Understanding the impact of a comprehensive range of strategic deep tillage practices on crop performance and soil properties for two water repellent soil types

Understanding the impact of a comprehensive range of strategic deep tillage practices on crop performance and soil properties for two water repellent soil types

Author: Stephen Davies, Department of Primary Industries and Regional Development (DPIRD); Tim Boyes, AgVivo; Chad Reynolds, Liz Petersen, Joanne Walker, DPIRD; Ty Fulwood, ‘Meenar’ Meckering; Rob Dempster, ‘Adair’ Goomalling; Joel Andrew, MapIQ. | Date: 26 Feb 2018

Key messages

- Grain yield increases from deep tillage soil amelioration practices ranged from 26-50% in the first year and 5-39% in the second, on pale deep sand over gravel at Meckering and by 2-93% on deep sand at Goomalling.

- Removing subsoil compaction is critical for yield responses in the first year, increasing crop root access to deep soil moisture and improving uptake of nutrients deeper in the profile, such as potassium and nitrogen. Removal of topsoil repellence and deeper soil mixing appears important for longer term responses.

- Most profitable treatment at Meckering over 2-seasons has been one-way ploughing, followed by ripping with spading and soil inversion (mouldboard plough). Only very deep ripping with or without topsoil inclusion or with one-way ploughing were profitable in the first year at Goomalling.

- Understanding the cost, benefits and longevity of amelioration approaches for specific soil types can guide improved decision making and profitability.

Aims

To compare and showcase the broad range of strategic tillage options for amelioration of sandplain soils and to assess their effectiveness at overcoming a range of soil constraints and increasing crop productivity.

Method

The experiments are randomised complete block designs with 4 replications and have been established on sandplain soils at Meckering and Goomalling. Plots were established within the growers’ existing controlled traffic system. Plots are 4-4.5m wide and 45m long and are located in the seeder wings, either side of the wheel tracks. The area between the wheel tracks has been left as an untreated buffer. Sites are seeded and managed by the grower throughout the season but harvesting is undertaken with a small plot header so yield can be assessed on individual plots.

Table 1. Experimental site location, soil type, annual and growing season rainfall and soil properties.

| Site | Rainfall (mm) | Water repellence rating | Soil pH (CaCl2) | Severe compaction depth (cm) | Soil fertility (0-10cm, %) | |||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Average annual | Growing season (Apr-Oct) | 0-10 | 10-20 | 20-30 | 30-40 | OC | P | K | S | |||

| Meckering (Gravelly pale deep sand) | 388 | 323 (2016) 253 (2017) | Severe | 5.9 | 5.2 | 4.7 | 4.6 | 22-42 | 0.8 | 13 | 37 | 11 |

| Goomalling (Deep yellow sand) | 365 | 181 (2017) | Moderate | 5.4 | 4.8 | 4.5 | 4.4 | 20-50+ | 1.0 | 16 | 67 | 4 |

Machines used for the tillage treatments included an Agrowplow deep ripper, Heliripper very deep ripper, Farmax rotary spader, Alpler 5-furrow reversible mouldboard plough, a 4-disc trial scale one-way plough with 55cm discs and a grower-built clay delver. All of the tillage treatments were applied and rolled prior to seeding.

The Meckering site was sown to Scepter wheat in both 2016 and 2017. In 2016 the site was sown on 28 June at 100 kg/ha with 12 kg/ha P, 18 kg/ha K and 42 kg/ha N. In 2017 it was sown on 29 May at 75 kg/ha with 12 kg/ha P, 25 kg/ha K and 22.4 kg/ha N. The Goomalling site was sown on 13 June 2017 to Calingiri wheat at 70 kg/ha with 13.5 kg/ha P, 15 kg/ha K and 26 kg/ha N.

Table 2. Experimental one-off deep soil tillage treatment details and application timing.

