Influence of header front on stubble micro-climate and winter crop growth

Author: John Broster, Nathan Hatty and Phil Eberbach (Charles Sturt University) and Michael Walsh (University of Sydney). | Date: 18 Feb 2020

Take home messages

- Reductions in wind speed of up to 90% were recorded in the stripper front stubble over summer.

- Significant reductions in air temperature were recorded within the stripper front stubble canopy over summer.

- Minimal differences in daily minimum air and soil temperature on or near the soil surface during winter.

Background

In recent seasons crop production systems have undergone significant changes with a focus on reduced tillage and increased stubble retention (Umberset al. 2017). Factors that have influenced the adoption of these practices include reduced fuel and labour inputs, reduced erosion and increased soil moisture conservation over the summer fallow period (Chan and Heenan 2006; Thomas et al. 2007; Llewellyn et al. 2012; Kirkegaard et al. 2014).

The introduction of the Shelbourne Reynolds stripper front into Australian farming systems has increased harvester efficiency through less material being processed by the harvester (Tado et al. 1998). The resultant increase in the amount of standing stubble after harvest over summer, in combination with disc seeding systems, provides an opportunity to maximise the benefits of a stubble retention system, however it may also introduce additional challenges for the system that need to be overcome.

Little research has been undertaken to quantify the benefits of using a stripper front compared with a conventional front to harvest cereal crops in Australia, despite repeated adoption of the disc seeding and stripper front harvesting system with only anecdotal evidence to support the benefits of the system. The impacts of the stripper front system on stubble canopy micro-climate, moisture retention and the subsequent crop have not yet been investigated.

Materials and methods

The trial was conducted at Marrar, commencing after the harvest of the wheat crop in December 2018 and ran until the subsequent vetch crop (sown in May) was harvested in October 2019. The site was established across three harvester front widths (each 12 metres) with the outer two harvested using a Shelbourne stripper front leaving the stubble standing at a height of 60cm and the centre row harvested using a D65 Macdon draper (‘conventional’) front with a cutting height of 15cm. The chaff fraction of the residues for both treatments were placed in a central chaff line 30cm wide while for the draper front treatment the straw fraction was spread across the width of the treatment by the harvester.

Measurements taken - summer period

Over the summer period wind speed was measured at a height of 45cm using a single anemometer for each plot with the average wind speed recorded every 10 minutes. From this data the daily wind run for each plot was calculated.

Air temperature readings were taken every 10 minutes with probes placed at 60cm, 35cm and 10cm above ground level Temperature probes were also placed 2.5cm below the soil surface in each plot, also recording every 10 minutes. These data were then used to determine the daily minimum and maximum temperatures calculated for each height in each plot.

Measurements taken - winter period

All instrumentation was removed from the plots the day before the site was sown and then re-installed the day after. Following sowing, additional temperature probes were installed to record temperature (every 10 minutes) at 10cm below the soil surface and on the soil surface but below the residue layer. Soil moisture probes were also located at 10cm below the soil surface recording moisture content every 10 minutes.

Results and discussion

There was no difference in the amount of total residue present between the two treatments after harvest. After harvest approximately 50% of the stripper front residue was found in the standing stubble, significantly more than the 21% in the draper front treatment. After sowing there was no difference in the proportion of standing stubble and surface residue between the treatments as the sowing operation knocked down the standing stubble. Visually the stubble residue layer in the stripper front treatment was a thicker layer with a rougher texture, due to the longer straw length present in this treatment.

