Regulatory changes for buffer zones – what’s changing and why?

Regulatory changes for buffer zones – what’s changing and why?

Author: Hugh Dawick (APVMA) | Date: 25 May 2021

Take home message

Stage 1 of the APVMA spray drift policy introduced in July 2019 provides greater flexibility in the derivation of buffer zones appearing on the label. It also facilitates the inclusion of new drift reduction technology (DRTs).

Stage 2 of the APVMA spray drift policy potentially involves an interactive spray drift management tool (SDMT) that would allow chemical users to recalculate buffer zone distances based on their own circumstances.

For this to occur products must have undergone a modern spray drift risk assessment with label instructions to reflect this. The APVMA has introduced a new process to facilitate this but uptake is slow and other incentives are required.

Brief background

Spray drift is the movement of spray droplets of a pesticide outside of the application site during, or shortly after, application. It does not encompass off-target movement of a pesticide caused by runoff, volatilisation, erosion, or any other mechanism that occurs after spray droplets reach their intended target.

The APVMA sets criteria to ensure that off target spray drift does not harm human health, the environment or Australia’s international trade through the establishment of mandatory downwind buffer zones. A ‘buffer zone’ is an area where pesticide application does not occur between the application site and an identified sensitive area, which is downwind from the application site.

APVMA’s approach for addressing the risk of spray drift was first implemented in March 2010 but there were a number of limitations with the previous policy including;

- A lack of flexibility and ability to adopt DRTs

- Assessment based on worst case scenarios

- No incentive to adopt best practice

- Deterrent to including some types of applications when registering products.

The current APVMA spray drift policy and supporting files were posted on our website on 19 July 2019 following almost 10 years of extensive collaboration and development with stakeholders (see the APVMA spray drift home page). The Spray drift risk assessment manual (SDRAM) is the primary document setting out the policy and represents a significant milestone for the APVMA and its stakeholders.

What has changed?

The methods of application considered within the current policy are boom sprayers, vertical sprayers and aerial application (fixed wing aircraft or helicopter) for which different deposition data apply depending on different operating conditions.

The five ‘sensitive areas’ are considered within the spray drift policy are:

- Bystander areas

- Natural aquatic areas

- Pollinator areas

- Vegetation areas

- Livestock areas.

The potential impact arising from the use of a pesticide product on each of these areas is considered as part of the APVMA risk assessment. In some cases, the risk may be unacceptable, and a buffer zone is needed to protect one or more sensitive areas. The presence of the buffer zone reduces (but does not eliminate) the amount of applied spray that reaches the sensitive area. It is important to note that without the use of buffer zones many products would not be available to growers. It is therefore important that the label instructions are adhered to.

The APVMA Spray drift policy was split into two stages. Stage 1 includes aspects up to establishing a product label or permit instructions. Stage 2 potentially involves an interactive SDMT that would allow chemical users to refine the standard assessment and recalculate buffer zone distances based on their own circumstances. Prior to the introduction of stage 2, an excel-based SDMT is used by the APVMA to set buffers relevant to the use patterns requested by applicants on labels or permits.

In the past, buffer zones were calculated based on worst case assumptions including the maximum rate of application and default values relating to boom height, wind speed, droplet quality etc. Under the new policy, the SDMT provides greater flexibility allowing reduced rates of application (within the approved rate range on the label), a range of boom heights, wind speeds and droplet sizes, providing greater choice to users. The full range of options available is shown in Table 1 below.

Table 1. Range of application parameters available within the SDMT

Application parameters | Application equipment | ||

|---|---|---|---|

Boom sprayers | Aircraft | Vertical sprayer | |

A reduced application rate (noting that this can be no lower than the minimum rate appearing on the label) | ✓ | ✓ | ✓ |

A droplet size other than that currently on the label | ✓ | ✓ | X |

Boom heights other than those currently on the label (that is, 0.5 and 1.0m) | ✓ | X | X |

Maximum release height other than those currently on the label | X | ✓ | X |

Maximum wind speeds of 7, 14 and 20km/hr | ✓ | ✓ | X |

Revised maximum application site width | ✓ | X | X |

Canopy type other than that currently on the label | X | X | ✓ |

Minimum depth of downwind natural aquatic area | ✓ | ✓ | ✓ |

Or any combination of the above | ✓ | ✓ | ✓ |

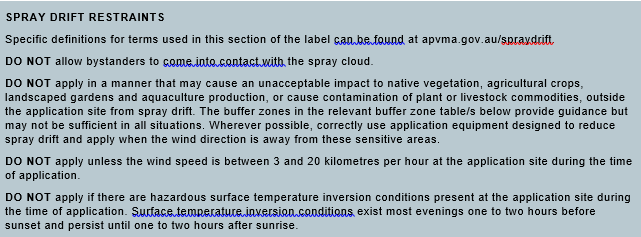

The way in which the spray drift instructions are set out on the label has also changed. For older labels, buffer zones and associated instructions were not standardised and often scattered throughout the label. Some examples of the different ways these were presented is contained within the Guidelines for updating spray drift instructions on labels when a full spray drift risk assessment has not been undertaken . The new labelling approach includes ‘general instructions’ relevant to any chemical product applied as a spray (see Figure 1).

