The economics of ameliorating sodicity with gypsum and lime

Author: David C McKenzie (Soil Management Designs) | Date: 02 Mar 2022

Take home messages

- Soil scientists from UQ have highlighted the magnitude of grain yield constraints associated with sodic soil in the Northern Region. Sodicity is a problem for grain growers when it causes the soil to be dispersive. Vertosols and Sodosols are the main cropping soil types with this problem. An over-reliance on EM surveys and topsoil nutrient testing means that most grain farms in eastern Australia have a serious lack of accurate and comprehensive soil profile data to guide productivity improvements and the provision of soil-related ecosystem services

- A team from USQ, UNE, QDAF and NSW DPI (GRDC funded) is evaluating diverse and novel treatments for both topsoil and subsoil sodicity. But so far there are only two years of yield data (2020-21) for most of the study sites. Two years of yield response data are inadequate for meaningful economic analysis; at least five years of measured yield response data are required

- In the meantime, while waiting for additional data sets from this initiative, we have to make the most of previous studies. Very little historical data is available apart from a study initiated by a Moree farmer and UNE Armidale student, Bill Yates, in the early 1970s and data generated by the widely reported GRDC SIP08 soils project some 13 years ago

- The two main study sites used by Bill Yates were near Gurley and Garah; they were Grey Vertosols with dispersive/sodic surface soil, minimal deep vehicle compaction and no serious nutritional limitations. Some of the treatments were persistent and continued to give impressive yield gains up to five wheat growing seasons (1973-77) following amelioration, particularly gypsum 12.5 t/ha. All of the gypsum treatments were profitable, particularly at near-zero interest rates and at a rate of 2.5 t/ha. Deep ploughing (discing) also was profitable, despite poor persistence at ‘Delvin’, but financial losses followed application of 12.5 t/ha chopped straw

- Lime is much less soluble than gypsum and was slow to give suppression of dispersion, but significant yield benefits were eventually observed at both ‘Gurley Station’ and ‘Delvin’.

- Yields close to potential were achieved in some years, e.g. gypsum 12.5 t/ha treatment at ‘Gurley Station’ in 1977, and at ‘Delvin’ in 1974. The annual cost of the estimated yield gap on the sodic soil without amelioration at these study sites exceeded $500 per hectare.

- Specialist soil assessment and management services are needed to assist growers and their agronomists to map and plan for the economic improvement of sodic/dispersive soil, in conjunction with integrated assessment and management of associated soil constraints such as compaction, pH imbalance, excessive flatness, salinity and nutrient deficiencies. If done professionally, this type of assessment allows soil constraints to be viewed as economic opportunities, when managed in conjunction with the use of ‘true variable rate’ precision agriculture techniques.

Introduction

Orton et al. (2018) have estimated that of the 11.34 million ha of cropping land in NSW and Qld, 69% is affected by sodicity and that observed grain yield gaps can at least partially be attributed to soil constraints, not just agronomic factors (suboptimal management of pests and diseases, weeds, nutrient uptake, time of sowing, crop density and variety choice). Across the wheat growing land of Australia, the total potential annual economic benefit of sodic soil amelioration using gypsum was estimated to be A$1.15 billion per annum.

With support from the Grains Research and Development Corporation (GRDC), leading grain farmers and their advisers are re-assessing management inputs to reduce significant soil related yield gaps, where economic feasibility can be demonstrated. Very little new land is available for development (Heard 2021). Soil amelioration options for dryland grain production on sodic soil prone to dispersion in eastern Australia include gypsum, lime, organic matter and deep ripping. But there is uncertainty about effectiveness and persistence of treatments and the associated economic risks.

