HARVEST OPTIONS FOR CANOLA WINDROWING TIMING, DIRECT HEADING, DESICCATION WITH REGLONETM AND TREATMENT WITH POD CEALTM - EFFECTS ON YIELD AND OIL PERCENTAGES

| Date: 28 Sep 2010

Background

Focus group meetings of winter 2009 highlighted interest in validating existing understandings of ideal windrowing times in canola. One common understanding is simply that by windrowing too early potential oil percentage could be reduced and by windrowing later, yield may be lost through excessive shelling and shattering.

Two trials were established in Coonamble and Dubbo to investigate the yield and oil responses in canola to various windrowing timings. The Coonamble trial went further by investigating yield and oil when direct heading and using pre harvest treatments with Pod CealTM and desiccation with RegloneTM.

Methods

Both Coonamble and Dubbo sites were large scale replicated trials. Windrowing was carried out by commercial machines at predetermined stages of maturity. The direct heading treatments were simply left and harvested the same time as the windrowed crop.

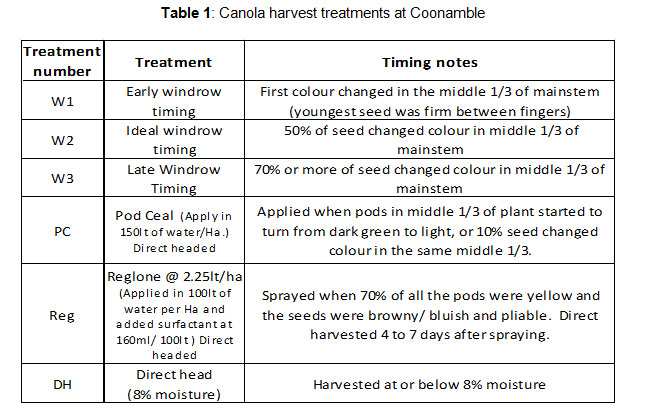

Coonamble

Treatment areas were at least 12 metres wide and continued for the length of the paddock. Treatments included windrowing at three timings (W1, W2 and W3); a RegloneTM (Reg) treatment at label recommendations which was then direct headed, Pod CealTM (PC) at label recommendations which was also direct headed and the final treatment which was direct headed with no other treatments. Sprayed treatments were applied by ground with no wheel tracks in the harvested areas. Windrowing was performed by a self propelled unit. The timings of the relevant treatments are contained in the table below.

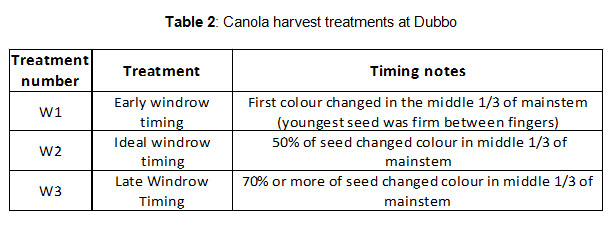

Dubbo

This trial only consisted of the three windrowing timings. Treatments were 6.1 metres wide and replicated twice. Windrowing was by a PTO windrower. The timings of the relevant treatments are contained in the table below.

