Annual ryegrass – managing and stopping seed set in northern cropping systems

Annual ryegrass – managing and stopping seed set in northern cropping systems

Author: Garry Onus (Nutrien Ag Solutions) | Date: 01 Aug 2024

Take home messages

- Don’t underestimate annual ryegrass (ARG) resilience – hit it small and hit it hard

- Use as many tools as possible to combat ARG

- Know your enemy – TEST your population for resistance

- Don’t be afraid of residual herbicides as they are a key part of the process

- Don’t ignore scattered plants. Manage ARG before it manages you

- Manage populations of ARG surrounding your paddocks to stop reinfestation.

Ecology of annual ryegrass (ARG)

Annual ryegrass usually emerges from late autumn to early spring. It is a highly competitive weed and dense stands of 80-100 plants / square metre can produce up to 45,000 seeds per square metre.

Ryegrass prefers to germinate from around 2cm deep and the volume of emerging plants reduce as depth increases until around 10cm, after which it ceases.

The seed has a relatively short survival time in the soil as is often the case with any weed that seeds prolifically.

The leaves of annual ryegrass have a shiny surface which can make it difficult to get some post emergent chemicals into the plant.

Stop seed set in fallow

The use of glyphosate to treat ARG in fallows is common and unless a population has developed resistance, generally achieves good levels of control. A crucial part of ensuring the ryegrass does not become a problem is to check for surviving plants and make sure they do not set seed.

The use of products such as paraquat to double knock any surviving weeds certainly helps keep the lid on populations of ryegrass as resistance to this chemistry in this weed is still rare at this stage.

The use of optical sprayers enhances the ability to control ARG by using more robust rates of products than would be applied in a broadacre spray.

If all attempts to control ARG using chemicals fail, don’t be afraid to get chippers in for sparse populations or if the population is out of control be prepared to do a ‘conservation tillage’ operation to dig them out.

Stop seed set in crop - herbicides

The use of residual herbicides in winter crops is a really good option to help get on top of an increasing ryegrass problem. Where practical, using combinations of residual herbicides with different modes of action can provide better control and reduce the resistance risk.

AHRI student researcher, Facundo Cortese (supervised by Dr Roberto Busi, Prof Hugh Beckie and Dr Danica Goggin), investigated the impact of applying pre-emergent herbicide mixtures to resistant annual ryegrass in a controlled pot trial. The mixture of pyroxasulfone (Sakura®) and prosulfocarb (Arcade®) increased the control of resistant annual ryegrass by 11% (vs prosulfocarb alone) and 29% (vs pyroxasulfone alone). Mixing two herbicides with different modes of action significantly decreased the survival and seed production of pyroxasulfone (Sakura) resistant ryegrass.

These residual products obviously come with rotational constraints that need to be managed. Some of the products available can be seen in the table below.

Table 1. Key pre-emergent herbicides used to target annual ryegrass in cereals and other key winter crops. IBS = Incorporated By Sowing, EPE = Early Post-Emergent.

Product | Group | Crops | Use method |

|---|---|---|---|

Sakura® | 15 (K) | Bread wheat, Triticale, Chickpeas | IBS |

Luximax® | 30 (T) | Bread wheat | IBS |

Mateno® Complete | 32, 15 (K) 12 (F) | Bread wheat, barley | IBS or EPE |

Overwatch® | 13 (Q) | Wheat, Barley, Canola, Fababeans | IBS |

Boxer Gold® | 15 (J,K) | Wheat, Barley | IBS / EPE |

Oats, Triticale, Chickpeas, Fababeans | IBS | ||

Triasulfuron | 2 (B) | Wheat | Pre-em |

Trifluralin | 3 (D) | Wheat, Barley, Chickpeas, Fababeans, Linseed | IBS |

The following photo shows how effective residual products can be on controlling ryegrass, with the Sakura® treated area at the bottom being virtually weed free and ryegrass filling the inter-row space at the top where the soil is untreated.

Figure 1. Photograph showing effectiveness of residual products on ryegrass.