Wind speed

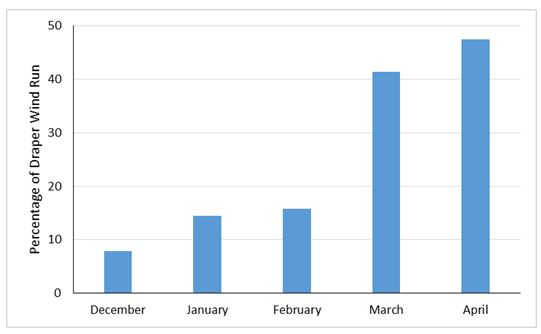

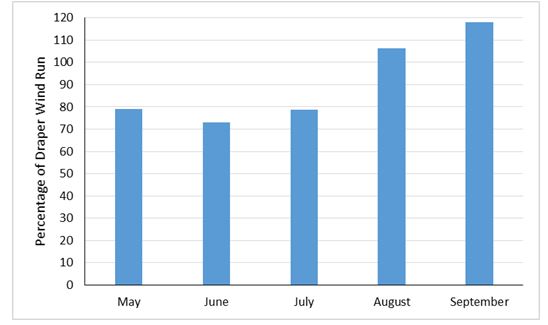

During the summer period the wind speed was reduced in the stripper front system compared with the draper front. For December there was a 90% reduction in wind speed however, this decreased to 50% at sowing due to collapse of standing stubble (Figure 1). The sowing operation knocked down the majority of the standing stubble in the stripper front system but for May through to July there was still a reduction in the wind speed of approximately 20%. It was only in August and September that no wind speed reduction was recorded (Figure 2).

Figure 1. Average daily wind speed over the summer fallow period for the stripper front system as a percentage of the average daily wind speed for the draper front system.

Figure 2. Average daily wind speed over the winter period for the stripper front system as a percentage of the average daily wind speed for the draper front system.

The stubble remaining after sowing in the stripper front system, while below the level of the anenometers, was still likely to impede the movement of air across the area. It was not until September when the vetch crop had grown above the level of the stubble residue that no differences in wind speed were observed between the two systems.

Air temperature

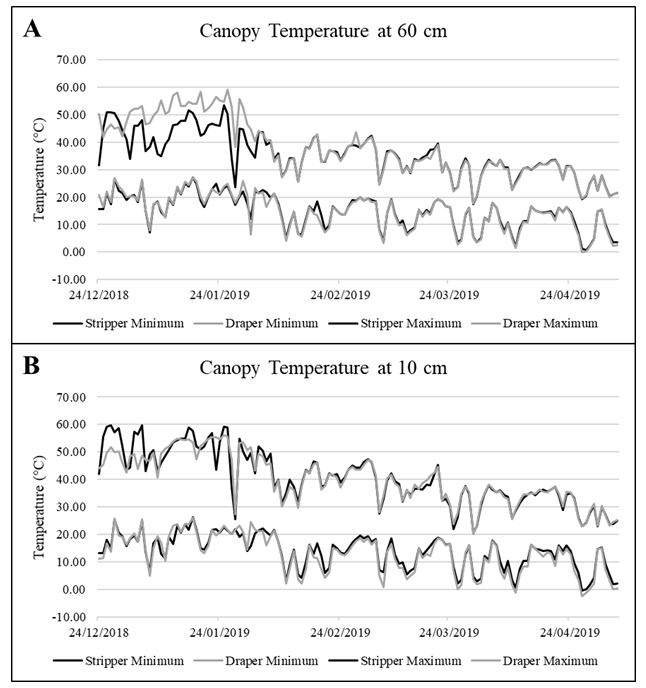

For December and January large differences were observed for the air temperature at 60cm above ground level, or near the top of the stripper front canopy. The average daily maximum temperature at this height for the stripper front system was 43.7°C, over 7°C less than the 51.2°C recorded for the draper front system (P<0.001) (Figure 3). There was also a reduction in the minimum average daily temperature at this height, but not to the same extent, 20.1°C compared with 20.7°C for the stripper and draper front systems respectively (P<0.05).

At 10cm the average daily maximum temperature for the stripper front system was 1.5°C higher than the draper front system (51.5°C compared with 50.0°C; P<0.05) while there was no difference (P>0.05) in the average daily minimum temperatures between the two systems (stripper - 18.6 °C; draper - 18.7 °C) (Figure 3).

Figure 3. Average daily maximum and minimum canopy temperature at (A) 60cm and (B) 10cm above the soil surface for the stripper and draper stubble treatments over the summer fallow.

