Herbicide strategies to manage feathertop Rhodes grass and other summer grasses - optimising tools in the tool kit

Herbicide strategies to manage feathertop Rhodes grass and other summer grasses - optimising tools in the tool kit

Author: Mark Congreve (ICAN) | Date: 23 Nov 2022

Take home message

- Herbicide resistance is changing summer grass weed management

- If utilising glyphosate as the foundation of fallow sprays, ensure application is optimised

- Restrict Group 1(A) herbicides to a single application per crop/ fallow

- Double knock all post-emergent herbicide applications

- Residual herbicides take the pressure off post-emergent strategies. Careful selection of residual herbicide will be required with regard to following crop choice.

Why do summer grass weeds cause so many problems in fallow?

Managing grass weeds in summer is becoming increasingly difficult. This is due to many years of no-till farming which has selected weed species adapted to a farming system without cultivation (especially surface germinating weeds) and for resistance to frequently used herbicides.

Over time, summer fallows have become dominated by a range of species which prefer to germinate on, or close to, the soil surface. Examples include feathertop Rhodes grass, awnless barnyard grass, sweet summer grass, flaxleaf fleabane and common sowthistle.

To complicate management, glyphosate resistance is now prevalent in most of these species (Table 1).

Table 1. 2021/2022 resistance survey – Central Queensland populations (QDAF unpublished)

No. | % Resistant | ||

|---|---|---|---|

Glyphosate | Haloxyfop* | ||

Feathertop Rhodes grass | 35 | 100 | 0 |

Sweet summer grass | 26 | 81 | 0 |

Awnless barnyard grass | 2 | 100 | 0 |

*Note – while this round of resistance testing did not pick up any survivors to haloxyfop, previous resistance screening has identified a low occurrence of resistance to Group 1 herbicides in summer grass weeds in the northern grains region.

For some weeds such as awnless barnyard grass, temperature is important for germination, with major weed flushes generally only occurring under warmer conditions. However, for many of the key fallow species, rainfall is the primary factor driving germination – in particular, rainfall patterns that are able to keep the soil surface wet for several days. This generally requires a higher volume of rainfall when conditions are hotter.

