Managing grain quality during storage

Author: Chris Warrick (Primary Business) | Date: 26 Jul 2022

Take home message

- Aeration cooling can help in a wet harvest but can’t replicate drying – understand aeration capacity

- Cool and dry storage conditions maintain chickpea seed viability significantly longer than warm, moist conditions

- Falling numbers could possibly improve after harvest – watch this space for research results.

Aeration

Until recently, aeration systems have relied on American research from 1951 to model fan performance requirements to overcome the backpressure of various types of grain at varying depths. In 2022 highly accurate pressure and airflow meters combined with an investment from the GRDC has enabled research to determine the backpressure and therefore fan performance required to aerate Australia’s commonly grown grains at typical storage depths.

Aeration is designed to achieve one of two main functions – cooling or drying. Understanding the difference is the first step, understanding the system requirements is the next, and of course then learning how to operate and manage storages with aeration cooling or drying is what makes it a valuable tool.

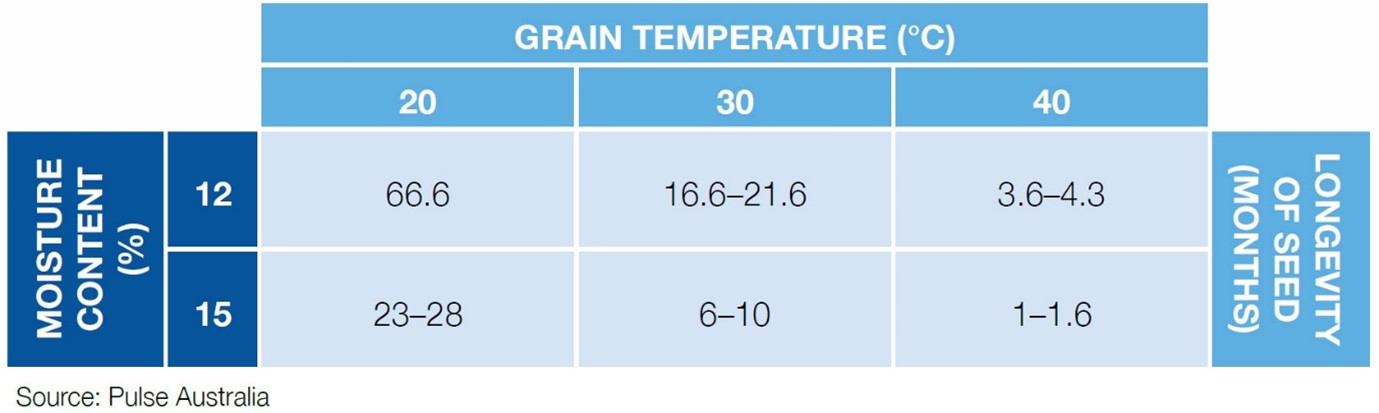

Existing Pulse Australia research tells us that chickpea seed longevity is sustained for significantly longer when stored in cool, dry conditions. Take for example chickpea harvested at 40 degrees Celsius and 15 per cent moisture content without aeration cooing, will have an expected seed life of 1 to 1.6 months. Compare that to chickpeas stored at 20degrees Celsius and 12 per cent moisture content having a seed life in excess of 66 months.

Figure 1. Storage life of chickpeas (months)

Research currently being undertaken in Horsham by Agriculture Victoria is also indicating grain colour, in particular in pulses can be maintained for longer in cooler storage conditions, i.e., with aeration cooling.

Cooling grain to maintain grain quality, prevent mould and deter or slow insect activity requires 2-4 litres of air per second per tonne of grain. To dry grain with aeration, flowrates have to be over 15 l/s/t to reliably carry moisture out of the grain bulk. Understanding that a one per cent drop in moisture content equates to 10L of water per tonne, or 1000L of water from 100t and the requirement for high airflows for drying make sense.

While the flow rates used for aeration cooling won’t dry grain, it can even grain moisture within a grain bulk to aid blending and prevent mould from developing around green grains or clusters of higher moisture grain. Aeration cooing can even be used to hold over moisture grain for a few months until it can be blended or dried. Anecdotally, growers are utilising aeration cooling to hold over moisture grain allowing harvest to start sooner, or earlier each day, then blending with low moisture grain harvested later in the season or in the afternoons.

