Investigating the application of electric weed control in Australian fallow scenarios

Investigating the application of electric weed control in Australian fallow scenarios

Author: Miranda Slaven and Dr Catherine Borger | Date: 28 Feb 2023

Key Messages

- Electric weed control uses high-voltage current to burst the shoot and root cells of the weed, either killing the weed or suppressing growth.

- Results from field trials showed that electric weed control is highly effective in fallow scenarios, with results comparable to herbicide treatments.

- Electric weed control was generally found to be more effective in controlling broadleaf weeds than grass weed species.

Introduction

Weed control in Australian agricultural systems is becoming increasingly challenging due to the rising prevalence of herbicide resistance. As a result, Australia needs to consider alternative, non-chemical forms of weed management. One such alternative is electric weed control, or “electroweeding”, with numerous companies globally producing machinery that uses this technology. Electric weed control provides weed management by passing a high-voltage electrical current through the target plant following electrode-plant contact. As a result, the plants’ cells burst, causing plant death or growth suppression.

Electric weed control, as a non-selective weed management strategy, is most likely a good fit for agricultural fallow management, as well as weed control in non-cropped or urban and industrial areas of Australia. Further, it can be used in smaller areas of problem weeds such as firebreaks, and along fences or roadsides. Electric weed control may offer a viable alternative to herbicides, currently applied as a single or double application (‘double knock’). The Department of Primary Industries and Regional Development (DPIRD) is conducting an Australian-first project in partnership with AGXTEND™ to evaluate the applicability of electric weed control as a non-selective weed management strategy.

Methods

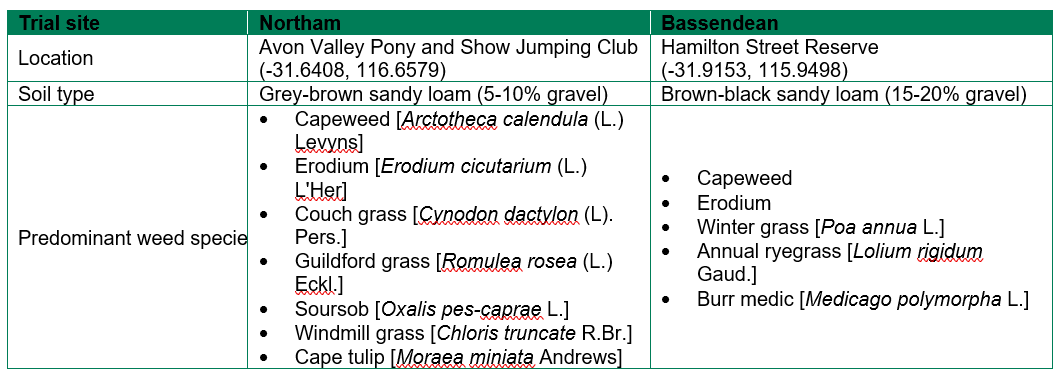

Two field sites in Western Australia were identified in 2022 to evaluate the effectiveness of electric weed control in of fallow scenarios for eliminating natural and long-established weed populations (Table 1). The first trial, located in Northam, compared the weed control efficacy of single and double knock applications of electric weed control at different speeds with that of herbicides. The second trial, in Bassendean, solely evaluated the efficacy of electric weed control. Treatments included an untreated control, a single or double application of electric weed control at 2 or 4km/h, and single application of glyphosate (Roundup Ultra® MAX 1.5L/ha, containing 570g/L glyphosate as potassium salt; Bayer, SC) or double application of herbicides (glyphosate, followed by paraquat/diquat (Spray.Seed® 250 1.5L/ha, containing 135g/L paraquat as paraquat dichloride and 115g/L diquat as diquat dibromide; Syngenta®, SL) at the Northam site only. Both the electric weed control and herbicide treatments were applied on the 30/6/2022 and 15/7/2022 at Northam, and electric weed control was applied on the 7/6/2022 and 28/7/2022 at Bassendean.