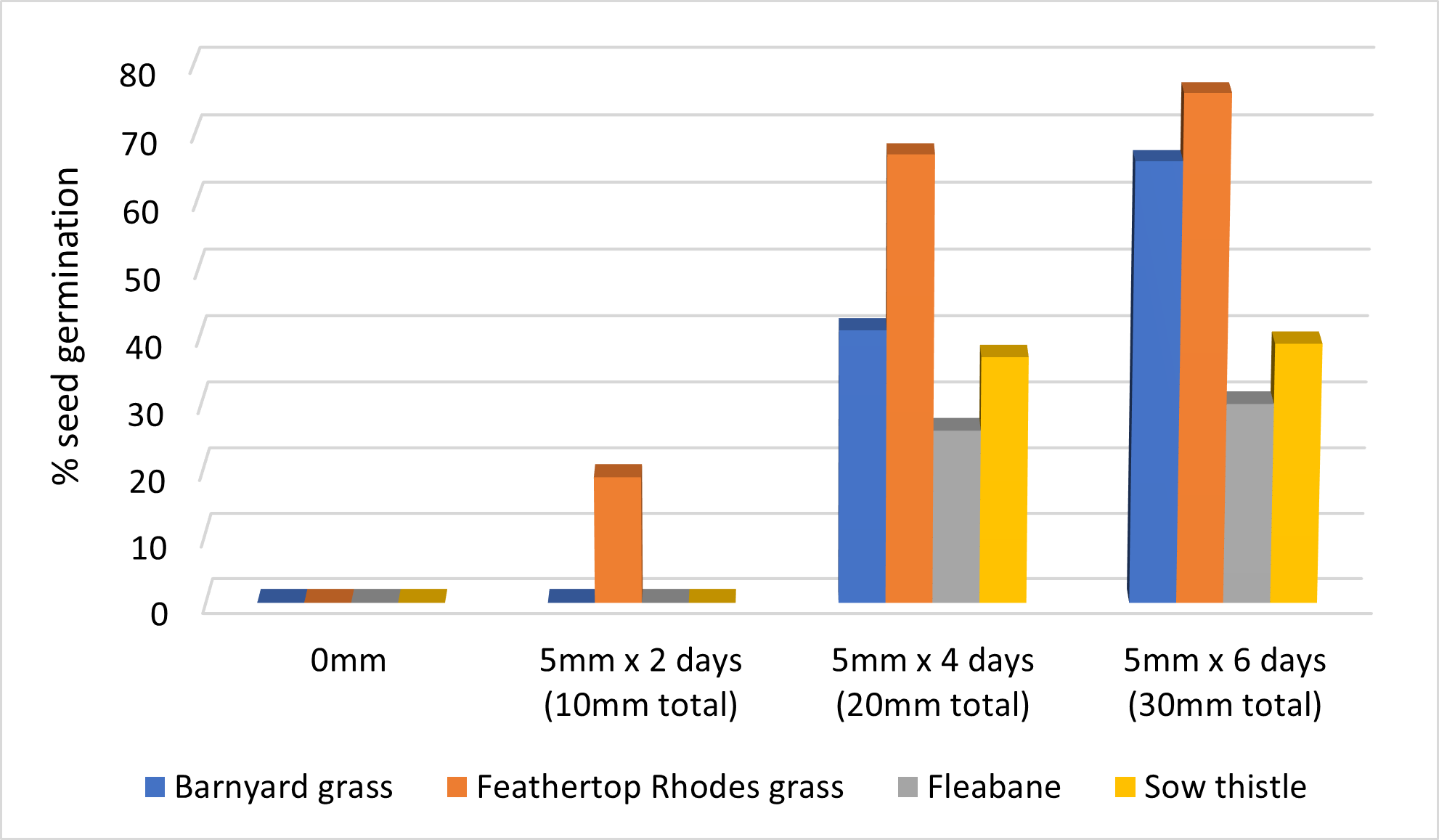

For example, a 30+mm rainfall event that keeps the soil surface wet for several days in spring or early summer will usually trigger a major weed germination of several species. However, a smaller event (e.g., 10mm) may not be adequate to trigger a germination at all for some species. Or the smaller rainfall event may only result in a few plants germinating.

Figure 1. Germination of 4 summer fallow weed species in response to simulated rainfall @ 15/25oC. Werth et al. (2017)

In particular, feathertop Rhodes grass (FTR) has been shown to germinate on lower rainfall events compared to several other fallow weeds. This can result in more FTR germinations per summer (compared to other species), although often these smaller rainfall events may only germinate a low number of seedlings each time. The management implication is that, when relying on post-emergent herbicides only for FTR control, more spray passes per summer are likely to be required when dealing with FTR, compared to other species that require a larger rainfall event to trigger a germination. This creates problems when glyphosate is often ineffective and Group 1 herbicides are limited in the number of times they are registered to be used in a fallow. Additionally, if the density of a FTR germination is not sufficient to justify a spray pass, then these weeds are likely to be too large to be able to be controlled at a following application, and hence escape and set seed.

As a result, growers who are successfully dealing with these small, but frequent FTR germinations have typically adopted a two-pronged management strategy that consists of an effective residual herbicide applied at the start of the fallow; coupled with optical sprayers which can be cost-effectively utilised to target any escapes as they germinate.

Starting the fallow clean – strategies to manage grass weeds in summer fallow

In the presence of glyphosate resistance, it is of increased importance to start the fallow clean after harvest. Also, there is far greater risk in strategies that delay fallow sprays in the hope of picking up the next weed emergence in the one spray.

Glyphosate is generally still the fundamental base of most broadcast applications in fallow, so optimising its performance is critical. Typically, resistance to glyphosate is not ‘strong’ (at least in the early stages of resistance selection) and control of ‘resistant’ individuals may still be possible by getting a high dose of glyphosate into the plant and having effective translocation to the roots.

10 tips to optimise glyphosate

(1) Weed size and growing conditions are important – especially for resistant individuals. Target small, non-stressed weeds.

(2) Keep application rates robust. Some labels have use patterns that allow higher application rates via broadcast and/or optical spot sprayer application.

(3) Glyphosate binds tightly to soil particles. Always use clean water and avoid ‘dusty’ application conditions.

(4) Understand your spray water quality. Glyphosate is adversely impacted by water high in cations or bicarbonates. Pre-treating water with ammonium sulphate fixes cation problems, partially fixes bicarbonates, improves physical compatibility with other herbicides and assists glyphosate movement within the plant.