No. | Treatment | Abbreviation | Effective Working Depth | Treatment Application Timing | |

|---|---|---|---|---|---|

Meckering | Goomalling | ||||

1 | Untreated control | CON | - | - | - |

2 | Deep ripping | DR | 32-34 | Apr-16 | May-17 |

3 | Deep rip with topsoil inclusion | DRI | 34-36 | Apr-16 | May-17 |

4 | Deep rip + spading | DR+SP | 33-35 | Apr-16 | May-17 |

5 | Very deep ripping | HR | 65-68 | Apr-16 | May-17 |

6 | Very deep ripping with topsoil inclusion | HRI | 62-65 | Apr-16 | May-17 |

7 | Very deep ripping + spading | HR+SP | 62-65 | Apr-16 | May-17 |

8 | Very deep ripping + one-way plough | HR+OWP | 62-65 | Jun-16 | May / Jun-17 |

9 | Very deep ripping with inclusion + spading | HRI+SP | 62-65 | Apr-16 | May-17 |

10 | One-way disc ploughing | OWP | 30-35 | Jun-16 | Jun-17 |

11 | Mouldboard ploughing (soil inversion) | MBP | 34-36 | Jun-16 | Jun-17 |

12 | Mouldboard plough + very deep ripping | MBP+HR | 62-65 | Jun-16/ Apr-17 | Jun-17 |

13 | Delving + spading | DLV+SP | 70+ | Apr-17 | Mar / May-17 |

14 | Delving + slow spading | DLV+SPs | 70+ | Apr-17 | Not included |

Measurements at each site included:

- preliminary soil profile sampling and analysis prior to treatment application

- in-season soil penetration resistance using digital cone recording penetrometers

- topsoil water repellence using the molarity of ethanol droplet (MED) test

- leaf analysis (whole plant or youngest emerged blade, depending on timing) for tissue nutrient concentrations

- NDVI (normalised difference vegetation index)

- plant (Meckering), tiller (Goomalling) and head counts (Meckering)

- grain yield and quality

Results and discussion

Rainfall

At the Meckering site, 2016 rainfall was good with 323mm growing season rainfall (Table 1) in addition to 77mm rain in March, while in 2017 growing season rainfall was lower at 253mm (Table 1) but there was significant summer (Jan-Mar) rainfall of 226mm. The finish to the season in 2017 at Meckering was good with 51mm rain in September (data not shown).

At Goomalling the 2017 season was much more challenging because, despite good summer rain (160mm Jan-Mar), there was only 33mm of rainfall over April-June (data not shown).

Soil constraints

Subsoil acidity was an issue for both of the sites below 20cm, but was worse at the Goomalling site with an average pHCa of 4.5 or lower. At Meckering the site has a good liming history reflected in soil pH levels of 5.9 in the topsoil and 5.2 at 10-20cm (Table 1), however subsoil pH’s from 20-50cm were still below the 4.8 target and with further acidification could become limiting.

The spading, one-way plough and mouldboard plough treatments can mix and bury the limed topsoil to the working depth. Soil pH results post treatment applications are not yet available for the sites but acidity is probably not the most limiting constraint for the sites presently but will become more limiting over time if further acidification is not prevented by applying lime.

