The impact of stubble on farming systems – managing high stubble loads

Author: Tom Johnstone (Cowra farming family), Peter Johnstone (Cowra farming family), Ben Johnstone (Cowra farming family) and Tony Swan (CSIRO Agriculture) | Date: 26 Jul 2023

Take home messages

- Don’t let stubble compromise weeds, disease, pests and timeliness of sowing

- Pro-actively manage stubble for your seeding system!

- Diversify your crop sequence and add legumes to the rotation

- Post-harvest management: If necessary, reduce stubble load by mulching, incorporation + nutrients, baling or grazing

- The Kuhn Excelerator mulcher has been instrumental to maintain all our stubble and carbon while creating a level seedbed and ensure even establishment of all crops including canola

- N tie-up can reduce cereal yield in modern stubble retain farm systems.

Background

Our family business has been operating a 1600 ha mixed farming enterprise in the Cowra region for the previous 112 years. The properties consist of a variety of soil types from alluvial creek and river flats, to rolling hillsides predominated by red clay loam andesite and granite red brown loam. The enterprise mix is currently 70 % cropping and 30 % livestock. In the 2023 season, we have established 650 ha of cereals, 300 ha of canola, 100 ha of pulse crops and approximately 550 ha of pastures and grazing only crops. Our main cropping rotation over the past decade has been wheat-canola-wheat-canola, but we have diversified the rotation in specific paddocks/topography/enterprise to include a pulse legume (chickpea, fababean or vetch). In the livestock enterprise, we manage 195 Angus breeding cows and 1000 Australian White ewes, with the aim to supply the feeder market for cattle and domestic slaughter and breeder market for the lambs. The pastures we establish generally consist of perennial grasses, such as cocksfoot, fescue and/or ryegrass with arrowleaf and/or subclover clover. This legume dominant pasture would generally remain for a period of 5-7 years, before being cropped for the following 5-10 years.

Over the past 20 years, our cropping philosophy has been to embrace no-till farming and implement strategies to retain as much, if not all, of the stubble from the previous crop to enhance water capture and storage, ‘soil health’ and crop yields. Over the past couple of wet seasons (decile 8-9), we have been required to deal with some of the highest stubble loads in our cropping enterprise history. As such, we have implemented a new management strategy (mulching), to assist us in maintaining this ‘no burn philosophy’ while ensuring the following crops could be sown in a timely manner.

Managing stubble using a flexible approach

1. Crop rotation (grazed and non-grazed enterprises)

One method of managing the stubble has been to diversify our canola-wheat rotation to include a pulse legume. Pulse legumes have included chickpeas, fababeans, vetch and ryegrass/clover mixes over the past 10 years. In our non-grazed crop rotation paddocks, chickpeas were productive and profitable in 2019 and 2020. However, difficulties selling the grain and managing disease in wet years have resulted in our business changing to fababeans. We have found that fababeans can establish through high stubble loads, handle increased pest pressure from slaters, earwigs and slugs better than canola, are significantly easier to manage than chickpeas (fewer fungicide applications), produce more plant biomass than chickpeas that can result in an increased concentration of nitrogen for the following crop, and assist in the breakdown of greater quantities of cereal stubble load to help produce a suitable seedbed for the following canola crop.

In our grazing paddocks a vetch legume or a ryegrass/clover mix have been included into the crop rotation (wheat – vetch or ryegrass/clover - dual purpose canola). These pulse crops are not only grazed during the season for finishing livestock but help stop weed seed set and provide additional soil nitrogen for the following double break canola crop.

2. Mechanical methods to reduce high stubble loads

Our business has implemented two mechanical methods of managing high stubble loads at different times. These include baling and mulching.

i. Baling: In 2017-19, all the cereal stubble from the header windrow was baled. This not only significantly reduced the stubble load for the following year but was very profitable as straw was sought after and fertiliser prices were low. The two major issues that we had to deal with were sowing into the chaff trails left behind after baling and the sustainability of the practice (loss of nutrients from the system); and

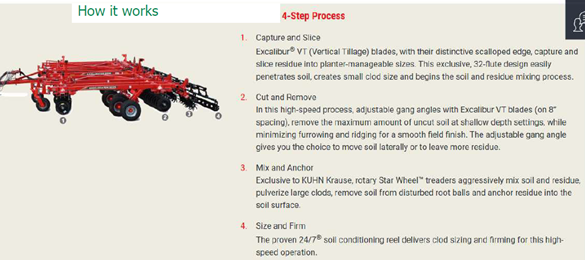

ii. Mulching: In late 2020 we purchased a Kuhn Excelerator® vertical tiller/mulcher (Figures 1 and 2) to be used to smash up the high stubble loads post-harvest so that we could maintain all our stubble (no burning). We had previously trialed the machine in 2016 but due to the drought and high demand for straw we opted to cut the straw short and bail the header tailings in 2017-2019. It also ensured we were able to sow through and establish all crop types using our parallelogram air seeder with coulters on 250mm row spacing. The mulcher proved extremely valuable in removing ruts and wheel tracks during these wet years to provide a level seedbed with sufficient stubble left to reduce evaporation, while ensuring even canola emergence in our wheat-canola rotation (Figures 3 and 4).