(5) Glyphosate is slow to enter the leaf. The more time a droplet of glyphosate stays wet on the leaf surface, the more gets in the plant.

- Leaf entry reduces considerably under hot (>30oC) and low humidity conditions

- Large spray droplets (VC+) have better survival under summer application conditions

- Rainfall within hours of application can wash glyphosate from the leaf surface before all has entered the leaf.

(6) Glyphosate enters the leaf fastest when the concentration gradient is high (i.e., high rate/ha in low water volume/ha). Noting that:

- Some labels require a minimum water rate of 50 L/ha

- If targeting small (1-2 leaf), upright grass weeds with large droplets then water rates of >80L/ha may be needed to ensure to ensure that there are enough droplets to hit the small target.

(7) Glyphosate acidifies the spray tank by itself. There is generally no advantage in adding a pH buffer for most water sources.

(8) The correct type and rate of surfactant is important. Follow label advice on when and where extra surfactant is required and what type to use.

- A general purpose ‘spreading’ non-ionic surfactant is generally not the right adjuvant for glyphosate and may reduce control in certain situations

- The addition of spray oils can often reduce performance on summer grass weeds.

(9) Glyphosate takes 2-3 days to fully translocate through a small annual plant

- Herbicides which have fast brownout (e.g., paraquat, high rates of Group 14(G), glufosinate) reduce glyphosate translocation

- Herbicides which affect hormone systems in the plant (e.g., 2,4-D, MCPA, dicamba, fluroxypyr) also reduce glyphosate translocation.

(10) Always double knock fallow applications, especially Group 1 (A) herbicides.

To delay herbicide resistance, all weeds must be prevented from setting seed. The most effective way to achieve this is via a double knock which is designed to control the one or two weeds that survived the first pass. These small number of survivors of the first pass are the individuals that are most likely to be resistant. For a double knock to be successful, the first pass application must be highly effective (i.e., generally >90% on its own), with the double knock then able to achieve 99+% control. If the first pass efficacy is poor (i.e., <80% on its own), then any following double knock strategy is unlikely to achieve the required efficacy to ensure 100% kill of all individuals required to slow the progression to resistance.

Alternate post-emergent grass herbicides for fallow

Paraquat based herbicides

- Contact herbicide. Works too fast to allow significant translocation

- Thorough coverage of all green material and especially the growing point (crown of grass weeds), is critical for effective control

- Works much better on very small weeds

- Increase water volumes as weed size increases (Table 2).

Table 2. Spray.Seed® herbicide label advice

Boom spray volumes | Summer rainfall areas |

50-100L/ha | Small plants (2-5 leaf) and well separated |

100-150L/ha | 5 leaf to early tillering/rosettes; 30-50% ground cover |

150-200L/ha | Advanced growth; dense and/or tall weed stands |

Use a split application @ 150L/ha | Very dense and tall weed growth |

- Clean water is essential

- Smaller droplets help achieve coverage, but these may evaporate before reaching the target under summer (hot, low humidity) conditions

- Typically, paraquat is most useful as the second pass in a double knock strategy (+/- a residual partner), applied at 80-100+ L/ha with a medium to coarse (M-C) spray quality.

Biffo® (glufosinate)

- Contact herbicide. Works too fast to allow significant translocation.

- Thorough coverage of all green material is required, including the crown of grass weeds. Label recommends a minimum water volume of 100L/ha applied at medium (M) or coarse (C) spray quality.

- Particularly sensitive to hot, low humidity conditions. Label recommends application below 33oC and more than 50% RH.

- Generally stronger on broadleaf weeds than grasses.

- Some (not all) labels support use on a range of broadleaf weeds in fallow at 3.75 L/ha (750 gai/ha).

- Nufarm Biffo® is registered for application via optical spray technology at 10 L/100L for selected broadleaf weeds plus awnless barnyard grass.

Group 1(A) herbicides

- Translocated, grass selective herbicides. However, translocation is ‘poor’ so they need to applied similarly to contact herbicides e.g. high leaf coverage on very small weeds.

- High potential for resistance selection

- Maximum of 1 application per crop or fallow (Table 3)

- Always double knock after application in fallow.