An ambitious new study of amelioration on dryland sodic cropping soil is described by Lester et al. (2022). The core site studies (and associated demonstration site; Roberton 2022) in southern Qld and northern NSW are evaluating diverse and novel treatments to address sodicity constraints in both topsoil and subsoil. Vertosols and Sodosols are the main soil types (as described using the Australian Soil Classification; Isbell 2016) with sodicity limitations in these regions. But so far there are only two years of yield data (2020-21) for most of the study sites. Two years of yield response data is inadequate for meaningful economic analysis; at least five years of measured yield response data are required covering a broad range of rainfall outcomes.

While waiting for additional data sets from core research sites, the only available option for farmers and their advisors requiring urgent advice about soil improvement techniques is to make the most of previous studies. This includes data generated by the widely reported GRDC SIP08 soils project some 13 years ago (Dang et al. 2006). Of particular value is the pioneering UNE-DPI work initiated by a Moree farmer and UNE Armidale student, Bill Yates, in the early 1970s (Yates 1972) and reported by Doyle et al. (1979) and Yates and McGarity (1984). The two main study sites were at ‘Gurley Station’, Gurley and ‘Delvin’, Garah; Grey Vertosols were present with inherently dispersive/sodic surface soil, minimal deep vehicle compaction and no serious nutritional limitations at that time. So and Onus (1984) estimated that 38% of cropping soil in the lower Gwydir Valley had a suppression of dryland wheat yield because of topsoil instability (dispersion index in the range 9 to 12).

Monitoring of the yield of dryland wheat grain occurred over five years (1973-77) following surface applications of gypsum (by-product phosphogypsum; calcium sulfate), lime (calcium carbonate) and organic matter. Deep ploughing (discing to 25 cm) also was evaluated, with the objective being to

- Physically lift calcium carbonate nodules closer to the surface (nodules are frequently present in these soils at depths of approximately 15 cm) to improve surface soil structural stability and

- Break any sub-surface compaction pans. Yates (1972) found that structural instability was not a problem in the Moree district where soil carbonate levels exceeded 0.28%.

The aim of this paper – 45 years after the field work was undertaken by Bill Yates, David Doyle and their colleagues – is to re-examine the economic performance of these treatments in relation to yield gaps. An important issue is the performance of lime as a possible substitute for gypsum when ameliorating dispersive/sodic soil. Also, challenges associated with extension of this information to grain growers via soil science specialists are discussed.

Gypsum-lime grain yield responses, 1973-77, in relation to estimated yield potential

Yield response data are shown in Table 1. Treatment details have been presented by Doyle et al. (1979). The economic data in Table 2 provide an overview of ameliorant profitability over the five years of the experiments. A more refined version of this analysis is being developed by colleagues associated with GRDC Project C, ‘Economics of Ameliorating Soil Constraints in the Northern Region’ at USQ.

Table 1. Grain yields of ameliorative treatments at ‘Gurley Station’ and ‘Delvin’ (Doyle et al. 1979). The modelled potential (rain limited) wheat grain yields were calculated using the equation of French and Schultz (1984) and rainfall data from the study sites.

Treatment | ‘Gurley Station’ | ‘Delvin’ | |||||||

|---|---|---|---|---|---|---|---|---|---|

A Series Experiments: Wheat grain yield, t/ha (Gypsum surface application was in January 1973) | |||||||||

| 1973 | 1974 | 1975 | 1976 | 1977 | 1973 | 1974 | 1975 | 1977 |

Control | 1.1 | 0.8 | 1.7 | 0.7 | 1.0 | 0.2 | 1.1 | 1.4 | 1.8 |

Chopped straw (12 t/ha) | 0.8 | 0.9 | 2.1 | 0.9 | - | 1.5 | 2.5 | 1.3 | 2.0 |

Deep plough (DP) 25 cm | 1.0 | 1.1 | 2.1 | 1.0 | 1.2 | - | 2.3 | 1.2 | 1.7 |

Gypsum (12.5 t/ha) | 1.8 | 1.0 | 2.6 | 1.5 | 2.0 | 1.4 | 3.3 | 1.7 | 2.6 |

Gypsum (12.5) + DP | 1.5 | 1.8 | 2.6 | 1.7 | 1.8 | 0.6 | 3.5 | 2.0 | 2.8 |

LSD (p = 0.05) | 0.5 | 0.6 | 0.6 | 0.3 | - | 0.3 | 0.5 | 0.4 | 0.3 |

B Series Experiments: Wheat grain yield, t/ha (Gypsum and lime surface application was in April 1974) | |||||||||

