Storage pests - clever ways to control them

Storage pests - clever ways to control them

Author: Philip Burrill and Greg Daglish, DAF Qld | Date: 03 Mar 2021

Take home messages

- Stored grain insect pests are not limited to farm storages, and can be caught flying across the wider rural landscape

- Flights can occur year-round in Queensland, with lower numbers in the cooler months

- Major pests can fly at least 1-2 km searching for grain

- Although small, grain beetles can live and reproduce for several months

- Finding 5 adult beetles in 1 litre of sieved grain means there could as many as 450 pests in that 1 litre. We simply cannot see the egg, larval or pupal life cycle stages easily

- Reducing grain temperatures in storage can slow down, or completely stop, the insect pest life cycle. Aeration cooling should aim to achieve grain storage temperatures of 18-23˚C during summer months and under 15˚C in winter.

Learning more about your enemy

For controlling agricultural pests, the more we understand their ecology, including life cycles and what conditions enable them to multiply and thrive, the better able we are to identify their weaknesses. Recent research, much of it in collaboration with the University of Queensland, has provided new insights into the ecology of insect pests of stored grain. This research information enables the development of an effective ‘package of control measures’ often referred to as an integrated pest management (IPM) strategy.

By using a combination of non-chemical and chemical control measures we can minimise storage pest numbers, grain losses and the costs they add to grain sales. The additional benefit is extending the useful life span of grain protectant and fumigation products used to control pests. Repeated overuse or reliance on chemical controls often lead to the development of pesticide resistance.

Examples of non-chemical pest control strategies include good hygiene, aeration cooling and regular monthly pest monitoring in conjunction with good storage record keeping. Combining these strategies significantly reduces over reliance and repeated use of valuable pest control products such as phosphine fumigation.

As we continue to conduct research on storage pests in the laboratory, and in the field around farm storage facilities, we learn how to refine the use of and extract the best results from hygiene, aeration, pest monitoring and strategic use of grain fumigations when required.

Storage pests on your property

Where do storage pests come from? The short answer is that they may

- Fly into a farm from other locations

- Already be present but undetected on the farm or

- Enter the farm via machinery (e.g. headers).

Recent research used traps to study storage pests on multiple grain farms in the Condamine region in Queensland. This research, as well as follow-up studies in Central Queensland and other states, has provided a clearer understanding of how far these insects can fly and when they are most active.

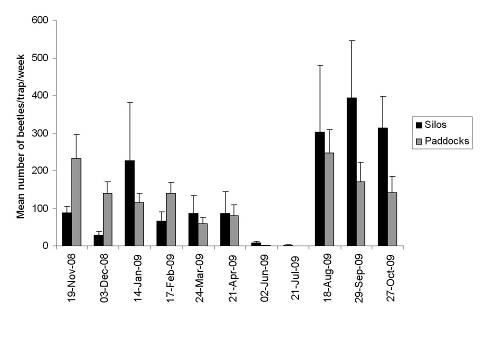

Two of the most common causes for grain rejections are the lesser grain borer (Rhyzopertha dominica) and the rust red flour beetle (Tribolium castaneum). These pests were trapped all year round in the Condamine region, although numbers were lower in the cooler months (see Figure 1 for lesser grain borers). Significantly, both pests were trapped away from grain storage areas (at least 1 km), including in native forests.

Genetic analysis of the trapped beetles provided further evidence of flight dispersal across the region.

Although less common, the rusty grain beetle, previously known as flat grain beetle (Cryptolestes ferrugineus) is of concern because it can develop a very strong level of resistance to the fumigant phosphine. Research conducted in New South Wales has confirmed that this pest is also an active flyer, and a study in Central Queensland showed it colonising experimental grain bulks at least 2 km from the nearest farm storages.

In contrast, the rice weevil (Sitophilus oryzae, Figure 2), has little or no flight activity. However, the closely related maize weevil (Sitophilus zeamais) which infests stored maize and potentially other cereals, has strong flight activity.

Although much more pronounced in southern regions, flight activity of storage pests is generally lower in winter than during other seasons. Flights of key storage pests is less likely when the daily maximum temperature is lower than 20°C.

These studies show that Queensland growers should be aware of the almost year-round threat posed by flying storage pests. Concerningly, all Australian trapping studies have shown a sudden increase in flying beetles (on farms and further afield) after winter but well before the start of the winter cereal harvest. This means that flying storage pests pose a threat to grain as it is put into storage.