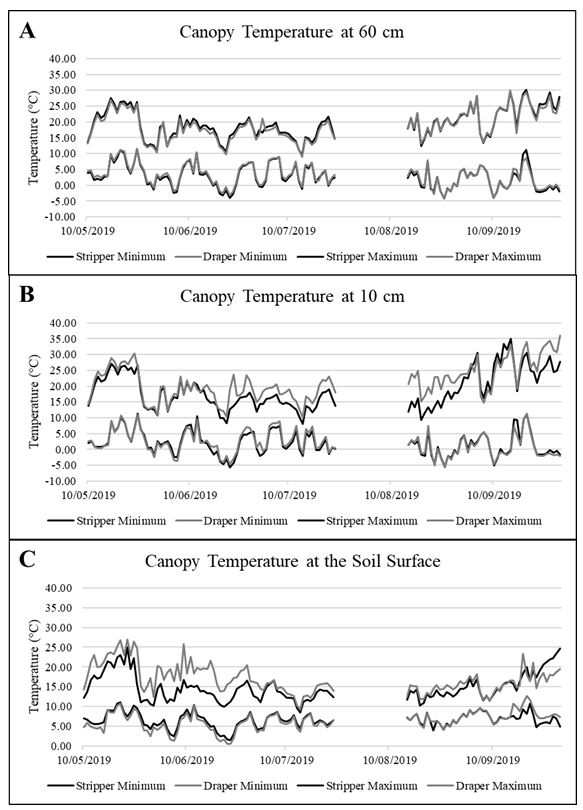

Figure 4. Average daily maximum and minimum canopy temperature at (A) 60cm and (B) 10cm above the soil surface and (C) at the soil surface for the stripper and draper stubble treatments over the winter growing season.

For the remainder of the summer period before sowing the average daily maximum temperatures for the two systems was lower and there was no difference between the stripper (60cm – 32.0°C; 10cm – 35.9°C) and draper (60cm – 32.0°C; 10cm – 35.9°C) front systems (P>0.05) (Figure 3). Unlike the December to January period the daily minimum temperature at 60cm was higher for the stripper front system (stripper - 12.6 °C; draper - 12.1 °C) than the draper front (P<0.001) rather than lower, and while there had been no difference between the systems in the daily minimum temperature at 10cm for December and January for rest of the summer period, the stripper front system recorded a higher average daily minimum temperature (stripper - 11.9 °C; draper - 10.6 °C; P<0.001) (Figure 3).

Over the winter period the stripper front system had higher average temperatures for the 60cm maximum (stripper – 19.5 °C; draper – 19.0 °C; P<0.001) and 0cm minimum (stripper – 6.6°C; draper – 6.4 °C; P<0.005) while the average temperatures were lower for 60cm minimum (stripper – 2.7 °C; draper – 3.0 °C; P<0.001), 10cm maximum (stripper – 18.8 °C; draper – 21.3 °C; P<0.001) and 0cm maximum (stripper – 6.6 °C; draper – 6.4 °C; P<0.05) while there was no difference between the minimum temperatures at 10cm (stripper – 1.8 °C; draper – 2.0 °C; P>0.05) (Figure 4).

The difference in air temperature within the stripper front treatment is most likely due to the reduced air movement, which has reduced the exchange of heat that would normally occur through increased wind speeds mixing the air and drawing the hotter air away, resulting in hot air being trapped in the standing stubble. The reduction in these differences over the summer period as the standing stubble falls down and the difference in wind speed reduces are also indications that the reduced wind speeds are influencing the canopy air temperatures.