Table 1. Details of the two trial sites in Northam and Bassendean including the location, soil type and the predominant weed species at time of application

Both trials were conducted using randomised block designs. Electric weed control was applied using the XPower XPU (36kW) produced by Zasso™. Measurements taken at each site included normalised difference vegetation index (NDVI) which were collected weekly following initial treatment applications and weed dry biomass which was collected six weeks after the initial weed control applications. Note that before weed control, the weeds at the Bassendean site were mown as part of standard management for a grassed site. The data was analysed using an ANOVA. Before analysing the dry biomass data, a logarithmic (base 10) transformation was performed to the Northam site data and a square root transformation performed on the Bassendean site data to normalise the residual distribution. Where a transformation was performed, the data is presented as back-transformed means. Letters are assigned to means to indicate significant differences based on the LSD.

Results

Northam

Electric weed control at 2km/h was found to be effective at controlling the weed population (Figure 1). Control of broadleaf species was more successful than grass species, as evidenced by visual observation (Figure 2), as the latter often grow in clusters that can shield individual plants from control methods. Windmill grass is an example of a species where a single ‘clump’ is composed of many individual plants. When some plants are shielded within the cluster, it is difficult for any weed control technique (electric weed control or herbicide) to kill all of them. Cape tulip is also a particularly difficult species to control with herbicides as the above-ground biomass is killed, but the weed can regrow from its bulb. Electric weed control at 2km/h removed the above ground biomass at three weeks after application and the bulbs were substantially smaller than in the untreated control (Figure 2). However, research is being conducted to determine if these smaller bulbs are still viable.

Figure 1. An application of electric weed control at 2km/h was effective at killing all weed species present at the Northam trial site (top) while those outside the treatment area were unaffected.

Figure 2. Windmill grass two weeks after electric weed control at 2km/h. Half of each plant ‘clump’ was killed, indicating that the plants at the front of the clump shielded plants behind them (left). Cape tulip bulbs were also smaller three weeks after this application (right).

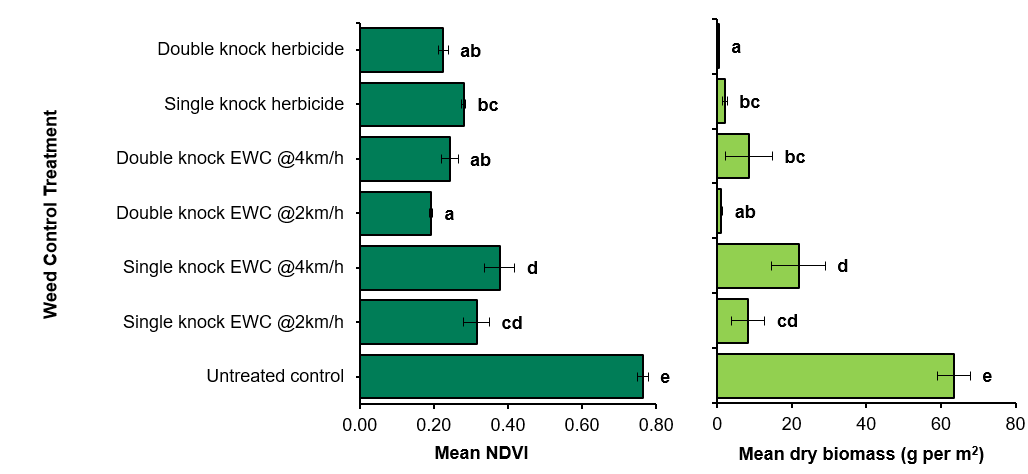

NDVI assessments of weed growth indicated that all applications of herbicides and electric weed control resulted in fewer weeds than the control (Figure 3). On average, the lowest NDVI (i.e., best weed control) was observed following the double application of electric weed control at 2km/h. However, it was not significantly different from the double application at 4km/h and double application of herbicide. The highest NDVI values were seen following the single application of electric weed control at 4 km/h. Dry weed biomass was comparable when a single application of herbicide or electric weed control at 2km/h were used and when a double application of herbicide or electric weed control at 2km/h was used. The highest weed biomass was observed following a single application of electric weed control at 4km/h, although it was still lower than the control (Figure 3).

