The key profit levers for sandy soils amelioration

Take home messages

Recent work in the Sandy Soils Project has focused on consolidating our knowledge on identifying constraints, optimising machinery set-up and selection to ameliorate the constraint, predicting the crop response to the treatment and analysing the profit/risk implications for these responses. Key levers for profit from amelioration of sandy soils include:

- Our ability to predict the response to amelioration which relies on knowing the constraint (and severity) and the tool to address the constraint

- The scale of the amelioration project (e.g., area ameliorated per annum, options for machinery investment)

- Our ability to manage the workflow effects of amelioration (post-amelioration traffic, seeding management, crop sequence management).

Background

Recent surveys of growers in southern region landscapes indicate that 50% of growers have ameliorated some sand in the last 5 years and they plan to double the amount of sand ameliorated in the next 5 years. There is recognition across the industry that understanding the constraint to be ameliorated, how to best tackle that constraint from an engineering perspective and how to integrate it into whole-farm management considerations is critical to the successful adoption of amelioration techniques.

Crop productivity on sandy soils is commonly limited by a range of soil constraints that reduce root growth, crop tillering and grain number. Constraints can include a compacted or hard layer preventing root proliferation, a water repellent surface layer causing poor crop establishment, soil pH issues (both acidity and alkalinity) and/or poor nutrient supply. The aim of the sandy soils project is to increase crop productivity in underperforming sandy soils in the Southern cropping region by improving the diagnosis and management of constraints.

Growers are experiencing a range of outcomes in response to amelioration efforts on deep sands. Understanding the constraints, and appropriate amelioration tool and a set up that will best address the constraint are critical to success. A profit-risk analysis can help growers and advisers think through the relevant components of the costs, the expected response and financial risks associated with amelioration of deep sands. This paper focuses on high soil disturbance interventions (deep ripping and spading) that require specialised machinery to break up compacted or hard-setting layers and/or mixing of repellent layers.

Method

Constraint Identification

The key measurements for constraint identification include water repellence (water drop test), soil strength (penetration resistance) or bulk density, pH and soil nutritional status. Practical approaches to assessing these constraints have been outlined in the factsheets listed under useful resources. We utilised the techniques outlined in our factsheets to categorise the sand constraints at each of our sites as low, moderate or severe.

Testing amelioration techniques

A range of research experiments were established across the low to medium rainfall environments of the Southern region with sites categorised according to their primary soil constraints identified. Experiments were established between 2014 and 2019 while a broader validation trial program was established between 2019 and 2021, including a range of deep ripping (30-60 cm deep), spading, inclusion ripping and/or inversion ploughing approaches, with/without additional amendments (fertiliser, N-rich hay, chicken manure, clay). Practical advice on the set up and operation of these treatments is outlined in the factsheets (see useful resources). In all experiments the effects of amelioration on crop growth and yield were monitored, while the research program had a further set of more detailed soil and crop measurements. In all there were 32 experimental sites with 105 site years of data collected. All yield results have been collated and analysed and are available via the SANDBOX App (which will be searchable via the CSIRO Data Access Portal in the coming months). In this paper we present yield responses according to machinery treatment (ripping, spading) and constraint category.

Economic analysis

Utilising grain yield responses, the discounted cashflow response to amelioration was evaluated for cost:benefit outcomes in response to ripping and spading, based on costs provided by grower and industry consultation (here we present ripping outcomes using a cost of $90-120/ha depending on ripping depth), 5-year average grain prices from the gross margin guide (wheat (APW) five-year price was $295/t, PIRSA, 2021) and a future discount rate of 6%. The cash flow outcome is presented here as the net present value (NPV) for ripping treatments. Where NPV is positive it reflects that the present value of the future cash flow is bigger than the initial investment.

Several case study farms were developed to evaluate deep ripping as a ‘farm investment project’. Using a 4800-ha cropping farm with three land classes of responsiveness to ripping, we had a base scenario where 317 ha were ripped in each year for five years (made up of 190 ha of class A responsive land, 95 ha of class B responsive land and 32 ha of class C responsive land), with fuel costs of $60/hr and a two-week program of work. Class A responsive land assumed 0.7 t/ha cereal benefit in year 1, 0.31 t/ha cereal benefit in year 2, 0.1 t/ha legume benefit in year 3, while Class B land achieved 70% of the Class A response and Class C achieved only 10% of the Class A response. The capital investment for this base scenario was an $80,000 ripper and 30% of tractor cost, which was disposed of in year 6. The base scenario was compared with scenarios of doubled fuel costs, a reduced responsive area by assuming 10% less class A land and 5% more Class B and C land, halved capital cost, utilised contracting for the ripping at $80/hr or doubled the treated area in each year.