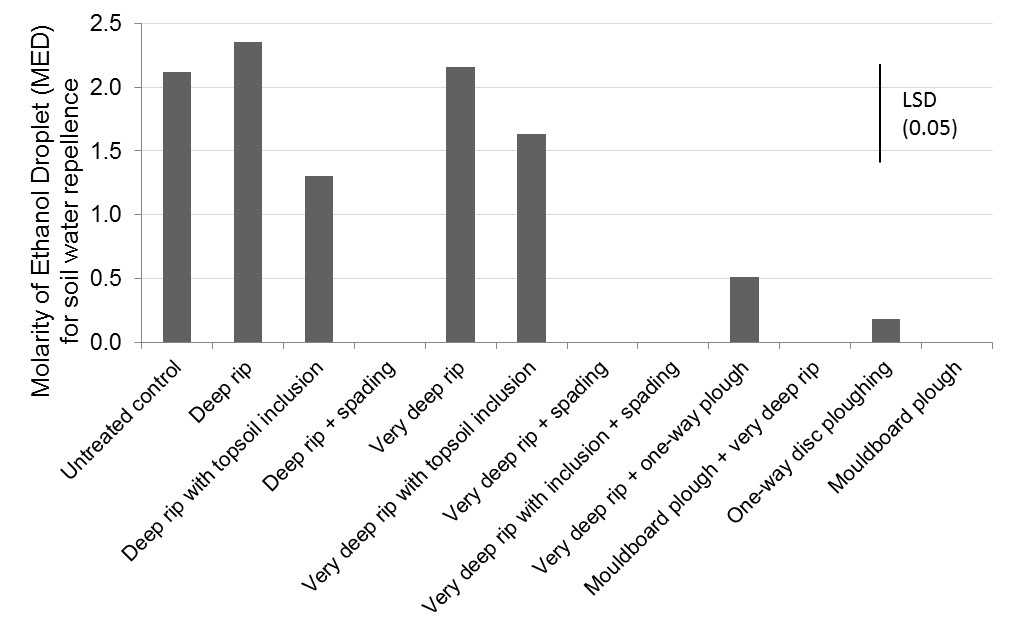

In the process of mixing or inverting topsoil the spader, one-way and mouldboard ploughs can also bury or dilute the water repellent topsoil. At the Meckering site repellence in control and both deep ripped only treatments was moderate to severe (Fig. 1). Addition of inclusion plates to the deep ripper resulted reduced the measured repellence but the mechanism behind this is unclear. Deeper mixing or soil inversion with the spader or one-way and mouldboard ploughs reduced the repellence to very low or nil levels (Fig. 1).

Figure 1. Soil water repellence as measured using the molarity of ethanol droplet (MED) test on gravelly pale deep sand at Meckering, Western Australia (2016). Bars represent the standard deviation of the mean.

