Killing glyphosate resistant ryegrass? Application does matter

Author: Maurie Street and Ben O'Brien (Grain Orana Alliance) | Date: 24 Feb 2022

Take home messages

- How and when herbicides are applied resulted in significant variation in the numbers of Annual Ryegrass (ARG) survivors as it influences the delivery of the ‘intended dose’

- Many factors can reduce the delivery of the ‘intended dose’ to the target weed, two major factors identified in this work are:

- Poor water quality

- Inappropriate spray quality and timing - Growers with poor quality water should consider using another water source or ameliorating the water

- The small target leaf area of seedling ARG means that large spray droplets were often ineffective.

- Delaying application, increased water rates, or using spray qualities more capable of contacting and adhering to the weed resulted in significantly fewer survivors - Herbicide resistance is not always the sole cause for spray failure

- Growers and advisors should critically assess spray failures, as resistance is one of many factors that may contribute to poor levels of control.

Background

In 2020, GOA presented a paper at the GRDC Updates reviewing GOAs recent experimental observations in controlling problematic annual ryegrass (ARG) populations. A copy of the paper can be found here.

These findings showed that in several cases the assumption of glyphosate resistance was incorrect despite poor control by commercial applications on the targeted populations. Furthermore, some of the populations with confirmed glyphosate resistance were also controlled with only moderate label rates.

These findings reminded us that the causes of commercial spray failures are not always due to resistance. Contributing factors to weed control failure could include but are not limited to; inappropriate water rates, poor water quality, inappropriate droplet size for the target plant, poor spray timing or antagonism with other tank mixed herbicides.

This is not to suggest that herbicide resistance is not real or not the sole reason for failure in some circumstances, however in the presence of resistance, shortcomings in our efforts to control weeds are being highlighted by poor control, which if rectified, could be much improved.

GOA has undertaken several investigations to better understand the potential influence of some key parameters of spray application. These are outlined below.

Delivering the intended dose

The investigations detailed in this paper focuses on annual ryegrass with glyphosate resistance.

Some resistance mechanisms are relatively weak, while others are very strong. If a resistance mechanism is relatively weak, the weed population can still be dose responsive, where increasing the rate applied increases weed mortality. In these cases, improved spray practices allowing one to ‘deliver more of the intended dose’, will often be reflected in improved levels of weed control. However, if the resistance mechanism is strong and the lethal dose required is higher than is commercially or legally possible, it is suggested that improving spray practice will have little or no benefits.

Results of herbicide resistance testing conducted on ARG sampled by GOA in the central west of NSW over several years has shown that weak glyphosate resistance is relatively common, and that many of these populations should be controllable at higher label rates. However, in a number of cases, despite appropriate rates of glyphosate being applied, commercial control was often sub optimal.

More detailed investigations suggested that many spray operations may not delivering the intended dose and consequently were instead providing only a sub lethal dose, resulting in spray survivors. For example, if a grower has an ARG population that has moderate levels of resistance at 1 L/ha of glyphosate but is rate responsive and the population can be controlled at 1.5 L/ha. If they were to apply 1.5L/ha to appropriately sized weeds, an acceptable level of control could be expected. However, if using poor quality water, the intended dose could be reduced by impurities in the water neutralising some of the glyphosate. If we then added a further complication of poor droplet contact and adherence to the target weed, it is plausible that the lethal dose is reduced further. In this example it is possible that the intended dose of 1.5L/ha is only being delivered to the ARG population at 1 L/ha and as such many ARG plants survive.

GOA has run a series of trials, detailed below, that has demonstrated the potential impact or water and spray practices on weed control outcomes.

All trial results are analysed by ANOVA with a confidence interval of 95%, results with the same lettering are not significant different.

