting and using the technology, including the problems and limitations of precision planting.

Results and discussion

Plot trials

The emergence rate of the trials varied considerably (Tables 2 and 3). In the canola trials there were both significant increases and reductions in seedling establishment with precision planting (Table 2), however there was a consistent improvement in the uniformity of the interplant spacing with a 20-40% reduction in the CV for interplant distance. In most trials there was no significant difference in the yields between the two seeders, with significant differences being measured in two of the nine trials; in both cases precision planting improved yields.

Table 2. Summary of the effects of conventional and precision seeding on crop establishment, the uniformity of plant spacing and grain yield in canola. The trial at Skipton used commercial seeding and planting equipment in large plots and the remaining experiment used a small plot seeder. The significance of the difference between the precision planter and the conventional seeder is indicated: *** - P<0.001; ** - P<0.001; * - P<0.05; NS = not significant.

Site and year | Conventional sowing | Precision planter | ||||

|---|---|---|---|---|---|---|

Crop establishment (%) | Interplant distance CV (%) | Grain yield (t/ha) | Crop establishment (%) | Interplant distance CV (%) | Grain yield (t/ha) | |

Hart 2018 | 90 | 101 | 1.38 | 65*** | 77*** | 1.39 NS |

Birchip 2018 | 64 | 103 | 0.35 | 59 NS | 80*** | 0.37 NS |

Hart 2019 | 67 | 99 | 0.54 | 64NS | 72*** | 0.61* |

Birchip 2019 | 105 | 103 | 2.15 | 82** | 66*** | 2.21 NS |

Roseworthy 2019 | 51 | 89 | 0.98 | 68*** | 61*** | 0.98 NS |

Merredin, 2019 | 88 | - | 0.34 | 69*** | - | 0.39 NS |

Skipton 2019 | 102 | 85 | 2.64 | 76*** | 78NS | 2.68 NS |

Hart 2020 | 48 | 94 | 1.01 | 52NS | 59* | 1.06 NS |

Rupanyap, 2020 | 100 | 99 | 3.40 | 83NS | 73*** | 3.62* |

Crop establishment in the pulses were generally higher than in canola, but as with canola, there was no consistent effect of precision planting on establishment and crop uniformity was improved substantially (Table 3). Precision planting improved grain yield by 18% or 22% in faba bean and significant increases of 10% (lupin) and 14% (lentil) were also measured. The results for canola and pulses indicated that despite variable effects on establishment, precision planting resulted in yields equivalent to or higher than those achieved with conventional sowing.

Table 3. Summary of the effects of conventional and precision seeding on crop establishment, the uniformity of plant spacing and grain yield in pulse crops. The trials at Skipton used commercial seeding equipment in large plots and the remaining experiment used a small plot seeder. The significance of the difference between the precision planter and the conventional seeder is indicated: *** - P<0.001; ** - P<0.001; * - P<0.05; NS = not significant.

Site and year | Conventional sowing | Precision planter | ||||

|---|---|---|---|---|---|---|

Crop establishment (%) | Interplant distance CV (%) | Grain yield (t/ha) | Crop establishment (%) | Interplant distance CV (%) | Grain yield (t/ha) | |

