Reducing GHG emissions in cropping systems – responding to drivers for change

Author: Warwick Badgery (NSW DPI), Aaron Simmons (NSW DPI), Richard Eckard (University of Melbourne), Peter Grace (Queensland University of Technology) | Date: 14 Feb 2024

Take home message

- There are things that you can do now as a grain producer to start a journey towards a low GHG emissions future. These include, understanding the data requirements to calculating a C footprint and choosing a suitable tool for the calculations.

- Once you understand the C footprint of your business, you can assess the options available to reduce GHG emissions. This will include the expected GHG reduction of a practice change and any effects on production and profitability.

- If considering sequestration in soil and trees to offset emissions, understand that this is often initially higher than the long-term rates and will need to be maintained permanently. This comes with risk in a variable and changing climate.

- There is risk associated with doing nothing, given the expected link between C footprints and price in the future. Initiatives funded by state and federal governments are available to help, so get involved.

Introduction

The need to reduce greenhouse gas (GHG) emissions to meet international climate targets has resulted in many corporations setting GHG emissions reduction targets. These targets have been set to demonstrate a commitment to climate action to their customers and investors in order to retain their social licence to operate and help maintain market share. The frameworks used to set these targets generally require corporations to include the GHG emissions associated with their entire supply chain, including the GHG emissions associated with their suppliers. Corporations that use grains in their business will seek to purchase grain with lower GHG emissions to meet their GHG emissions reduction target. It is anticipated that the Australian grains sector will need to reduce the GHG emissions associated with production to remain competitive in global markets.

The drive for low GHG emission commodities is generating uncertainty in many agricultural sectors. Producers are not only uncertain about which management changes are likely to reduce GHG emissions but also how they demonstrate their GHG emissions intensity (i.e. kilogram of GHG per tonne of commodity) to the supply chain. Whilst these changes may be new for a large proportion of grain producers, what is not well known and may provide some assurances is that growers have been managing this process for several years already. In 2009, legislation was introduced that required any biofuel feedstocks imported into the EU to have a GHG emissions intensity 50–65% lower than that of conventional fuels. The EU biofuel market is a key trade outlet for WA canola growers, so they have been estimating and reporting the GHG emissions intensity of their canola production to meet market requirements for several years now. In addition, the process of demonstrating the emissions intensity of grain production is likely to be relatively simple with existing calculators (e.g. Cool Farms, CSIRO FarmPrint, PICCC Grains-GAF) able to tap into existing farm management record software with grower consent to automatically generate the emissions intensity.

GHG emissions

There are several GHGs that contribute to grain farming emissions, including carbon dioxide (CO2), nitrous oxide (N2O) and methane (CH4). These gases have different contributions to global warming and different residence times in the atmosphere. The global warming potential (GWP) or CO2 equivalent (CO2-e) of these gases is given a standardised value for the impact they have on the environment over a 100-year period. These values have changed over time, as the method for estimating the impact of GHG’s on global warming has been refined. In the Intergovernmental Panel for Climate Change (IPCC) Fifth Assessment Report the GWP values for N2O and CH4 are 265 and 28 CO2-e’s respectively, while CO2 is one.

Baseline emissions

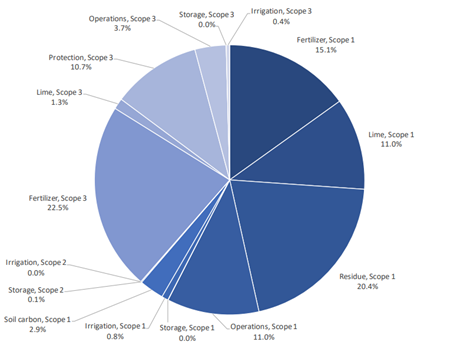

The first step in reducing the GHG emissions associated with grain production is to understand the source of GHG emissions. Sevenster et al. (2022) assessed the GHG emissions for the Australian grains sector (Figure 1) and showed that, on a CO2-e basis, on-farm GHG emissions (“Scope 1”) comprise 61% of emissions and are dominated by nitrogen (N) fertiliser and lime emissions (26%), residue emissions (i.e. N loss from decomposing plant residue; ~20%) and fuel use (11%). Off-farm GHG emissions (“Scope 3”) are dominated by emissions associated with fertiliser (22.5%) and crop protection chemical (11%) production. These emission sources can be summed for any given season or year to estimate the total GHG emissions of a paddock, farm, or the sector. However, many corporations use emissions intensity or GHG footprint (the GHG emissions for a unit of product) not the total emissions to determine purchases. Currently, the GHG emission intensity of Australian grain production is 315 kg CO2-e/tonne grain, which is relatively low compared to other grain production countries (Sevenster et al., 2022). However, the Australian grains sector needs to have a pro-active stance and work towards low GHG emissions intensity to ensure any market advantage is maintained.

Figure 1. Contribution of emissions sources for the Australian grain sector (From Sevenster et al., 2022). Scope 1 - Direct emissions from the company’s operations; Scope 2 - Indirect energy emissions; and Scope 3 – Other indirect emissions.

The above assessment of GHG emissions sources is for all crops across Australia. The GHG emissions intensity of a crop will differ for each farm business and producers can estimate the GHG emissions intensity of their grains using one of a number of existing GHG calculators that are compliant with the Australian GHG accounts (see previous examples). These calculators can be used to undertake a simple analysis of an individual paddock or a few paddocks prior to making an investment decision. Governments at the state and federal level are investing in training to assist producers to baseline GHG emissions and to plan management changes to reduce GHG emissions. Interested producers should consider participating in the Carbon Farming Outreach program, a federal government funded program to educate producers on GHG accounts, that will be rolled out in 2024.

