Liquid Nitrogen: pros and cons of different formulations

Liquid Nitrogen: pros and cons of different formulations

Author: Stuart Doyle, AgVista Australia P/L | Date: 05 Mar 2013

Stuart Doyle, AgVista Australia P/L

Take home message

Liquid fertiliser is an important fertiliser ‘tool’ that allows growers to apply meaningful amounts of Nitrogen and other important elements strategically within a growing season. Understanding the formulations and their relative strengths / weaknesses can enable growers to utilise the products available to them to maximise productivity.

Understanding available application methods and ideal environmental conditions for nutrient uptake will also enable growers to get the best chance of success with Liquid N products.

The use of liquid nitrogen fertiliser is not new to australian grains production. Workers such as Strong (1982), Smith (1985), Powlson (1989), Kettlewell (1987) and Gooding (1989) delivered foundation research into the use of urea solutions as a useful foliar suppliments to grain crops. However liquids have not been widely used by farmers until the 2000’s. A Kondinin group survey in 2003 showed 18% of respondants countrywide were using some liquid forms of nitrogen. Market activity would suggest this figure would have increased significantly during the last decade.

This shift towards liquids has not always been for consistent reasons, this paper will seek to explore the market leading products and share some of the authors experiences to answer the five most commonly asked questions about liquid N

Common questions

The five most common questions asked when growers and avisors are looking at using liquid nitrogen sources are

- How much will it cost?

- Can I spray this product on the ground – how much will I lose?

- What can I mix it with?

- Will it burn the crop? How much burn is acceptable?

- What is the best set up to apply this product – is it corrosive?

Costs

Most farmers and advisors relate Nitrogen fertiliser costs back to the underlying Urea prices and doing so reveal that kg/kg liquid forms range from 30% to 75% dearer per unit of nitrogen. However when applied the per unit applied cost can be comparable depending on the rate of N applied. see Table 1 below:

Table 1: Applied N cost comparison 30 Kg N|

Product |

UAN |

AN Solution |

Urea |

Urea |

Urea Solution |

UAS |

|

Application |

Dribble Band |

Dribble Band |

Banded Planter |

Ground Spread |

Foliar |

Foliar |

|

|

(Liquid) |

(Liquid) |

(Solid) |

(Solid) |

(Liquid) |

(Liquid) |

|

Analysis (N) |

42% |

25% |

46% |

46% |

24% |

27% |

|

Delivered Cost / L or Kg |

$0.95 |

$0.63 |

$0.59 |

$0.59 |

$0.45 |

$0.55 |

|

Kg N to be applied |

30 |

30 |

30 |

30 |

30 |

30 |

|

Rate / Ha Kg or L |

71 |

120 |

65 |

65 |

125 |

111 |

|

$ / Kg N |

$2.26 |

$2.52 |

$1.28 |

$1.28 |

$1.88 |

$2.04 |

|

Product cost / ha |

67.86 |

75.60 |

38.48 |

38.48 |

56.25 |

61.11 |

|

Application Cost/Ha |

9.00 |

10.00 |

36.00 |

16.00 |

10.00 |

10.00 |

|

|

|

|

|

|

|

|

|

Total cost / Ha |

76.86 |

85.60 |

74.48 |

54.48 |

66.25 |

71.11 |

To some farms the improved handling characteristics enable a reduction in casual operations staff and better spray-rig utilisation. To some operators the convienience and ability to effectively apply Nitrogen independent of incorporating rain out-weighed the significant extra cost.