Control | 0.5 | 1.0 | 0.7 | 1.0 | 0.7 | 1.5 | 1.5 | ||

Gypsum (1.25 t/ha) | 0.5 | 1.6 | 1.0 | 1.3 | 1.5 | 1.5 | 1.9 | ||

Gypsum (2.5 t/ha) | 0.9 | 2.1 | 1.1 | 1.5 | 1.7 | 2.1 | 1.8 | ||

Lime (5 t/ha) + S | 0.7 | 1.9 | 1.0 | 1.5 | 0.7 | 1.9 | 1.9 | ||

LSD (p = 0.05) |

| ns | 0.5 | 0.3 | ns |

| 0.7 | 0.4 | 0.4 |

Potential yield, t/ha (French & Schultz 1984) | 4.3 | 3.3 | 5.3 | 4.3 | 2.2 | 3.0 | 3.5 | 3.3 | 6.4 |

Yields close to potential were achieved in two from nine ‘site years’; gypsum 12.5 t/ha treatment at ‘Gurley Station’ in 1977, and at ‘Delvin’ in 1974. But the usual outcome was yield outcomes far short of potential, even though amelioration had occurred.

The 12.5 t/ha gypsum treatment gave permanent displacement of sodium in topsoil and part of the subsoil (to a depth of 45 cm at ‘Gurley Station’; McKenzie 1982). The 1.25 t/ha and 2.5 t/ha gypsum treatments, however, only provided a temporary electrolyte improvement (Loveday 1976) in the topsoil.

Some treatments were persistent and gave impressive yield gains that were still present after five wheat growing seasons (1973-77), particularly gypsum 12.5 t/ha (Table 1). The gypsum treatments were profitable (Table 2), particularly at near-zero interest rates. Of the rates under consideration, gypsum (2.5 t/ha) was the most profitable. Despite poor persistence at ‘Delvin’, deep ploughing also was profitable; but financial losses were associated with applications of 12.5 t/ha chopped straw.

Table 2. Net Present Value (NPV) of wheat grain yield improvements following soil amelioration at ‘Gurley Station’ and ‘Delvin’ (A series experiment 1973-77, B series experiment 1974-77). Economic assumptions are: Wheat price = $250/t, 2021 ameliorant costs (D-A An-Vo pers. comm.) and three interest rates (0%, 5%, 10%). In 1976 at ‘Delvin’ there was no crop due to failure of sowing rains.

Treatment | Ameliorant Cost ($/ha)* | ‘Gurley Station’ NPV ($/ha) | ‘Delvin’ NPV ($/ha) | ||||