Assessing changes to grain production systems to reduce GHG emissions

It is critical that grain producers examine potential management changes through the same lens as they currently make business decisions and ensure that risk and profit impacts are well-understood and appropriately managed. Some examples of what grain producers need to consider when assessing whether management changes to reduce GHG emissions are compatible with their current system are listed below.

- Check if claims for GHG emissions reductions or carbon sequestration are supported by credible scientific evidence. Claims of unrealistic GHG emissions reductions, for example inflated estimates of soil organic carbon sequestration, are prevalent and grain producers need to ensure that any estimates of GHG emissions reductions are well proven, realistic and persist into the future. The most reliable peer-reviewed information will come from state-based agencies, reputable industry bodies or universities.

- Prioritise avoidance of GHG emissions over C sequestration. There is a high degree of certainty that implementing a strategy to avoid emissions (e.g. improve N use efficiency to reduce N2O emissions) will result in a reduction of GHG emissions. Sequestration, in soil particularly, is higher risk because it must be maintained permanently and there is a high chance of reversal with a variable and changing climate.

- Potential impacts on productivity. Perhaps the most critical consideration is the impacts of management changes to reduce GHG emissions on the long-term productivity and profitability of the farm business. For example, reducing N inputs into the system can reduce the GHG emissions intensity of grain production yet doing so has the potential to not only reduce yields and profit but also increase reliance on N mineralised from soil organic matter that will result in a decline in fertility and a loss of soil organic carbon. Similarly, cutting back on lime applications where soil acidity limits production will also have long-term negative impacts on productivity.

- Are carbon credits needed? Carbon credits are not required for a GHG footprint. Further, if carbon credits are generated and sold to someone else then they cannot be used to offset emissions within the business, which may be required to maintain market access in the future.

- Assess direct and indirect costs. There is a direct cost associated with changing management to reduce GHG emissions however the indirect costs associated with a management change may be more critical to assess (e.g. yield reductions with lower N levels). There can also be indirect benefits, (e.g. pastures phases improving organic matter, mineral N supply and soil physical properties) associated with management changes. It is important to assess costs on a $/t CO2-e basis (i.e. marginal abatement cost).

Some of the main GHG emission reduction strategies are outlined in Table 1, along with the potential for GHG avoidance and sequestration.

Conclusion

Changing management to reduce GHG emissions intensity requires a strategic approach to ensure the change is a good fit for the system. The first step in this process is to establish an emissions baseline for your business then assess the options available to reduce GHG emissions including the expected GHG reduction of a practice change and any direct or indirect effects on production and profitability. An assessment of changes needs to take a long-term view, as issues like a gradual rundown in soil fertility may be masked by short-term seasonal variability. There are initiatives funded by state and federal governments and industry to baseline GHG emissions and plan management changes to reduce GHG emissions that producers can take part in.

Table 1. Summary of management options to avoid GHG emissions or to sequester C in a grain farming system.

Management strategy | Avoidance | Sequestration | Comments |

|---|---|---|---|

N fertiliser efficiency | Yes | Possible | Applying N fertiliser efficiently (e.g. variable rate, split applications, not in waterlogged conditions) to optimise crop yield and replace N removal. Excess N fertiliser above crop removal rates increases the risk of N losses and N2O production, higher fertiliser (balanced for NPKS) may lead to higher soil C1. |

N fertiliser coating | Yes | No | Using enhanced efficiency fertilisers (EEFs; e.g. N inhibitors) can reduce N2O emissions by up to 80% but generally do not increase yield to offset the higher price1,2 |

N fertiliser production | Yes | No | Green ammonia1 can reduce scope 3 emissions from production. Possible modular production available on-farm2. |

Lime use efficiency | Yes | No | Lime neutralises acid soils but also omits CO2. Improve the efficiency of lime by using precision application. Consider lime alternatives. |

Legumes in rotation | Possible | Possible | Legume N may reduce N fertiliser needs and the emissions associated with production. Higher N may also be associated with higher soil C. |

Biochar | Yes | Yes | Biochar can neutralise soil acidity reducing the use of lime. It also has a negative priming effect that can stimulate additional soil C storage. Currently it is not viable in extensive grain production systems. |

Increasing pasture phases | Yes | Yes | Soil C often continues to decrease with cropping, but pasture phases increase soil C and N, and increase mineralisation of N for subsequent crops. |

Cover crops and reducing fallows | Uncertain | Uncertain | Legume cover crops may supply additional N to subsequent crops but also increase the N fertiliser needs in the short-term as N is used from fallows. Cover crops and reducing fallows may increase soil C in some situations. |

Revegetation with trees | No | Yes | Revegetation with trees can sequester C but removes land used for cropping from production. |

1 Further detail on N strategies to reduce GHG emission in: Norton R, Gourley C, Grace P, Kraak J (2024) Securing access to nitrogen for food production, a GHG perspective. GRDC Updates.

2 Not to be confused with green urea, which is a coated fertiliser product to reduce N2O emissions.

Reference and further reading

Sevenster M, Bell L, Anderson B, Jamali H, Horan H, Simmons A, Cowie A, Hochman Z. (2022) Australian Grains Baseline and Mitigation Assessment. Main Report, CSIRO.

Norton R, Gourley C, Grace P, Kraak J (2024) Securing access to nitrogen for food production, a GHG perspective. GRDC Updates.

Contact details

Warwick Badgery

NSW DPI

Ph: 0427 274 034

Email: warwick.badgery@dpi.nsw.gov.au

Date published

February 2024

Was this page helpful?

YOUR FEEDBACK