Faba bean | ||||||

Skipton, 2018 | 125 | 84 | 1.33 | 115* | 34*** | 1.57* |

Skipton, 2019 | 129 | 86 | 3.95 | 124NS | 41*** | 3.91NS |

Roseworthy, 2019 | 86 | 81 | 2.23 | 72** | 39*** | 2.25NS |

Rupanyap, 2020 | 69 | 104 | 4.56 | 89** | 66*** | 5.57** |

Lentil | ||||||

Hart, 2018 | 101 | - | 1.21 | 77* | - | 1.38* |

Birchip, 2018 | 97 | 102 | 0.91 | 106NS | 63*** | 0.88NS |

Hart, 2019 | 59 | 95 | 2.55 | 50** | 70*** | 2.43NS |

Birchip, 2019 | 114 | 99 | 0.69 | 81*** | 73*** | 0.64NS |

Lupin | ||||||

Merredin 2019 | 105 | 0.70 | 94NS | 0.77* | ||

Chickpea | ||||||

Hart, 2020 | 64 | 89 | 0.99 | 60NS | 58*** | 1.10** |

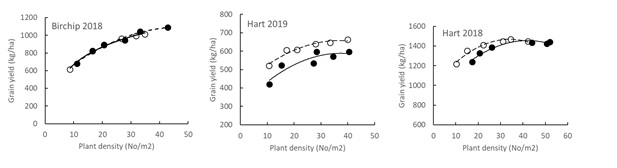

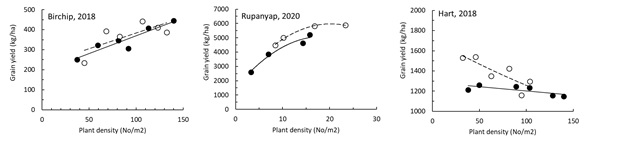

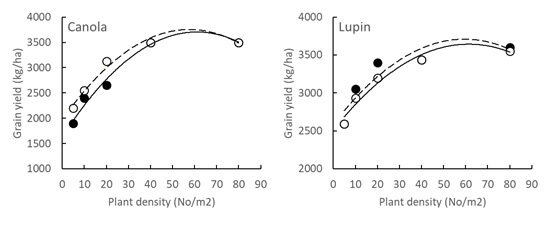

The relationships between grain yield and established plant number were examined because of the variable effects of precision planting on both plant number and yield. Among all the trials, three types of responses were evident (Figure 1 and 2): no difference in the response to plant density between the conventional and precision planting, a consistent yield advantage of precision planting over a range of plant densities and a greater ability to maintain yields at low density by precision planting. A consequence of the latter two responses is that precision planting would allow a reduction in plant density with little or no yield penalty. Similar relationships were reported by Harries et al. (2019) in comparisons between unevenly spaced and evenly spaced plantings (Figure 3), suggesting the responses observed in the current trials were associated with differences in the uniformity in plant spacing within the crop. The potential economic benefit of this is the saving on seed costs from producing the same yield with fewer plants/m2 and little yield penalty. However, the responses to precision planting varied among experiments and it is still unclear what the main factors that influence the response are.

Figure 1. The relationships between the established number of plants/m2 and the yield of canola sown either with a conventional cone seeder (●) or a precision planter (○) at 3 sites.

Figure 2. The relationships between the established number of plants/m2 and the yield of pulse crops sown either with a conventional cone seeder (●) or a precision planter (○). The crops were lentil (Birchip, 2018, Hart 2018) and faba bean (Rupanyap, 2020).

Figure 3. The response to plant density in canola and lupin by plants that were unevenly spaced (●) or evenly spaced (○) in trials in Western Australia (after Harries et al. 2019).

Precision planting grower survey

A small number of growers are pioneering the use of precision planters in winter cropping across the southern and western regions, with most located in Vic. There was a wide range of equipment used, ranging from old summer crop planters to newer, high-technology precision planters. About half the growers grew irrigated crops with a significant component of maize cropping, while in dryland systems numerous growers have also grown opportunity summer crops, often as part of their adoption of precision planters. The standard planting equipment comprised twin disc row units, with only one planter in WA using tyne-based row-units. Precision planters were used mainly to sow canola and a range of pulse crops (faba bean, lentil and chickpea), with some limited attempts at planting cereals.

The reasons given for initially adopting the technology included an anticipation of improved accuracy of seed placement with discs, resulting in better and more even crop emergence, an even distribution of seeds in-furrow to minimise interplant competition, and reports from overseas of reduced seed costs per hectare. The growers confirmed these benefits and reported reduced seed costs per hectare, especially with hybrid canola, as well as more uniform crop emergence and vigour, and improvements in accuracy of seed placement. Improved yields were not always reported, but when cited, occurred mainly in canola and faba bean. However, improved yields were often not the primary aim of adopting precision planting: major considerations were improving crop establishment and increasing the uniformity and vigour of the crop stand, improved crop-weed competition and providing growers with the option of reducing seed costs without a loss in yield. Some growers did not consider seed cleaning and grading (which is necessary for precision planting) as additional costs because they considered these as part of best practice for integrated weed management, irrespective of the seeding system.

The main problem and limitation that the growers encountered with the use of precision planters was the lack of local technical support and advice, unlike growers and dealers in the northern regions where precision planter technologies are well-known. Growers who had acquired lower cost, older generation planters encountered the most difficulties with adapting their equipment (designed for summer crops) to winter cropping. Key issues highlighted by the growers included:

- Row-unit spacing was too wide for pulses and canola, necessitating two passes at planting.

