2021 Rethink your approach to canola harvesting to optimise crop performance

2021 Rethink your approach to canola harvesting to optimise crop performance

Author: Maurie Street and Ben O’Brien (Grain Orana Alliance) | Date: 15 Jul 2021

Take home messages

- Timing of windrowing of canola can have a huge impact on profitability through its influence on yield and oil%

- Profit could be reduced by up to $50/day for every day that crops are windrowed before they are ready

- The window for windrowing on time is relatively small so it is difficult to logistically windrow all crops in the ideal period

- Direct heading of canola is a viable and comparable alternative to well-timed windrowing and can outperform windrowed crops

- In contrast, the window for direct heading crops to maximise yield and profit may be much larger than the window to windrow crops for optimum yields

- Desiccation, other than that for weed control, in most cases will not significantly speed up crop maturity.

Background

Windrowing of canola in the central west of NSW has been the traditional approach adopted by most growers. Survey data collected in 2017 by Grain Orana Alliance (GOA), a GRDC Grower Solutions Group, indicated that a decade ago, between 65% - 80% of canola growers were exclusively windrowing (GOA, 2019).

In 2009 GOA was asked to investigate if windrow timing (WRT) was impacting canola performance, specifically the oil percentage of harvested grain. In response, GOA established two trials in 2009 that compared different windrow timings. In both trials, the early windrowing resulted in significant yield penalties of up to 0.5t/ha, but only low levels of impact on oil content.

The outcomes from these two trials inspired subsequent trials undertaken by GOA, not only investigating the impact of WRT, but investigating the fit of direct heading, the use of desiccants, the use of PodCeal™, the impacts of delays in direct heading and Podguard™ technology.

In response to the work undertaken by GOA, more in-depth studies were undertaken by NSW DPI under the GRDC ‘Optimised Canola Profitability Project’ (CSP00187). These confirmed GOA’s findings and developed new guidelines and resources for optimum windrowing timing.

GOA has previously presented and published on these topics. Detailed presentations and papers can be found on either the GRDC or the GOA websites. This paper summarises the key findings and presents a case for growers to reconsider how they might approach harvesting canola in the future.

What is the ideal windrowing timing?

WRT is the stage of crop maturity when the crop is cut and placed into windrows to dry and be later harvested when the grain has dried down to a deliverable moisture content (DMC) of 8%. The crop stage is identified by the percentage of the seed that has changed colour. For example, the previously accepted recommendation for the timing of canola windrowing was -

“Windrowing should commence when 40-60% seed in the middle third of the main stem has changed colour from green to brown, black or red” (Carmody, 2009).

The changing colour is an indicator of those seeds reaching physiological maturity. At this point seed has reached its full potential in terms of seed size and oil content. Prior to this the seed is still growing (increasing in size) which is contributing to increasing yields and oil content. The recommendation of 40%-60% colour change infers that only 40-60% of the seed in the referenced part of the crop is mature and reached its full size. Immature seed at the time of windrowing will have any further growth or accumulation of oil stopped abruptly which will forgo potential further increases in yield or oil%. Windrow too early and yield and oil% will be forgone, with later timings giving the crop more time to realise its full yield potential.

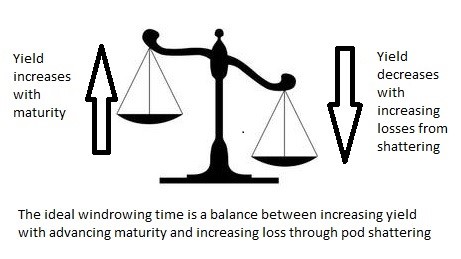

However, what also occurs as the crop matures is an increase in brittleness. The process of windrowing can be aggressive and often results in seeds being lost from pods, ultimately ending up on the ground and reducing harvested yield.

Figure 1. Illustration of the balance needed between increasing yields and increasing potential losses with advancing maturity.

Ideal WRT should aim to maximise the increasing crop yield but not be too late as to reduce harvestable yield by shattering out canola either before but more likely during the windrowing process.

So what did GOA find?

Large scale replicated field trials run by GOA showed that WRT could have an impact on oil% but it was often quite small. The effect of WRT on crop yield however was often much larger, both in magnitude and economic impact. One of the first trials undertaken by GOA at Coonamble in 2009 showed that delaying WRT from 10% seed colour change (SCC) to 70% SCC, or eight days, yields increased by 500kg/ha. The increase represented a 30% yield improvement and at current canola prices, assuming $650/t ex farm (Newcastle port price less freight, July 2021), this would be worth $325/ha.

