Spray application tips and tactics

Author: Bill Gordon, Nufarm Australia | Date: 28 Feb 2017

Take home message

Product choice and rate, timing and total application volume will normally have the largest impacts on the efficacy achieved from any spray job. The sprayer setup and operating parameters can also have a significant effect on the outcome by affecting the spray coverage on the target, as well as the drift potential. Assessing spray coverage is a simple process that can help to improve the sprayer setup.

Introduction

Throughout the season there are a number of situations where spray applications are made to very different types of targets, often with products that have different types of translocation. This variation generally requires a change in nozzle type or orifice size and the operating parameters to achieve a change in total application volume and/or spray quality.

After adjusting the sprayer setup, being able to determine where the spray droplets are landing allows the operator to change the sprayer setup to improve the coverage for particular spray jobs. Often this requires that the operator is able to assess the impact of changes to the set up on where the droplets land.

A starting point – how many setups should the operator have?

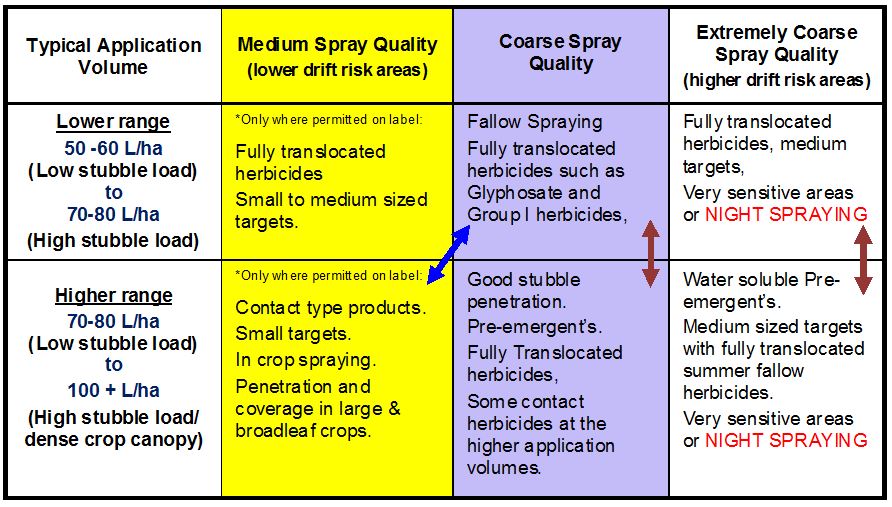

As a general guide, the main spray jobs, application volumes and typical spray qualities required by an operator are covered in table 1. This highlights the fact that often more than 2 sets of nozzles are required to cover all situations.

For each type of spray application there may be subtle variations in the sprayer setup or operation that can be made to improve the coverage. This paper discusses some of the practical considerations the operator should take into account when choosing the set up for various spray jobs throughout a typical season, including the factors influencing spray coverage and how to compare setups and operating parameters for continual improvement.

Table 1. Typical spray quality and total application volume for different situations

*note, the arrows indicate that one nozzle may be able to do more than one type of application, provided the spraying speed, application volume and operating pressure are suitable

Suggestions to improve fallow applications

The following points have been included to provide a guide or starting point for the sprayer setup. Some of the important things to consider include:

Total application volume: For fully translocated products typically volumes above 50L/ha for a coarse spray quality in low stubble environments, and above 70L/ha in heavy stubble environments. Typically this volume should be increased by 10 to 20 L/ha when using an extremely coarse spray quality. For contact type products (translaminar) the total application volume should be above 70L/ha in low stubble environments, and up to 100 L/ha in heavy stubble situations.

Spray quality: For small vertical targets (grasses) operating at the small end of the coarse spectrum will normally provide good retention of droplets on a range of weed types, however using coarser spray qualities may also be useful for many broadleaf weeds. Often operating at the small end of the coarse spectrum will provide a good balance for a range of targets and products. This is normally suitable for daytime conditions, but may not reduce the spray drift potential if considering spraying at night.

Nozzle spacing: Using narrow nozzle spacings, e.g. 25cm compared to 50cm, can improve deposition into standing stubble. However before deciding to plumb the machine this way ensure that the orifice size and spray quality will be suitable if operating with nozzles that have smaller orifice sizes.