Results and discussion

Yield responses

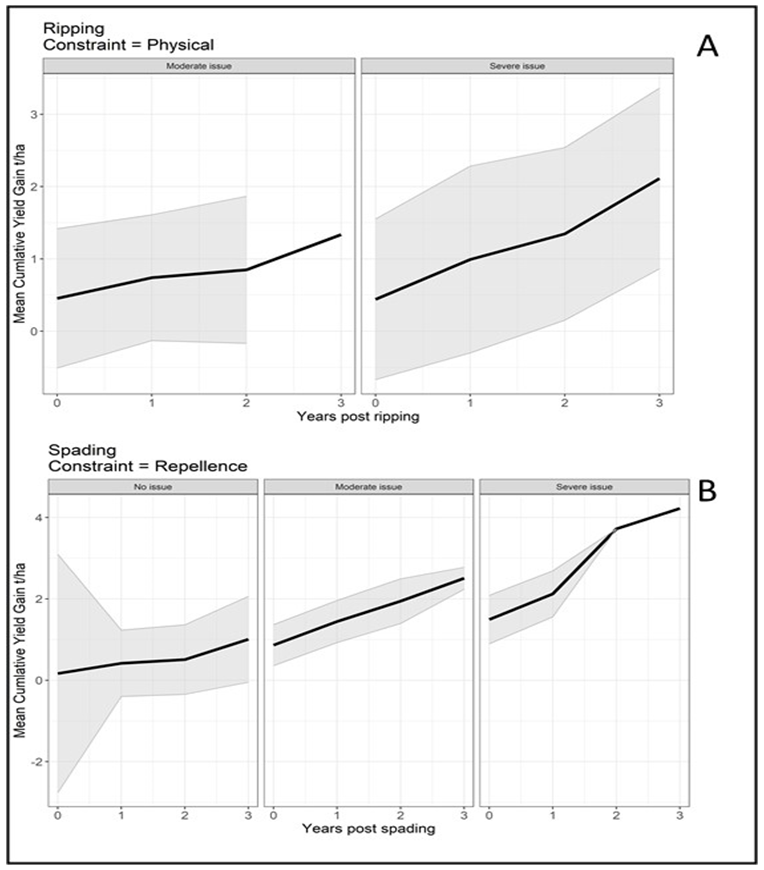

The crop response to sandy soil amelioration varies according to primary constraint. Figure 1A shows the level of ripping responsiveness over time for soils with moderate and severe physical constraints. While the initial response to ripping is similar for both categories, the cumulative response is greater for sands with a severe physical constraint. Figure 1B shows the level of spading responsiveness over time for soils with nil through to severe repellence. The amelioration of repellence relies on the mixing or dilution of surface soil with repellence. The results show that more repellent sands generate a greater cumulative yield response to spading. The shading (r coefficient of variation) in the figure demonstrates that there is still quite a range of possible outcomes within each category of constraints, which arises due to seasonal constraints, variation in the soil constraint and post-amelioration management (e.g. nutrient input, crop establishment, erosion etc.).

Figure 1. Southern sandy soils project cumulative yield responses (as mean in bold line and cv in grey shadow) over time to ripping (A), and spading (B) (amelioration occurred in year 0). The responses have been separated according to the category of constraint and we present the examples of ripping responses according to categories of soil physical constraint (measured by soil strength) and spading responses according to repellence (measured by water drop penetration test).

Net present value (NPV) responses

With rapid changes in the costs associated with soil amelioration, it is imperative to continually review the economic outcome of treatment responses across the project database.

Table 1. Cumulative net present value in response to ripping treatments (compared with an unripped control) implemented across the southern cropping region.

Site | Rip depth (cm) | Rainfall deciles | Physical constraint | Repellence constraint | Total years since treatment | Cumulative net present value ($/ha) |