More recent (2015, 2016 & 2017) trials by NSW DPI under the GRDC co-funded ‘Optimised Canola Profitability Project’, have looked more closely at the impact WRT can have on yields and oil%. This work has shown in some cases that yield impacts were even greater than those seen in GOA’s trials. One trial at Trangie in 2016 showed a 48% yield loss when the crop was windrowed at 6% SCC as opposed to ~60% SCC. At Edgeroi 2016 a 55% (~1.3 t/ha) yield loss from windrowing 8-10 days earlier than the peak yield was measured. Tamworth 2016 showed a potential yield loss of 1.2 t/ha or 32% from premature windowing. (Graham et al, 2018).

The consistent message from both GOA and NSW DPI is that WRT earlier than the current recommended timings of 40-60% SCC, has consistently resulted in significant yield penalties.

The trials have also demonstrated the potential to increase yields further by delaying WRT past the old, recommended timings. The GOA trial at Coonamble showed a further 16% increase in yield (280kg/ha) from only a five-day delay in WRT from 50% SCC to 70% SCC (Street, 2014). Delaying WRT at Trangie in 2016 from ~60% SCC to the 100% SCC increased yields by a further ~800kg/ha (Graham et al, 2018. Several other trials also support these findings, where delaying WRT past 60% SCC increased yields. This outcome is not unexpected given that up to 100% SCC some immature seeds within the crop are still developing and so could still contribute to yield. The question remains however, at what point do the losses from pod or seed shatter negate any further increases in yield?

So, what has changed and why does later windrowing perform so much better?

Plant populations have generally reduced over the years. Street (2014) suggested that with lower plant populations, proportionally less yield is carried by the main stem where we assess windrow timing. Graham (2018) confirmed that greater than ~70% of the crop yield may be carried on branches as opposed to the mainstem and that more importantly, the stems were less mature than the mainstem. As such, estimating crop maturity based on the mainstem also overestimated average crop maturity. Windrowing crops based on mainstem maturity meant that much of the crop was immature and still had substantial yield potential unrealised if windrowed then.

Varieties have also evolved. Variety trials are seldom if ever windrowed but direct headed. Varieties susceptible to pod shatter would likely experience a higher level of yield loss compared to other more resilient varieties, thus reducing the likelihood that any such varieties would progress to commercialisation against other varieties that are more resistant to pod shattering.

This also suggests that varieties of 20-30 years ago may have been more likely to shatter at earlier level of SCC ,tipping the scale towards an earlier windrowing time than it would be with today’s varieties.

So when should I windrow?

As an outcome of this work new recommendations have been put forward to target the optimal windrow timing for canola, with two key changes:

- Crop maturity should be based on the whole crop not just the mainstem

- The optimum SCC has also moved later from 40-60% to 60-80%.

The current recommended timing is:

’Crops should be windrowed when 60-80% of the seed sampled from the middle third of the mainstem and the branches has changed colour from green to red, brown or black.’

A kit has recently been released ‘Canola - Windrow on Time, Reap the Rewards’ which details more the methodology to assess SCC and some illustrative references to help determine the level of SCC in your crops. An online version is available at https://grdc.com.au/canola-windrow-on-time,-reap-the-rewards

What has also been demonstrated is the rapid rate at which seed colour change can occur. Results from a NSW DPI trial in 2017 demonstrated that seed colour change went from 29% to 90% in only a 5-day period. In GOA’s 2010 trial at Coonamble, SCC went from 10% to 70% in just eight days and the trial at Warren in 2010 matured from 40% to 95% SCC in seven days. These results demonstrate that to windrow at the optimum timing of 60-80% SCC would only be a fraction of these times. As such, the window to windrow at an optimum crop stage can be very small.

Given the yield and financial impact that premature windrowing has, optimising yields in windrowed crops over a large area can be extremely difficult to achieve in practice. The fact that much of the canola crop, both the individual growers’ and the districts’, will require windrowing in the same small window, increases the difficulty in getting a windrower when needed.

How late is too late to windrow?

