The continuing evolution of HWSC systems

The continuing evolution of HWSC systems

Take home messages

- Chaff grazing increases annual ryegrass emergence by removing chaff residues.

- Widespread adoption of harvest weed seed control (HWSC) is driving the development of impact mill technology.

- There is a need for independent testing of new impact mill systems.

Background

Since the introduction of chaff carts in the early 1990s there has been ongoing development of harvest weed seed control (HWSC) systems where growers can now choose from six general approaches; chaff carts, narrow windrow burning, chaff lining, chaff tramlining, bale direct and chaff impact mills. The adoption of HWSC systems has increased dramatically over the last decade with the recognition of the weed control benefits from the long-term use of these systems. With most Australian growers now using some form of HWSC, there is demand for new and more refined user-friendly systems. At present the most popular systems are chaff lining and chaff tramlining as they are relatively cheap and simple to install, there is no requirement for after-harvest treatment, and they are suitable for mixed farming systems. Similarly, impact mill systems for chaff processing are also increasing in popularity. The advantage of the latter approach over other HWSC systems is that weed seeds are destroyed during harvest along with the retention and dispersal of all harvest residues. Over the last five years industry research and development efforts have focussed on the refinement of current impact mill systems and the development of new systems. This paper aims to provide an update of recent research and development activities with chaff lining, chaff tramlining and chaff impact mills.

Methods

Influence of grazing on chaff lines

The impact of sheep grazing on annual ryegrass emergence from chaff lines was assessed in a field trial near Marrar, NSW, about 40km north of Wagga Wagga from November 2018 to April 2019. Wheat plant samples were collected from 20 quadrats (1m x 35cm) on 19 November 2018, the day before harvest, for the determination of wheat biomass and grain yield. Samples were collected in five (1m x 35cm) quadrats in each of four harvester swaths (12m wide) and placed in separate bags. After oven drying for 48hrs at 70°C, dry weights were recorded. These wheat plant samples were then threshed with the grain collected and weighed to determine yield.

To determine the amount of chaff production, five collection trays (75cm x 35cm) were placed in each swath on the path of the chaff line immediately prior to harvest. As each swath of wheat crop was harvested, the chaff samples were collected in these trays resulting in 20 samples. After harvest the collected chaff was placed into paper bags. These were then oven dried at 70°C for 48hrs, then weighed. This chaff material was sieved with annual ryegrass seed collected and counted to determine a seed number/m chaff line.

To examine the impact of grazing on annual ryegrass emergence from chaff lines immediately after harvest (26 November 2018) exclusion cages (five) were placed on each of the four chaff lines. This allowed for five replicates of each of the four harvester swaths, for a total of 20 exclusion cages.

The paddock was continuously grazed by sheep without any supplemental feed from 14 December 2018, until the end of the trial on 22 April 2019. No herbicides or pesticides were used on the paddock throughout the duration of the trial.

Following a dry summer period, rainfall at the end of March/start of April 2019 stimulated the germination and emergence of annual ryegrass. Annual ryegrass emergence was counted on 9 April in 1m chaff line lengths inside the exclusion cages and on adjacent chaff lines outside of the exclusion cages. Chaff samples were collected from the grazed and ungrazed areas from five randomly chosen cages and adjacent areas.

All chaff collections were made by measuring 1m lengths of chaff line for the grazed and ungrazed areas. Collected samples were placed in a paper bag and oven dried at 70°C for 48hrs then weighed. Chaff samples were then sieved to collect and count the ryegrass seed remaining in the chaff.

One-way analyses of variance were performed on chaff biomass, annual ryegrass seed number and annual ryegrass seedling emergence data with means compared using LSDs (P=0.05).

iHSD and seed terminator evaluation

A Western Australian grower at Newdegate has two identical Case harvesters (8230), one fitted with an integrated Harrington Seed Destructor (iHSD) and the other with a Seed Terminator (ST). The seed destruction efficacy of these impact mills was evaluated during the harvest of a 2.4t/ha wheat crop on 16 December 2017.