Losses

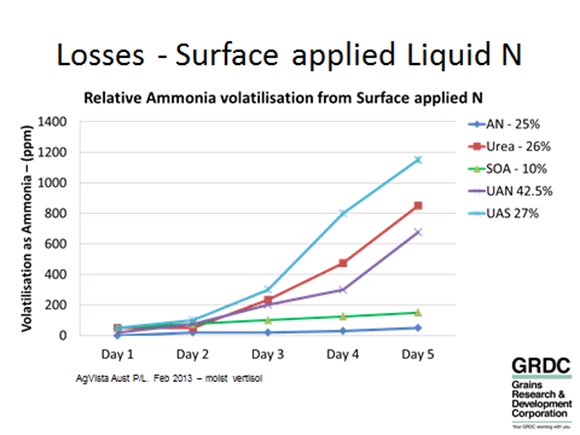

Liquid fertiliser behaves in a very similar fashon to solid fertiliser of the same make-up. Most liquid nitrogen sources have Urea as part of their make-up r are volatile on the soil surface in the presence of moistre, a pH greater than 7 and carbonates in the soil. See Figure 1 for the relative N loss from a simple experiment conducted at ambient temperatures during February 2013.

This type of demonstration is easily set up using a growers own soil and actual fertiliser of choice and incubating for 10 days using a Drager ammonia concentration tube to measure ammonia volatilised in ppm. Yara ASA have published a brochure and distribute a kit that gives detailed instructions and an estimation of a 15% loss occurring when theDrager ammonia tube has turned blue.

This simple test will surprise some growers as it shows the striking differences in volatilisation between fertilisers, soil moisture and soil type. This is a very visual test that may encourage the sensible use of Nitrogenous fertilisers – not just liquid N.

Despite some new research suggesting that N sources may not be as volatile as first thought, this kit demonstrates that ammonia is released by surface applied liquid Nitrogen products.

Mixtures

Manufacturers and chemical suppliers will dictate what is labelled and advisors should refer to these sources for recommended mixtures. Experiences of what not to mix these products with however can be shared and may be just as useful.Do not mix foliar nitrogen sources with propiconazole, as the rapid translocation of such products to the leaf tip will induce severe tip and marginal scorch in cereals. Amine formulations are generally not compatible with liquid N as a carrier as ‘salt out’ occurs. Caution is advised when consulting fertiliser company ‘compatibility charts’ as these rarely indicate biological compatibility or a likely damage rating. Whilst some mixtures are physically compatible they can reduce selectivity of herbicides causing crop damage.

Leaf Scorch

Leaf damage (scorch) from liquid N comes in two major forms (1) spotting and (2) tip and margin burn. These are two very different forms of damage.

Leaf burn from spotting is dessication to localised areas from too high a salt concentration in the fertiliser solution leading to cell-burst and necrosis, leaf tip and marginal burn is from very rapid uptake and translocation without metabolism of predominantly Urea (can also be from ammonium).

Spotting is commonly seen with Ammonium Nitrate solution, Ammonium Sulphate solution and UAN, with the former being the most potent. This is largely due to the oily nature, high salt index and hydroscopicity of these compounds causing them to be injurious to leaf tissue when left concentrated and in contact. Canopy retention will give this form of burn fom poorly set-up streaming nozzles, wind or machine speed causing droplet separation from streams and applications made during hot weather.

Margin and tip burn is perhaps the most common yet least understood by growers and advisors. This burn is caused when urea is concentrated to toxic levels at the leaf tip and leaf margins through rapid translocation . This process may occur for various reasons including

- Hight E/T load on the plant from hot conditions

- Low metabolic rate from frost, drought stress, herbicide injury or general stress

- Nickel deficiecy inhibiting urease activity – not allowing urea to be metabolised

- Excessive rate of nitrogen applied in perfect conditions for uptake

- Mechanical leaf damage from wind or low clearance sprayers

- Enhanced cuticular penetration & translocation from adjuvants or mixtures with compounds such as propiconazole

Damage from leaf scorch can be quite extreme and is very visual, see below:

Leaf Scorch can be minimised by

- Do not apply is frost has occurred that day or forecast next day. Avoid any conditions that induce a slowing of metabolic rate.