Water quality, adjuvants, or water conditioners

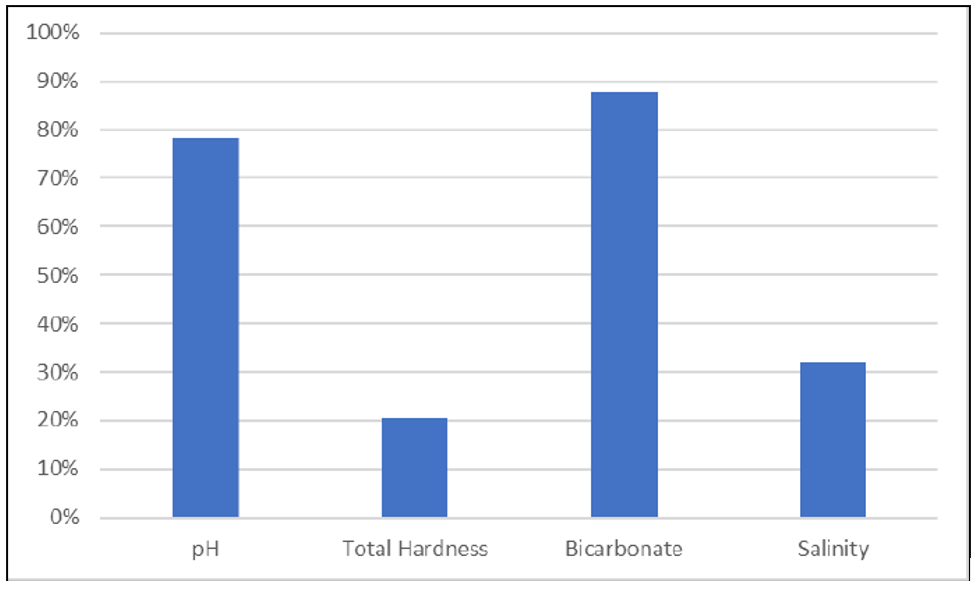

In 2018 SOS Macquarie analysed 180 ground water sources (bores) used for spraying throughout the region. The results summarised in Figure 1 below show that ~80% samples exceed acceptable limits for either pH or bicarbonate levels as a spray carrier. Accompanying information for the samples submitted indicated that for many growers, this was their only reliable source of spray water (Hulme, unpublished).

This data shows that spray water quality for many growers is less than ideal for use without some sort of amelioration (which may not always be possible) and that is likely to impact herbicide performance. In response to this many growers are adding either sulfate of ammonia (SOA) or Li700® to address issues associated with water quality.

Of the water quality issues listed in Figure 1 above, total hardness and bicarbonate levels are the factors most critical to consider when applying glyphosate. High levels of calcium and magnesium in hard water will cause glyphosate to bind-up, thus reducing its efficacy.

SOA precipitates much of the calcium out of solution before glyphosate is added to the tank, thus minimising the impact that hard water has on glyphosate efficacy. Additionally, SOA can help glyphosate move across the leaf membrane and aid uptake by the plant.

Li700 is primarily used to reduce spray water pH although it also has properties as a wetting agent. However, pH is less of an issue to consider when applying glyphosate, as glyphosate is a weak acid it benefits from application in a slightly acid solution but will, by itself reduce spray water pH. As such, the addition of Li700 as an acidifying agent does not add much to efficacy (except where pH is very high, water rates are high and glyphosate rate is low), however its use may still be warranted for its wetting agent characteristics.

Results

In 2021 GOA established a trial to investigate the relative impact of water quality and the use of these two common additives when used with glyphosate on ARG control.

The trial was established in the Autumn of 2021 at Narromine NSW. At the time of application there was a population of three leaf to early tillering ryegrass present at 120 plants/m2. A ’Quick-Test’ confirmed the population to have dose responsive glyphosate resistance as shown in Table 1.

Table 1. Herbicide resistance testing results to applications of glyphosate on annual ryegrass populations sampled at Narromine in 2021

Herbicide | Herbicide Group | Paddock Sample | |

|---|---|---|---|

Survival % | Rating | ||

Glyphosate @ 285 g.a.i./ha | Group M | 80 | RR |

Glyphosate @ 541 g.a.i./ha | Group M | 10 | R |

Glyphosate @ 855 g.a.i./ha | Group M | 0 | S |

The trial tested three water sources- rainwater, bore water and the same bore water after filtration through a commercial ‘PureDrop’ desalination plant (RO water). The PureDrop plant filters water by reverse osmosis to separate much of the salts from the bore water and can treat 30,000 L per day and runs off 240-volt mains power. This process improved the water quality to be very similar to that of the rainwater tested (Table 2).

Table 2. Results of water analysis of three water sources used for herbicide applications near Narromine 2021

Analyte | Unit | Bore | Reverse osmosis | Rain |

|---|---|---|---|---|

pH | 7.3 | 6.6 | 5.8 | |

Electrical conductivity | dS/m | 2.2 | 0.02 | 0.02 |

Bicarbonate alkalinity | mg CaCO3/L | 330 | 14.00 | 8.90 |

Bicarbonate alkalinity | meq/L | 6.6 | 0.28 | 0.18 |

Water hardness | mg CaCO3/L | 550 | 2.30 | 2.50 |

Calcium (dissolved) | mg/L | 38 | <0.10 | 0.19 |

Chloride | mg/L | 480 | <15 | <15 |

Sodium (dissolved) | mg/L | 300 | 3.4 | <0.5 |

Salinity class | 3 | 1 | 1 | |

Total dissolved ions | mg/L | 1,500 | 15 | 11 |

Sodium adsorption ratio (SAR) | 5.60 | 0.97 | 0.14 | |

Sodicity class | 1 | 0 | 0 | |

Total alkalinity | mg CaCO3/L | 330 | 14 | 8.9 |

The trial also tested two different spray additives, two water rates (50 L/ha & 100 L/ha) and two rates of glyphosate (low & high). All treatments were applied with AIXR110-015 nozzles at 3 bar pressure applying a coarse spray quality. Speed was varied to apply the two water rates.