Seed preparation

Annual ryegrass seeds were dyed by immersing in a 2% edicol dye (blue (iHSD) and red (ST)) solution for 15 minutes then spread on paper towel to dry overnight, this would allow the seed to be differentiated from the native seed after processing. Ten replicated seed lots of 5000 seed were counted out for blue dyed and red dyed seed. The viability of dyed seed lots was established prior to testing by placing three replicates of 100 seed on 0.6% (w/v) agar-solidified in petri dishes in a temperature-controlled laboratory at 25/15°C and 12hr photoperiod. Over 28 days, geminating seed were counted and removed. Seeds were classified as viable if they germinated. Seeds were also considered viable but dormant if they did not germinate but did not decay. This test established the proportion of viable seed in the seed lots used for testing.

Harvest procedures

During the harvest of 10m long by 14m wide areas of wheat crop, 5000 annual ryegrass seeds were introduced through a 10cm diameter tube mounted directly over the top of the left hand mill of either the iHSD or ST. Seed introduction commenced after the mill had started to process chaff material. A 0.5mm nylon mesh bag was attached to the outlet chute of the mill to collect the processed chaff material exiting the mill.

At the end of each plot the threshing and cleaning systems were operated until the harvester was empty and there was no material exiting. The collected chaff material was then transferred into a separate woven poly bag and the mesh bag reattached to the mill outlet. Harvester speed throughout testing was approximately 5km/h. Annual ryegrass seed destruction efficacy was tested in ten plots each (replicates) for the iHSD and ST systems.

Chaff sample processing

Chaff samples were weighed before any further processing was undertaken.

To examine the effects of mill type on the size distribution of chaff fractions the chaff sample from each mill was mixed thoroughly and then a 1kg subsample was collected for sieving. Each subsample was passed through six hand sieves in descending order of mesh size: 11, 7, 3, 2, 1 and 0.5mm. Using a method practised by Guzzomi et al (2017), the sieve was shaken by hand, twice per second for two minutes, turning the sieve 90o every 30 seconds. The chaff remaining on each sieve was collected and weighed.

All chaff samples were then manually sorted to retrieve dyed annual ryegrass seed and seed fragments. Collected fragments were then weighed and stored until all chaff samples had been sorted. Once all samples were sorted the viability of seed and seed fragments was determined by allowing them to germinate on 0.6% (w/v) agar-solidified in plastic trays (17cm x 12cm x7cm). Germination was counted after 14 days and 28 days with remaining seed fragments checked for viability as described previously.

Single and vertical impact mill testing

Similar procedures were used to test the efficacy on annual ryegrass seed of the single (for class 6 and 7 harvesters) and vertical mill systems during wheat crop harvest at Corrigin 2017 (single mill) and Broomehill 2018 (vertical mill). Prior to testing, 12 plots were marked out in an area of wheat crop that was free of annual ryegrass. Plot length was 20m, with plot width determined by harvester width, 10m at Corrigin and 12m at Broomehill. To test the weed seed kill when the mills were operating under different loads, plots were harvested at three speeds. The mill systems were tested at three harvester speeds (8, 10 and 12km/h at Corrigin and 4, 6 and 8km/h at Broomehill) with four replicates for each speed. The respective speeds chosen represented when the harvesters were operating below capacity, at capacity and above capacity.

During the harvest of each plot, dyed germinable annual ryegrass seed (5000) were introduced into the mill through a 5cm diameter plastic tube using the same procedures described above for the impact mill testing.

Collected chaff samples were processed at Charles Sturt University, Wagga Wagga to determine the level of seed survival for each plot. Subsamples (100g) were collected from the well mixed bags of chaff. These samples were spread thinly across the surface of trays filled with potting mix. A light covering of potting mix was spread over the chaff material. To ensure the germination of any surviving annual ryegrass seed, trays were watered daily to maintain soil moisture near field capacity. Each day over a four week period annual ryegrass seedlings were counted and removed.

Results and discussion

Influence of grazing on chaff lines

The establishment of chaff lines during harvest using a 12m front resulted in the concentration of a high amount of chaff from a relatively low yielding wheat crop. The narrow (35cm) chaff lines established during harvest using a chaff lining system produced chaff lines with 274g chaff/m row which was equivalent to 8.5t/ha of chaff (Table 1). This level of wheat chaff has been shown in pot trials to have only a small suppressive effect on annual ryegrass emergence (approximately 5-10%) (Ruttledgeet al. 2018).