0% | 5% | 10% | 0% | 5% | 10% | ||

A. Control | $0 | ||||||

A. Chopped hay (12 t/ha) | $1,800 | -1700 | -1721 | -1738 | -1100 | -1155 | -1203 |

A. Deep plough (DP) (25 cm) | $60 | 215 | 171 | 137 | 165 | 149 | 135 |

A. Gypsum (12.5 t/ha) | $875 | 25 | -108 | -214 | 250 | 131 | 33 |

A. Gypsum (12.5) + DP | $925 | 100 | -46 | -163 | 175 | 40 | -70 |

B. Control | $0 | ||||||

B. Gypsum (1.25 t/ha) | $88 | 212 | 175 | 144 | 212 | 185 | 162 |

B. Gypsum (2.5 t/ha) | $176 | 424 | 358 | 303 | 299 | 260 | 226 |

B. Lime (5 t/ha), S (120 kg/ha) | $340 | 135 | 79 | 33 | -140 | -167 | -189 |

* Gypsum $70/t, Lime $50/t, chopped hay $150/t, deep ploughing $60/ha

Lime is much less soluble than gypsum and was slow to suppress soil dispersion, but significant yield benefits were eventually observed at both ‘Gurley Station’ and ‘Delvin’. In many parts of the Northern Region, lime provides a lower-cost source of calcium than gypsum. For example, where gypsum costs $70 per tonne and lime is $50/t, the cost of calcium from gypsum is $265/t, but only $125/t when derived from lime. Because many grain farms are closer to lime quarries than to gypsum sources, the use of lime as a sodic soil ameliorant can also provide transport savings. Sodic soil has in the past been assumed by many as being too alkaline for added lime to be effective, but the topsoil pH (CaCl2) values at ‘Gurley Station’ and ‘Delvin’ were below the threshold of ~6.6 nominated by Richards (1954) for adequate dissolution of lime to improve sodic soil. Emerson (1977) noted that calcium carbonate could be used instead of gypsum, provided time is given for the carbonate to be reprecipitated as clay sized particles so as to increase its solubility.

Assuming a wheat price of $250 per tonne, the annual cost of the yield gap on the sodic soil without amelioration at these study sites (1973-77) averaged $725 per hectare at ‘Gurley Station’ and $619 per hectare at ‘Delvin’. Without intervention, this is a cost that recurs year after year and adds up to a significant total over several decades where sodicity/dispersion is widespread across a farm. It should be noted however that yield gap numbers are theoretical and to be realised; successful management must be implemented, and yield gains realised to bridge this gap.

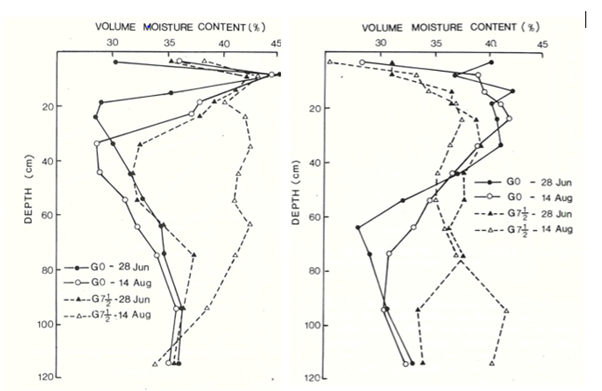

In a nearby follow-up experiment described by So and McKenzie (1984), it was shown that the deep movement of rain water was increased greatly by 7.5 t/ha gypsum – see Figure 1. Rainfall following the application of gypsum (by-product phosphogypsum) in March 1978 was well above average. The deeply infiltrating water on the gypsum treated soil had an elevated electrolyte concentration because of dissolved gypsum, but profile chloride concentrations were reduced (McKenzie 1982). Under these circumstances, losses of nitrate-N via deep leaching can be significant and may result in crop growth restrictions because of N deficiency.

Figure 1. Volumetric water content as a function of depth on poor-yielding sodic soil at ‘Delvin’ Garah and ‘Wyndella’ Gurley in the winter of 1978, with and without gypsum (7.5 t/ha) at two times 6 weeks apart (So and McKenzie 1984).

The Doyle et al. (1979) study did have several shortcomings:

- The study needed to be >5 years duration, especially for the evaluation of lime which appears likely to have a greater persistence in sodic soil than gypsum following a series of wet years

- No split applications of gypsum were included in the experimental design. Loveday (1976) has noted the importance of adding follow-up split applications of gypsum to maintain the beneficial electrolyte effect until permanent displacement of exchangeable sodium by calcium has been achieved

- Gypsum-lime blends and subsoil applications were not assessed

- Alternatives to the by-product gypsum (phosphogypsum) used by Doyle et al. (1979) need to be assessed, e.g. coarse mined gypsum with relatively low solubility (Abbott and McKenzie 1996).