|---|---|---|---|---|---|---|

Bute | 50 | 2/10/3/2/1/6/4 | Severe | Moderate | 7 | 1244 |

Lowaldie | 60 | 2/7/2 | Severe | Moderate | 3 | 574 |

Younghusband | 50 inclusion | 7/6 | Severe | Severe | 2 | 517 |

Murlong | 40 | 2/2/5/5 | Severe | Severe | 4 | 454 |

Ouyen | 30 | 6/2/2/8/2 | Severe | Low | 5 | 453 |

Lowaldie | 40 | 2/7/2 | Severe | Moderate | 3 | 386 |

Koolonong | 50 | 1/9/4 | Moderate | Low | 3 | 358 |

Mt Damper | 45 inclusion | 3/4/4 | Moderate | Moderate | 3 | 315 |

Karkoo | 40 | 6/6/7 | Moderate | Low | 3 | 274 |

Murlong | 30 | 2/2/5/5 | Severe | Severe | 4 | 258 |

Younghusband | 50 | 7/6 | Severe | Severe | 3 | 235 |

Kybunga | 50 | 1/4/3 | Moderate | Moderate | 3 | 231 |

Karkoo | 40 inclusion | 6/6/7 | Moderate | Low | 3 | 230 |

Warnertown | 50 inclusion | 2/9/3 | Moderate | Moderate | 3 | 170 |

Kybunga | 30 | 1/4/3 | Moderate | Moderate | 3 | 168 |

Warnertown | 50 | 2/9/3 | Moderate | Moderate | 3 | 147 |

Tempy | 50 | 2/8 | Moderate | Moderate | 2 | 73 |

Warnertown | 30 | 2/9/3 | Moderate | Moderate | 3 | 71 |

Bute Boundary | 30 | 2/1/6/4 | Moderate | Low | 4 | 66 |

Tempy | 50 inclusion | 2/8 | Moderate | Moderate | 2 | 31 |

Buckleboo | 45 | 1/6/5 | Severe | Low | 3 | 15 |

Buckleboo | 45 inclusion | 1/6/5 | Severe | Low | 3 | -39 |

Buckleboo | 35 | 1/6/5 | Severe | Low | 3 | -48 |

Cummins | 30 | 4/5/5 | Severe | Moderate | 3 | -50 |

Carwarp | 30 | 1/1/5 | Severe | Low | 3 | -53 |

Waikerie | 60 | 1/1/8/1 | Severe | Low | 4 | -106 |

Carwarp | 60 | 1/1/5 | Severe | Low | 3 | -115 |

Sherwood | 30 | 3/6/4 | Moderate | Low | 3 | -123 |

Yenda | 60 | 2/1/2/8/7 | Severe | Low | 5 | -137 |

Waikerie | 30 | 1/1/8/1 | Severe | Low | 4 | -143 |

Bute Boundary | 50 | 2/1/6/4 | Moderate | Low | 4 | -254 |

Here we restrict the presentation of data to the ripping responses and demonstrate that despite the shifts in costs and prices over the project timeframe, there were still substantive gains from amelioration responses in many cases (Table 1). We have also related the site and treatment to the soil constraints, run of seasons with respect to rainfall (shown as deciles) and number of years that the response was monitored for. This additional information explains the level of response as NPV in many cases (Table 1), where the response may have been limited by either having only a moderate constraint or due to a very poor run of seasons (e.g., Carwarp and Waikerie), but some uncertainty remains for some sites where the physical constraint was categorised as severe (e.g., Buckleboo and Cummins) but the response did not generate a positive NPV.