Table 1. Wheat biomass and grain yield at harvest and the amount of chaff concentrated in narrow rows during harvest. Number in brackets represent standard error (n=20).

Wheat Biomass (t/ha) | Grain Yield (t/ha) | Chaff (g/m chaff row) |

2.44 (0.09) | 0.61 (0.03) | 273.87 (18.47) |

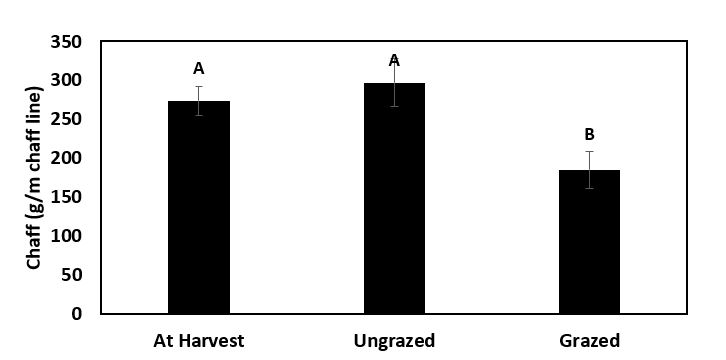

Over-summer grazing resulted in a 38% reduction (P<0.05) in chaff biomass (equivalent of 3.2t/ha) compared to the ungrazed chaff lines. With little or no rainfall over the summer-autumn period there was little or no chaff decomposition resulting in no difference (P>0.05) in chaff amounts present at harvest and in the ungrazed chaff lines in autumn (Figure 1). Thus, even with a low yielding wheat crop the concentration of chaff in lines enabled the consumption of a substantial amount of chaff biomass by grazing sheep.

Figure 1. Chaff biomass weights collected during trial. Bars represent standard error (n=20 for harvest, n=10 for ungrazed and grazed, respectively). Different letters indicate significant differences (P=0.05).

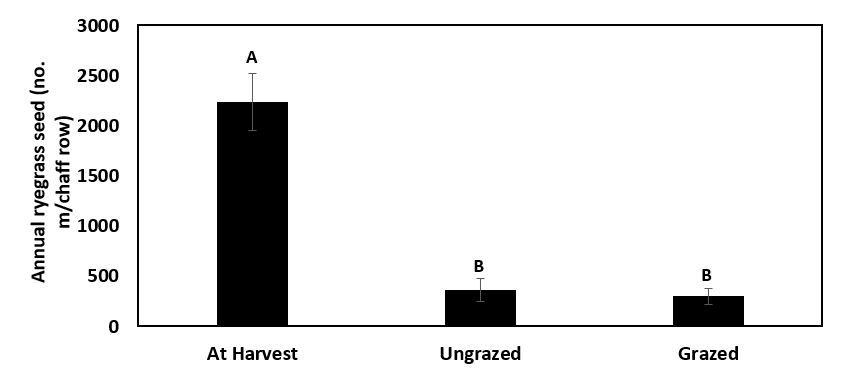

Very high numbers of annual ryegrass seed were collected and concentrated in narrow windrows during harvest. There was an average of 2237 annual ryegrass seeds per m/chaff row (Figure 2). In autumn at the end of the trial annual ryegrass seed numbers were reduced to 364 and 302 seeds per m/chaff row in the grazed and ungrazed treatments, respectively. Thus, regardless of grazing treatment there were similar amounts of seed loss of approximately 85%. Annual ryegrass seed concentrated in chaff material at harvest migrates though that material to the soil surface over summer (Walsh and Powles, 2007) and therefore, is unlikely to be consumed by grazing livestock. With little or no rainfall recorded over this period in this region it is likely that seed predation and not seed decay was the most likely cause for these seed losses (Spafford Jacobet al., 2006).

Figure 2. Annual ryegrass seed numbers present in chaff in autumn. Bars represent standard error (n=20 for at harvest, n=10 for ungrazed and grazed). Different letters indicate significant differences (P=0.05).

