Spray drift hazard warning system

Author: Graeme Tepper (MicroMeteorological Research and Educational Services) | Date: 21 Jul 2022

Take home message

Utilising real time and forecast guidance of hazardous inversion spray conditions for your local region from a drift hazard warning system, will negate the need for guesswork as the prime input into critical spray decisions. This should lead to significant reductions in drift events. Less drift will reduce the loss of valuable crop protection products and associated off target damage to sensitive areas and crops.

Spray drift hazard warning system

The spray drift hazard warning system is a new and leading-edge technology developed in Australia, for Australian conditions. It offers detailed real time information of environmental conditions impacting spray operations and the dispersion of potential drift. It replaces inadequate and antiquated guesswork and the visual cues currently relied on to determine critical spray conditions, including the presence of hazardous temperature inversions. While the system delivers around the clock information, a key benefit is to provide support to those growers wishing to spray during night hours. When fully functional, it will enable for more efficient night-time spraying through identification of hazardous conditions in real time. The network utilises remote sensing technology and new proprietary software to provide growers and spray applicators with a 2-hour forecast (Nowcast) of the presence or absence of hazardous inversions. Ongoing research and development into WAND will see the rollout of a 24-hour forecast. This longer forecast will allow growers to have better insight into weather conditions to better manage their spraying and labour.

Spray drift still impacts many industries, the environment and human health

Spray drift represents as loss of product and a potential reduction in efficacy at the application target site. While direct drift can have an obvious source i.e., when damage occurs downwind from the application site, widespread drift damage having no visible gradients is most likely caused by the release of a component of the spray volume with droplet sizes small enough to allow for its continued suspension and movement in localised laminar air streams. These drift incidences, commonly associated with hazardous temperature inversion conditions, are caused by a lack of atmospheric turbulence to effectively disperse these suspended spray particles.

Under hazardous inversion conditions, spray particles may remain suspended for long periods of time, allowing for the particles from single or multiple application points to combine into much higher concentrations before deposition. Higher concentrations lead to greater impacts regardless of the susceptibility of affected off target crops and plants. Spray drift can negatively impact crops, flora, fauna, waterways and human health. It can cause harm to Australian exports and impact the future availability of valuable crop protection products.

Some recent examples of impactful drift:

- The sudden defoliation of hundreds of plants west of Dubbo has raised fresh concerns about chemical spray drift from local cotton farms and stoked tensions between landowners and aerial operators (2021)

- In 2018, while less than 10% of the Australian cotton crop was reported as impacted by spray drift, the financial impact was significant - costing an estimated $18 million in production losses

- In 2016 an estimated 26% of the cotton crop was affected by spray drift (Source: Cotton Australia)

- Sorghum crops on the Darling Downs and Central Queensland have been impacted

- Vineyards in the Riverland and Clare Valley have suffered

- Almond farms in the Mallee have been damaged.

Even coarse spray quality can drift

Bill Gordon found that:

- “With a coarse spray quality, drift may travel 300 to 400 meters by day (and further- but difficult to detect)

- Spraying at night using the same products, nozzles and ground speed can leave up to 5 times more chemical in the air. Resulting in spray drifting 10 to 20 kilometres or more at night

- This is unacceptable for other farmers, the community and the environment.”

Spraying at night when hazardous inversion conditions exist

- Will lead to the highest possible concentrations (sometimes combinations from multiple applications across thousands of hectares) of pesticides floating and spreading horizontally

- Spray drift is caught up in local winds transporting it at between 2 and 11 kph; sometimes more.

Current regulations permitting pesticide application

- DO NOT apply if there is hazardous surface temperature inversion conditions present at the application site during the time of application

- When application occurs in an area not covered by recognised inversion monitoring weather stations, all surface temperature inversion conditions must be regarded as hazardous.

- For full details please see the APVMA website

Definitions of ‘hazardous’ and ‘recognised inversion monitoring’

Based on research of Grace and Tepper 2022:

- Hazardous inversions occur when the atmosphere is strongly stable and the intensity of turbulence is so weak that drift is not dispersed vertically

- Recognised monitoring systems have sensors to measure the intensity of vertical turbulence.

- Refer to spray drift definitions at APVMA website

Warning system infrastructure and layout

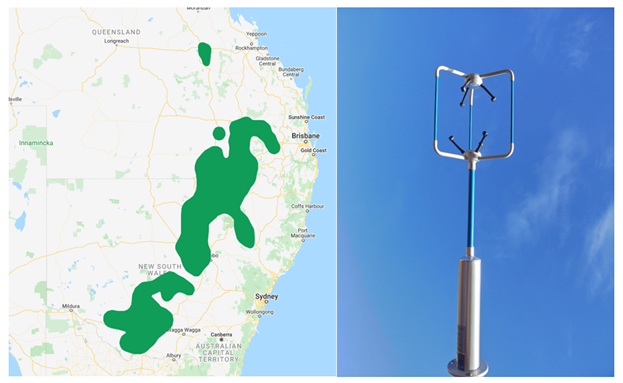

The network coverage of 100, 10 m high, Profiling Automatic Weathers Stations (PAWS) to be established before the summer of 2022/23 is depicted below (Figure 1).

