Securing access to nitrogen for food production, a greenhouse gas perspective

Securing access to nitrogen for food production, a greenhouse gas perspective

Author: Rob Norton (University of Melbourne, & Norton Agronomic), Cameron Gourley (University of Qld), Peter Grace (Queensland University of Technology), Jeff Kraak (Fertilizer Australia), Graeme Sandral (GRDC) | Date: 14 Feb 2024

Take home message

- The challenge is to know the nitrogen removal to use ratio – you cannot manage what you cannot measure. Growers are encouraged to make field scale N input and removal (NUE) estimates using the best tools available

- Adopt N management strategies that provide ‘just enough’ nitrate in the rootzone to meet crop demand, such as N budgeting, enhanced efficiency fertilisers, zoned nutrient management, split applications, fixed N from legumes and in-soil N placement

- The production of ‘green ammonia’ as feedstock will significantly reduce GHG footprint of N fertiliser.

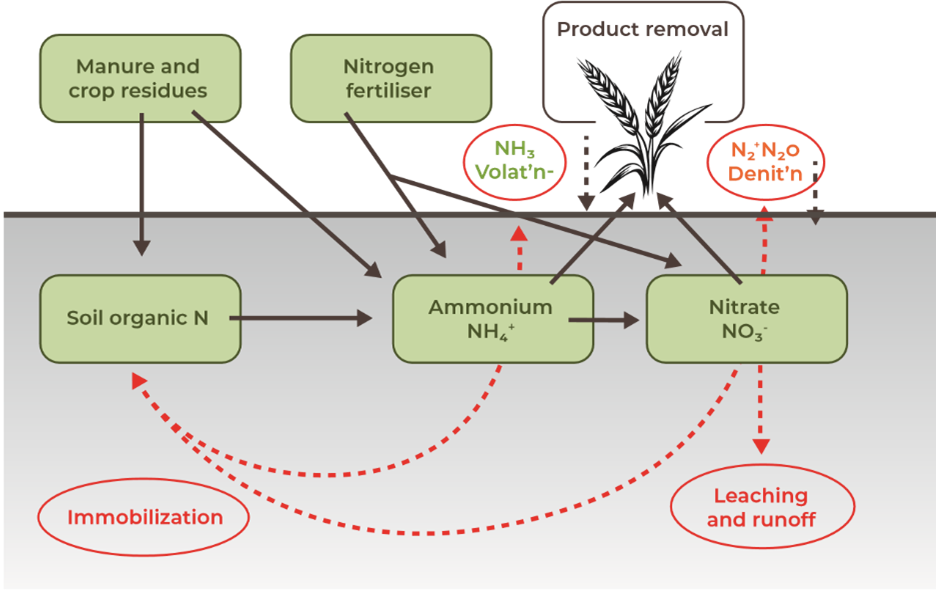

As N cycles from the air to soil and into plant products, ammonia (NH3) volatilisation, nitrate (NO3-) leaching and nitrification/denitrification can result in environmental impacts. Denitrification is the principal process where NO3- is biologically reduced by removing one or more of its oxygen atoms to create N2, NO or N2O, depending on soil conditions. Gaseous NH3 and N2O emissions can be derived from all N sources, including manures, composts, crop residues, biological fixation and fertilisers (Figure 1).

Figure 1. A simplified nitrogen cycle showing the inputs and pools of nitrogen, along with loss and transfer pathways in red dashed lines (International Plant Nutrition Institute). (Volat'n = volatilisation; Denit'n = denitrification). Gaseous N can redeposit.