- Limited or no ability to band fertiliser with the seed, requiring a separate operation and expected lower fertiliser use efficiency.

- No seed plates suitable for winter crop seed sizes, shapes and seed rates, necessitating the trial-and-error development of new ones or making do with sub-optimal seed delivery.

- Unsuitable row-hopper capacity for winter grain crops.

- Regular checks needed because there was no control system providing real-time feedback on performance.

- Planting performance was significantly affected by speed and paddock roughness.

The practical difficulties growers faced with trying to adapt new technology to their farming systems led to some limited dis-adoption of precision planters, but not a rejection of the technology. One early adopting and innovative grower commented they were now “...waiting for better technology to handle sticky clay conditions…. despite some definite success.” Growers provided the following key recommendations for adopting and operating precision planters:

- Precision planting = precision placement 1st and seed singulation 2nd (i.e., the benefits of seed singulation are not realised unless accurate seed placement can be delivered, through technology features, settings and operation, and including low paddock roughness).

- Plan the shift to precision planting, and address soil constraints, paddock preparation, seed grading/cleaning/quality, residue, weed management and logistics.

- Do some homework; research, talk to users and manufacturers, and look internationally for up‐to‐date information.

- Ensure technical support is available with the choice of technology or be ready to struggle.

- Be confident in your choice of planter or delay selection until you are.

- Hi‐Tech planters may not imply higher cost‐effectiveness.

- Use clean seeds, graded and of high quality.

- Keep an eye on performance, monitor regularly, be conscious of speed.

- Precision planting of larger seeds is less challenging when starting.

Field survey: precision planters versus air seeders

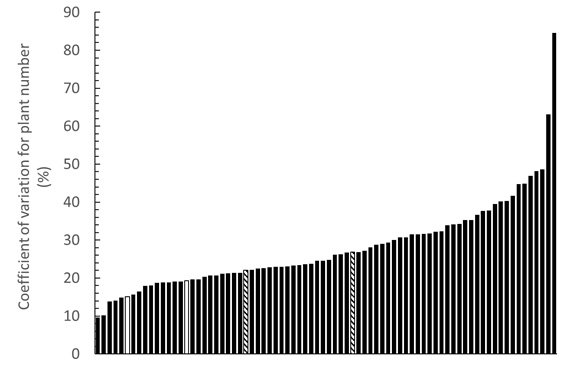

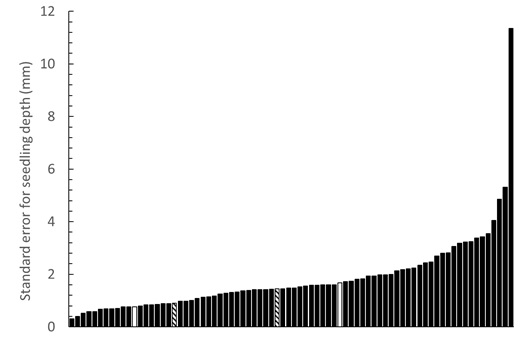

The paddock survey on crop establishment included four paddocks of two growers currently using precision planters, which allowed a limited comparison of commercial performance relative to conventional air-seeders. One grower was from the southern region and one from the western region. There was no consistent difference in crop establishment between paddocks sown with precision planters and conventional seeders (data not shown). In comparison with canola crops sown using conventional seeders, three of the four paddocks sown with a precision planter had lower-than-average variation in plant numbers and seedling depth (Figure 4 and 5), but there were also a number of paddocks sown with air-seeders that showed similar or greater uniformity in plant number and seedling depth. These results suggest that while precision planters increase the ability to improve the uniformity of crops stands, there are still substantial gains that can be achieved using conventional air-seeder equipment and good results can also be achieved through careful settings and operations, and with the adoption of ‘precision seeding systems’.

Figure 4. The range in the coefficient of variation in mean plants/m2 across 10 sampled seeding rows for 78 canola paddocks surveyed in the southern and western regions in 2018 and 2019. Paddocks sown with precision planters from the southern regions are indicated by white columns and from the western region by cross-hatched columns.

Figure 5. The range in the standard error for mean seedling depth in 10 sampled seeding rows among 78 canola paddocks surveyed in the southern and western regions in 2018 and 2019. Paddocks sown with precision planters from the southern regions are indicated by white columns and from the western region by cross-hatched columns.