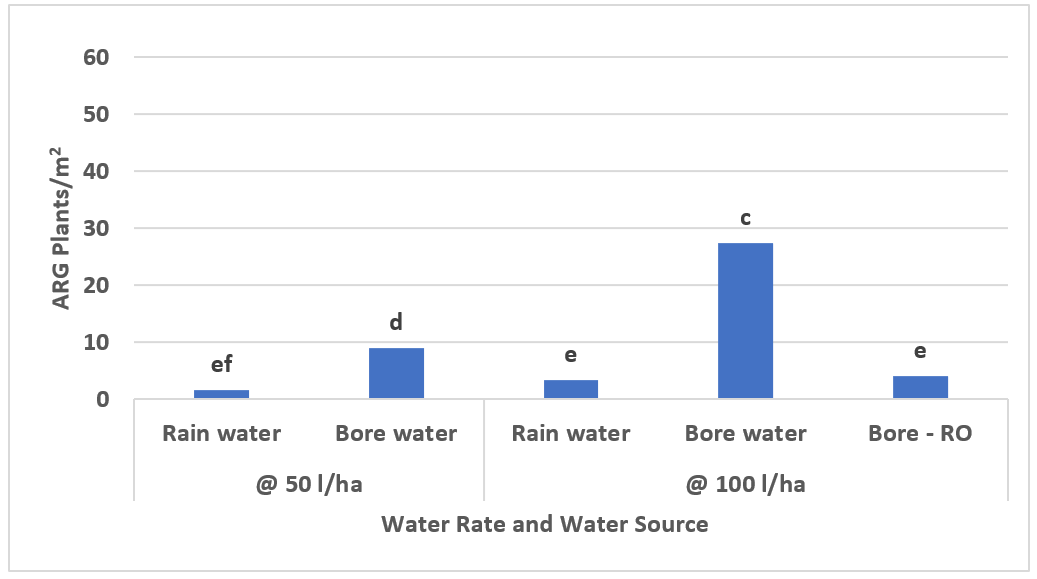

As can be seen in Figure 2, using rainwater resulted in fewer ARG survivors than using bore water at either water rate. Increasing the water rate when using rainwater did not impact on ARG survivors but did when using bore water. Using the RO bore water resulted in fewer ARG survivors, similar to that achieved by the use of rainwater.

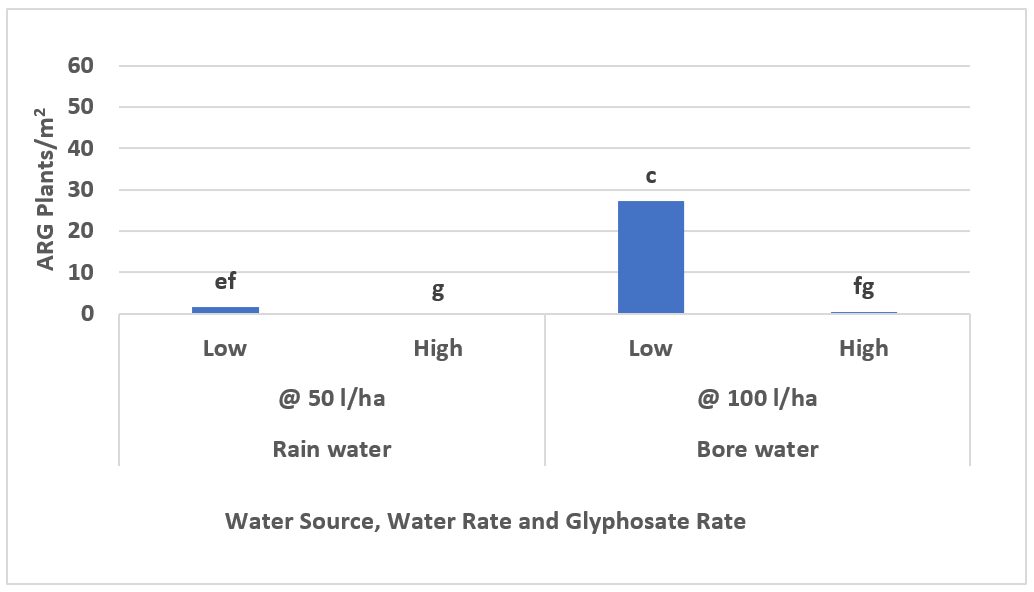

Increasing the rate of glyphosate when using bore water, at the higher water rate, resulted in significantly fewer ARG survivors. Increasing the rate of glyphosate when applying 50 L/ha of rainwater also reduced survivors from 1.6 plants/m2 down to less than 1 plant in 10m2 as illustrated in Figure 3.