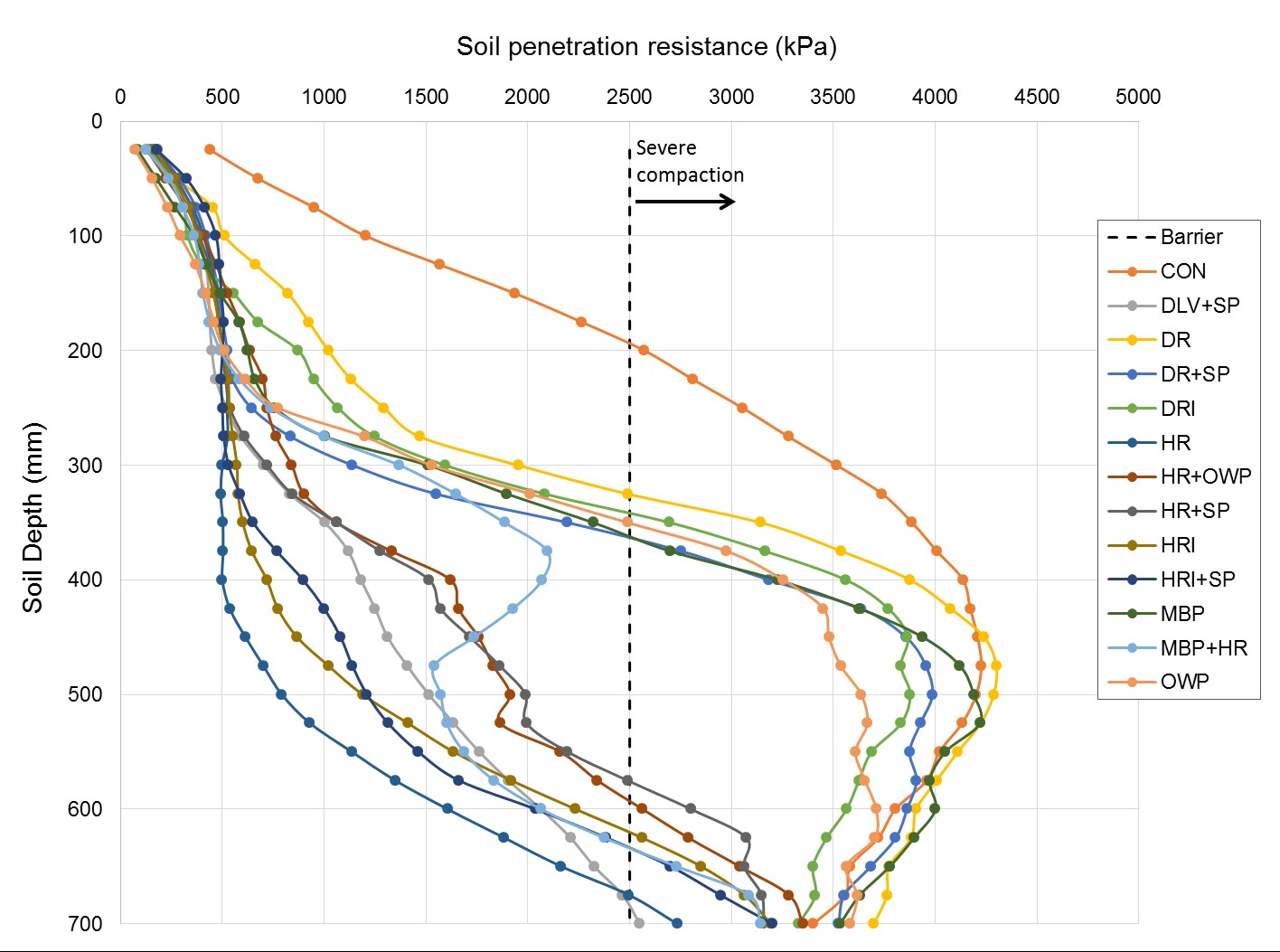

Figure 2. Soil penetration resistance (kPa) as a measure of soil strength in response to one-off deep tillage soil amelioration treatments on deep yellow sand at Goomalling, Western Australia. The hatched line (Barrier) at 2500kPa represents the resistance at which compaction is considered severe and crop root growth is significantly reduced.

Both sites have severe compaction layers. Severe compaction, defined as the point at which the penetration resistance exceeds 2500kPa, occurred at a depth of 23-40cm at the Meckering site (data not shown) and below 20cm at the Goomalling site (Fig. 2). All treatments reduced the soil strength of the top 28cm of soil to a penetration resistance less than 2000kPa (Fig. 2). The treatments with deep ripping, mouldboard ploughing and one-way ploughing reduced the penetration resistance below 2500kPa to a depth of 32-35cm while very deep ripping or delving increased the depth of loosened soil to 57cm or more (Fig. 2).

Meckering - Crop growth and grain yield

Despite moderate to severe water repellence at the Meckering site crop establishment in the untreated control plots has been good in both seasons. In 2016 the control plots had on average 169 plants/m2 with equivalent numbers in all other treatments except for a 14-18% reduction in plant numbers in the treatments with spading, a 21-26% reduction for one-way ploughing and 34-42% reduction for treatments with mouldboard ploughing (data not shown).

Similarly, in 2017 the control treatments had adequate plant establishment with an average of 148 plants/m2 but establishment was reduced by 24-27% in the one-way ploughed and very deep ripped treatments without spading and by 42-45% in the mouldboard ploughed and 2017 delved and spaded treatments (data not shown). Those treatments that had been spaded in 2016 did not have reduced establishment in 2017.

For the mouldboard plough and to a lesser extent one-way plough treatments poor establishment appeared to be a result of uneven seeding depth and furrow infill resulting in some rows with very poor establishment. Difficulties with seeding depth, topsoil cementation and herbicide damage (Edwards et. al. 2018) can exacerbate this further.