The nature of soil constraints at ‘Delvin’ and ‘Gurley Station’, in relation to soil limitations across other parts of the Northern Region

Dispersion associated with sodicity must not be considered in isolation from other soil factors that adversely affect crop growth. Table 3 provides a comprehensive framework for the planning of sodic soil amelioration. The main circumstance under consideration by Doyle et al. (1979) was ‘1. Surface dispersion/sodicity with neutral pH’ (Dispersive Vertosols; Tight budget).

GRDC Projects B and C are studying a broad range of Northern Region grain paddocks where several other constraint scenarios exist (Lester et al. 2022).

The following notes explain the assumptions used when creating Table 3.

- For the amelioration strategy with a 'tight budget', the focus is on topsoil improvement. This will work well in years with favourable rainfall patterns but won't be so good in dry years when crop roots have to grow deeply into untreated subsoil.

- For the more expensive amelioration strategy with 'credit not limiting', both topsoil and subsoil are improved. This allows crop roots to grow deeply and function well in both wet and dry years.

- However, it should be noted that a Grey Vertosol or Brown Sodosol, ameliorated to a depth of say 60cm, will still be moderately constrained when compared with a soil such as a low-salinity Black Vertosol that can allow root penetration to at least 2m deep.

- The aim of the 'Gypsum - split dose' approach (gypsum costs spread over several years) is to overcome dispersion via the electrolyte effect of dissolved gypsum (Loveday 1976), and to eventually achieve permanent replacement of exchangeable sodium by exchangeable calcium (target ESP = 3). Shainberg et al. (1980) noted that in distilled water, clay dispersion and hydraulic conductivity decrease at ESP values as low as 1 to 2%.

- The Oster and Jayawardane (1998) equation is used to calculate gypsum requirement for permanent replacement of exchangeable sodium by calcium.

- Where the pH (CaCl2) is less than 6.6, the soil is considered to be sufficiently acidic for applied lime instead of gypsum when overcoming sodicity constraints (Richards 1954).

- It is assumed here that split application of gypsum for overcoming subsoil dispersion is not feasible because of the high cost of the associated repeated deep ripping.

- Large additions of organic matter to the subsoil (both natural and synthetic, e.g. PAM) is not yet a proven cost-effective soil amelioration option (Doyle et al. 1979), so at this stage is not included on the ameliorant list.

- There also is economic uncertainty about the use of elemental sulfur to lower pH and produce gypsum in situ in soil containing CaCO3 nodules; the best option for strongly alkaline zones may be selection of crop varieties with natural adaptation to high pH.

- The up-front cost of intensive and comprehensive soil assessment (soil sampling, analysis and mapping) will be similar for both 'tight budget' and 'credit not limiting' amelioration scenarios. The importance of considering these soil testing costs as capital expenditure rather than annual expenditure in farm budgets is emphasised by Bennett et al. (2021). A favourable development is the refinement of proximal soil sensing methods with potential to greatly reduce the cost of soil analysis.

Table 3. ‘Soil Amelioration Options’ to consider for constrained soil in the GRDC Northern Region.

Soil Types (Australian Soil Classification) | Dispersive Vertosols & Sodosols | Self-mulching Vertosols (sodic subsoil) | ||

Soil amelioration strategies to focus on: Not to be ranked - they all are important for each paddock/soil/yield gap zone under consideration (Liebig's ‘Law of the Minimum’ is assumed to apply whereby crop growth is restricted by the most limiting factor influencing plant performance). | ||||

The main constraint combinations | Tight budget | Credit not limiting | Tight budget | Credit not limiting |