Table 3. Group 1(A) herbicides registered for use in fallow (Oct 2022)

Barnyard grass | Button grass | Crowsfoot grass | Feathertop Rhodes | Liverseed grass | Rhodes grass | Summer grass | Sweet summer grass | Stink grass | Windmill grass | ||

Firepower 900 | haloxyfop |

|

|

|

|

|

|

|

|

|

|

Shogun® | propaquizafop |

|

Additional APVMA permits for fallow situations

- In addition to the Firepower registration above, PER12941 (expires 31 July 2024) is in place for Queensland only to allow the use of 520 g/L haloxyfop formulations in fallow for the control of feathertop Rhodes grass, provided the following crop is mungbean.

- PER91513 (expires 31 January 2025) is in place for NSW and Queensland only to allow the use of Arysta Select Xtra Herbicide (clethodim) for control of glyphosate resistant / tolerant annual grasses such as feathertop Rhodes grass, windmill grass or barnyard grass, when followed by Gramoxone 360 Pro Herbicide (paraquat) as a double knock.

- PER90223 (expires 31 December 2026) allows the use of specified formulations of quizalofop, haloxyfop, clethodim, butroxydim and fluazifop (and selected other herbicides) in fallow when applied via optical spot spray technology.

In all cases, refer to actual permits for additional critical comments for use.

Can I mix Group 1(A) herbicides with glyphosate?

It is common for users to wish to mix glyphosate and Group 1(A) herbicides to control a broader spectrum of weeds. While this mix has often been used successfully, there are several considerations:

- Some (but not all) trials have demonstrated reduced control on summer grasses from the mix when compared to the Group 1(A) herbicide applied alone. The follow up double knock application generally covers for any antagonism

- Group 1(A) herbicides typically perform best with a crop oil concentrate adjuvant (e.g., Uptake®, Hasten®) which are a blend of spraying oil + high load of surfactant. Crop oil concentrates can antagonise glyphosate, so any tank mix will result in a compromise for surfactant choice

- Group 1(A) herbicides work best when applied at water rates above 80 L/ha and a medium to coarse (M-C) spray quality. Glyphosate typically works best (especially in summer) when applied at lower water rates (typically 50-60 L/ha) and a coarse to very coarse (C-VC+) or larger spray quality (depending on conditions and the weed target). So, any tank mix will require a compromise in sprayer set up

- Do not add Group 4(I) herbicides (e.g., 2,4-D, fluroxypyr) when using Group 1(A) herbicides, either alone or in mixes with glyphosate. A major reduction in grass weed control will occur.

Residual herbicides in fallow

Widespread glyphosate resistance, coupled with resistance concerns surrounding Group 1(A) herbicides limiting application to one spray per fallow and the logistics of the increasing number of summer fallow sprays is driving many growers to incorporate residual herbicides into fallow programs.

Several residual herbicide options are now available for fallow use on grass weeds (Table 4). The selection of which herbicide to use, is often driven by the length of persistence required, the intended following crop and activity on broadleaf weeds.

Table 4. Key residual herbicides registered for use in fallow and examples of grass weeds controlled (Oct 2022)

Barnyard grass | Button | Feathertop Rhodes | Liverseed grass | Crowsfoot grass | Persistence | ||

Dual® Gold | s-metolachlor |

|

|

|

| Short – Moderate | |

Valor®/ | flumioxazin |

|

|

| Short – Moderate | ||

Balance® | isoxaflutole | S |

| Short – Long | |||

Palmero TX | isoxaflutole + terbuthylazine |

|

| Short – Long | |||

Impose® | imazapic |

|

|

| Very long |

S = suppression

Key factors to consider when using residual herbicides in fallow

- Even deposition on the soil surface is the application objective. Typically, this is best achieved using large, solid droplets applied at higher pressures and water rates that will result in less droplet interception by stubble and existing weeds. This may be a compromise with sprayer set up for a knockdown herbicide partner where the objective is higher coverage on existing weeds (and stubble by default)

- Residual herbicide deposited on green leaf material will be taken up by the plant in the hours following application. For some herbicides this may add to knockdown control, however this percentage of herbicide deposited on green leaf material will not reach the soil and therefore is not available for residual control

- Applying a residual herbicide in combination with a knockdown herbicide on dense weed infestations may result in reduced length of residual herbicide performance, as less residual herbicide will reach the soil

- If paddocks are weedy, it is best to achieve knockdown control prior to applying the residual herbicide. In less dense weed populations, applying the residual herbicide with the second pass of a double knock program is often acceptable.