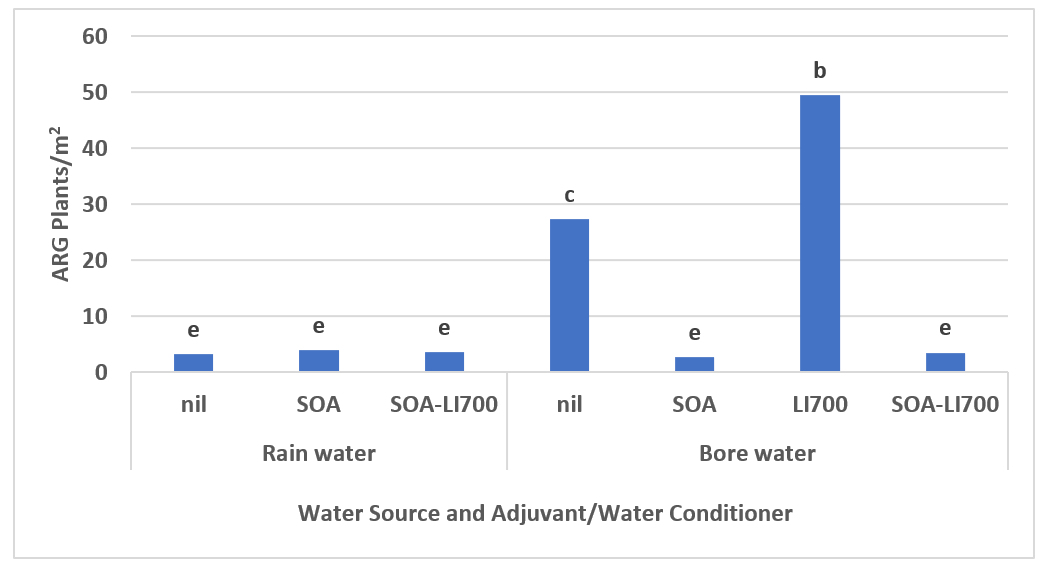

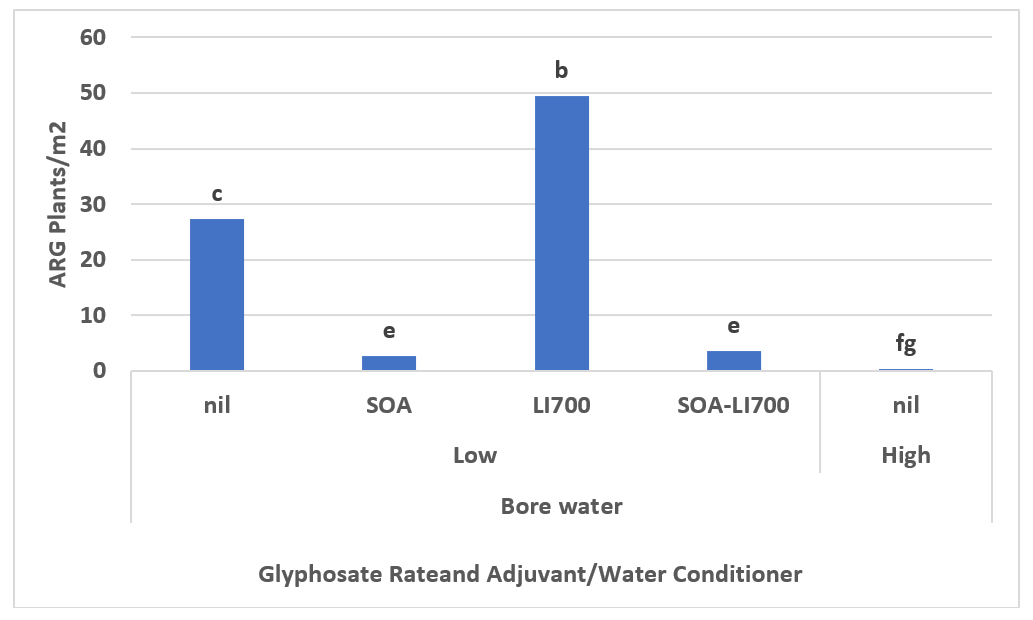

Adding SOA or SOA + Li700 to bore water at the low rate of glyphosate resulted in fewer ARG survivors compared with no spray additives. Where Li700 alone was added to bore water, it resulted in more ARG survivors than bore water with no spray additives as shown in Figure 4).