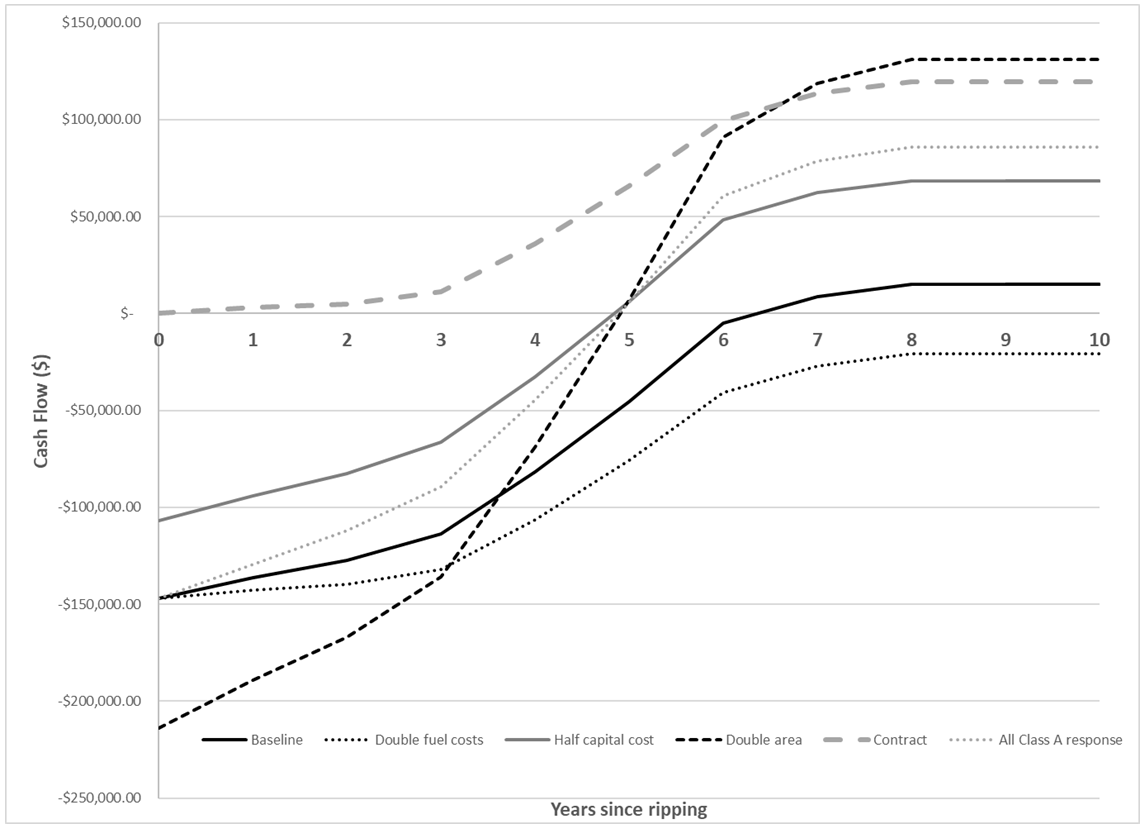

Farm level responses

Here we present one case study farm from a Mallee environment as an example of the several that we have produced across the project geography. Relative to the range of possible outcomes shown in Figure 1 and Table 1, the baseline scenario is for a farm with a relatively moderate level of response (1 t/ha yield benefit in the first 3 years) which has a payback period of 6 years (Figure 2). The scenario of assuming all Class A responsive land demonstrates the scaled-up outcome if we assume that the responses observed in field trials occur across all the ripped land on a farm. This has a shorter payback period with significantly more cash flow which shows the baseline scenario is relevant for growers who have a range of different sand types and who have co-occurring constraints which might restrict the response to ripping (Figure 2). The scenarios of half the capital investment (e.g. machinery sharing options) and the utilisation of a contractor demonstrate the impact that alternative approaches to the capital expense of implementing amelioration projects have for on-farm profitability. The example of doubling fuel costs highlights the need to monitor and estimate costs, particularly in low rainfall regions when average yield gains can be limited (Figure 2).

Figure 2. Case study farm predicted cash flow in response to changes in the farm amelioration ‘project’ including doubling fuel costs, halving the capital cost, doubling ripped area, assuming all ameliorated land has a ‘Class A’ level of response and utilising a contractor instead of upfront machinery investment.

There are some important post-amelioration considerations that ensure success. These include paddock trafficability, the ability to successfully establish the first crop and the effect that the ameliorated area has on workflow across the paddock. While we have a limited set of experiments that have tested the role of seedbed preparation (McBeath and Moodie 2020) and crop type or sequence effects (Moodie et al. 2022) on amelioration outcomes, recent grower interviews indicate that the need to understand these factors can be important barriers to the adoption of amelioration of sandy soils.

Conclusion

The ability to predict the profitability of sandy soil amelioration is dependent on understanding the constraint and the tool that best ameliorates that constraint. This is challenging because these constraints in a paddock can change in both space and time. However, the approach to the amelioration ‘project’ on the farm with respect to the amount of land ameliorated per year and the level of investment made in required machinery are decisions that can also have a major influence on profitability.

Acknowledgements

The research undertaken as part of this project is made possible by the significant contributions of growers through both trial cooperation and the support of the GRDC, the author thanks them for their continued support. We thank the technical teams who deliver the experimentation for the Sandy Soils Project. GRDC project CSP00203 research and validation activities are a collaboration between the CSIRO, the University of South Australia, the SA Government Department of Primary Industries and Regions SA, Mallee Sustainable Farming Inc., Frontier Farming Systems, Trengove Consulting, AgGrow Agronomy, AIREP, and MacKillop Farm Management Group.

References

McBeath T and Moodie M (2020) Perils of ripping on sandy soils-what can be learnt from hindsight? Kimba GRDC Update.

Moodie M, Brand J, Mawalagedera S and Roberts P (2022) Soil amelioration a ‘little ripper’ for Mallee pulses. Groundcover Supplement.

PIRSA (2021) Farm Gross Margin and Enterprise Planning Guide

Useful resources

Measuring constraints on sands to inform management. Diagnosing sandy soil constraints: water repellence and pH extremes Factsheet

Measuring soil strength with a penetrometer. Diagnosing sandy soil constraints: high soil strength Factsheet

Crop nutrition for sandy soils. Diagnosing sandy soil constraints: Nutrition Factsheet

Understanding passive inclusion ripping

Understanding the process of soil profile mixing with rotary spaders. Soil mixing by spading Factsheet.

Technology considerations for cost-effective subsoil loosening. Ripping technology Factsheet.

Contact details

Dr Therese McBeath

CSIRO Agriculture & Food, Waite Road, Urrbrae, SA 5064

Phone: +61 8 8303 8455

Email: therese.mcbeath@csiro.au

Date published: February 2023

GRDC Project Code: CSP1606-008RMX,

Was this page helpful?

YOUR FEEDBACK