Figure 3. Effect of single/double knock applications of herbicide and single/double knock applications of electric weed control (EWC) at 2 or 4km/h on normalised differential vegetation index (NDVI, left) and amount of dry biomass (right) of the weed population at the Northam trial site four (NDVI) and six (dry biomass) weeks after initial weed control application (n=6; mean ± s.e.). Bars annotated with the same letter have means that were not significantly different at P<0.001 according to a one-way post-hoc Fisher’s Unprotected LSD test performed on the data.

Bassendean

Visual observation at the Bassendean site indicated that, similar to the Northam site, electric weed control was more effective at controlling broadleaf weed species than grass weeds (Figure 4). Control of winter grass was particularly challenging, with reduced control observed at 4 km/h, possibly due to taller plant species shielding the shorter species.

Figure 4. Weed control four weeks after the application of electric weed control at the Bassendean site. The untreated control area shows the original species composition (top), electric weed control at 4km/h with surviving winter grass (middle) and electric weed control at 2km/h with no surviving plants (bottom).

NDVI assessments of weed growth indicated that all applications of electric weed control resulted in fewer weeds than the control, except for the single application at 4km/h (Figure 5). The lowest NDVI was observed following the double application of electric weed control at 2 and 4km/h. However, the results were not significantly different from the single application at 2 km/h. Electric weed control also had a significant effect on the amount of dry weed biomass. All electric weed control treatments resulted in significantly less biomass than the control.

Figure 5. Effect of single/double knock applications of electric weed control (EWC) at 2 or 4km/h on normalised differential vegetation index (NDVI, left) and amount of dry biomass (right) of the weed population at the Bassendean trial site four (NDVI) and six (dry biomass) weeks after initial weed control application (n=4; mean ± s.e.). Bars annotated with the same letter have means that were not significantly different at P<0.01 according to a one-way post-hoc Fisher’s Unprotected LSD test performed on the data..

Figure 5. Effect of single/double knock applications of electric weed control (EWC) at 2 or 4km/h on normalised differential vegetation index (NDVI, left) and amount of dry biomass (right) of the weed population at the Bassendean trial site four (NDVI) and six (dry biomass) weeks after initial weed control application (n=4; mean ± s.e.). Bars annotated with the same letter have means that were not significantly different at P<0.01 according to a one-way post-hoc Fisher’s Unprotected LSD test performed on the data..

Conclusion

The results from these two field trials indicate that electric weed control is a highly effective method of controlling weeds in fallow scenarios and is comparable to herbicide control. However, electric weed control was found to be more successful for broadleaf weeds than grass species. This is likely due to differences in weed height or the ability of clumping grass species to shield younger and shorter plants, reducing the effectiveness of electric weed control. Increasing the speed of application from 2 to 4km/h was expected to reduce control efficacy as it decreases the amount of energy transferred (comparable to reducing herbicide rate). The difference in speeds was not significant differences were determined in these trials, but a second application may be required at some sites depending on the weed species, density, and age. In conclusion, preliminary results from this Australian-first project suggest that electric weed control could play a viable role in integrated weed management of Australian agricultural systems.

Acknowledgments

The research undertaken as part of this project was made possible by the significant contributions of AGXTEND Europe and their collaboration with Zasso™, as well as the support of the GRDC, Wine Australia, AHA Viticulture and the CRDC and the author would like to thank them for their continued support. We would also like to thank project staff Dave Nicholson, Nerys Wilkins, and Bowen Zhang, as well as Melanie Davies, Jenny Abbott, and Caitlyn White of the West Australian Local Government Association. Thanks are also due to Arslan Peerzada for reviewing this paper.

Contact Details

Miranda Slaven

Department of Primary Industries and Regional Development

75 York Rd (PO Box 483) Northam WA 6401

Ph: 0457 002 063

Email: miranda.slaven@dpird.wa.gov.au