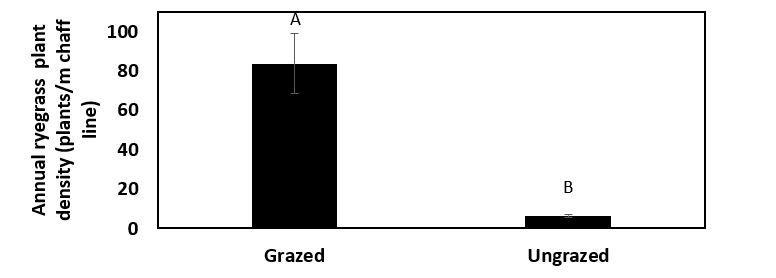

Annual ryegrass emergence was greater on the grazed chaff lines due to the removal of chaff material. Annual ryegrass emergence of 84 plants/m2 in the grazed chaff lines was substantially higher (P<0.05) than the seven plants/m2 recorded in the ungrazed chaff lines (Figure 3). With similar levels of annual ryegrass seed present on the soil surface, the 13-fold decrease in emergence is likely due to the influence of the chaff material remaining in the ungrazed treatments. This approximate 90% reduction in emergence is substantially higher than the levels previously observed in pot trials for this level of wheat chaff (Ruttledge et al. 2018).

Figure 3. Annual ryegrass seedling emergence, grazed versus ungrazed. Bars represent standard error (n=20). Different letters indicate significant differences (P=0.05).

iHSD and seed terminator evaluation

Chaff output

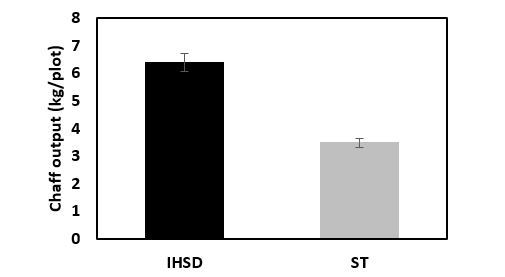

Much lower amounts of chaff material were collected from the ST than the iHSD during the harvest of equivalent areas of similar yielding wheat plots. Approximately 40% less wheat chaff was collected exiting the ST than the iHSD (Figure 4). On average there was approximately 3.5kg of chaff collected from the exit chute of the ST compared to 6.4kg collected from the iHSD during the harvest of a 10m long by 14m wide wheat plot. With a lower baffle height (approximately 10cm) in the ST system it is possible that much less chaff material entered the ST. It is also possible that the action of ST resulted in a high proportion of fine material that was not collected by the 0.5mm mesh bags used to collect the processed chaff during testing.

Figure 4. Amount of processed chaff collected from the outlet from one of the iHSD and ST mills during the harvest of a wheat plot (10m length x 14m width). Bars represent standard error for the mean of 10 replicates.

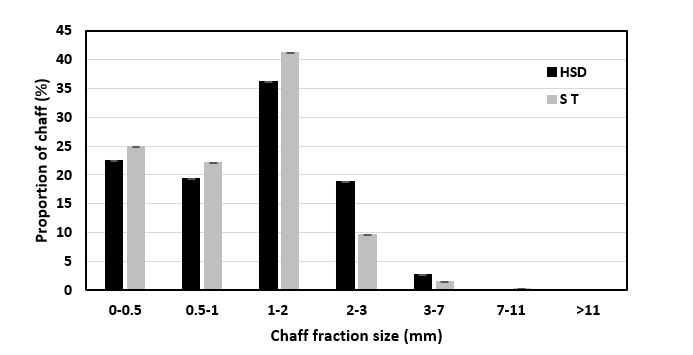

Processed chaff fraction sizes

The action of the ST resulted in generally more finely processed chaff material than the iHSD (Figure 5). There were greater proportions of chaff material in the smaller fraction sizes (< 2mm) of chaff processed by the ST compared to chaff processed by the iHSD. This indicates that the ST processed the chaff material to a greater extent than the iHSD.

Figure 5. Distribution of chaff fraction sizes for iHSD and ST processed chaff material. Bars represent standard error for the mean of 10 replicates.