Apart from bulk stored grain, pests can breed in small grain residues present in headers and other farm machinery and infest newly harvested grain. Grain spillages may also provide infestation sites. Rust-red flour beetles can also be found in cotton seed, and recent research suggests that adults are probably feeding on micro-fungi growing on the lint but not reproducing on the cotton seed.

Evidence of storage pest breeding in the standing crop is limited. Exceptions include the maize weevil and the cowpea weevil (Callosobruchus maculatus) which infests stored mungbeans and other pulses.

Despite their small size, recent research shows that adult storage pests can be surprisingly long-lived. For example, adult lesser grain borers and rust-red flour beetles trapped in flight in Central Queensland, and then held in the laboratory, typically lived for more than 3 months, with females producing 100s of adult progeny. Population growth can be rapid as Figure 3 shows for lesser grain borers in wheat.

Figure 1. Numbers of flying lesser grain borers (Rhyzopertha dominica) trapped each month on 15 farms in the Condamine region, Queensland at the silos and 1 km away from storages in paddocks.

Figure 2. The rice weevil (Sitophilus oryzae), a serious pest of stored grain, is not a good flyer

Pest control – non-chemical strategies

1. Manage grain temperatures in storage

Storage pests, like all insects, rely on the external environment for heat and this has major implications for their ecology and management. Australia’s climate and our late spring to summer harvesting of wheat and barley, provide conditions that are well suited to storage pests. Straight out of the paddock, we typically see wheat and barley grain temperatures of 30-35˚C going into storage. These temperatures are known to be ideal for rapid breeding and population increase of the main storage pests: lesser grain borer (Rhyzopertha dominica), rust-red flour beetle (Tribolium castaneum), rusty grain beetle (Cryptolestes ferrugineus), saw-toothed grain beetle (Oryzaephilus surinamensis), rice weevil (Sitophilus oryzae) and cowpea weevil (Callosobruchus maculatus).

Unless grain temperatures are reduced quickly in storage using aeration cooling (Figure 4), pest numbers will increase rapidly, along with the associated grain damage.

Figure 4. Silos fitted with aeration cooling and also designed to be sealable (air-tight) when required for effective fumigations

Figure 4. Silos fitted with aeration cooling and also designed to be sealable (air-tight) when required for effective fumigations

The rust-red flour beetle is a common storage pest and the following published laboratory information provides an example of the impact of lowering grain temperatures on the breeding rates of storage pests.

With a starting population of 100 adult rust-red flour beetles placed on wheat at a grain temperature of 30-35˚C, the population increases to 24,000-25,000 in 8 weeks. When grain temperature was reduced to 25˚C, numbers increased to 15,000. However, if grain temperature was reduced to 20˚C, the population of beetles did not increase, remaining at only 100 after 8 weeks.

Practices to reduce grain temperature in storage include:

- Aeration cooling: ensure each component of aeration equipment on silos (fans, ducting, vents and the fan auto-controller) are designed and managed to achieve the best results

- Run fans as soon as the first few truckloads go into storage at harvest time

- Monitor the grain temperatures in storage each month with a grain temperature probe. Aeration should achieve 18-23˚C during summer months and under 15˚C in winter.

2. Hygiene to reduce pest numbers

Cleaning out old grain residues and dust from empty silos and any grain handling equipment is the first important step in reducing pest populations around grain storage facilities.

A good strategy is to clean out silos as they become empty – ‘clean as you go’.

However, it is also worthwhile to combine this with a timely, once a year, major storage facility hygiene clean-down that includes silo repairs and maintenance. Research on the field ecology of various storage pests has identified winter time, when insect flight activity is minimal, is the most effective time for a major annual hygiene effort on storages (e.g. Figure 1).

For lesser grain borers, rust-red flour beetles and rusty grain beetles, the colder winter months of June and July were when beetles were not very active. This is the ideal time to do the main storage hygiene clean down and maintenance work, well before the massive increase in flight actively starting in August. Leaving the silo clean down to just before harvest in November is too late.

How far can storage pests fly? Field research in the Condamine region and Central Queensland showed that various storage pests had little trouble flying 1-2 km to find grain to infest. So, even a farm with good hygiene should be alert to the possibility of incoming pests.

Be careful with old grain residues. If dumped in a heap on the property, storage pests will breed in it and fly back to your grain storage facility. Burn, bury or spread the waste grain out to less than 20 mm deep.

Hygiene practices for improved pest control:

- Aim to make small changes and improvements to storage facilities that allow for easy silo and equipment clean-down

- Before purchasing new silos, check internal design for ease of clean out. Consider hygiene when planning a new farm storage facility

- Either physically clean, or wash out grain residues from empty silos, followed up with a diatomaceous earth (DE) (e.g. Dryacide®) dust or slurry treatment. Remember to clean out under aeration ducting

- Clean out empty silos within 1-2 weeks of out-loading. Plan for an annual hygiene and storage maintenance time during winter. This will reduce the large spike in pest numbers taking flight in August.