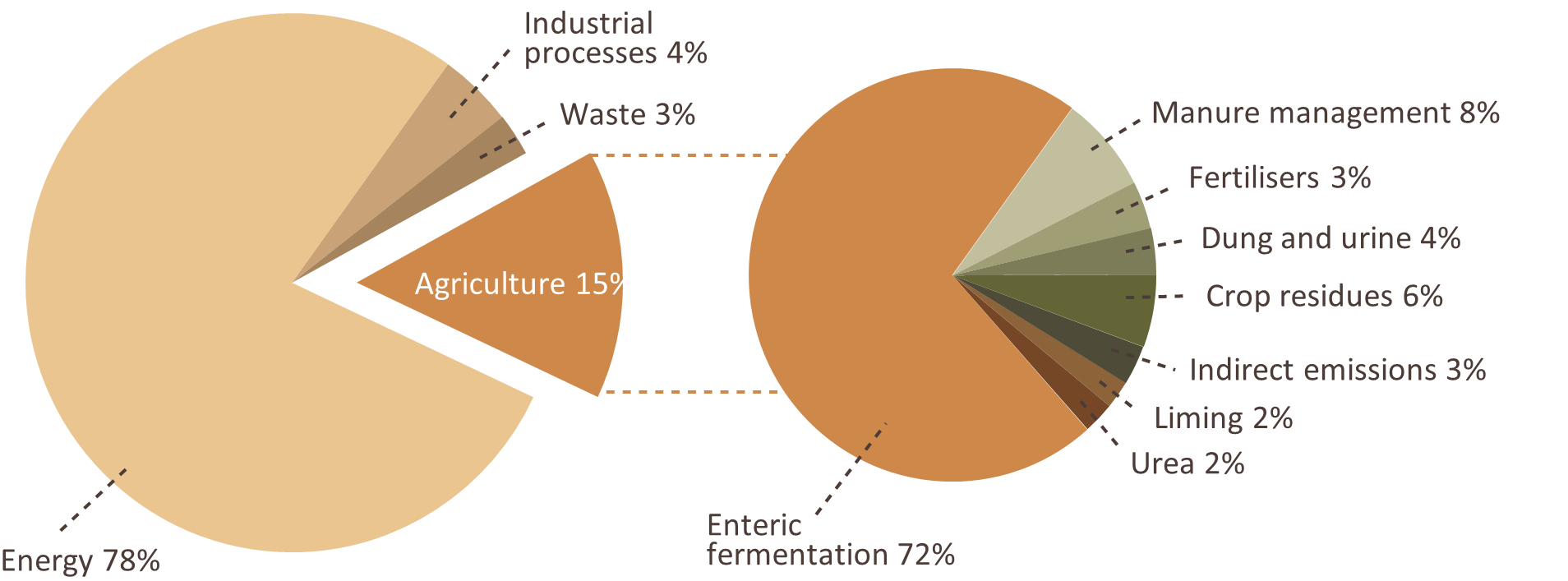

Nitrous oxide (N2O) is one of the main greenhouse gases associated with N fertilisers. Agriculture produces around 15% of Australia’s greenhouse gas emissions, and N2O represents about 15% of the emissions from agriculture or 8.1 Mt carbon dioxide equivalent (CO2e). Direct (Scope 1) N2O emissions from agriculture are derived from fertilisers (30%), decomposition of crop residues and organic materials (30%), the direct deposition of dung and urine (35%), and where animal manure is stored, and land applied (5%) (Figure 2).

Figure 2. Total greenhouse gas (GHG) emissions for Australia by United Nations Framework Convention on Climate Change, net of Land Use, Land Use Change and Forestry sector (left) and the breakdown of agricultural emissions by IPCC source.

There are additional Scope 1 greenhouse gas (GHG) emissions from urea fertilisers due to the 20% carbon content, released as CO2, not N2O. The GHG inventory estimates this adds 1.76 Mt CO2e. Significant GHG emissions are embedded in the production of N fertilisers, although the amount varies depending on the place of manufacture and the different N sources. For example, when urea fertiliser was produced in Australia, it had a GHG ‘cost’ of 3.3 t CO2e per tonne N, while urea produced in China, using coal-derived energy, has twice this GHG ‘cost’.

The production of N2O is intimately connected to the levels of NO3- and the presence of warm, wet or waterlogged soils. The amount of N2O produced is indexed against the amount of N fertiliser supplied by the ‘emission factor’ (EF). Australian research (Grace P et al., 2023) has measured an average EF for all N sources of 0.57%, ranging from 0.17% (non-irrigated pastures) to 1.77% (sugar cane). Emission factors were independent of topsoil organic carbon content, soil bulk density and pH, but increased with rainfall for every 100 mm over 300 mm. Emission factors were not always linearly related to N input, with some farming systems showing a two component EF model with linear and exponential components.

What is the issue?

Options to reduce GHG emissions is a focus across many industrial activities and agriculture is no exception. The National Farmers Federation 2030 Roadmap identified that low GHG emissions credentials are important to keep our commodities in export markets. Methods to assess GHG footprints are being developed and refined, along with management strategies where emissions can be reduced to guide towards a low emissions future.

The challenge is that as N fertiliser use in Australia increases to meet the demands of high and more sustainable production, the increase in production is somewhat greater, proportionately, than the increase in N – with the result that emission intensity (kg CO2-e per tonne of grain) declines. The Sevenster et al., 2022 report suggests that the 2005 GHG emission intensity for cereal production was 315 kg CO2e/tonne grain and suggested that fertiliser manufacture and use contributed 40% of the total emissions. Estimated GHG levels for individual farms can now be calculated using tools like:

- Cool Farms

- CSIRO FarmPrint

- PICCC Grains-GAF (https://www.piccc.org.au/resources/Tools).