GOA undertook four trials that investigated the effects of delaying WRT past the previous timing recommendations. These trials used commercial windrowers and headers and reported harvested yields. They consider the potential losses from delayed windrowing through shattering; however, they are not quantified. In these trials there was no measurable decline in harvested yields even where WRT was delayed up to 95% SCC on the main stem. This is not to say that delayed WRT did not result in small increases in pod shattering, but any losses were compensated by increases in yields from other more immature parts of the plant.

In one trial however there was a measured a downturn in yield of 250 kg/ha as a result from a delayed WRT. However, the delay was measured as 7 days after 100% SCC and so represented an extreme case of late windrowing. This demonstrates that you can windrow too late and if growers are unable to windrow by the later stage of 80% seed colour change (whole plant) and/or significant pod shattering is likely during windrowing, leaving the crop to direct head may be a better choice.

Is direct heading a viable alternative to windrowing?

GOA has run several trials which have shown that yields from direct headed situations have generally matched the yields of a well-timed windrowing. However, when compared to that of an ill-timed windrowing i.e. too early or too late, direct heading outperformed the windrowed treatment.

Direct heading has often been made out to be very risky and not worth considering. Stories of very small harvesting windows before pod shattering occurs, increased exposure to weather damage, reductions in harvesting hours, delays to harvest commencement and slow harvest rates are common, however many such stories are not well founded.

Delayed direct heading and pod shattering

Results of a trial conducted in 2013 (Figure 2), demonstrated that the yields were stable in a standing direct headed crop and did not decline for two weeks after the first harvesting opportunity (Day 0). At this point there was a weather event resulting in a yield decline, after which the yield plateaued again. This suggests that in this situation, yield decline when harvesting is delayed tends to be stepped rather than linear and that shattering yield losses are most likely a function of weather extremes, which are fortunately infrequent but also unfortunately unpredictable.

Figure 2. Harvested grain yields in response to delay in direct heading from the first harvest timing ‘day 0’- Wellington 2013

PodGuard™ Canola promises of enhanced shatter tolerance

A unique genetic trait ‘PodGuard™’ has been bred into selected canola varieties which has increased tolerance to shattering. This trait may allow growers to either delay WRT until later stages of crop maturity to capture higher yields or allow growers to have confidence that pre-harvest shattering will be minimised in crops left to direct head.

GOA in conjunction with Bayer tested shattering tolerance of a PodGuard™ variety against a non PodGuard™ variety in a trial conducted in 2015. A severe shattering event was simulated consisting of dragging a two-inch steel pipe twice through the podding zone at harvest (i.e. 100% maturity) for a normal and delayed harvest timing.

At the first harvest timing (H1) without the simulated shattering event, the yields of the two varieties were comparable. However, when the simulated shattering was applied only the yield of the non Podguard™ variety 45Y25 was impacted, with yield reduced by around 600 kg/ha (~25%). Delaying harvest by 14 days (H2) resulted in no statistically significant yield decline in the PodGuard™ variety however the yield of the 45Y25 was reduced by ~500 kg/ha. Combining the simulated shattering event with the delay in harvest, the 45Y25 suffered around a further 500 kg/ha yield loss, while the PodGuard™ variety experienced no loss of yield, see Figure 3.

Figure 3. Harvested yield in response to harvest timing and simulated shattering by variety- Wellington 2015. H1 is harvested ‘on time’, H2 harvested with a 14-day delay. IH51RR contains PodGuard technology, 45Y25 does not.

During this trial, measurements were made to quantify the source and timing of the losses encountered. Details of these are covered in the full trial report on the GOA website which can be found at www.grainorana.com.au/documents?download=39

In summary, the PodGuard™ variety IH51RR has shown good potential to resist shattering from delays in direct heading or severe shattering events such as high winds or hail but worth also noting that although the 45Y25 suffered some yield loss from delays to harvest, it was not a complete disaster.

GRDC have also produced a ‘Direct Heading Factsheet’ that can be found at www.grdc.com.au/GRDC-FS-Direct-Heading-Canola

This factsheet examines many of the pros and cons and suggests that on top of yield advantages, farmers should also consider the additional benefits including the elimination of windrowing costs, applicability for heavy lodged crops that cannot be windrowed and for lighter crops where small windrows may be unstable in windy conditions.