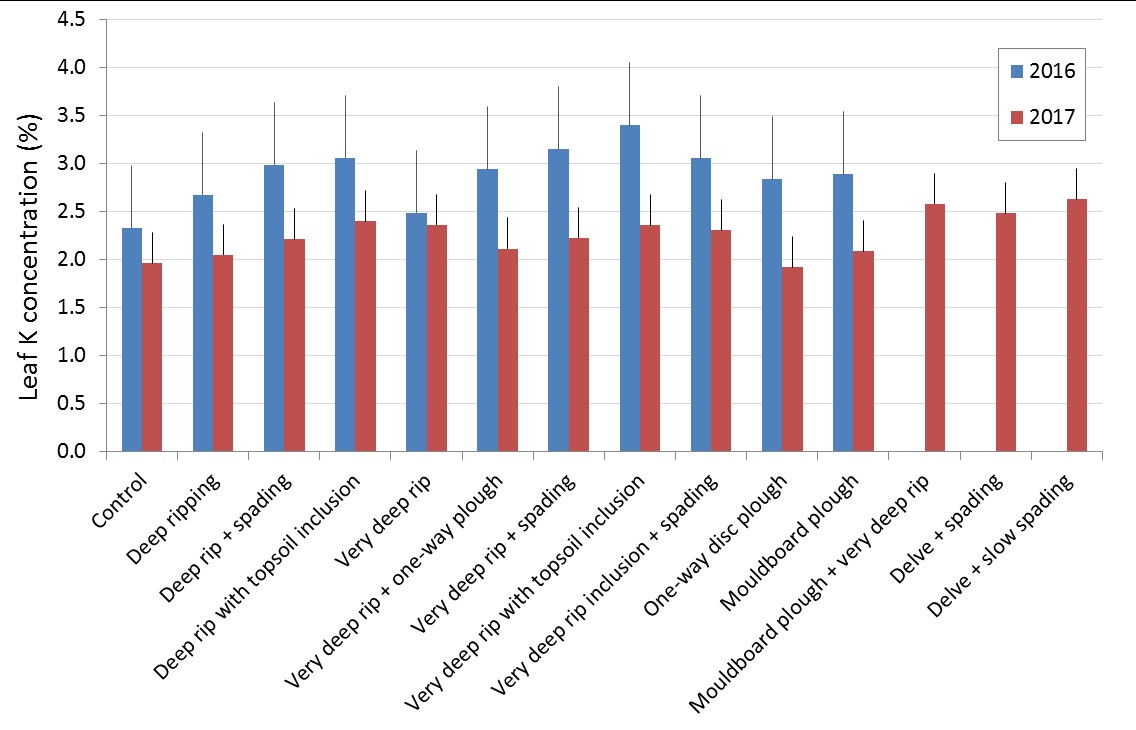

Early crop growth at Meckering in both seasons was not particularly different across the treatments. In 2017, NDVI measurements on 25 July were the same, averaging 0.39, across all treatments except for the 2017 delved treatments which were significantly lower at 0.26 due to poor establishment and missing rows (data not shown). As the season progressed, growth and canopy colour differences became more apparent. In both seasons leaf tissue K concentration was higher for some of the soil amelioration treatments than the control despite higher crop biomass (Fig. 3).

In 2016 any of the ripping treatments with topsoil inclusion or spading had 29-46% higher leaf K concentrations. In 2017 deep ripping with inclusion, very deep ripping with and without inclusion, and very deep ripping with inclusion and spading had 18-22% high leaf K concentration, while mouldboard ploughing with very deep ripping and both delving treatments had 27-34% higher leaf K concentration (Fig. 3). In 2016 leaf sulphur concentrations were higher for either of the ripping treatments with topsoil inclusion or spading and for mouldboard or one-way ploughing (data not shown).

In 2017 leaf phosphorus concentrations were 10-16% higher for treatments with mouldboard ploughing or delving (data not shown). Concentrations of manganese, magnesium and calcium were lower for some tillage treatments in 2017 (data not shown), though in each case these were still well above critical concentrations for wheat (Reuter and Robinson 1986). For the other nutrients leaf tissue concentrations were either the same or variable across the treatments.

Figure 3. Youngest emerged leaf potassium concentration (%) for wheat in response to one-off deep tillage soil amelioration treatments on gravelly pale deep sand at Meckering, Western Australia. Bars represent LSD (0.05) = 0.65% K for 2016 data and LSD (0.05) = 0.32% K for 2017.

Grain yields at the Meckering site ranged from 2.1-3.2 t/ha in 2016 and 3.8-5.3 t/ha in 2017 (Table 3). While 2016 was a good season the yield potential was lower because this was sown 1-month later in late June compared to late May in 2017. Despite the late sowing in 2016, those tillage treatments which included deeper ripping (HR) gave the biggest yield responses, ranging from 0.81-1.05 t/ha, an increase of 38-49% (Table 3).

Deep ripping with topsoil inclusion (DRI), deep ripping plus spading (DR+SP) and one-way ploughing (OWP) increased yields by 0.57-0.74 t/ha, a 26-34% grain yield increase (Table 3). In 2017 the only deep ripping treatments to still provide a significant yield benefit were those that had also been spaded (DR+SP; HR+SP; HRI+SP), with large increases of 0.92-1.25 t/ha, an increase of 24-33% (Table 3). Proportionally this increase was similar to that achieved in 2016.

Similar yield increases in 2017 were also seen for those treatments that included some soil inversion, either with a one-way (OWP) or mouldboard plough (MBP; MBP+HR), by 0.97 t/ha (26%) for the one-way plough and by 1.21-1.49 t/ha (32-39%) for the mouldboard plough treatments (Table 3).

Goomalling - Crop growth and grain yield

At Goomalling plant counts were not undertaken but it was observed that establishment tended to be poorer in the control, ripped only and mouldboard plough treatments. Overall with the dry start to the season at Goomalling, establishment and early growth was poor and this was reflected in low tiller numbers assessed on 14 August (Table 3). On average there were 49 tillers/m2 in the control (CON) treatment.

There were higher tiller numbers for treatments with mouldboard ploughing (MBP; MBP+HR), delving (DLV+SP) and very deep ripping with one-way ploughing (HR+OWP), and spading on top of very deep ripping either with (HRI+SP) or without (HR+SP) topsoil inclusion (Table 3).