It is useful for growers or their advisors to go through this analysis to establish a benchmark along with an understanding of how they compare to others in the industry so measures can be taken to reduce emissions intensity.

In addition to meeting our national emissions targets, it is clear that other countries are undertaking GHG assessments for their own production systems, but also considering international emissions transfers through commodity trading – termed Carbon Border Adjustment Mechanisms (CBAM). The European Union (EU) was the first jurisdiction to announce a program for implementing a CBAM. The mechanism is designed to reduce carbon leakage and create a level playing field for domestic producers in industries that pay a carbon price as part of the EU emissions trading scheme (EU ETS) (European Parliament, 2022). Other countries, in response, have similarly announced consideration of adopting similar policies (Deloitte Access Economics, 2023).

Significance of Australia's N use to GHG

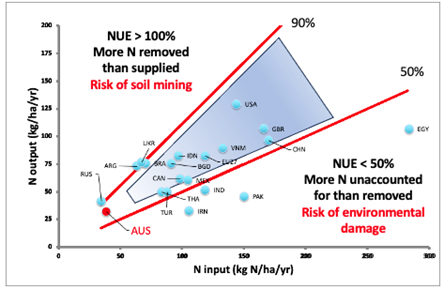

Australia uses less than 1.5% of the total elemental fertiliser N consumed globally and is the 17th largest consumer of 117 countries reporting N use. Domestic N fertiliser use has increased 9-fold since 1960 to almost 2 Mt N, but represents <1.5% of global use. Legume species also supplement fertiliser N supply, but N fixation is challenged by a decline in land area, lower biomass and weak symbiosis (Peoples et al., 2001). The relatively low N fertiliser rates predominately used for extensive cropping, at around 30–70 kg N per ha, is compensated by the large area of cropped land and makes up around 66% of all N fertiliser used. Compared to other countries, our rates of use and removal are modest (Figure 3) with average NUE for wheat, other cereals, canola, cotton, and sugarcane, of 0.82, 0.68, 0.88, 0.48 and 0.44, respectively (Norton et al., 2023). Of note is that substantial cropped areas have N use efficiency (NUE) >1, effectively drawing down soil N and organic matter.

Figure 3. NUE (partial nutrient balance for N) for cereals, graphed as the output (removal) of N against the fertiliser input N. The thick red lines show values of NUE according to the relation between inputs and outputs. Biological N fixation and manure use are not considered in this example. The ‘safe’ operating area as proposed by the EU Expert Panel is shaded. Each circle represents a country indicated by UN Country 3 letter code.

What to do?

It is an old saying that you cannot manage what you cannot measure, and so the first step in managing N and GHG fertiliser emissions is to know the nitrogen use efficiency (NUE). NUE in its simplest form is the nutrient removal to use ratio, which is the efficiency of a recovery of N in the produce. NUE is more correctly termed the partial nutrient balance (PNB) of N and in much of the literature this simple measure of NUE is used because it is scalable from field to farm to region to national and even global. It can also be estimated as repeated measures over time, and most importantly, informs management.

NUE (%) = (sum of outputs / sum of inputs) * 100

Where the sum of outputs (kg N/ha) = (grain yield (t/ha) * protein (%) * 10) / 5.7

e.g., 4 t/ha * 12% protein * 10 / 5.7 = 84 kg N/ha,

and the sum of inputs (kg N/ha) = (urea rate (kg/ha) * 0.46) + (MAP rate * 0.10)

e.g., 140 (kg urea/ha) * 0.46 (% N in urea) + 60 kg MAP * 0.10 (% N in MAP) = 70 kg N/ha.

NUE is 84 / 70 = 120% which means 120 kg N /ha is exported for every 100 kg N applied. The Australian wide average NUE/PNB value for cereals for 2018 was reported as 83% (Norton et al. 2023).

In a balanced system, the NUE would be 100%, with all the N supplied being removed in the produce. Nitrogen use efficiency, as used here, does not describe any N transformations within a system, nor is it a direct quantitative assessment of N loss from the system. Nitrogen supplied but not removed in the plant products might remain on site and accumulate in the soil. However, over the long term, low NUE (e.g. <0.7) will usually mean N is being lost to the system, with adverse economic outcomes for growers and poor environmental outcomes. Conversely, if the NUE is high over time (e.g., >1.4), soil resources are being exploited and long-term soil fertility will decline ultimately adversely affecting the sustainability of productivity. A direct consequence of high NUE is most obviously a decline in soil organic matter, which supplies the N demand not met by mineral N.