However, it should be noted that windrowed crops are not immune to the impacts of adverse weather. Windrows, particularly those in light crops are highly susceptible to wind movement and subsequent yield loss. Hail can also impact windrows, as it can a standing crop, but in both cases, these are an insurable risk. Wet weather may also see some differences in grain quality. Anecdotally windrowed crops will stay wetter for longer after rain, delaying harvest and prolonging the risk of sprouting. This could lead to lower test weights and yields along with longer delays in recommencing harvesting.

How does timing of harvest vary between direct headed or windrowed crops and will desiccation help alleviate any differences?

One common concern for growers when considering direct heading is the perceived delay in the commencement of harvesting. It is thought that compared to windrowed crops, crops left for direct heading take a week or longer to dry down to acceptable grain moisture content before harvesting can commence.

One option to potentially manage this issue in direct headed crops is to apply a desiccant to the crop ahead of harvest to speed up the ripening process. Reglone™ has been registered for this purpose for some time, but its cost, difficulties in application and perceived unreliability often deters many from its use.

More recently glyphosate formulations such as Weedmaster™ DST marketed by Nufarm has been registered for use in canola for pre-harvest application. While the main label claim is for pre-harvest weed control, it also registered as a ‘harvest aid’, suggesting that it may also speed up the ripening process.

Over three years GOA has run four trials investigating the relative effectiveness of Weedmaster DST and Reglone, in reducing grain moisture content (GMC) to facilitate earlier harvesting. The key findings from this work were that Reglone, when applied to canola, showed some limited advantage in bringing GMC down quicker than natural ripening. In two of the 4 trials, there was no advantage to using Reglone (Geurie 2014 and Wellington 2015). At Wellington in 2013 the Reglone treatment would have allowed harvest to start approximately five days earlier. At Coolah in 2014, Reglone may have allowed an earlier harvest, but all treatments including the untreated was below 8% GMC within one more day and so offered little benefit.

Weedmaster DST applied pre-harvest also showed little practical benefit at bringing harvest forward with no significant difference in GMC at any harvest timing between any DST treatment and the untreated crop.

Further details of the trials can be found here.

An interesting observation in these trials was the rate at which the crops ripened without any desiccation and the relevance this may have to potential time differences between harvesting of a windrowed crop and direct headed one. Reglone in the trials detailed above was applied at ~70% SCC and considering the new windrowing recommendations, this crop stage is within an optimal WRT. It can be seen in the graphs above the time it takes the untreated crops to dry down to 8% GMC in relation to 70% SCC.

Both Wellington trials took only 13 or 17 days for the untreated canola crop to reach 8% moisture, but in 2014, Geurie reached 8% moisture in under 8 days and Coolah within 10 days. Typical district experience would suggest windrows often cure for at least 10-14 days most years and thus suggest the time to harvest a direct headed crop would be within days of one that is windrowed and not weeks as often thought could be the case.

The view of longer delays to this may be brought about though early windrowing. The earlier a crop is windrowed, the sooner it is dry enough to harvest relative to a crop left standing to ripen naturally. It could be suggested that in many cases if growers do experience lengthy delays in commencement of direct heading in comparison to similar ones around, it could indicate windrowing has commenced too early, which we now know could be incurring significant yield penalties. Looking at this from the other way, is that if growers adopt the later WRT, the difference between harvesting of windrowed crops and direct headed crops is likely to be less than previously experienced.

Windrowing allows me to get started on harvest earlier so as not to interfere with harvesting of my other crops.

Many growers argue their preference for windrowing canola as it hastens harvesting. However, as evidenced above, the difference may not be as large as some think if windrowing at the correct timings. Windrowing may offer several days which may be useful, but for many, this may still not be enough. If growers choose to windrow early to result in more available days to complete harvesting, it should be remembered this could come at a significant cost. Numerous trials have shown that premature windrowing could be costing growers up to $50/ha/day.

This issue may be magnified in crops with mixed maturities due to uneven establishment or major soil type changes etc. There is no debate that windrowing crops with significant maturity differences will allow harvest of the greener areas sooner than if left for direct heading. However, it is worth the grower considering the relative proportions of each maturity, and to which the windrow timing be set on. But the green areas may well be the highest yielding areas of the paddock and windrowing those areas early to suit the more advanced low yield areas may seem counterproductive. Setting windrowing to the greener parts of the paddock may risk shattering during windrowing in the more mature parts. It could be argued that there is no right time to windrow a crop with significant areas of contrasting maturity. If the areas are less balanced it will become an easier question to answer, but it will always be a compromise for some part of the crop.