Figure 1. Excelerator mulcher in a cereal crop

Figure 1. Excelerator mulcher in a cereal crop

Figure 2. How the Excelerator works

Figure 3. Sowing canola into mulched cereal stubble

Figure 3. Sowing canola into mulched cereal stubble

Figure 4.: Canola emergence in the wheat-canola rotation

Figure 4.: Canola emergence in the wheat-canola rotation

3. How we incorporate the mulcher into our system?

On the heavy cereal stubbles, we have found that two passes of the mulcher at 7-10 degree opposing angles from the sown stubble provides an excellent result for the following crop.

In our grazing paddocks, the summer grazed stubbles and the grazed vetch or ryegrass/clover brown manure paddocks may only need to have a single pass of the mulcher. We generally mulch stubbles in March onto moist soils, except where we aim to sow an early dual-purpose crop. Here we mulch earlier, sometimes directly after harvest to ensure we can sow these crops when the early rainfall occurs.

The main advantages of incorporating the mulcher into our farming systems has been too:

- Level out bog marks and wheel ruts

- Ensure we can maintain our stubble

- We don’t have to burn which avoids loss of nutrients, stop smoke pollution for the environment and no permits are required

- We can chop up any weed residues such as wireweed

- Ensure we are able to sow with our tine seeder in a timely manner and produce an even germination; and

- Our tine seeder is important especially in the grazed paddocks as the deep tine opens up the heavy red country, especially after grazing with cattle).

The two main disadvantages of incorporating the mulcher into the system are:

- It’s another operation and machine to maintain; and

- The operation costs approximately $33/ha per pass.

Economics

The gross margins of the five different crop types used in rotation in our system are illustrated in Table 1.

Table 1. Gross margin comparison of 5 different crop types

Costs | Wheat-rotation | Canola rotation after legumes | Vetch rotation | Faba rotation | Canola after wheat |

|---|---|---|---|---|---|

Seed | 176 | 120 | 18.5 | 90 | 120 |

Fertiliser ($/ha) | 570.84 | 474.84 | 108 | 108 | 610.84 |

Sprays + Adjuvants ($/ha) | 173.52 | 150.22 | 122.62 | 256.35 | 150.22 |

Operations ($/ha) | 151 | 213.50 | 139 | 224 | 243.50 |

TOTAL COSTS | 1071.36 | 958.56 | 406.21 | 640.35 | 1124.56 |

INCOME | |||||

Tonnes/ha | 5.5 | 3.3 | No DSE/ha/grazing days provided | 4.7 | 3 |

$/tonne | 350 | 700 | $ DSE | 400 | 700 |

$/ha | 1925 | 2310 | - | 1880 | 2100 |

Gross Margin ($/ha) | 853.64 | 1351.44 | -406.21 (+ grazing value) | 1239.65 | 975.44 |

The vetch crops are generally sown early, then grazed before locking up and being kept for seed or sprayed out as brown manure (Table 1). The main benefits include fattening livestock and additional nitrogen for the following canola and cereal crops. No livestock grazing value is included in gross margin, so this needs to be factored into the calculations when using this data. The average gross margins over a three-year period for three different crop rotations: wheat-faba-canola; wheat-canola-wheat; and wheat-vetch-canola are outlined in Table 2. All three rotations are profitable in our farming system for the different landscapes/topography where they are implemented, with the diverse system that includes the pulse legume being as profitable or more than the canola-wheat rotation in our farming system (Table 2).

The Kuhn Excelerator has proven to be a valued asset in managing high stubble loads, especially in the canola-wheat rotation. A breakdown of operation costs of the Kuhn Excelerator vertical tiller/mulcher is provided in Table 3.

Table 2. Average gross margins over a three-year period for three different crop rotations

Average over three years | Wheat-faba-canola rotation | Wheat-canola-wheat rotation | Wheat-vetch-canola rotation |

|---|---|---|---|

Total costs/ha | 2670 | 3267.28 | 2436 |

Total costs per year/ha | 890 | 1089 | 812 |

Income | |||

Total income/ha | 6115 | 5950 | 4235 |

Average income per year/ha | 2038 | 1983 | 1411 |

Gross Margin ($/ha) | 1148 | 894 | 599 (+ grazing value) |

Table 3. Operations costs of the Kuhn Excelerator vertical tiller/mulcher

Work rate (ha/hour) | Fuel (L/hour) | Tractor + implement costs ($/ha) | Overheads + variable costs ($/ha) |

|---|---|---|---|

10.2 | 45.6 | 14.89 | 33.77 |

What else we may do to improve the system!

We had planned to apply extra nutrients (GranAm®) at a rate of 100-150kg/ha before using the mulcher in the cereal stubble in the wheat-canola rotation. Research to date from John Kirkegaard has shown that by adding nutrients to the stubble and incorporating, we can increase the amount of stubble that is converted into humus. Increasing the percentage of humus and therefore fertility of the soil, will assist in maintaining high yields and profits in this rotation, where canola is a nitrogen hungry plant.

Conclusion

The benefits of retaining stubble in our soils have long been foretold, however the constant struggle has been how to do this without getting in the way of growing profitable, agronomically sound crops. To achieve this the system needs to be fluid and interchangeable, and we need a way of capturing the value of carbon in the ground. The ability to capture carbon and maintain our soil is only going to become more important and valuable in the future, particularly in terms of sustainability. This paper explores some of the methods we have been employing to achieve this.

Contact details

Tom Johnstone

Cowra

Ph: 0427 450 366

Email: tjohns33@hotmail.com

® Registered trademark

Was this page helpful?

YOUR FEEDBACK