Within any cropping system, NUE varies from paddock to paddock and year to year, and so N input and removal estimates for a paddock need to be developed over 4 or 5 years to assess whether N is in deficit or in surplus. Consideration of N loss through grain, residue removal, leaching, erosion and denitrification are balanced against fertiliser addition (see examples calculations above) and N fixation (Biomass dry weight at 30% podding * 19.5 = Net N contribution in kg N/ha, see Brill et al 2023). Further refinements can be applied where farm machinery permits the development of N removal maps [(grain yield (t/ha) * protein (%) * 10) / 5.7] on a 3 ha or so grid basis and N supply delivered on the same grind basis. This allows PNB for N to be estimated on the 3 ha grid so checks can be applied to areas that maybe outside the ideal range of 0.8 to 1.2.

General initiatives to reduce GHG intensity.

- Where there are large differences between water limited potential yield and achievable yield, check for production limiting factors and apply remedies.

- Most approaches that improve water use efficiency will reduce GHG intensity as efficiency of the conversion of inputs to outputs is improved.

Initiatives to reduce the GHG footprint of fertilizer N

It’s important to recognise that management options to improve NUE and reduce N2O emissions are complementary strategies.

- Best practice guides such as the Fertcare® series covering various industry sectors incorporate the 4R (right rate, right source, right placement, and right timing) nutrient stewardship principles.

- ‘Right rate’, use appropriate N budgeting strategies aided by soil testing and tissue testing to improve the ‘right rate’ as part of nutrient stewardship.

N budgeting based on yield estimates from Harries et al. (2022), Sadras and Rodriguez (2007) and French and Schultz J (1984) indicate water limited potential yield (WLPY) as:

Wheat = (WU – 75)*25 / 1000 = t/ha

Barley = (WU – 80)*24 / 1000 = t/ha

Canola = (WU – 110)*15 / 1000 = t/ha

Where WU (mm) = (0.20*Nov–Mar rain) + Apr–Oct rain

Economic yield (EY) is estimated by WLPY * 0.8

Therefore, for wheat where WU is 280 mm the WLPY is 5.1 t/ha and EY is 4.1 t/ha.

Crop N demand for EY is calculated as 4.1 t/ha (EY) x 40 kg N/t of grain production providing a total of 164 kg N/ha. From this pre-sowing soil N is subtracted (say 60 kg of pre-sowing soil N/ha) leaving the amount of N to be supplied from fertiliser, in this example 104 kg N/ha of fertiliser N is required. Converting to urea the 104 kg N/ha is divided by 0.46 to provide the urea application rate (e.g., 226 kg urea/ha). In the case of canola 80 kg N/t of grain production is used.

Note that the above calculations assume no other yield limiting factors. It is common for paddocks or parts of paddocks to be yield limited by nutrient deficiencies other than N, soil acidity, soil sodicity, low infiltration rates leading to surface water flow, or poor soil water holding capacity. Where one or more of these or other factors limits yield then a revised potential yield (RPY) needs to be estimated and replaces the water limited potential yield (WLPY) value in the calculations provided above. These insights are particularly important in avoiding any over fertilisation with N which increases the risk of GHG emissions. - ‘Right timing’, use split applications of N fertilisers to address the ‘right timing’ as part of nutrient stewardship. This approach reduces the nitrate spike in the soils and increases the efficiency of use by plants, leaving less N to be lost to the atmosphere, leaching or potential denitrification. This ‘right time’ approach ensures an improved matching between plant N demand and N fertiliser supply. In cereals N demand increases significantly from the commencement of stem elongation.

As part of the ‘right timing’ approach, avoid applying N under waterlogged conditions and improvements in soil drainage will significantly reduce GHG emissions. Low soil oxygen combined with the high soil nitrate favours the conversion of NO3- to N2O and N2 gas. While denitrification rates are generally low, if these conditions occur in conjunction with warm soil temperatures the denitrification losses can be extreme. Split N applications are particularly suited to sites that may be prone to temporary waterlogging or leaching. - ‘Right source’, gaseous N losses as N2O can often be reduced by up to 80% by using nitrogen stabilisers such as nitrification inhibitors (NI). The gains in productivity from the use of NI products can be small, suggesting that the adoption of these enhanced efficiency fertilisers will likely need to be incentivised.

- ‘Right source’, incorporate legume N from crops or pastures in the crop sequence to provide organic N. The advantage of organic N is that in this form it is not subject to losses and will only mineralise to nitrate (NO3) at significant rates when soil moisture and temperature conditions are favourable for plant growth.