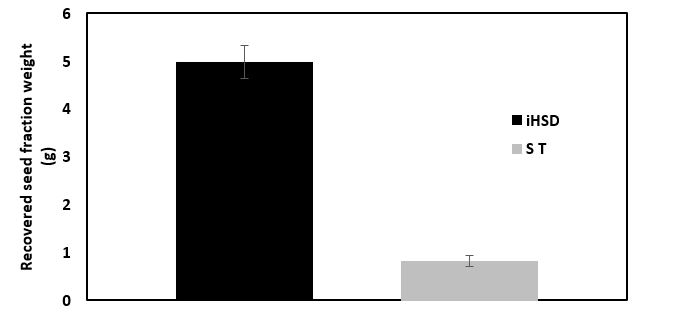

The larger amount of annual ryegrass seed fractions recovered from the iHSD processed chaff further indicates the higher degree of processing by the ST but also the possibility that less ryegrass seed entered the ST. There was approximately 5g of dyed annual ryegrass seed fractions recovered from chaff processed by the iHSD compared with 0.8g recovered from ST processed chaff (Figure 6). The increased processing by the ST (Figure 5) may have contributed to the difficulty in recovering seed fractions. It is also possible that with less chaff material passing through the outlet (Figure 4), not all introduced annual ryegrass seed passed through the mill.

Figure 6. Weight of seed fractions manually recovered from processed chaff collected from the outlet of a single iHSD and ST mill during the harvest of a wheat plot (10m length x 14m width). Bars represent standard error for the mean of 10 replicates.

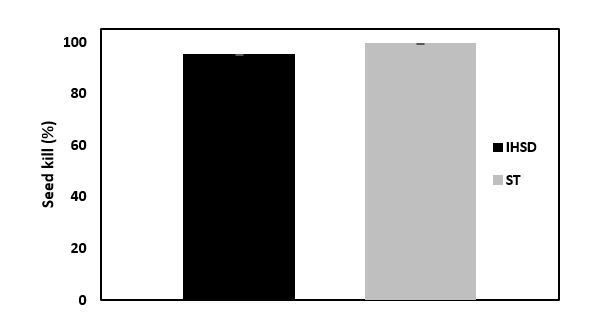

The efficacy of the ST was slightly greater than the iHSD with both systems producing very high (>95%) levels of annual ryegrass seed kill. Annual ryegrass seed kill was 95% for the iHSD and slightly higher for the ST at 99% (Figure 7). The very low standard errors highlight that these high seed kill levels were consistent across all replicates.

Figure 7. Proportion of seed that was killed by the action of the iHSD and ST harvest of a wheat plot (10m length x 14m width). Bars represent standard error for the mean of 10 replicates.

Impact mill developments and the need for independent testing

Since the introduction of the initial impact mills there has been considerable and ongoing development that is increasing the range of available options.

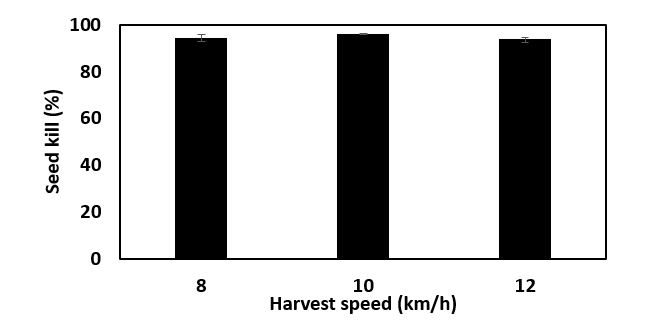

Single mill system

The single mill system maintained high levels of annual ryegrass seed kill during wheat crop harvest. Annual ryegrass seed kill was consistent (94 to 96%) across all three indicating that mill performance was not severely affected by harvester load (Figure 8). These results highlight the ability of the single mill to effectively process chaff material for class 6 and 7 harvesters.

Figure 8. Annual ryegrass seed kill by a single iHSD mill system on a class 7 header during the harvest of wheat as influenced by increasing harvester speed. Bars represent standard error for the mean of four replicates.

Vertical mill system

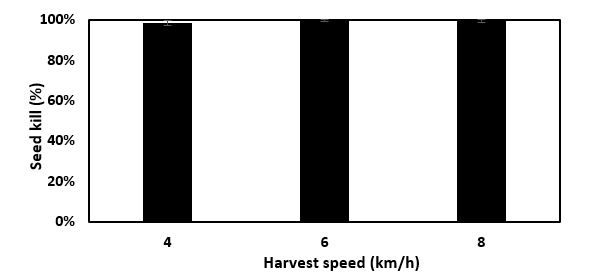

When tested across all three operating speeds the vertical mill maintained high (approximately 98%) levels of annual ryegrass seed kill (Figure 9) equivalent to previously recorded levels for horizontally mounted mills (Walsh et al. 2018). These results indicate that mill alignment (vertical versus horizontal) does not interfere with mill efficacy.