- Match N to moisture – only apply what the crop is capable of utilising

- Minimise mixtures – never apply Propiconazole with liquid N

- Do not use adjuvants – urea is an excellent cuticle disruptor and has no trouble entering the leaf if maintained as a solute

- Watch weather conditions – more than 18 Km/hour has been shown to break streams and is thought to cause waxy platelets in the cuticle to separate

Equipment and corrosion

All fertiliser solutions are salts and are corrosive to a degree. Ammonium Nitrate and Ammonium Sulphate based solutions are the most aggressive and will rapidly destroy copper, brass, bronze, galvanising and any carbon steel. For these compounds it is essential to use polyethylene or stainless steel in application equipment. Urea solutions will cause rust, however may be safely stored in carbon steel tanks and pumped with carbon steel or alloy pumps. See table 2 below.

It is not wise to put AN/ AS/UAN based solutions through sprayers with large amounts of exposed circutry such as weed seekers® or other camera sprayers with out first protecting circutry. There are several readily available ‘spray-on’ protectants and some contractors simply use crop-oils or vegetable oils through a hand sprayer to coat components that need protection from corrosion.

Table 2. Products available in nth NSW

|

Liquid Product |

Product examples |

N % (w/v) |

N form % |

Use |

Volatility |

Physical compatability #* |

Best fit / crops |

Corrosive ? |

|

Liquid Urea |

Ranger®, N26®, Promax |

20-26% N |

Urea |

Soil / Foliar |

Volatile |

No to Propiconazole. |

Foliar winter Cereal, water run |

mild |

|

Liqud AS |

SOA, AMSul |

10% N |

NH4 |

Soil Only |

Volatile |

No to SC's. No to Amines as a carrier. |

Glyphosate carrier, soil applied |

V. Aggressive |

|

Liquid AN |

AN25, Liquifert Pinnacle® |

23-28% N |

50% NH4/ 50% NO3 |

Soil only |

Low |

No to Amines as a carrier |

Cold climate top dress. High chloride. Fallow herbicide carrier. |

V. Aggressive |

|

UAN |

EasyN®, N42®, |

42.5 % N |

25% NO3: 25% NH4: 50% Urea |

Soil / Foliar |

50 % N volatile |

No to propiconazole |

Cereals top dress - soil applied, summer crop side dress |

Aggressive ( inhibitor added) |

|

UAS |

Sulsa® |

27% N: 7% S |

20% Urea: 7% NH4 |

Soil / Foliar |

Volatile |

No to SC's. No to propiconazole |

Cereals Foliar, Canola Foliar / Soil |

Aggressive |

|

ATS |

Easy ATS®, ATS®, ThioSul® |

16% N: 34% S |

NH4 |

Soil only |

Low |

Wide range |

Cereals / Canola pre-plant |

Very Mild to carbon steel |

These experiences have been ammassed through 8 years of working closely with growers to try and gain the most value from liquid Nitrogen in Nth NSW and are by no means and exhausted list of good ideas. As the industry reaches more maturity more ideas from other parts of the world and locally developed techniques will improve the application and efficiency of these products. Table 3 below shares some of the interesting resources that the author has found useful. The IFA has just released a particularly good reference manual for those interested in foliar fertiliser and the science behind the successful application see http://www.fertilizer.org/ifacontent/download/95508/1400327/version/1/file/2013_foliar_fertilization_HR.pdf

Table 3: Useful resources

|

Manufacturers

|

Application Equipment

|

|

www.rutec.com.au

|

www.millerstn.com

www.bfs.uk.com

|

|

Organisations

|

Authors

|

|

www.grdc.com.au

www.fluidfertilisers.com.au

|

Gooding & Davies (1992)

Smith. J.J. (1985)

Powlson. D. (1989)

Strong. W.F. (1982)

Lafond. G. (2012)

Grant. C. (1996)

Gooding. M,J. (1986-1992)

Kettlewell. P. (1987)

Raun, W.R. (2002)

Schwenke, G. (2011-12)

Fenandez, sotiropoulos, Brown (2013) |

Contact details

Stuart Doyle

Ph: 0428 800 488

Email sadoyle@bigpond.net.au