Boom height: Operating at heights above that required for a double overlap at top of the stubble or weed (whichever is the taller) will reduce coverage and increase drift potential. Increasing boom height from 50cm above the target to 70cm above the target can increase the airborne fraction of spray by up to 4 times.

Adjuvant selection: adjuvants should always be chosen to increase efficacy, however many adjuvants have the potential to change the spray quality and drift potential in unexpected ways. Most non-ionic wetter 1000 type products can more than double the drift potential from some air inducted coarse nozzles. For fallow spraying it is important to select adjuvants that do not increase the drift potential of the spray application.

Spraying speed: Reducing spraying speed can reduce dust and wheel tracks, will improve penetration into stubble and crop canopies and can reduce shadowing.

Nozzle design: There are a number of nozzle designs that have twin patterns, where one pattern is angled forward and the other angled backwards. Generally twin nozzles are best utilised for increasing deposition onto vertical targets, which may also increase stubble interception. Twin nozzles are best operated at lower spraying speeds, commonly less than 16 km/h.

Risk assessment: Before any spray application it is important to fully assess any risks including the weather conditions, sensitive areas and volatility risk.

Pre-emergent herbicides

Most applications of pre-emergent herbicides will benefit from using coarser spray qualities to increase penetration through stubble and by increasing the total application volume, however volumes above 150 L/a generally do not provide further significant improvements in efficacy.

For products with relatively low water solubility, such as trifluralin and pendimethalin, avoiding the tie up of product onto stubble is critical to maximising herbicide contact with the soil. When using a conventional nozzle spacing of 50cm, a VC spray quality or larger (such as XC) set to produce a double overlap at the top of the stubble can minimise retention on stubbles, however the uniformity of the spray deposit onto the soil surface will be more variable than compared to a coarse spray quality due to the lower number of droplets produced.

For reasonably water soluble products such as atrazine, simazine and metalochlor, interception by the stubble may have a smaller impact on efficacy, provided a reasonable rainfall event can wash the product back onto the soil. Where rainfall is anticipated, the more water soluble products may be applied in a lower total application volume, typically above 70-80 L/ha.

Generally reducing spraying speeds will improve the penetration into stubble and improve the evenness of the application. Narrower nozzle spacings can also be of benefit, provided the spray quality and boom height are suitable.

Alternately, many operators have plumbed machines with nozzle spacings to match the crop row width. Where nozzles are positioned in the centre of the inter-row gap between standing stubble lines, the nozzle height may be lowered to obtain an overlap close to the base of the stubble. This may improve soil contact and reduce interception by the stubble, provided spraying speeds and wind speeds do not excessive.

Early season grass sprays in-crop

Droplet retention on small, vertical grasses is usually optimised when using a medium spray quality (where permitted on label), however in a heavy standing stubble, the smaller droplet sizes tend to increase the amount of product deposited onto the stubble. Generally a spray quality at the smaller end of the coarse spectrum (towards medium) combined with total application volumes above 70-80 L/ha will provide a reasonable outcome.

Where operators typically operate at higher spraying speeds, or with larger than coarse droplets, they may notice increased shadowing of small weeds behind stubble. Where this is occurring, slowing down would help, but ensuring that each new job is driven in the opposite direction to the last can also improve overall level of control, particularly when a ‘double knock’ strategy is employed.

When using a Group A product, always ensure that an appropriate adjuvant is used, through a nozzle that will not significantly alter the spray quality with the addition of the adjuvant (see table 2). Also ensure the water quality is suitable by testing for bicarbonate levels before the application.