The addition of SOA or SOA & Li700 to rainwater and the low rate of glyphosate did not impact ARG survivors (Figure 4), while adding SOA when applying glyphosate in bore water reduced the numbers of ARG survivors similar to that of when using rainwater.

Increasing the glyphosate rate in bore water with no spray additives resulted in almost no ARG survivors (Figure 5).

Spray quality, water rate and application timings

In Autumn 2021, GOA established three trials to investigate the effects of spray qualities, water rate and time of application on the control of seedling ARG.

The trials tested three spray qualities, achieved using differing nozzles including, Turbo Teejet (TT) Air Induction Extended Range (AIXR)] and Turbo Teejet Air Induction (TTi) at 4 bar operating pressures. The nozzles produced a Fine (F), medium (M) and extremely coarse (XC) spray qualities, respectively. Two water rates were tested by manipulating application speeds- 8 km/h to apply 100L/ha and 16 km/h for 50L/ha. All treatments were applied using rainwater as the carrier.

NOTE: Some brands/formulations of glyphosate have labelled, minimum spray quality requirement of no smaller than coarse to very coarse to be used, additionally some tank mix partners may also require minimum spray qualities larger than those tested in this work regardless of the brand or formulation of glyphosate.

At each of the sites, two application timings were tested. The first targeted at ARG in the 1-3 leaf stage and the second at 9-11 days later. The major flush of ARG germinated at the trial sites during rain events about 21 days prior to the first application.

Table 3. Trial location and application dates - 2021

Trial Location | Date of first application | Date of second application |

|---|---|---|

Forbes | 7th April 2021 | 16th April 2021 |

Peak Hill | 8th April 2021 | 19th April 2021 |

Coolah | 9th April 2021 | 20th April 2021 |

Forbes trial

The Forbes site had an ARG population of 300 plants/m2. Subsequent resistance testing demonstrated the population to have rate responsive glyphosate resistance as shown in Table 4 below.

Table 4. Herbicide resistance testing results to glyphosate in annual ryegrass populations, Forbes 2021

Herbicide | Herbicide Group | Paddock Sample | |

|---|---|---|---|

Survival % | Rating | ||

Glyphosate @ 285 g.a.i./ha | Group M | 40 | R |

Glyphosate @ 541 g.a.i./ha | Group M | 15 | R |

Glyphosate @ 855 g.a.i./ha | Group M | 0 | S |

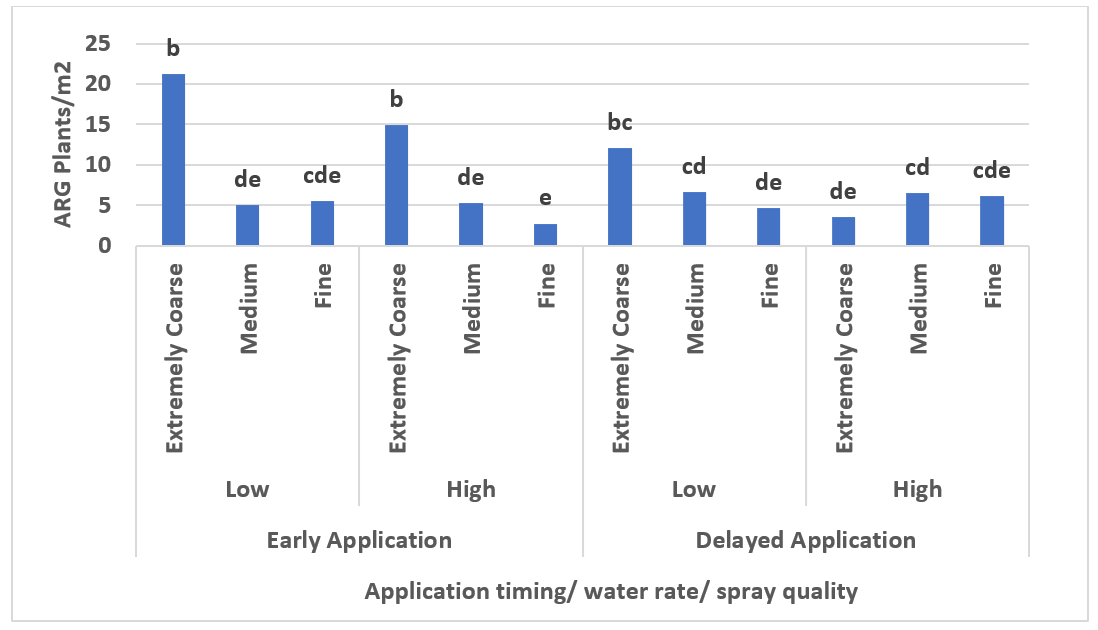

Using an XC spray quality at the earlier spray timing and low water rate resulted in the highest surviving population of ARG (Figure 6). Increasing the water rate, using a XC, did not significantly improve the results at the earlier timing. Only where application was delayed, and the high-water rate was used was there a significant reduction in ARG populations when using an XC spray quality.