- All fallow residual herbicides work best when rain falls soon after application

- Flumioxazin, isoxaflutole and imazapic are relatively stable on the soil surface and can ‘wait’ for subsequent rainfall

- Flumioxazin and isoxaflutole work best when left on the soil surface. Do not cultivate after application

- S-metolachlor can be lost to UV degradation over time if not incorporated by rainfall or shallow cultivation. Should incorporation be delayed, then length of residual control will be reduced. S-metolachlor usually works best when applied in front of a 5mm+ rainfall event.

- Length of residual

- Flumioxazin and s-metolachlor breakdown relatively fast under summer conditions providing the soil is moist. Length of control is highly influenced by the application rate used

- Breakdown of isoxaflutole-based herbicides is mostly influenced by the frequency and intensity of rainfall

- Imazapic persistence is very long, particularly on acidic soils. Be aware of the rotational crop constraints before using this herbicide. The Impose® herbicide label contains the most recent plantback information for imazapic

- All herbicides will persist longer where there are periods of time when the topsoil dries out, and hence microbial degradation stops until further rainfall wets the top 10-15cm of soil profile.

Managing FTR in spring / summer

Research has shown that the Achilles heel for FTR is its short seedbank life – with two consecutive years of zero seed set resulting in major declines in future germinations (unless the paddock is subject to wind or surface water movement that introduces new seed).

In paddocks with dense FTR, often the best management strategy will be two consecutive summer broadleaf crops such as mung beans or (solid plant) cotton. The combination of effective pre-emergent and early post-emergent herbicides available in these crops, coupled with crop competition and potential for interrow cultivation and/or chipping should result in crops clean of FTR at harvest, and therefore significant depletion of the seed bank.

Spring / summer fallow may also be a viable strategy to drive down the seed bank. However, the ability of feathertop Rhodes grass to germinate on small rainfall events, coupled with limited effective knockdown options, will require the use of a residual herbicide, followed with several passes of knockdown herbicides applied via an optical spot sprayer to pick up weed escapes.

Careful consideration should be given to growing sorghum or maize in paddocks known to have significant FTR seedbanks. Typically in CQ, sorghum or maize is sown on 1m (or wider) row spacing, providing little crop competition in the inter-row. At-planting applications of s-metolachlor are unlikely to last through to harvest (especially in wet years) and there are no post-emergent control options should FTR establish in-crop other than inter-row tillage. This combination of factors often results in these crops becoming an FTR ‘blow-out’, allowing a massive FTR seedbank increase – often requiring several years and significant dollars to bring the seedbank back under control.

Ideally sorghum should only be grown in paddocks that are known to be relatively free of FTR seed, while also ensuring any initial plants are completely controlled before planting and a full rate residual herbicide (Dual® Gold) strategy is implemented.

Recent research by Northern Grower Alliance (NGA) has been investigating the timing of residual herbicide applications to manage FTR in sorghum, with various treatments being applied from late winter through to early post-emergent timing in spring sorghum and comparing this to the conventional approach of applying Dual Gold at-planting only. The key finding of this research, conducted over several seasons, shows that commencing a residual herbicide program early (i.e., late winter) before any FTR has germinated consistently resulted in cleaner sorghum crops, as opposed to waiting for a planting rainfall event and trying to manage FTR germinating on this rainfall (refer to the Richard Daniel (NGA) paper in these proceedings). As almost all grain sorghum in central Queensland is sown in the later sowing window (January), the applicability of this strategy requires validation in the CQ environment.

Acknowledgements

The research undertaken as part of this project is made possible by the significant contributions of growers through both trial cooperation and the support of the GRDC, the author would like to thank them for their continued support.

References

Werth J, Keenan M, Thornby D, Bell K and Walker S (2017) Emergence of four weed species in response to rainfall and temperature. Weed Biology and Management 17, 29–35

Contact details

Mark Congreve

Independent Consultants Australia Network (ICAN)

M: 0427 209 234

E: mark@icanrural.com.au

® Registered Trademark

GRDC Project Code: ICN1912-002SAX,