Many of the residual herbicides used in winter cereals can damage the crop if the herbicide gets too close to the seedling, so most are applied IBS (Incorporated By Sowing with a tyne and press wheel) and don’t fit well with disc planter systems. The IBS technique leaves the seed trench with no residual herbicide to control weeds, so we often end up with ryegrass germinating in the seed trench, especially in paddocks that have been recently cultivated and have seed below the furrow. This is a problem if we are striving for 100% control. Some products have an EPE (Early Post-Emergent) registration which can help deal with this problem if the season goes with you i.e. they require rainfall soon after application to wash the herbicide into the soil. Triasulfuron (e.g. Logran®) applied immediately after planting to paddocks sown to wheat has been successful at providing control of ryegrass in the seed trench area, where the ryegrass is still susceptible to Group 2 herbicides.

If weeds escape from the residual herbicide, it is a good idea to come back in with a post-emergent product such as Axial® Xtra, or another effective post-emergent herbicide to try to minimise seed set.

Table 2. Effect of treatments in 2016 on reducing the ryegrass populations the following autumn.

Treatment | % reduction in autumn |

|---|---|

Fallow (no crop, weeds controlled) | 98% d |

Sakura® + Axial® + Autumn burn | 97% cd |

Sakura® + Axial® | 94% bcd |

Sakura® alone | 93% bc |

Axial® alone | 86% b |

Autumn burn (no herbicides in crop) | 86% b |

Trifluralin + Logran® | 34% a |

Spray topping and crop topping

Spray topping is the late application of selective herbicides to crops to prevent seed set. This technique is usually used for broadleaf weeds in winter cereals.

Crop topping is the late application of non-selective herbicides, such as glyphosate or paraquat, to kill weeds or sterilise seeds and prevent late viable seed set. This strategy is an opportunistic one which usually works best in feed barley and pulses where there is a late flush of ryegrass as the crops ripen. Glyphosate is registered for this use pattern in wheat, feed barley (not malting barley), canola and pulses but paraquat is not. Paraquat is registered for use in pulses and pastures.

There is a very good GRDC Update paper on ‘Optimum crop-topping timing – getting better ryegrass control’ from August 2022 which covers this subject very well. It is available on the GRDC Website.

In the following trial (Table 3), barley was at soft dough and the head was at 48% moisture. (Crucial® label says “Apply to mature crop from late dough stage (28% moisture) onwards”.) The awns had turned white. The ryegrass was just out of the boot and some had flowered.

Glyphosate at either 1.0 or 1.5L/ha applied at the flowering stage of ryegrass was very effective in reducing the viability of seed set, however, the lower rate of glyphosate (0.5L/ha) was ineffective. At a later application timing (data not shown) glyphosate was not effective at any rate. Diquat did not provide seed set control of ryegrass irrespective of the timing of application. Herbicide treatments applied to barley at either the soft dough or firm dough stage of grain fill had no significant impact on individual grain weight, the viability of the grain or early plant vigour.

Table 3. This table shows herbicide treatments applied to flowering annual ryegrass and the effect on viable seed per head on ryegrass and grain quality of barley.

Flowering | Ryegrass | Barley | ||

|---|---|---|---|---|

Germination | Control | Grain weight | Germination | |

% | % | (mg) | % | |

Nil | 65 | 0 | 40.1 | 96 |

Glyphosate @ 0.5 l/ha | 61 | 7 | 37.6 | 89 |

Glyphosate @ 1.0 l/ha | 11 | 84 | 37.6 | 91 |

Glyphosate @ 1.5 l/ha | 2 | 97 | 38.4 | 95 |

Diquat @ 0.75 l/ha | 61 | 7 | 38.3 | 91 |

Diquat @ 1.13 l/ha | 70 | -7 | 38.0 | 100 |

Diquat @ 1.5 l/ha | 64 | 2 | 37.9 | 97 |

Crop competition

The use of crop competition is also a very successful strategy to help reduce weeds generally and particularly for ryegrass. Ensuring an even crop establishment with an adequate population makes weed control a lot easier to achieve and more effective.

Table 4. The trial below is one example of the impact that plant population can have on ryegrass density and seed production.