Applying a F or M spray quality at the earlier timing resulted in significantly fewer ARG and there was no advantage to delays in application or increasing water rates using these spray qualities.

Peak Hill

The Peak Hill site had an ARG population of 200 plants/m2. Subsequent resistance testing of the population demonstrated a very low level of resistance to glyphosate as shown in Table 5.

Table 5. Herbicide resistance testing results to glyphosate in annual ryegrass populations sampled at Peak Hill in 2021

Herbicide | Herbicide Group | Paddock Sample | |

|---|---|---|---|

Survival % | Rating | ||

Glyphosate @ 285 g.a.i./ha | Group M | 10 | R |

Glyphosate @ 541 g.a.i./ha | Group M | 0 | S |

Glyphosate @ 855 g.a.i./ha | Group M | 0 | S |

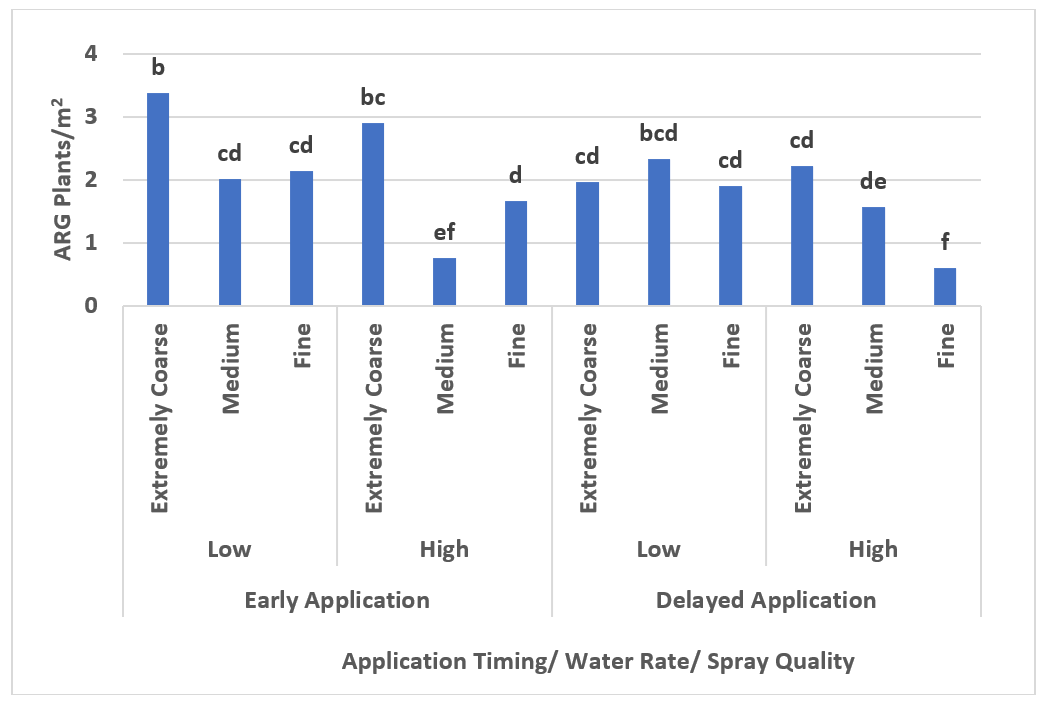

The highest surviving populations of ARG were observed in the early spray timing, with the low water rate applied as an XC spray quality (Figure 7). Increasing the water rate at the early timing and same spray quality did not result in fewer ARG survivors. Delaying the application time with XC spray quality did result in fewer ARG survivors than the XC applied early, but there was no difference between water rates at the later timing.

Applying a F or M spray quality at the early timing resulted in fewer ARG survivors compared with XC spray quality for both water rates. There was no advantage to delaying spraying when using F or M at any given water rate. Where spraying was delayed there was no difference between any of the three spray qualities or water rates, except when a F quality was applied in the high-water rate.

Coolah

The Coolah trial had a dense population of 414 plants/m2. Subsequent resistance testing demonstrated a very high level of resistance to glyphosate as shown in the Table 6 below.