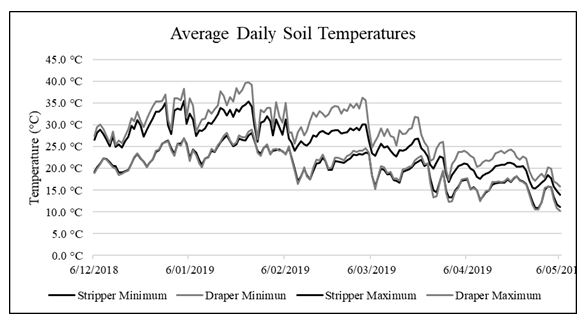

Soil temperature

Over the summer period there was an approximately 10% decrease in daily maximum soil temperature (2.5cm) in the stripper front system (stripper – 26.0 °C; draper – 28.8 °C; P<0.001) however there was no difference between the two systems in daily minimum temperatures (stripper – 20.3 °C; draper – 20.4 °C; P>0.05) (Figure 5).

Figure 5. Average daily maximum and minimum soil temperature over the summer fallow period.

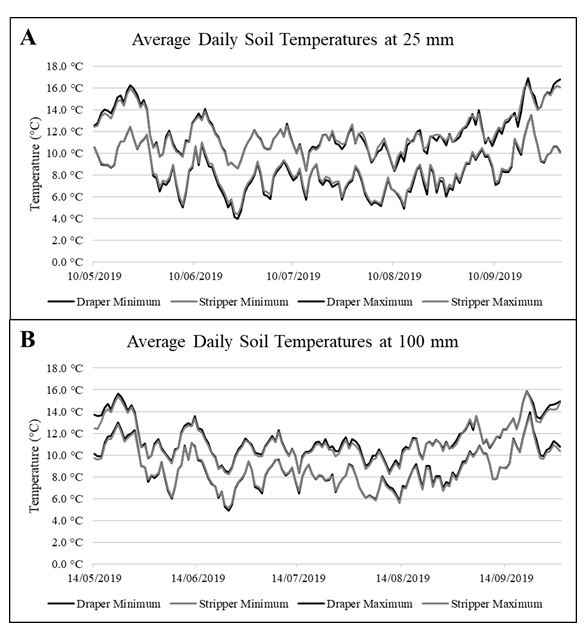

Over the winter period there was no difference between the daily maximum temperature for both of the systems while the daily minimum was higher for the stripper front system (stripper – 8.3 °C; draper – 8.1 °C; P<0.001). At the 10cm depth both the daily minimum and maximum soil temperatures were slightly lower in the stripper front system than the draper front system (maximum - stripper – 11.3 °C; draper – 11.5 °C; P<0.001, minimum - stripper – 8.6 °C; draper – 8.7 °C; both P<0.001) (Figure 6).

Over summer the soil temperature was nearly 3°C higher for the stripper front system than the draper front system, while the amount of residue is the same; much of the stripper front residue is standing while for the draper front residue it has passed through the header and is laying on the ground. The decreased ground cover recorded in the stripper front system could allow the soil to be heated via radiant heat while the soil in the draper front system was more protected. Over the winter period when the stubble in both treatments is flatter the loss of soil temperature overnight is similar for both treatments. Although the differences in minimum daily 0cm air and 2.5cm and 10cm soil temperatures were statistically significant during the winter period, the greatest difference for any of these parameters was 0.2°C.

Figure 6. Average daily maximum and minimum soil temperature at a depth of (A) 2.5cm and (B) 10cm over the winter growing period

Soil moisture

While there was a statistical difference in the average daily moisture content at 10cm below the soil surface between the two systems (stripper – 22.3%; draper – 22.4%; P<0.01) it is unlikely that the difference (0.1%) would have any influence on plant growth (data not shown).

Plant emergence and growth

There were no differences observed between the two systems for total emergence, time to emergence, dry matter production (July, August, September and October) and ground cover (September). The only recorded difference was in the amount of ground cover recorded for the crop in July with the stripper front system having significantly less cover (5.1%) than the draper front system (12.1%) (data not shown).

Conclusions

Differences between the two header front systems were recorded for many of the parameters measured over both the summer and winter periods (Table 1). Over the summer fallow period the taller stubble from the stripper front system increased upper canopy temperatures but reduced average wind speed and soil temperatures. The reduction in wind speed and soil temperature should result in increased soil moisture retention due to reduced evaporation but possibly due to the low rainfall experienced over the experimental period this was not recorded.