Table 2. Variation in the Dv0.5 (VMD) produced by selected low drift nozzles* operated at 3.0 bar, expressed as the standard deviation +/- from the Dv0.5 (VMD)1 in micrometers (μm) for 3 spray solutions

Spray Solution | water | clopyralid | pinoxaden + methylated oil | Average Standard Deviation |

|---|---|---|---|---|

Nozzles Tested (all nozzles were operated at 3.5 bar) | Standard Deviation + / - micrometers (μm) | |||

7.33 | 4.69 | 4.45 | 5.49 | |

Bellericay Bubblejet ABJ 110-015 | 28.62 | 26.01 | 14.52 | 23.05 |

Bellericay Bubblejet ABJ 110-02 | 9.60 | 5.11 | 3.54 | 6.08 |

TeeJet AITTJ60-110-02 | 8.40 | 8.72 | 9.78 | 8.97 |

TeeJet AIXR 110-015 | 5.44 | 10.28 | 9.06 | 8.26 |

TeeJet AIXR 110-02 | 19.63 | 16.40 | 12.80 | 16.28 |

Hypro Guardian Air 110-015 | 15.92 | 14.27 | 10.61 | 13.60 |

Hypro Guardian Air 110-02 | 6.14 | 8.17 | 8.73 | 7.68 |

Lechler IDK 120-02 | 4.64 | 6.35 | 4.84 | 5.28 |

Lechler IDKT 120-02 | 6.32 | 8.23 | 4.29 | 6.28 |

Hardi Minidrift MD-110-02 | 4.16 | 3.73 | 3.10 | 3.66 |

Hardi Minidrift Duo-110-02 | 5.23 | 2.30 | 3.53 | 3.68 |

TeeJet TTI 110-015 | 13.04 | 10.51 | 14.04 | 12.53 |

TeeJet TTI 110-02 | 5.39 | 8.71 | 12.25 | 8.78 |

Teejet TTJ60-110-02 | 41.71 | 11.69 | 5.83 | 19.74 |

Hypro ULD 120-015 | 7.75 | 14.11 | 8.54 | 10.13 |

Hypro ULD 120-02 | 7.63 | 3.39 | 3.89 | 4.97 |

1Dv0.5 or VMD is the droplet size (diameter in micrometers or μm) at which half of the spray volume produced by the nozzle will exist as droplets smaller than this size, and the other half will exist as dropets larger than this size.

*note the range of nozzles listed in this table does not include all of the nozzles tested by J Connor Ferguson

Broadleaf sprays in crop

Fully translocated products such as the Group I herbicides should be applied with a coarse spray quality or larger at application volumes above 60 L/ha. Where a product with contact activity is used the application volume should be increased to 80 L/ha or more.

Late season applications into dense canopies

Late season fungicide and insecticide applications, along with pre-harvest desiccation, typically require that the droplets are able to penetrate into the canopy. The size of the canopy and the architecture of the plants will greatly influence how far droplets can penetrate into the canopy.

Leaf type, leaf shape and leaf surface all affect how well droplets will be retained. Droplet retention on most cereals and large grass type crops will be improved by using a medium spray quality (where permitted on label), however penetration through a canopy may be increased using a coarse spray quality. Droplet retention on many broadleaf crops may allow for good retention when using coarse spray qualities.

With a standard boom sprayer there are only a limited number of things the operator can do to potentially improve the penetration into the canopy, those include:

- Reducing the spraying speed

- Increasing the application volume

- Manipulating the spray quality, and

- Utilise a narrower nozzle spacing

To make a greater impact on penetration into the canopy generally requires the use air assistance to help transport droplets into the canopy. While the addition of air into the equation can add another layer of complexity to the sprayer setup, it can also provide large improvements in canopy penetration when correctly setup and adjusted.

To assess which variations in the sprayer setup and operating parameters can actually improve the penetration into dense canopies, useful tools include water sensitive paper (WSP) and the SNAPCARD app, which can help the operator to determine where improvements are being made.

Consider assessing spray deposits to improve your spray coverage

Using tools such as water sensitive paper will allow the operator to look at where the droplets are landing and to compare various sprayer setups to see which ones provide the best coverage.

Often it is difficult to see small improvements in coverage. A tool that can measure the level of spray deposit can assist when trying to evaluate changes. The SNAPCARD app allows spray operators to measure the spray deposits onto water sensitive paper by indicating a ‘percent coverage.’ Taking regular measurements and recording this information allows for continual improvements in the sprayer setup for different types of spray applications.

Further reading

GRDC Grow Note on Spray Application

Contact details

Bill Gordon

Nufarm Australia Limited

11 Hienneman Road, Wellcamp, Q.4350

Ph: 0418 794 514

Email: bill.gordon@nufarm.com

Was this page helpful?

YOUR FEEDBACK