Table 6. Herbicide resistance testing results to glyphosate in annual ryegrass populations, Coolah 2021

Herbicide | Herbicide Group | Paddock Sample | |

|---|---|---|---|

Survival % | Rating | ||

Glyphosate @ 285 g.a.i./ha | Group M | 100 | RRR |

Glyphosate @ 541 g.a.i./ha | Group M | 100 | RRR |

Glyphosate @ 855 g.a.i./ha | Group M | 80 | RR |

No measurable effects were detected in any of the treatments applied in this trial.

Discussion

ARG populations at all sites were high and the level of control was also high following many of the treatments applied, with most achieving over 90% control, a threshold often quoted as achieving commercially acceptable control. Despite these very high levels of control, high numbers of ARG survived in some cases. For example, at Forbes, the worst performing treatment achieved 93% control when compared to the untreated control (Figure 6), but around 20 plants/m2 survived the application. Some of the better performing treatments at the same site reduced populations to as low as 3 plants/m2 equating to 99% control (Figure 6).

In fallow situations ahead of sowing the poorer levels of control achieved by some treatments in these experiments would be commercially unacceptable and would require follow up control measures, such as a double knock. However, improving control by only a few percent is very worthwhile and, achievable as has been demonstrated by this research.

It should also be noted that the populations these trials were carried out on were all confirmed with varying levels of glyphosate resistance. Three of four sites are suggested to be typical in the region with resistance detected at lower rates of glyphosate and rated as susceptible at higher rates. At these three sites, more acceptable control was achieved simply by employing several practical and affordable measures - manipulating water source/quality, water rate, spray timing and spray quality.

At the fourth site, which had very high levels of resistance, no discernible difference in control was achieved from the treatments tested. This demonstrates that as the level of resistance exceeds appropriate labels rates, the ability to counter resistance by ‘delivering the right dose correctly’ is diminished. This re-enforces the benefits in testing populations to not only confirm the presence of resistance, but also to what level.

Water quality

The water quality trial highlighted the importance of using good quality water. In this case rainwater resulted in the best results without the need to add anything to the water. With good quality water there was also minimal upside or downside to using higher water rates. However, it should be remembered glyphosate is best applied in concentrated droplets to improve uptake. Increasing water rates can dilute spray concentrations. Longer term, growers who lack a supply of good quality water should consider investment in filtration systems (such as reverse osmosis) or installation of additional rainwater tanks or seek other ‘better quality’ sources of spray water. If this is not an option growers could look to modify or address the quality issues.

SOA is beneficial in addressing water hardness and bicarbonates common in bore water sources and resulted in significantly less ARG survivors when using bore water. The SOA acts to tie up the calcium and magnesium ions that can bind to and inactivate glyphosate.

Li700 primarily reduces the spray solution pH which should have been on face value, useful with the higher pH of the bore water. However, glyphosate is a weak acid and ample evidence is available that its use alone is sufficient to reduce the spray solution to acceptable pH levels. Interestingly, survival of ARG was significantly higher where it was used alone.

Water rates

Optimum water rates are most commonly accepted to be influenced by spray quality and the type and size of the target. Using ‘contact’ type products as opposed to translocated product like glyphosate will also change this dynamic.

But this work has also shown that it also interacts with water quality. As was shown at the Narromine trial, increasing water rates when using poor quality water increased ARG survival. The same effect was not evident with rainwater. These results illustrate the impact that dilution of glyphosate in more water with high levels of hardness reduces the intended dose of glyphosate before it can be delivered to the target.

SOA can be used to overcome water quality issues but that comes at an added cost, and the cost increases with water rate as its use rate is set based on water volume rather than the area on which the spray is applied. Consequently, water rates should be kept to a minimum when using poor quality water to minimise the potential tie-up of glyphosate and/or costs of amelioration and maximise the glyphosate concentration in the spray solutions. If using good quality water, only the latter is applicable.

Lower water rates need to be balanced against the needs to achieve sufficient coverage of the target weed, which is also linked to spray quality but glyphosate being a translocated product has a less reliance on good coverage to control weeds compared to many other herbicides.

Spray quality

The target weed for these trials was seedling ryegrass, a small upright weed with a waxy leaf that can prove difficult to both hit with a spray droplet and for that droplet to be retained without bouncing or rolling off the leaf.

These trials showed that the XC spray quality resulted in significantly more ARG survivors. And increasing water rates did not improve the outcomes in any trial unless spraying was delayed allowing the target to grow to a larger size suggesting that the droplets were just too large to be retained on the target at that growth stage.

It is worth noting at this point that the first time of application was already three weeks after the germinating rain. The delayed application was applied some 4 ½ weeks after the germinating rain, way too late to be spraying effectively for the other weeds most likely present to facilitate sowing or conserve moisture. Arguably delaying application was simply not a practical option in these situations.