3. Monitor storage pests and conditions – keep storage records

Regular monthly checks of grain in storage is essential to ensure the storage facility is an asset to the business and not a liability. Storage pests are not easily seen in grain and can do significant damage in 2-3 months.

Unfortunately the vast majority of a pest population in stored grain is virtually invisible. The immature stages – eggs, larvae and pupae – are very difficult to see. Table 1 shows the results from sampling of farm silos for storage pests. The results show that if we sieved 600 adult beetles in a tonne of grain, there could be close to 60,000 eggs, larvae and pupae that we do not see.

Table 1. Numbers of adult beetles versus undetected immatures (eggs, larvae or pupae) in four silos containing wheat. *After sieving out the adults the samples were held in the laboratory for a number of weeks until all the eggs, larvae or pupae developed into beetles.

Silo | Insects per tonne | |

|---|---|---|

| Beetles | Immatures* |

1 | 588 | 59,413 |

2 | 250 | 21,913 |

3 | 0 | 4,220 |

4 | 0 | 15,533 |

Monitoring and storage record keeping for reliable results:

- Clearly number each silo and keep up-to-date storage records of where each variety and grain quality segregations are stored. Record any grain treatments for a commodity vendor declaration (CVD)

- Use grain insect sieves and probe traps to check for storage pests each month (Figure 5). Identify and record pest numbers

- Use a grain temperature probe to measure grain temperatures in storage. This helps understand the performance of the aeration cooling system and current insect pest activity

- Fixed cables inside silos such as OPI™ grain cables may be an option for monitoring storage conditions (for example, click here). Warning-cables with sensors measuring both temperature and relative humidity may suffer damage to the relative humidity sensor following a phosphine fumigation, as phosphine gas is corrosive and will damage exposed electrical components.

Regular monthly checks for pests helps minimise costly delays at the time of delivery. Your business reputation as a reliable supplier of grain is improved when you consistently supply quality grain for sale without pest detections.

Up-to-date farm storage records support successful marketing by know where each grain quality segregation is stored and the condition it is in.

Summary - Top five practices for successful storage

- Aeration: When correctly designed, installed and managed, it provides cool grain temperatures and promotes more uniform grain moisture conditions. Aeration reduces storage problems such as moulds and insect pests, plus helps maintain grain quality, seed germination and vigour

- Hygiene: A good standard of storage hygiene is crucial in keeping storage pest numbers to a minimum. Good hygiene for silos, augers and trucks reduces the risk of grain contamination

- Monitoring: To prevent serious damage, undertake monthly checking of grain in storage for insect pests (sieving / trapping) as well as checking grain quality and temperature. Keep monthly storage records, including any grain treatments applied

- Fumigation: In Australia, only fumigant gases (e.g. phosphine) are registered to deal with live insect pest infestations in stored grain. To achieve effective fumigations, the silo must be sealable and gas-tight to the Australian Standard AS2628 to hold the gas concentration for the required time. Use fumigants according to the label directions

- Grain protectants: Grain protectant insecticide sprays provide another line of defence against storage pests. Always check with potential grain buyers first. Treat cereal grain at harvest time with a registered grain protectant. Use according to label directions.

Warning: Grain protectant notes do not apply to the grains industry in Western Australia where their use is restricted. In all cases, refer to product labels to determine correct use patterns.

Further information

- GRDC GrowNotes – Grain Storage, National, June 2020

- Grain storage information web site

- or phone 1800 WEEVIL for GRDC grain storage extension specialist

Acknowledgements

The authors acknowledge the RD&E support from GRDC. The authors would also like to thank DAF’s postharvest grain protection team, GRDC’s national grain storage extension team, along with valued support from growers and industry collaborators.

Contact details

Philip Burrill

Department of Agriculture and Fisheries,

AgriScience Queensland

Hermitage Research Facility

604 Yangan Road, Warwick Qld. 4370

Ph: 0427 696 500

Email: philip.burrill@daf.qld.gov.au

Greg Daglish

Department of Agriculture and Fisheries,

AgriScience Qld.

EcoSciences Precinct, Dutton Park, Brisbane

Email: greg.daglish@daf.qld.gov.au

® Registered trademark

TM Trademark

GRDC Project Code: CRCNPB50089, CRCNPB50149, PBCRC3039,