1. Surface dispersion/sodicity | Gypsum - Split dose | Gypsum - All at once | n/a | n/a |

2. Subsoil dispersion/sodicity | DELAY | Gypsum - All at once | DELAY | Gypsum - All at once |

3. Surface compaction | Ripping if possible + Controlled Traffic (CTF) | Ripping (if compaction is severe) + CTF | ||

4. Subsoil compaction | Deep ripping if possible + CTF | Deep ripping (if compaction is severe) + CTF | ||

5. Surface dispersion & surface compaction combined | Gypsum (Split) + Rip | Gypsum (All) + Rip | n/a | |

6. Surface dispersion & subsoil compaction combined | Gypsum (Split) + Rip | Gypsum (All) + Rip | n/a | |

7. Subsoil dispersion & surface compaction combined | DELAY | Gypsum (All) + Rip | DELAY | Gypsum (All) + Rip |

8. Subsoil dispersion & subsoil compaction combined | DELAY | Gypsum (All) + Rip | DELAY | Gypsum (All) + Rip |

9. Acidic surface pH | Lime | n/a | ||

10. Acidic subsoil pH | DELAY | Lime | n/a | |

11. Acidic surface pH + (5) | Lime + Gypsum (Split) + Rip | Lime + Gypsum (All) + Rip | n/a | |

12. Acidic surface pH + (6) | Lime + Gypsum (Split) + Rip | Lime + Gypsum (All) + Rip | n/a | |

13. Acidic surface pH + (7) | DELAY | Lime + Gypsum (All) + Rip | n/a | Lime + Gypsum (All) + Rip |

14. Acidic surface pH + (8) | DELAY | Lime + Gypsum (All) + Rip | n/a | Lime + Gypsum (All) + Rip |

15. Alkaline surface pH | Elemental sulfur (ES) ?? | Elemental sulfur (ES) ?? | ||

16. Alkaline subsoil pH | DELAY | ES ?? | DELAY | ES ?? |

17. Alkaline surface pH + (5) | ES + Gypsum (Split) + Rip | ES + Gypsum (All) + Rip | n/a | |

18. Alkaline surface pH + (6) | ES + Gypsum (Split) + Rip | ES + Gypsum (All) + Rip | n/a | |

19. Alkaline surface pH + (7) | DELAY | ES + Gypsum (All) + Rip | DELAY | ES + Gypsum (All) + Rip |

20. Alkaline surface pH + (8) | DELAY | ES + Gypsum (All) + Rip | DELAY | ES + Gypsum (All) + Rip |

21. Nutrient deficiency - in addition to any of the above scenarios | Fertiliser | Fertiliser | ||

22. Paddock too flat - in addition to any of the above scenarios | Earthworks to improve surface drainage | n/a | ||

23. Paddock erodible - in addition to any of the above scenarios | Erosion control earthworks &/or stubble | Erosion control earthworks &/or stubble | ||

24. Saline subsoil - in addition to any of the above scenarios | Select salt tolerant crop varieties | |||

OVERCOMING MISTAKES | ||||

24. Subsoil remains compacted because of ineffective ripping | Repeat deep ripping; do it effectively | Repeat deep ripping; do it effectively | ||

25. Re-compaction of soil following CTF failure | Repeat deep ripping; improve CTF | Repeat deep ripping; improve CTF | ||

26. Soil returns to being dispersive because of split doses being overlooked | Gypsum - Split dose | n/a | n/a | |

Specialist soil assessment and management services are needed to assist growers and their agronomists (soil management ‘general practitioners’) with the accurate mapping and improvement of sodic/dispersive soil, in conjunction with integrated assessment and management of associated soil constraints such as compaction, excessive paddock flatness, pH imbalance and subsoil salinity.

If done professionally, this type of assessment allows soil constraints to be viewed as economic opportunities. Large improvements in farm returns on investment and land values are possible (Bennett et al. 2021) via this approach, in conjunction with the use of ‘true variable rate’ precision agriculture techniques. It is important, when developing improved soil management strategies, to think critically when selecting soil survey methods of relevance to the soil landscapes under consideration. Unless soil sampling sites are chosen sensibly, the maps of key soil factors such as poor aggregate stability in water usually lack accuracy, which often results in economic losses because of the application of ameliorants in the wrong locations and/or at inappropriate rates. EM survey data, for example, often correlate poorly with maps of soil instability in water (dispersion).