Deliverables

The system will support more informed decision making. It will:

- Provide applicators with real time data indicating the presence or absence of hazardous inversion conditions

- Deliver short term 2-hour forecast (Nowcast) of the presence or absence of hazardous inversions to assist in decision making if spray operation should commence, continue or cease.

System benefits

Currently, the vast majority of growers rely on guesswork and limited visual cues, to determine if hazardous inversions exist. Decisions based on these tenuous clues are fraught with uncertainty, false detections and missed events.

Use of the system will:

- Replace guesswork as the main support for critical decision making

- Provide real time data updated every 10 minutes

- 24-hour short-term forecasting (Nowcast) in support of planning and decision making

- Provide less skilled labour clear indications of when to GO/STOP

- Archived data will provide in-depth local knowledge of typical conditions and trends to be expected by month and season

- In-depth knowledge will support improved deployment of manpower and equipment

- Provide all the standard weather data at greater granularity then currently available

- Deliver data to current and future automatic spray systems.

Figure 1. System coverage and the turbulence and wind sensor.

Figure 1. System coverage and the turbulence and wind sensor.

Figure 2. System infrastructure.

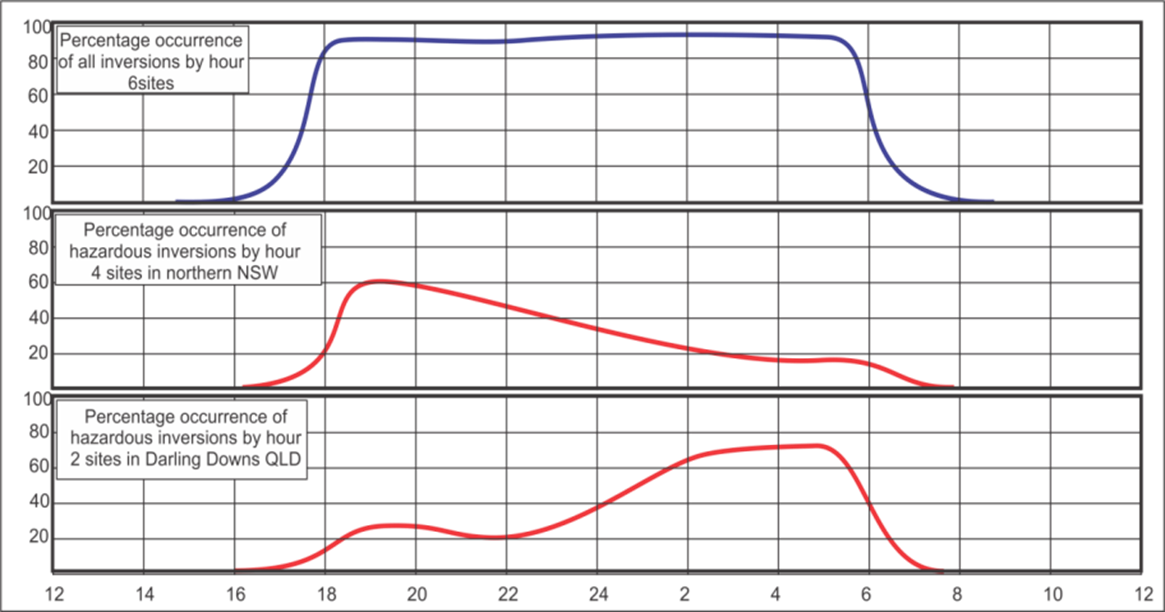

Figure 3. In some regions hazardous inversions are most frequent in the early evening. Percent of inversion occurrence by hour (top ‘at 6 sites’, middle ‘at 4 sites in NNSW’ and bottom ‘at 2 sites on the Darling Downs’)

A grower trial of the spray drift hazard warning system indicated that its use leads to:

- Spraying longer in optimal conditions

- Avoidance of hazardous conditions.

Growers found that the flow on effects of utilizing the system were:

- Improved practices and efficiencies:

- in the timing of applications, and

- improved allocation of manpower/machine (operating hours operators did not sit around waiting for good conditions).

Common response from users: The system was a real eye opener. They learnt a lot.

Future potential

The system will differentiate between hazardous and non-hazardous inversions and increase spray hours.

Data and advice could potentially be integrated into automated sprayer systems.

Acknowledgements

The research undertaken was made possible by the significant contributions of growers through both trial cooperation and the support of the GRDC, CRDC, and DPIRD. The author would like to thank them for their valued support.

GRDC funded - Management of spray drift through inversion risk awareness- supported and managed by DAFWA- DAW 00231 - 01/07/2013 to 30/06/2016). GRDC - Air inversion modelling to manage spray drift, MRE00002; 01/02/2016 to 30/06/2019 with 3 extensions through to 2022.

CRDC funded - Development of a Spray Drift Hazard prediction system, MRES 2101, 1/07/2016 to 30/06/2019: and Spray decision systems and resources grower testing, MRES 2001, 15/02/2020 to 11/06/2020.

References

Research methods and outcomes are published in the Journal of Applied Meteorology and Climatology.

Micrometeorological Aspects of Spraying within a Surface Inversion by Warwick Grace and Graeme Tepper 2021.

Contact details

Graeme Tepper

Director of MicroMeteorological Research and Educational Services

Email: G.tepper@bigpond.net.au

GRDC Project Code: MRE1602-001RTX,

Was this page helpful?

YOUR FEEDBACK