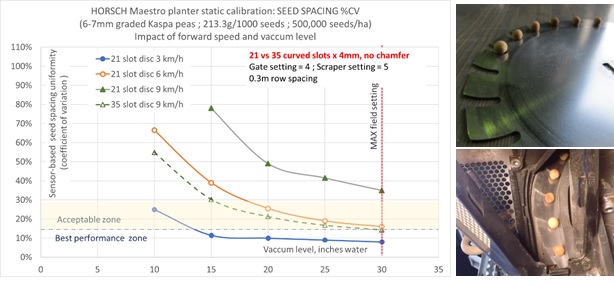

The project also evaluated the impact of precision planter settings on performance, highlighting the rapid negative impacts of high planting speed and sub-optimal vacuum levels on seed singulation quality. Figure 6 shows an example of a calibration with field peas on the coefficient of variation output by the sensor-based monitoring system. The data, which correlated very well with weight-based seed rate calibration, show good to excellent singulation quality (%CV≤15) at 3km/h and very satisfactory quality (15≤%CV≤30) at 6km/h with sufficient vacuum level (> 18 “ H2O). Performance at 9km/h was sub-optimal with the 21-slot disc used, while a 35-slot disc could slow down the disc rotation by 40% and align the 9km/h performance between that of the original 3 and 6km/h.

Figure 6. The impact of singulation vacuum setting and planting speed on the coefficient of variation of inter-seed spacing, with 2-disc plate designs (left); view over the singulation disc and in operation (right).

Current developments in precision planting technology

There is a wide range of precision planter technologies commercially available, increasingly trending towards ‘Intelligent Planting’, using hi‐tech sensor-based real-time monitoring and automation. Information from the major manufacturers and suppliers (John Deere, Precision Planting Inc., Väderstad, Horsch, Great Plains Australia, Monosem) provide some examples of current developments and features:

- Row-by-row seed delivery rate control, with curved pathway compensation and shut-off control for zero-overlap on headlands.

- Row- by-row monitoring of singulation performance using either seed mass or shape-based sensing (e.g., % skips/doubles, seed spacing index, ride quality).

- Row- by-row liquid fertiliser delivery rate monitoring and control, with swath-off control when crossing on headlands.

- Real‐time sensing of in‐furrow properties (e.g., organic matter, moisture content, CEC, temperature, presence of residue, general furrow uniformity).

- Pressurised or belt-guided seed delivery to furrow for high-speed planting.

- Serrated disc blade technology for improved residue cutting.

- Synchronised 200mm wide twin row configuration with triangular seed delivery pattern.

The sensor data acquired can be used to automatically self-adjust settings (e.g., weight-transfer down‐force, planting depth range, furrow closing pressure, zonal rate of seed and fertiliser by row) or just inform the operator who can respond by centrally adjusting settings on-the-go (e.g., planting speed, vacuum level, average down force, row cleaner engagement). Data can also be used to generate paddock maps (e.g., soil strength, furrow-read properties and planter performance) for adaptive management purpose.

Precision planter technology is increasingly catering for winter grain crops, including:

- Improved singulation with winter grain dedicated plates and meter accessories;

- control systems suited to linear seed rate of winter grain crops;

- narrower row spacings within the 190-380mm range;

- central commodity (bulk fill) system for broadacre applications; and

- liquid and/or granular fertiliser banding options.

To improve the versatility of singulation planters, downgrading to ‘bulk metering’ disc plates can be done selectively with crops where singulation may be unreliable, to ensure accurate bulk seed rate is still achieved (e.g., Great Plains Ag. Yield-Pro HDP planters).

Intermediate technologies also exist to improve the uniformity of seed distribution across seeding rows, such as single-row metering rollers (e.g., SeedMaster Ultra Pro II) where row-to-row variation can be 50% less than with centralised air-seeding (PAMI, 2019). Seed singulation row-kits are also emerging as optional features on broadacre disc seeding machines – which can be selected on a paddock by paddock basis (e.g. Horsch Funk metering SingularSystem, and the upcoming Bourgault Air-Planter eXact Placement XPTM meter). This integration of singulation kits onto air-seeders combines the flexibility of fertiliser placement and separation options available with air-seeding systems. Their integration with tyne-based seeding systems presents specific challenges and to date has been limited to prototypes, while limited tyne-disc hybrid systems are now commercially available. Developments of these intermediate technologies in the future could increase the versatility of precision planting in winter cropping systems in a range of soil conditions, but their mainstream adoption will rely on them being practical, cost-effective and not affecting the timeliness of sowing within a cropping programme.