Growers are often concerned that delays in canola harvest will impact on traditional wheat harvest periods, increasing harvest downgrade risks in wheat. Worth noting that windrowing early to accommodate an earlier start to wheat harvest will almost certainly incur a loss, while a weather downgrade to wheat may not even occur. It is also worth considering crop values. Canola in 2021 is twice the price of wheat and more than three times the price of barley. It could also be suggested that crop harvest order should not need to be set in stone. Traditionally canola has been harvested ahead of barley and wheat, but there is no issue with harvesting barley ahead of canola.

Pulling it all together

Windrowing will remain popular with many growers for several reasons, however growers should strive to windrow to the new recommended timings of 60-80% SCC across the whole crop. Failure to do so could result in significant yield penalties and with current pricing of canola, this can amount to a significant financial penalty. Windrowing crops in the optimal window, which can be quite small, can be logistically difficult and some growers may need to sacrifice yields by starting windrowing of large areas earlier, but again this can be at an additional cost in lost income.

Direct heading of canola is a worthy alternative to windrowing and much of the negative connotations of the past are not as common as often thought. Direct heading will allow for the whole crop to reach its full potential yield and oil%, and trial work suggests that it will yield as well as a correctly timed windrowed crop. If the alternate is to windrow too early or too late because of weather complications or availability of a windrower, direct heading may be the best option.

Concern over rapid yield loss with delays to direct heading have not really been demonstrated in trial work or with commercial experience, which has shown yields to be often quite stable post crop maturity. With ever improving varieties or PodGuard varieties, concerns could be even further allayed.

Time differences between windrowed and direct headed crops may also not be as different as thought, provided windrowing of crops is done at the latest recommended timing. If growers choose to windrow early to finish early, that decision will come at a significant price paid in terms of decreased yield and oil%.

GOA’s trial work on desiccation products has shown little advantage in terms of closing the gap on harvest timing, with Reglone, while not consistent, performing better that Weedmaster DST but overall neither achieving practically useful results.

Useful resources

Direct heading canola factsheet

Canola best practice management guide for south-eastern Australia

References

Carmody, Paul (2009) Canola best practice management guide for south-eastern Australia- Chapter 14, Windrowing and Harvesting https://grdc.com.au/resources-and-publications/all-publications/publications/2009/08/canola-best-practice-management-guide-for-southeastern-australia

Graham R, Jenkins L, Brill R, Hertel K, McCaffery D (2016) Assessing seed colour change for improved harvest decisions in canola: include branches with the main stem. In proceedings 19th Australian Research Assembly on Brassicas. Melbourne, Australia 3-6 October 2016

Graham R, Jenkins L, Hertel K, Brill R, Bombach R, McCaffery D, Brennan N (2018) Improving harvest management decisions in canola – implications of seed colour change and windrow timing on seed yield and oil concentration. Sourced at- https://grdc.com.au/resources-and-publications/grdc-update-papers/tab-content/grdc-update-papers/2018/02/improving-harvest-management-decisions-in-canola-implications-of-seed-colour-change-and-windrow-timing-on-seed-yield-and-oil-concentration

Grain Orana Alliance (2019). ’2017 Practice Change Survey- Canola Harvest and Nutrition‘ sourced at: http://grainorana.com.au/documents?download=78

Hertel K (2013) “Canola: the economics and physiology of the timing of windrowing” sourced at: https://grdc.com.au/Research-and-Development/GRDC-Update-Papers/2013/02/Canola-the-economics-and-physiology-of-the-timing-of-windrowing

Street M (2014) ‘To windrow or not to windrow in 2014? This is the question, but if so, when?’ sourced at: https://grdc.com.au/Research-and-Development/GRDC-Update-Papers/2014/02/To-windrow-or-not-to-windrow-in-2014--This-is-the-question-but-if-so-when

Acknowledgements

The research undertaken as part of this project is made possible by the significant contributions of growers through both trial cooperation and the support of the GRDC, the author would like to thank them for their continued support.

Contact details

Maurie Street

Grain Orana Alliance

PO Box 2880 Dubbo NSW 2830

Ph: 0400 066 201

Email: Maurie.street@grainorana.com.au

TM Trademark

GRDC Project Code: GOA00002,