As a consequence of low tiller numbers grain yields were low, 0.8 t/ha for the untreated control (Table 3). Due to the severe compaction (Fig. 2) yield increases were largely driven by deeper ripping, with either the very deep ripper (HR) or delver (DLV), resulting in yield increases of 0.55-0.74 t/ha, an increase of 74-93%.

The only other treatment to increase yield was mouldboard ploughing (MBP) on its own with a 0.44 t/ha, 55% yield increase (Table 3).

Table 3. Summary head or tiller density, grain yield and yield change data for 2016 and 2017 at Meckering and 2017 at Goomalling. Values significantly different from the control are highlighted in green for LSD at 5% level and blue for LSD at 10% level.

Treatment | Meckering 2016 | Meckering 2017 | Goomalling 2017 | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

Head | Grain | Yield | Head | Grain | Yield | Tiller | Grain | Yield | ||||

#/m2 | t/ha | t/ha | % | #/m2 | t/ha | t/ha | % | #/m2 | t/ha | t/ha | % | |

CON | 236 | 2.14 | - | - | 204 | 3.80 | - | - | 49 | 0.80 | - | - |

DR | 224 | 2.47 | 0.33 | 15 | 241 | 3.99 | 0.19 | 5 | 58 | 0.81 | 0.01 | 2 |

DRI | 220 | 2.71 | 0.57 | 26 | 223 | 4.09 | 0.29 | 8 | 39 | 0.86 | 0.06 | 8 |

DR+SP | 237 | 2.88 | 0.74 | 34 | 280 | 5.05 | 1.25 | 33 | 50 | 0.89 | 0.09 | 12 |

HR | 250 | 2.97 | 0.83 | 39 | 225 | 4.34 | 0.54 | 14 | 59 | 1.54 | 0.74 | 93 |

HRI | 256 | 2.97 | 0.83 | 39 | 228 | 4.28 | 0.48 | 13 | 55 | 1.35 | 0.55 | 69 |

HR+SP | 249 | 2.95 | 0.81 | 38 | 246 | 4.72 | 0.92 | 24 | 62 | 1.39 | 0.59 | 74 |

HR+OWP | 216 | 2.40 | 0.26 | 12 | 233 | 4.15 | 0.35 | 9 | 76 | 1.47 | 0.67 | 84 |

HRI+SP | 249 | 3.19 | 1.05 | 49 | 273 | 4.98 | 1.18 | 31 | 80 | 1.47 | 0.67 | 84 |

OWP | 235 | 2.86 | 0.72 | 34 | 263 | 4.77 | 0.97 | 26 | 59 | 0.92 | 0.12 | 15 |

MBP | 269 | 2.37 | 0.23 | 11 | 248 | 5.01 | 1.21 | 32 | 65 | 1.24 | 0.44 | 55 |

MBP+HRa | 216 | 2.51 | 0.37 | 17 | 219 | 5.29 | 1.49 | 39 | 69 | 1.40 | 0.60 | 76 |

DLV+SP | n/a | n/a | n/a | n/a | 195 | 3.83 | 0.03 | 1 | 70 | 1.52 | 0.72 | 91 |

DLV+SPs | n/a | n/a | n/a | n/a | 196 | 4.22 | 0.42 | 11 | n/a | n/a | n/a | n/a |

LSD (0.05) | 37 | 0.49 | - | - | 57 | 0.72 | - | - | 15 | 0.16 | - | - |

LSD (0.10) | 31 | 0.41 | - | - | 47 | 0.60 | - | - | 12 | 0.14 | - | - |

a Note very deep ripping (HR) component of the mouldboard + very deep ripping (MBP+HR) treatment at Meckering was not implemented until early 2017.

n/a = treatment not present in given season or location.

Economic returns

Measured grain quality was used to determine wheat grade for each Meckering treatment in 2016. In the absence of grain quality information at the time of writing for 2017, a wheat grade of ASW1 was assumed for both sites using farm-gate prices of $231/t for ASW1 and $246/t for APW2 (Table 4).

The gross economic benefit of each treatment over the control (Table 4) is calculated as the difference in yield for the treatment compared with the control multiplied by the farm-gate price. The net benefit is calculated as the gross benefit minus treatment costs. Very deep ripping with topsoil inclusion plus spading (HRI+SP) provided the highest economic benefit in 2016 for Meckering, and mouldboard plus very deep ripping (MBP+HR) the highest economic benefit in 2017.