However, spray qualities of F and M resulted in significantly fewer ARG survivors even at the earlier application timing and in most cases increased water rates or delays in application were not justified to improve control further. However, the risk of increased drift and/or evaporation losses from using these finer spray qualities should be taken into consideration as they can result in a reduction in efficacy, represent a loss from the system (increased cost). Further to this several glyphosate labels and potential tank mix partners now stipulate spray qualities to be coarse (C)-very coarse (VC) so using the finer spray qualities tested in this trial are not legally able to be done. Growers and advisors must check the specific labels of their intended products of use because there are differences.

It should be also noted that the XC spray quality in this trial is far coarser than the M tested. It is plausible that employing a spray quality in between the two tested such as a C-VC spray quality may have achieved similar results as the M without the downside risks noted above but this may require further testing to confirm.

However, the nozzle combinations were chosen as they are common nozzles that growers use. A survey completed by SOS Macquarie in 2019 showed the most common nozzle types were the TTi (XC) and the AIXR (M). Less than 9% of survey respondents indicated they possess a nozzle capable of producing coarser spray qualities than an AIXR but finer than the TTi, that is. they cannot produce a C-VC spray quality.

This highlights the need for growers to consider purchasing additional nozzle options to increase the spray qualities available to them. But in the interim, for most growers the selection of a AIXR producing a M spray quality is far more effective than selecting a XC.

Using higher herbicide rates

In these experiments, the use of higher glyphosate rates, that were still within label limits, resulted in the lowest numbers of survivors at the two sites where resistance was at low levels. But the benefits from increasing glyphosate rates was most evident when using poor quality water, seemingly ‘trumping’ the negative impacts of poor quality water, even when used at high rates.

This serves to highlight the benefit of using robust rates for the weeds targeted. However, in these situations the addition of SOA would also be recommended. The combination of robust label rates and addressing the issue of low-quality water would ensure the best possible outcome from the money invested.

Again, resistance testing to determine rate responsiveness of any given population may give a good indication of suitable application rates.

Slow growing annual ryegrass

An observation at all sites was the slow growth in the ARG populations established with early autumn rainfall. At all three trial sites the first time of spraying was approximately 3 weeks after the germinating rains. It would be generally accepted that spraying should be completed by this time, yet much of the ARG was still quite small at 1-3 leaf and control proved to be variable in response to spray applications.

This places growers into a conundrum when there are early seasonal breaks as experienced in 2020 and 2021. Spray timing for most Autumn/Summer weeds may be too early for ARG resulting in escapes surviving through sowing and into the crop (Figure 8). The shift toward using coarser spray qualities in summer fallows (which is now a legal requirement for phenoxy herbicides and for some glyphosate formulations) is likely to have exacerbated the problem.

Conclusions

Addressing factors that limit the plant receiving the ‘intended dose’ can improve control. Key factors can be optimising- water source/quality, water rate, spray quality, herbicide rate and timing. However, the improved control achieved using lower water rates where water quality is poor was quite stark as was the reduction in control when using XC spray quality as opposed to the other spray qualities tested.

Growers with poor quality spray water should look to other sources of water where possible otherwise consider ameliorating the water. The RO bore water proved as good as the rainwater when tested and the addition of SOA to bore water proved valuable in most cases.

The small spray target in seedling ARG proved very difficult to control with the XC spray quality in these trials and simply increasing water rates was not effective in improving outcomes. Spraying had to be delayed to achieve good control, which is not always an ideal option.

Alternatively, growers could target a M spray quality which improved control and reduced the need to delay spraying and/or increase water rates. Further work may be useful to investigate if spray qualities between the M and XC tested remain effective but reduce the risks associated with finer qualities.

Getting spray application right will not be enough to control highly resistant populations but in populations with lower or developing levels of resistance it is of paramount importance. Knowledge of the resistance status (including rate responsiveness) via testing will inform management decisions for such populations.

These outcomes further support the suggestion that all spray failures, even in resistant populations are not always just the because of ‘resistance.’ To assume that it is, will leave valuable control opportunities on the table. Growers and advisors should critically assess spray failures, as resistance is one of many factors that may contribute to poor levels of control.

Acknowledgements

The research undertaken as part of this project is made possible by the significant contributions of growers through both trial cooperation and the support of the GRDC, the author would like to thank them for their continued support.

References

Street M and Obrien B (2020). Is our ryegrass really getting harder to kill through our over reliance on glyphosate.

Contact details

Maurie Street

Grain Orana Alliance

PO Box 2880, Dubbo NSW 2830

Ph: 0400 066 201

Email: maurie.street@grainorana.com.au

® Registered trademark

GRDC Project Code: GOA2006-001RTX,

Was this page helpful?

YOUR FEEDBACK