Over the winter growing period a reduction in wind speed early in the season was still experienced in the stripper front system compared to the draper front system and there also tended to be a slight decrease in air and soil temperature. While both treatments contained similar amounts of stubble, the straw in the stripper front treatment tended to be longer resulting in an increased thickness of residue cover and a resultant greater insulating effect. The reduction in temperatures recorded was not enough to result in any differences in the growth of the vetch crop. While the increased thickness of the stubble cover may prevent radiant heat from the sun from warming the soil it could also slow heat loss in colder periods as shown by the increase in minimum daily air temperatures on the soil surface (under the stubble layer).

Table 1. Summary of differences for stripper front systems compared with draper front systems (summer air temperatures analysed for two periods, bold indicates difference from draper front is greater than 10%, * = not measured)

Summer | Winter | |

|---|---|---|

Wind speed | Decrease | Decrease |

Air temperature 60cm maximum | Decrease / None | Increase |

Air temperature 60cm minimum | Decrease / Increase | Decrease |

Air temperature 10cm maximum | Increase / None | None |

Air temperature 10cm minimum | None / Increase | None |

Air temperature 0cm maximum | * | Decrease |

Air temperature 0cm minimum | * | Increase |

Soil temperature -2.5cm maximum | Decrease | None |

Soil temperature -2.5cm minimum | None | Decrease |

Soil temperature -10cm maximum | * | None |

Soil temperature -10cm minimum | * | Decrease |

Moisture content -10cm | * | Decrease |

Further research

Analysis of the data collected in 2019 is still ongoing (for example; 35cm air temperature) as only limited analysis was undertaken as part of the Honours project. This research is continuing at two different sites to gain further knowledge with soil moisture measurements taken over the summer fallow period. A different crop will be sown at each of the two sites and one the sites contains a stubble residue removed (baled) treatment to further investigate air and soil temperatures near the surface.

Acknowledgements

The research undertaken as part of this project is made possible by the significant contributions of growers through both trial cooperation and the support of the GRDC, the authors would like to thank them for their continued support.

This trial was undertaken as a Charles Sturt University Honours project for Nathan Hatty. The Graham Centre provided a scholarship for Nathan Hatty and the GRDC through Project US00084 provided some additional support. The authors would also like to acknowledge the support of David and Dan Fox on whose property the trial was undertaken.

References

Chan, K, Heenan, D (2006) Earthworm population dynamics under conservation tillage systems in south-eastern Australia. Soil Research44, 425-431.

Kirkegaard, JA, Conyers, MK, Hunt, JR, Kirkby, CA, Watt, M, Rebetzke, GJ (2014) Sense and nonsense in conservation agriculture: Principles, pragmatism and productivity in Australian mixed farming systems. Agriculture, Ecosystems & Environment 187, 133-145.

Llewellyn, RS, D’Emden, FH, Kuehne, G (2012) Extensive use of no-tillage in grain growing regions of Australia. Field Crops Research 132, 204-212.

Tado, C, Wacker, P, Kutzbach, H (1998) Development of stripper harvesters: A review. Journal of Agricultural Engineering Research 71, 103-112.

Thomas, G, Titmarsh, G, Freebairn, D, Radford, B (2007) No-tillage and conservation farming practices in grain growing regions of Queensland - a review of 40 years of development. Australian Journal of Experimental Agriculture 47, 887-898.

Umbers, A, Watson, P, Watson, P (2017) Farm practices survey report 2016. GRDC, Barton (ACT). Available at

Farm Practices Survey Report 2016 _ GRDC.

Contact details

John Broster

Charles Sturt University

Locked Bag 588, Wagga Wagga NSW 2678

02 6933 4001; 0427 296 641

jbroster@csu.edu.au

@JohnCBroster

GRDC Project Code: US00084,

Was this page helpful?

YOUR FEEDBACK