Conclusions

The pioneering work of Moree farmer and UNE student, Bill Yates, in the 1970s on naturally sodic/dispersive soil under dryland wheat has been underestimated and overlooked by many soil managers in the Australian grains industry. An outstanding feature of the work by Yates and his colleagues (including David Doyle, NSW DPI, Tamworth) was the duration of time (5 years) over which the amelioration impacts were monitored.

Gypsum benefits were shown to persist for at least 5 years, and sometimes the improved yields were close to the modelled potential yields, i.e. a substantial narrowing of the yield gap. The annual cost of the modelled yield gap on the sodic soil without amelioration at these study sites exceeded $500 per hectare during the period 1973-77.

All of the gypsum treatments were profitable, particularly when interest rates are close to zero and at a rate of 2.5 t/ha. Deep ploughing also was profitable, despite poor persistence at ‘Delvin’, but financial losses were associated with applications of 12.5 t/ha chopped straw.,

Lime is much less soluble than gypsum and was slow to suppress soil dispersion, but significant yield benefits were eventually observed at both ‘Gurley Station’ and ‘Delvin’. In many parts of the Northern Region, lime provides a lower-cost source of calcium than gypsum. For example, where gypsum costs $70 per tonne and lime is $50/t, the cost of calcium from gypsum is $265/t, but only $125/t when derived from lime.

However, the work by Yates, Doyle and colleagues only dealt with a single soil constraint scenario. The circumstance under consideration by Doyle et al. (1979) was ‘1. Surface dispersion/sodicity with neutral pH’ (Dispersive Vertosols; Tight budget). It appears that compaction damage was not a severe constraint. GRDC Projects B and C are studying a broad range of Northern Region grain paddocks where several other constraint scenarios exist (Lester et al. 2022).

A list of ‘Soil amelioration options’ to consider for constrained soil in the GRDC Northern Region has been presented. No two paddocks are exactly the same in terms of the 3D spatial variations of key soil factors influencing crop growth (not just sodicity/dispersion, but also problems such as compaction, excessive paddock flatness, pH imbalance and subsoil salinity), and the changes in soil health over time. On all farms, specialist soil science input is required to help farmers and agronomists develop the most cost-effective way of collecting the required soil data (in conjunction with other layers of information such as yield data and remote sensing information) with adequate accuracy, and to then select an appropriate variable-rate soil amelioration strategy to maximise return on investment. An over-reliance on EM surveys and topsoil nutrient testing means that most grain farms in eastern Australia have a serious lack of accurate and comprehensive soil profile data to guide productivity improvements and the provision of soil-related ecosystem services. A vital step is consideration of the expense of accurately measured soil survey data, and the soil amelioration inputs that follow, as capital expenditure instead of annual costs (Bennett et al. 2021).

References

Abbott TS and McKenzie DC (1996) Improving soil structure with gypsum and lime. NSW Agriculture Agfact.

Bennett JMcL, Roberton SD, Ghahramani A and McKenzie DC (2021) Operationalising soil security by making soil data useful: Digital soil mapping, assessment and return-on-investment. Soil Security

Dang YP, Dalal RC, Routley R, Schwenke GD and Daniells I (2006) Subsoil constraints to grain production in the cropping soils of the north-eastern region of Australia: an overview. Australian Journal of Experimental Agriculture 46, 19-35.

Doyle AD, Taylor DW, Yates WJ, So HB and McGarity JW (1979) Amelioration of structurally unstable grey clays in the north-western wheat belt of New South Wales. Australian Journal of Experimental Agriculture and Animal Husbandry 19, pp. 590-598.

Emerson WW (1977) Physical properties and structure. In ‘Soil factors in crop production in a semi-arid environment’ (Eds. JS Russell, EL Greacen). University of Queensland Press / Australian Society of Soil Science Inc.