Results

Yields

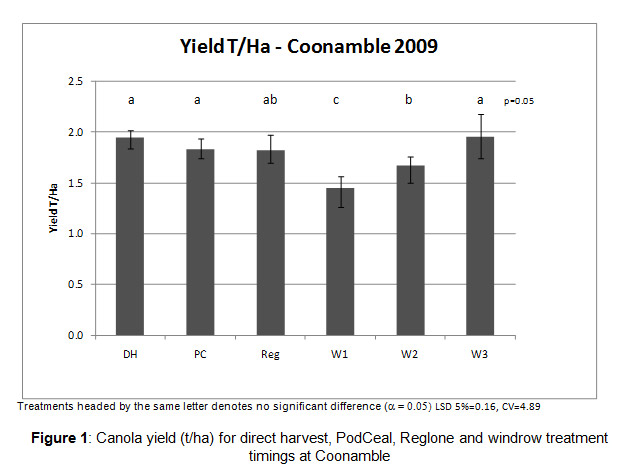

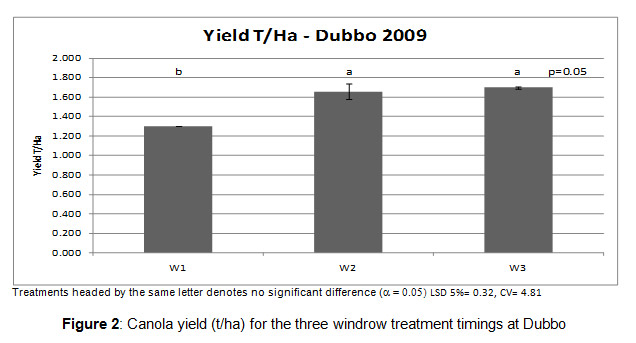

The following graphs depict the yield and oil of the Coonamble and Dubbo trials. Yields have been adjusted for moisture to 8%.

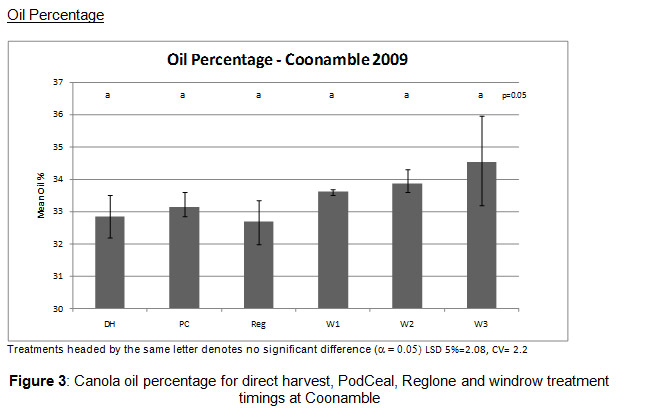

At the Coonamble site

• W1 was the lowest yielding treatment of the 3 timings.

• Each of the three windrow timing were significantly different and increased as windrowing was delayed

• The yields between direct headed (no other treatment), Pod Ceal, desiccation with RegloneTM and W3 were not significantly different and were the highest yielding treatments.

• Desiccation with RegloneTM and W2 were not significantly different

From the trials at Dubbo it can be seen

• W3 was the highest yield treatment but was not significantly different to W2

• W1 was the lowest yielding treatment

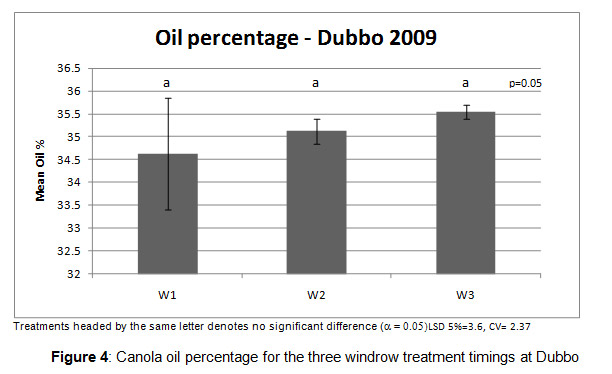

There was no significant difference between oil percentages for the three treatment timings at the Dubbo site.

As the data indicates, yield from delaying windrowing shows a trend to increase. These increases are statistically significant in some of the cases but the comparison is not consistent. The trend however does appear to be consistent. The yields gained through the direct heading treatments, Pod CealTM, RegloneTM and direct heading without additional treatments were also statistically higher than some of the earlier windrowing timings, however there were no significant differences between Pod CealTM, RegloneTM and direct heading.

Discussion

Yield

The process of windrowing requires the plant be cut off from the root system when the pods are still green and pliable enough not to shatter. This facilitates the even drying of the windrow and the grain within it. Windrowing also lessens the likelihood of pod shatter as the crop moves into the header.