Wheat Seeding Rate | Ryegrass plants/m2 | Ryegrass heads/m2 |

|---|---|---|

40 kg/ha | 3.2 | 14.2 |

70 kg/ha | 4.1 | 4.9 |

100 kg/ha | 3.9 | 5.7 |

Central Murray Ag Group – Bunnaloo, NSW

Row direction

The row orientation can also have an impact on weed densities and their ability to compete with the crop. It has been shown that crop rows running east-west usually have fewer weeds than those that run north-south. This is another strategy that may be able to be utilised in the cropping program to combat ryegrass.

The benefit of row direction is less pronounced in summer or in more northern geographies where there is less shading during the day as a result of the sun being more directly overhead.

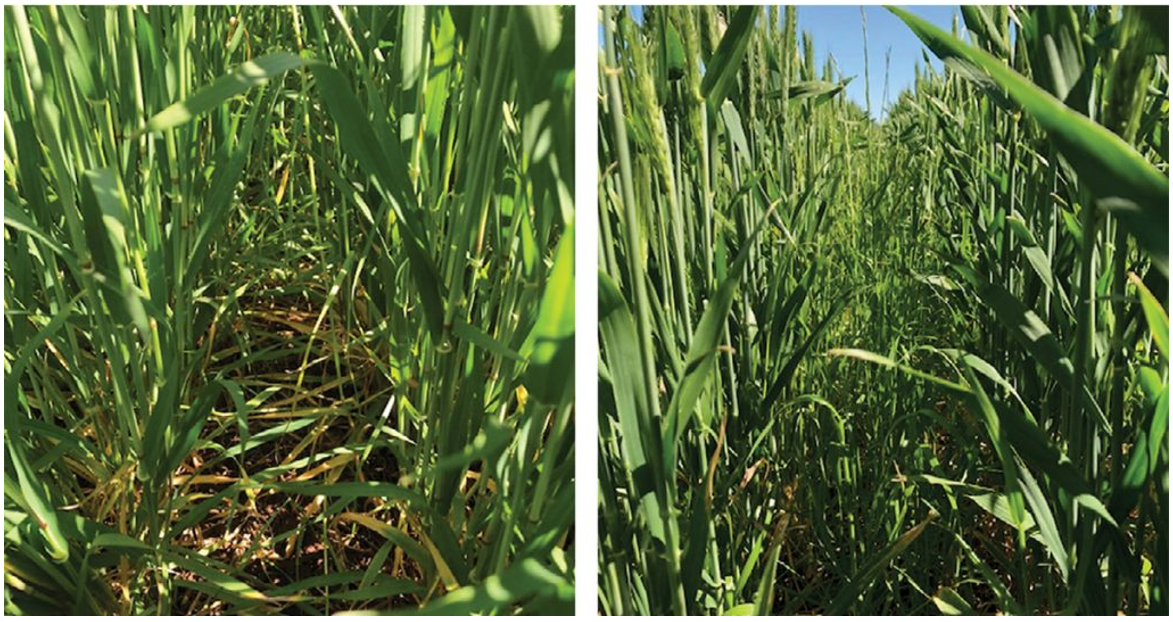

Figure 2. E/W sown barley (left) v N/S sown wheat (right).

Source: Chris Davey, Agriservices Agronomist, YP AG

Crop rotation

Another tactic available in the northern region is rotation between summer and winter crops. If ryegrass numbers are increasing and becoming difficult to manage in winter crops it may be possible to rotate the paddock to a few years of summer crops. This enables different strategies to be used in the winter fallow to drive down the ryegrass seedbank, before returning to a winter crop rotation. However, caution is advised if your only winter fallow control strategy is glyphosate followed by more glyphosate as you will be selecting for resistance over time!

Conclusions

There are many tools available to combat ryegrass in fallows and in crop, some of which are outlined in this paper. Using a combination of as many of these tools as possible in your farming system will assist greatly in managing this potentially problem weed.

There is a lot of good reference material on both the GRDC website and the Weedsmart website.

References

Contact details

Garry Onus

Nutrien Ag Solutions Moree

Mobile: 0428 795512

Email: garry.onus@nutrien.com.au

Date published

August 2024

® Registered Trademark