The highest and only positive net economic returns in 2017 for Goomalling were achieved by very deep ripping with (HRI) or without (HR) topsoil inclusion or very deep ripping with one-way ploughing (HR+OWP). The next best, with only small net deficits in the first year at Goomalling were soil inversion using either a mouldboard (MBP) or one-way plough (OWP; Table 4).

Table 4. Estimated economic benefits over control for a range of deep tillage treatments and year to break-even assuming sustained or declining yield response trajectories over time for 2016 and 2017 at Meckering and 2017 at Goomalling, Western Australia.

Treatment | One-off cost ($/ha) | Meckering | Goomalling | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

2016 wheat gradea | Gross economic benefit over control ($/ha) | Cumulative 2016 + 2017 net benefit over control ($/ha)c | Years to break-evend | 2017 Economic benefit over control ($/ha)a | Years to break-evend | ||||||

2016 | 2017 | Sust. | Decl. | Gross | Net | Sust. | Decl. | ||||

DR | 45 | ASW1 | 76 | 45 | 75 | 1 | 1 | 3 | -42 | >10 | >10 |

DRI | 50 | ASW1 | 131 | 68 | 148 | 1 | 1 | 14 | -36 | 4 | >10 |

DR+SP | 150 | ASW1 | 171 | 290 | 310 | 1 | 1 | 21 | -129 | 7 | >10 |

HR | 90 | ASW1 | 193 | 126 | 228 | 1 | 1 | 172 | 82 | 1 | 1 |

HRI | 95 | ASW1 | 192 | 112 | 208 | 1 | 1 | 128 | 33 | 1 | 1 |

HR+SP | 190 | ASW1 | 186 | 213 | 210 | 2 | 2 | 137 | -53 | 2 | 2 |

HRI+SP | 195 | ASW1 | 243 | 273 | 321 | 1 | 1 | 155 | -40 | 2 | 2 |

HR+OWP | 140 | APW2 | 64 | 82 | 6 | 2 | 2 | 155 | 15 | 1 | 1 |

MBP+HR | 200 | APW2 | 91 | 345 | 236 | 2 | 2 | 139 | -61 | 2 | 2 |

OWP | 50 | APW2 | 177 | 225 | 352 | 1 | 1 | 28 | -22 | 2 | 3 |

MBP | 120 | APW2 | 57 | 280 | 217 | 2 | 2 | 102 | -18 | 2 | 2 |

DLV+SP | 350 | APW2 | n/a | 8 | -342 | >10 | >10 | 167 | -183 | 3 | >10 |

DLV+SPs | 375 | APW2 | n/a | 98 | -277 | 5 | >10 | n/a | n/a | n/a | n/a |

a Estimated farm-gate price for wheat grade ASW1 of $231/t and APW2 of $246/t.

b Assuming an ASW1 wheat grade with estimated farm-gate price of $231/t.

c Net benefits include gross economic benefits for 2016 + 2017 (Meckering) or 2017 (Goomalling) minus treatment cost

d Years to break-even with either a sustained 2017 yield response (Sust.) or declining (Decl.) yield response trajectory, where economic returns halve each year. Note treat findings with caution when extrapolating only 1-2 years yield results over 10 years.

n/a = treatment not present in given season or location.

The year to break-even (Table 4) is estimated either assuming a sustained trajectory (economic returns generated in 2017 are sustained through time) or a declining trajectory (assuming economic returns halve each year). Many treatments cover their costs in the first year although this depends on the site (Table 4). Very deep ripping or with (HR) or without (HRI) topsoil inclusion covered costs in the first year at both sites.

The economic benefits derived from a number of other treatments are almost as large as the cost of the treatment, in which case the year to break-even is year 2 irrespective of a sustained or declining trajectory. In a few cases, the economic benefits of treatments are significantly below their cost, first year delving (DLV+SP; DLV+SPs) treatments in the case of Meckering and standard ripping treatments (DR) and delve plus spading (DLV+SP) in the case of Goomalling (Table 4). In these cases, the payback period is significantly shorter if the trajectory of economic benefits is sustained rather than declining.