The windrowing process of severing the plant tops from the root system rapidly terminates many of the key processes within the plant, namely, photosynthesis and respiration. These effect both plant growth, and in this context, one could assume, grain fill. This termination of a plants primary function may have then had the potential to effect how immature seeds may further develop after windrowing. Characteristics such as final grain size, density and oil content that develop in the late stages of plant growth may be influenced. Desiccation with a product such as RegloneTM that rapidly removes photosynthetic area could potentially have a similar effect. Any seed that has already reached maturity at the time of windrowing/ desiccation would be expected to be unaffected by the timing of such an operation.

Therefore, when considering ideal windrowing timing we must question how much seed has already reached maturity and how much has not. For the immature portion, how much will be able to reach its full potential between windrowing/desiccation and harvest compared to if it was left standing and able to mature naturally as it would be if it was to be direct headed?

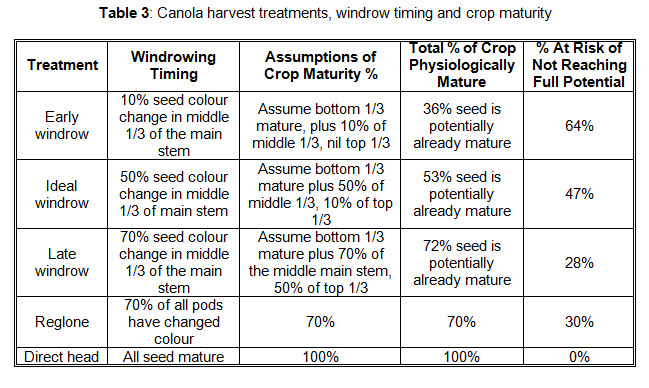

To do this we must determine what is considered as physiologically mature. For the purpose of this discussion let’s assume that colour change in the seed is an indicator of maturity. From here we can start to form a theory for any potential yield variability.

From the various windrow timings, we can start to hypothesise what proportion of the crop is mature at the time of cutting and how much of the crop is immature and may not reach full potential. This can be demonstrated by the following table.

As the timing of windrowing advances, the proportion of the crop that has achieved its full potential for its environment increases or in the case of direct heading where the crop is allowed to mature naturally all seed is able to reach its true maximum.

The inverse of this is that the relative proportion that is immature at the time of cutting or desiccation increases as windrowing is brought forward. This immature seed at the time of windrowing/desiccation must complete its maturation process on stored reserves within the plant as both respiration and photosynthesis will cease quickly after cutting.

Given that no more seed will be formed after even the earliest windrowing or desiccation, it must be this proportion of the crop that would be responsible for the variations in yields of treatments within the trials?

These trials cannot answer the question of how much potential is there for immature seed to mature on stored substrate. However logic would suggest that the greater the proportion of physiologically mature seed at time of cutting places less demand on these stored substrates.

Therefore delaying any action that has the potential to cease plant growth whilst some seed is immature has the potential to have a positive impact on yields. The magnitude of this increase can only be commented on in the context of these trials.

However this potential maximisation of yield must be weighed against the risks associated with delaying windrowing or indeed direct heading. Other advantages that an earlier windrowing timing may offer needs to be also considered. Potential for increased risk of crop losses through pod shatter before, during or after windrowing have been a primary concern to growers. To leave the crop to mature further before windrowing or direct heading sees the brittleness of the crop increasing and so does the potential for pods to split and shatter.

Earlier windrowing may mitigate this risk by some amount but it may have other advantages as well. These may include longer harvesting windows, less exposure to hail damage, less risk of shattering due to high winds.

Advances in machinery may also help minimise the potential losses in direct heading situations. Modern headers with draper fronts or conventional fronts with extendable tables may also limit any potential losses.

There are a number of new products in the market place to manage potential shattering. One such product is Pod Ceal which was trialled at the Coonamble site. Pod CealTM aims to minimise pod shatter through a coating applied over the pod. In this trial treatment with Pod CealTM was not statistically different to either direct headed after desiccation with Reglone or direct headed with no other treatment. However this site in all treatments had minimal shattering problems. If the site experienced greater shattering the advantages of such a product could well be justified.