Figure 9. Annual ryegrass seed kill of a vertically mounted iHSD mill during the harvest of wheat as influenced by increasing harvester speed. Bars represent standard error for the mean of four replicates.

New mill systems - The continued interest

Seed Control Unit

In 2018 Redekop® introduced a twin impact mill system, with seed control unit that is incorporated with their MAV straw chopper system. The Redekop system is similar in design to the iHSD and ST twin mill systems with circular rows of bars on spinning base plates and fixed top plates. At present this system has only been installed on John Deere harvesters. It is believed that the intention is for this system to be available through John Deere as an optional extra when purchasing a new harvester. At present there is no independent testing data available for this system, however Redekop testing indicates high weed kill efficacy of approximately 98%.

Figure 10. Photo of Redekop® twin impact mill system.

Tecfarm WeedHog

After four years of development, in 2019 Tecfarm have made significant progress with their impact mill system. This machine represents a radical shift in impact mill design from the currently available systems. The WeedHog design is focused on the principles of reduced energy requirement and low cost. Tecfarm test results indicate that an 80% seed kill for annual ryegrass can be consistently achieved, with room for improvement. Independent testing is planned for the 2020 harvest. Tecfarm have indicated that they intend to have a limited number of units available to Western Australian growers for the 2020 harvest.

Recognised standard for testing impact mills

As the weed seed control efficacy of impact mills cannot be readily observed there is a need for the development of a testing standard for current and new impact mill systems. The efficacy of impact mills on weed seeds needs to be confirmed by a recognised standard testing procedure. This testing is required to provide growers with confidence in knowing the efficacy of an impact mill system which cannot be readily observed in the field. With many weed species, such as annual ryegrass persisting from a viable seedbank, the efficacy of impact mills in targeting weed seeds during the grain crop harvest will potentially remain unknown for many years by growers relying on visual observations. Without some assurance of the efficacy of an impact mill system, understandably there will be doubts about seed kill efficacy when visual responses are not readily observed.

Conclusion

The increasing interest in HWSC systems in general continues to drive the research and development on new and existing HWSC systems in line with grower preferences. These efforts now appear to have resulted in the development of new and more durable impact mill systems. With the adoption of impact mill systems now reaching significant levels there is a need to establish a recognised testing standard to provide growers and the industry a level of confidence in their efficacy.

Acknowledgements

The research undertaken was made possible by the significant contributions of growers through both trial cooperation and the support of the GRDC, the authors would like to thank them for their continued support. Mill efficacy testing was supported by USyd, CSU and GRDC.

Allison Chambers and the Charles Sturt University students who spent many months manually sorting through chaff samples looking for annual ryegrass seed.

References

Guzzomi AL, Ryan M, Saunders C, Walsh MJ (2017) Reducing the Integrated Harrington Seed Destructor Power Requirements through Chaff Fraction Optimization. Applied Engineering in Agriculture 33:695

Ruttledge A, Widderick MJ, Walsh MJ, Broster J (2018) The efficacy of chaff lining and chaff tramlining on controlling problem weeds GRDC updates. North Star (https://grdc.com.au/resources-and-publications/grdc-update-papers/tab-content/grdc-update-papers/2018/07/the-efficacy-of-chaff-lining-and-chaff-tramlining-in-controlling-weeds)

Spafford Jacob HS, Minkey DM, Borger C, Gallagher RH (2006) Variation in post-dispersal weed seed predation in a crop field. Weed Sci. 54:148-155

Walsh MJ, Powles SB (2007) Management strategies for herbicide-resistant weed populations in Australian dryland crop production systems. Weed Technol. 21:332-338

Contact details

Michael Walsh

University of Sydney

12656 Newell Highway, Narrabri 2390

02 6799 2201; 0448 847272

m.j.walsh@sydney.edu.au

John Broster

Charles Sturt University

Locked Bag 588, Wagga Wagga NSW 2678

02 6933 4001; 0427 296 641

jbroster@csu.edu.au

@JohnCBroster

GRDC Project Code: US00084,