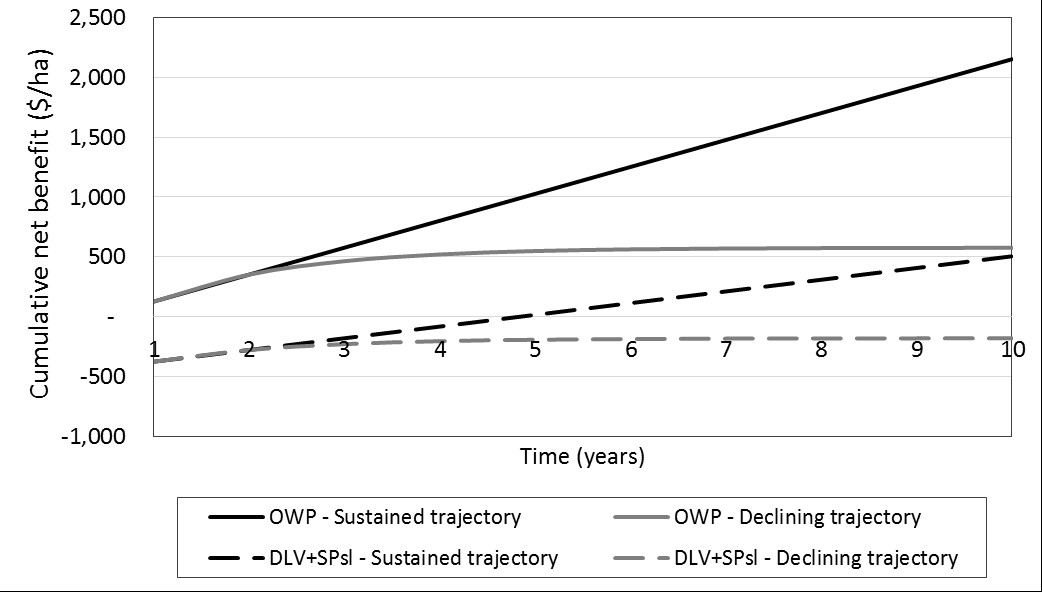

Although the type of trajectory does not influence the payback period greatly for many treatments, it has a significant impact on the cumulative net benefit of treatments over time. This is illustrated for one-way ploughing and delving plus spading slow treatments at Meckering (Fig. 4). Note that caution should be taken when extrapolating two years of data over a 10-year period, and that Fig. 4 is used for illustrative purposes only.

The payback period for one-way ploughing is within the first year, but cumulative net benefits over time are much higher for the sustained trajectory compared with the declining trajectory. The payback period for delving plus spading slow is 5 years for a sustained trajectory with positive cumulative benefits over 10 years. With a declining trajectory it is unlikely to break-even or reach a positive cumulative net benefit (Fig. 4). This illustrates the importance of sustaining the benefits of deep tillage practices.

Figure 4. Cumulative net benefit of select Meckering soil amelioration treatments, one-way plough (OWP) and delving plus slow spading (DLV+SPs) with sustained or declining yield response trajectories over a 10-year period. Note treat with caution when extrapolating only 1-2 years yield results over a 10 year period, figure is intended to illustrate the benefits of having a sustained yield trajectory.

Conclusion

New strategic deep tillage methods for ameliorating a range of soil constraints have been developed in recent years that sit alongside established approaches. This research compared these approaches at several grower-managed sites with different soil-types.

On the deep sand over gravel site at Meckering removal of deeper compaction and improving root access to K and N at depth were critical drivers of improved productivity in the first year.

More sustained yield responses in year two at Meckering were achieved with those treatments that had additional topsoil and subsoil modification with deep soil mixing (spader) or inversion (one-way or mouldboard).

On deep yellow sand at Goomalling water repellence removal was important to achieve better crop establishment while deep compaction removal, particularly in a dry season, was important to improve root access to more profile moisture and increase yield.

References

Edwards T, Davies S, McDonald G, Hall D, Moore J (2018) Understanding interactions between pre-emergent herbicides and inversion tillage. 2018 GRDC Grains Research Updates, 26-27 February, Perth, Western Australia. GIWA research updates

Reuter DJ and Robinson JB eds. (1986) Plant Analysis: an Interpretation Manual. Inkata Press.

Acknowledgments

The research undertaken as part of this project is made possible by the significant contributions of growers through both trial cooperation and GRDC investment; the authors would like to thank them for their continued support.

The authors acknowledge and thank the Fulwood and Dempster families and staff for hosting, implementing and assisting with the management of the research sites.

This research is undertaken through DAW00244 soil water repellence project which is one of the GRDC Soil Constraints West group of projects.

Varieties displaying this symbol beside them are protected under the Plant Breeders Rights Act 1994.

GRDC Project Number: DAW00244, AVP00003-A (RCSN Albany & Kwinana-West)

Peer Reviewed By: Dr Ed Barrett-Lennard

GRDC Project Code: DAW00244 and AVP00003-A,