Figure 1. General instructions

APVMA compliance instructions for mandatory COARSE or larger droplet size categories are no longer required in the general instructions. Some of the additional detail such as spray droplet size categories have been relegated to the glossary section of the spray drift manual. Specific droplet size classification standards, for example ASAE S572 will no longer be included on the label since this is now covered in the definitions given on the website. Where possible, recommended droplet size for spray applications that are given as VMD (Volume Median Diameter) in microns (µm) will be replaced by the equivalent droplet size classification.

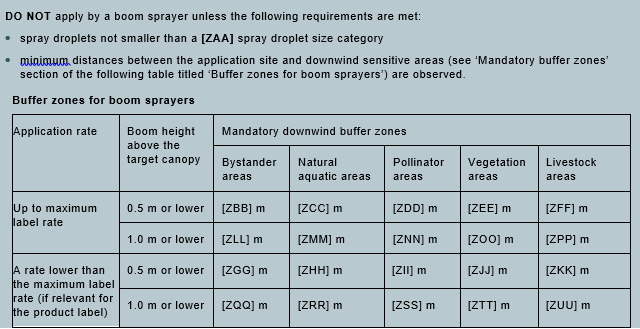

Where a spray drift risk assessment has been undertaken requiring the inclusion of buffer zones, three further tables could appear depending on the method of application. Figure 2 gives the relevant instructions for a boom sprayer.

Figure 2. Boom sprayer instructions

In some cases where the calculated buffer zones exceeds the maximum distances available according to the data, a ‘DO NOT apply by ….’ statement will appear indicating that no acceptable use can occur for a method of application. A ‘DO NOT apply by …’ statement might also be included at the request of the applicant, because they do not wish to support a particular method of application.

Greater flexibility to include new DRT on labels

Registrants or third parties may submit spray drift data based on new DRT including nozzles, application equipment or drift reducing adjuvants. The standard instructions can be refined, reduced or expanded in accordance with the nature of that application. For example, a label may stipulate a certain type of nozzle and operating pressure for use in a boom sprayer e.g. ‘only to be applied with a make A model B nozzle up to a maximum pressure of C bar’. A custom deposition curve derived from the data submitted would allow buffer zones to be calculated based on these data differing from the standard deposition curves in the SDMT.

Another example could be when an application proposes the addition of a drift-reducing adjuvant, an example of potential additional instructions is ‘only to be applied when [adjuvant product name and number] is used in a tank mix at label rates’

More generally, applicants may wish to provide additional risk management instructions in relation to spray drift. For example, as buffer zones may not always be completely protective of agricultural crops or aquacultural production, applicants may wish to include specific statements about these areas through custom use instructions. This may be particularly useful when there are known risks posed to certain crops or aquacultural species (including at certain development stages) by a certain product

How will labels be updated?

The new spray drift management approach will automatically be applied to products containing new active substances or active substances subject to chemical review for which 2,4-D is the first example. All 2,4-D labels should be updated by October this year reflecting the new spray drift policy.

For the majority of existing products, the APVMA will update the label with the new instructions and existing buffer zones (if present) into the new format for any application requiring a label update. The APVMA will undertake a new spray drift risk assessment at the applicants request or where a variation application requires it. Details of the new process is provided in Guidelines for applications to update spray drift instructions, update the spray drift risk assessment and recognise new drift reduction technology.

The new process has been in place since October 2020, but the uptake is slow as there is little incentive for registrants to voluntarily request a new risk assessment given this could result in buffers that aren’t specified on competitor product labels. This is unfortunate because it will be a requirement in any future web or application based SDMT tool that the product has undergone a modern assessment. Some further incentives for registrants are needed to support the future development of the tool and provide users with greater choice.

Acknowledgements

I would like to thank members of the Technical Committee of the National Working Party on Pesticide Application (NWPPA) for their continued support in developing the APVMA spray drift policy and spray drift permit.

Contact details

Mr Hugh Dawick

Australian Pesticides and Veterinary Medicines Authority

GPO Box 3262, SYDNEY NSW 2001, Australia

Ph: 02 6770 2396

Mb: 0436 817 147

Email: hugh.dawick@apvma.gov.au