French RJ and Schultz JE (1984) Water use efficiency of wheat in a Mediterranean environment. II. Some limitations to efficiency. Australian Journal of Agricultural Research 35, 765-775.

Heard G (2021) Australia close to peak planted area for grains. The Land, September 16, 2021, p. 8. Online version: https://www.theland.com.au/story/7430501/australian-cropland-area-set-to-plateau/?cs=4942

Isbell RF, National Committee on Soil and Terrain (2021) The Australian Soil Classification: Third edition. CSIRO Publishing.

Lester D, Silburn C, Birchall C, Flavel R, Guppy C, Bennett JMcL, Roberton S, McKenzie D (2022). Ameliorating sodicity; what did we learn about ameliorating sodicity constraints with a range of treatments? Yield responses to ripping, gypsum and OM placement in constrained soils. Paper prepared for GRDC Grains Research Updates (Online, March 2022).

Loveday J (1976). Relative significance of electrolyte and cation exchange effects when gypsum is applied to a sodic soil. Australian Journal of Soil Research 14, 361-71.

McKenzie DC (1982) Evaluation of gypsum as an ameliorant for cracking-clay soils of the Moree District, NSW. M. Sc. Agric. Thesis, University of New England, Armidale, NSW.

Orton TG, Mallawaarachchi T, Pringle MJ, Menzies NW, Dalal RC, Kopittke PM, Searle R, Hochman Z and Dang YP (2018). Quantifying the economic impact of soil constraints on Australian agriculture: A case‐study of wheat. Land Degradation & Development 29(11), 3866-3875.

Oster JD and Jayawardane NS (1998). Agricultural management of sodic soils. In: ‘Sodic Soils’ (Eds. ME Sumner, R Naidu). Oxford University Press: New York.

Richards LA (Ed.) (1954). Diagnosis and Improvement of Saline and Alkali Soils. USDA Agriculture Handbook No. 60.

Roberton S (2022). Satellite Sites – Ameliorating spatially variable soil constraints. What did growers try, what was done and how has it worked so far? Paper prepared for GRDC Grains Research Updates (Online, March 2022).

Shainberg I, Rhoades JD and Prather RJ (1980) Effect of low electrolyte concentration on clay dispersion and hydraulic conductivity of a sodic soil. Soil Science Society of America Journal 45, 273-77.

So HB and McKenzie DC (1984) Use of gypsum in the management of the grey and brown clays of the lower Gwydir Valley, NSW. In: The Properties and Utilisation of Cracking Clay Soils (eds. J.W. McGarity, E.H. Hoult & H.B. So), pp. 329‑334. University of New England, Armidale.

So HB and Onus GC (1984) The extent of unstable grey and brown clays in the Lower Gwydir Valley, New South Wales, and its relationship to wheat yields. In: The Properties and Utilisation of Cracking Clay Soils (eds. J.W. McGarity, E.H. Hoult & H.B. So), pp. 132-135. University of New England, Armidale.

Yates WJ (1972) Factors affecting the structural instability of clay soils in the Moree area, NSW. M.Rur. Sc. Thesis, University of New England, Armidale NSW.

Yates W and McGarity J (1984) Structural instability in grey clay surface soils. The Properties and Utilisation of Cracking Clay Soils’.(Eds JW McGarity, EH Hoult, and HB So.) pp, 123-131.

Acknowledgements

This paper has been inspired by the findings of numerous soil science and agronomy colleagues who have worked on the assessment and management of agricultural soil constraints over the past 45 years. The author is particularly indebted to members and supervisors of the GRDC funded Project A, B, C and D teams, and co-operating farmers, who have stimulated high quality discussions about soil constraints in the Northern Region since the initiative commenced in 2018.

Contact details

Dr David McKenzie

Soil Management Designs

Orange NSW 2800

Ph: 0458 497 574

Email: david.mckenzie@soilmgt.com.au

GRDC Project Code: USQ1803-002RTX, USQ1803-003RTX,

Was this page helpful?

YOUR FEEDBACK