Unfortunately this trial was not able to quantify any losses through pod shatter between the treatments or the source of these losses other than visual assessments where losses would be described as minor.

Oil levels

As indicated in the data from both trials there was no significant difference in oil percentages to different windrowing timings or compared with any of the direct heading treatments. In most situations it appears there may be some trend towards increasing oil content with delays in cutting time or windrowing. It should be noted that the differences are of a magnitude of only approximately 1%. This is not a significant explanation of the low oils experienced by many growers in the region often 4-5% lower than the base oil of 42%.

Conclusion

In these trials it could be concluded that windrowing timing has had a limited affect on oil percentages in canola.

Delaying windrowing or direct heading has resulted in significant increases in yields of canola in these trials. These yield variations may be explained by the proportion of immature seed present at cutting and the risk this seed experiences as to the ability to fill to its full potential. For this seed to mature it must draw on stored substrate and this may be influenced by cutting height, time of day or even the variability on the level of maturity within the crop. These aspects may require further investigations.

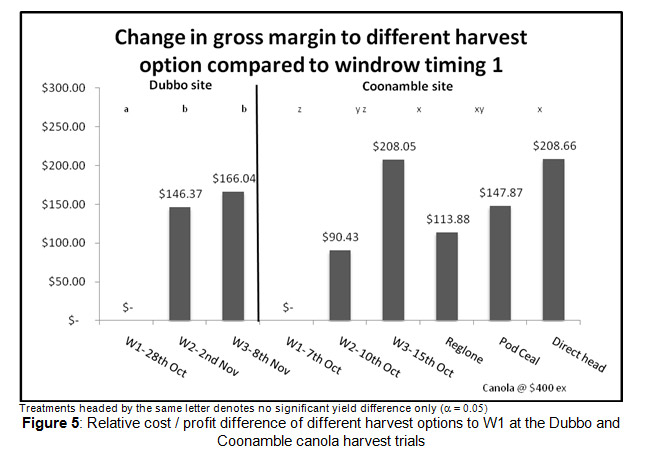

The differences in yield coupled with additional costs all contribute to significant increases in net returns for the various treatments. The following graph depicts the benefits for the average of all the treatments, taking into account average yields, additional costs as well as oil penalties/bonuses.

The limited nature of these trials does not allow an “ideal” timing of windrowing to be put forward. What it does hope to do is to demonstrate the potential economic benefit gained by getting it right. Each paddock will be different, seasons will be different and growers risk adversity will be different. When formulating a windrowing timing it is best to remember that whilst there is immature seed in the paddock there is potential upside to allowing this to mature before windrowing or desiccation. And by ceasing that plants growth during the filling of these seeds, yields could be reduced.

Therefore, a balance must be made between potential yield maximisation by delaying windrowing or desiccation, against the potential increases in yield loss through shattering. This should be weighed against the growers risk adversity or other advantages offered through windrowing. Potential risk in terms of pod shattering may be managed by use of products such as Pod Ceal.

There may be advantages in further investigation into

• Time of day of windrowing and the relevant impact of maturation of immature seed

• Windrowing height - more stem may leave available more substrate to facilitate grain fill and lead to less yield losses and variability

• Quantify potential sources of losses - standing crop, windrowing losses, losses whilst in the windrow.

Acknowledgements

Special thanks to:

Clyde Agriculture “Netherway” Coonamble,

Graeme Callaghan- Graeme Callaghan & associates, Dubbo

Garry Evans- “Larry’s Plains”, Dubbo

Lindsay Northcott, North-Hill harvesting, Young

Syngenta crop protection, Australia

Agspec, Australia (Pod CealTM Distributors)

Contact details

Maurie Street

Grain Orana Alliance

PO Box 2880

Dubbo NSW 2830

0400 066 201

maurie.street@grainorana.com.au

GRDC Project Code: GOA 00001,

Was this page helpful?

YOUR FEEDBACK