- Manage cropping soils with minimum tillage and retain residues to slow organic matter breakdown.

- Tillage often causes a spike in N mineralisation and microbial growth increasing CO2 emissions from microbes as they consume soil carbon. It also increases the risk of nitrate exposure to loss pathways (e.g., release of N2O and N gas) at a time of no or low plant demand for N.

- Burning residues releases CO2 and retaining residues allows a proportion of the stubble to be incorporated into the soil carbon pool.

- ‘Right place’, where possible, place N in the soil rather than on the surface. This can reduce losses from ammonia as products like urea are first converted to ammonium and from ammonium are converted to either ammonia or nitrate. Urea placed in the soil allows for any ammonia to be re-converted to ammonium as the ammonia moves away from the high pH of the urea granule and encounters a lower pH soil environment. The high pH around the urea granule is a temporary spike caused by hydrolysis of the urea. Typically, in acid soils there is a low risk of ammonia loss.

- ‘Right place’, precision placement of N using protein maps, N offtake, N sensors and other Precision Agriculture tools is helpful in avoiding over supply of N that also increases the risk of N losses and GHG emissions.

- ‘Right rate’, use appropriate N budgeting strategies aided by soil testing and tissue testing to improve the ‘right rate’ as part of nutrient stewardship.

- Decarbonising N fertiliser manufacture: Urea is the main N source used in cropping systems and as discussed earlier it has significant Scope 3 carbon emissions embedded in its manufacture. There are technologies to produce ammonia - the feedstock to urea production - by using renewable energy (wind, solar, geothermal) to power traditional Haber-Bosch synthesis, as well as the development of electrolytic processes to generate hydrogen from water rather than deriving it from fossil fuels (methane). There are also options for carbon capture and sequestration (CCS) to offset carbon generated through the Haber-Bosch process, and this is termed 'blue" ammonia. The shift towards the production of ‘green’ and 'blue' ammonia will reduce the Scope 3 emissions embedded in N fertilisers. New and modular production facilities that can be deployed for N fertiliser production represent a significant disruptive technology for the fertiliser industry.

References

This paper is a brief summary of parts of the 2023 commissioned publication ‘Nitrogen fertiliser use and greenhouse gases - An Australian assessment: Challenges and Opportunities.’ by Norton RM, Gourley C, Grace P. Fertilizer Australia, Canberra. 69 pp. Copies can be obtained from Fertilizer Australia

Brill R, Moodie M, Street M, Obrien B, Price T, Morris B, Haskins B and Whitworth R (2023) Pulse performance in regionally relevant environments. GRDC Update Paper 14 February 2023.

Deloitte Access Economics (2023) Carbon border adjustment mechanisms: Implications for Australian Agriculture. Agrifutures Australia.

French R, Schultz J (1984) Water use efficiency of wheat in a Mediterranean-type environment. I. The relation between yield, water use and climate. Australian Journal of Agricultural Research 35, 743-764.

Grace P, de Rosa D, Shcherbak I, Strazzabosco A, Rowlings D, Scheer C, Barton L, Wang W, Schwenke G, Armstrong R, Porter I and Bell M (2023) Revised emission factors for estimating direct nitrous oxide emissions form nitrogen inputs in Australia's agricultural production systems: a meta-analysis. Soil Research 62, SR23070.

Harries M, Flower KC, Renton M, Anderson GC (2022) Water use efficiency in Western Australian cropping systems. Crop and Pasture Science 73, 1097-1117.

Norton R, Gourley C, Grace P and Kraak J (2023) Nitrogen Fertiliser Use and Greenhouse Gases - An Australian Assessment: Challenges and Opportunities. Fertilizer Australia, Canberra, ACT

Norton R, Bruulsema T, Robert T, Snyder C. 2015 Crop nutrient performance indicators. Agricultural Science, 27 (2), 33-38.

Peoples MB, Bowman AM, Gault RR, Herridge DF, McCallum MH, McCormick KM, Norton RM, Rochester IJ, Scammell GJ, Schwenke GD. (2001) Factors regulating the contributions of fixed nitrogen by pastures and crop legumes in different farming systems of eastern Australia. Plant and Soil, 228 (1):29-41.

Sadras V and Rodriguez D (2007) The limit to wheat water-use efficiency in eastern Australia. II. Influence of rainfall patterns. Australian Journal of Agricultural Research 58(7)

Sevenster M, Bell L, Anderson B, Jamali H, Horan H, Simmons A, Cowie A, Hochman Z (2022) Australian grains baseline and mitigation assessment.

Contact details

Rob Norton

Email: robnorton001@gmail.com

Date published

February 2024

® Registered trademark