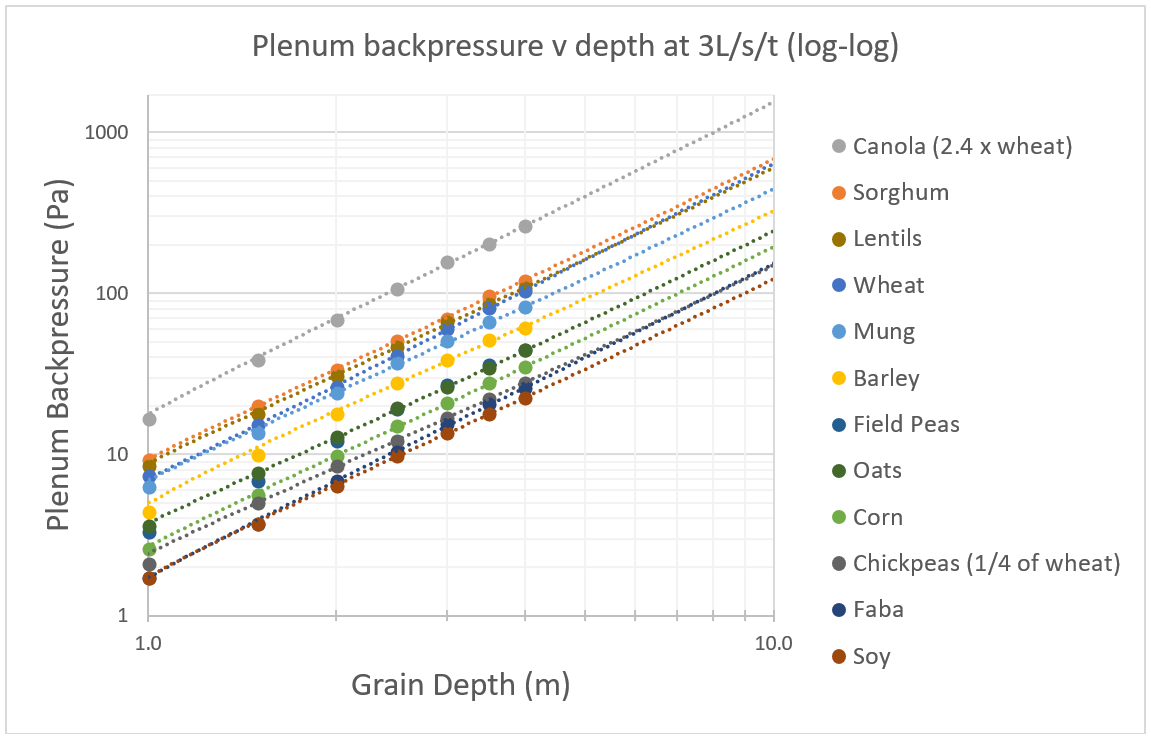

The 2022 GRDC research revealed that aeration backpressure increases exponentially with grain depth and air flowrate. Aeration cooling in canola requires a fan that can perform against nearly two and a half times the backpressure of wheat in a ten-metre-high storage. In contrast, aeration cooling chickpeas requires a fan to work against only one quarter the of backpressure of wheat in a 10m high storage.

Figure 2. Aeration cooling backpressure by grain type (Source: GRDC)

Matching fans to storages require a decision of the main function – cooling or drying, then of what grain types and to what depth. For most growers, storages are used for many grain types so the most efficient system may require variable speed fans, or multiple fans that can be turned on or off as required. It’s worth noting that multiple fans have to overcome the back pressure of each other before the backpressure of the grain, so doubling the number of fans may increase the air flow, but will not double the air flow.

Falling numbers after harvest

Anecdotally, some growers have reported improved falling number test results on weather damaged grain after it has been held in storage. Unable to find any reliable laboratory or field research, the GRDC swiftly commissioned research in 2022 to test the observation.

The aim of the research is to answer initial questions in a short space of time with the opportunity of weather damaged grain from 2021. The main question being, can falling number test results be improved with time in storage?

Secondary questions are, if possible, how far could we expect test results to improve, how long does it take, does grain storage temperature and moisture influence results and are there varietal differences? If proven possible, further research may be required to test the effect on milling and malting quality of weather damaged grain if its falling number test has been improved with time in storage.

Stay tuned for results to be released via the GRDC communication channels and Stored Grain later in 2022.

Acknowledgements

GRDC Grain Storage Extension Project. Ben White, Philip Burrill, Alex Conway, Jo Panozzo, Felicity Harris

The research undertaken as part of this project is made possible by the significant contributions of growers and supply chain businesses through both trial cooperation and the support of the GRDC, the author would like to thank them for their continued support.

Contact details

Chris Warrick

Primary Business under contract by the GRDC

Horsham Victoria

1800 WEEVIL (1800 933 845)

Email: info@storedgrain.com.au

GRDC Project Code: PRB2011-001SAX,

Was this page helpful?

YOUR FEEDBACK