A list of suppliers of and support for precision planting technologies is given in Table 4.

Table 4. A list of companies currently providing precision planting technologies in Australia*.

Manufacturer or distributor | Associated precision planting technologies | Web address |

|---|---|---|

AGCO Australia, Vic | White Planters, Precision Planting Inc. | |

Boss Agriculture, NSW | Precision Planting Inc., John Deere | |

Bourgault Australia, NSW | Bourgault Air-Planter XP meter and components | |

CNH Australia, NSW | Case-IH, Precision Planting Inc. | |

Great Plains Ag. - Australia (Kubota Australia), Qld | Great Plains | |

Groundbreaker Precision Agriculture (Toowoomba Engineering - Precision Ag-Solutions), Qld, N-NSW | Precision Planting Inc., Monosem, Ag-Leader, Groundbreaker components | |

John Deere Australia, Qld | John Deere, Deere-Bauer, Deere-Orthman | |

Landpower Australia, Vic | Väderstad | |

Muddy River Agricultural, Vic | Horsch | |

NDF Ag Design, NSW | Precision Planting Inc. , NDF downforce control | |

NORSEMAN Machinery, Qld (N-NSW) | Norseman, Kinze | |

Precision Seeding Solutions, NSW (Qld) | Precision Planting Inc. | |

Spot-On-Ag, Vic | Harvest International, Precision Planting Inc. Prescription Tillage Technologies | |

Vanderfield (RDO Australia Group), Qld, NSW, NT, (WA) | John Deere, Dawn Equipment, Monosem, Horsch |

* This is an extensive list to the best of the researcher’s knowledge, please consult your local retailer for more information.

Conclusions

Precision planting trials conducted over the last three years demonstrated an improved uniformity of crops stand and resulted in grain yields equivalent to or better than those achieved with conventional sowing. In numerous cases, plant density could be reduced with precision planting without a yield penalty, allowing a reduction in seed costs. However, the magnitude of the effect varied considerably and further work is required to understand the main environmental and management factors that determine the agronomic benefits of precision planting. In dedicated calibration evaluation, planter performance was shown to be easily affected by suboptimal planter settings and operation.

A small number of growers using precision planting technology for winter grain crops in the southern and western regions have struggled with lack of technical support and information and with trying to adapt old technology to winter cropping. Nevertheless, some have experienced sizeable benefits with specific crops and are optimistic that gains in productivity and profitability can be achieved by more uniform seed placement along the row. Commercial precision planters increasingly cater for winter grain crops planting, use smart technology to monitor and automate adjustments on-the-go, while singulation kits are now slowly appearing as an additional feature of air-seeders for use on selected crops. The mainstream adoption of precision planters will require their use to not only be cost-effective but also practical, versatile and not significantly reduce seeding timeliness.

Acknowledgements

The research undertaken as part of this project is made possible by the significant contributions of growers through both trial and survey cooperation, and information sharing, and the financial support from the GRDC. The authors would like to thank them for their continued support. The support from Muddy River Ag., Landpower Australia, Spot-on-Ag and Toowoomba Engineering with machinery and technical backstop for trials are gratefully acknowledged.

References

Harries M, Seymour M, Boyce S (2019). Geometric uniformity improves yield of canola and lupin. In 'GRDC Research Update'. Perth, Western Australia

McDonald G, Noack S, Browne C, Minkey D, Midwood J, Schmitt S, Clarke G, Pearse E, Amgouris A (2020) A survey of crop establishment in canola and lentil: what have we learnt? In 'GRDC Research Update. ' Bendigo, Victoria)

PAMI (2019). Air seeder distribution and seed damage testing and validation – Final report. 44p. Prairie Agricultural Machinery Institute: Humboldt, SK Canada. Accessed January 2021.

Yang C, Gan Y, Harker NK, Kutcher HR, Gulden R, Irvine B, May W (2014) Up to 32% yield increase with optimised spatial patterns of canola plant establishment in western Canada. Agronomy of Sustainable Development 34, 793-801.

Contact details

Glenn McDonald

School of Agriculture, Food and Wine

Waite Campus

The University of Adelaide

(08) 8313 7358

glenn.mcdonald@adelaide.edu.au

GRDC Project Code: UOA1803-009RTX,