Spray application manual

8 June 2025

Module 5: Completing a spray plan

5.4: Completing the spray plan

Published 24 January 2025 | Last updated 20 January 2025

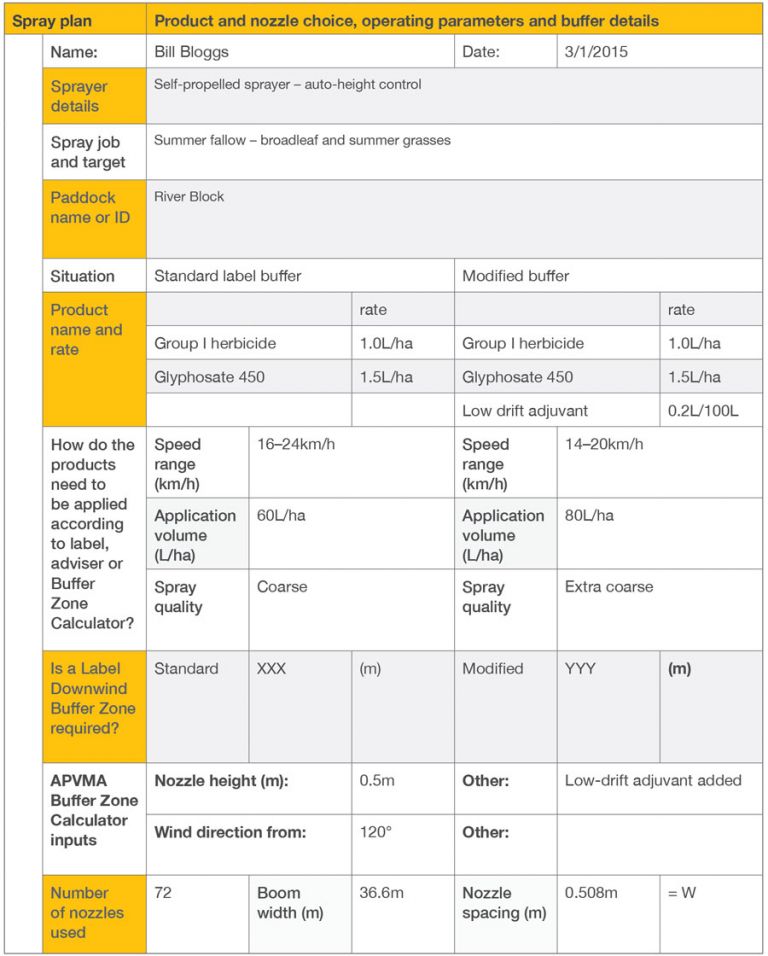

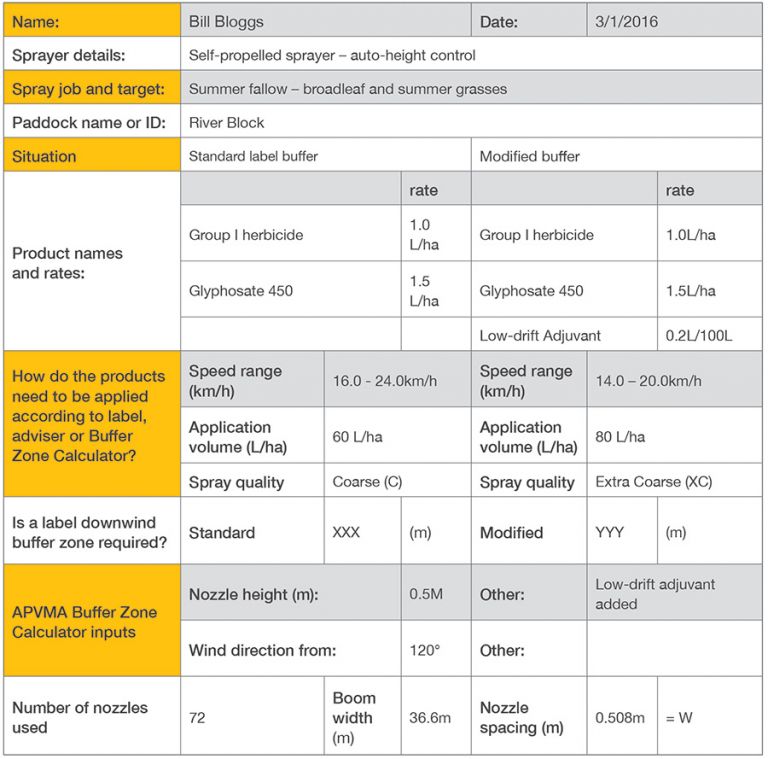

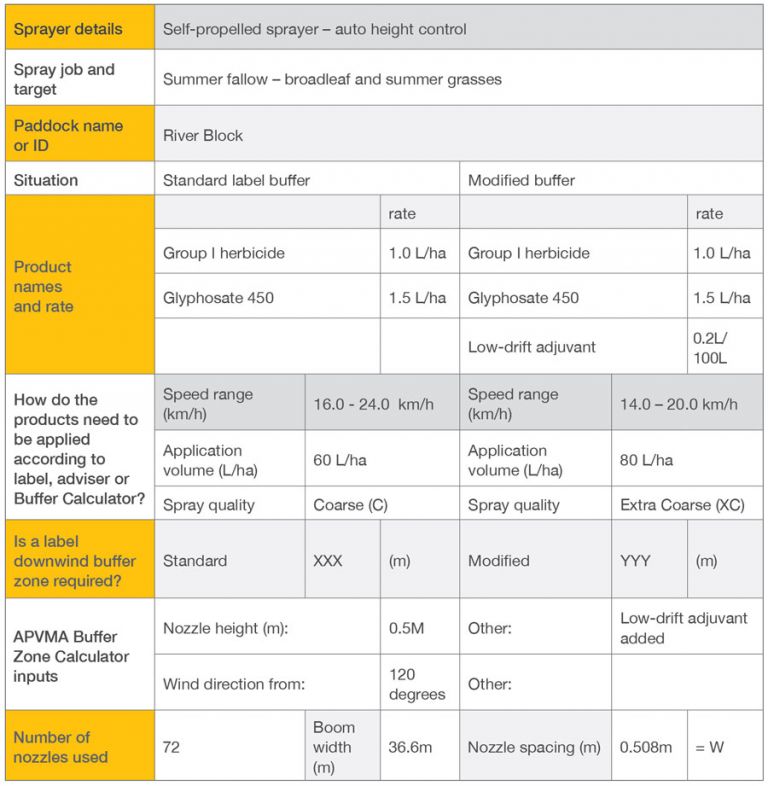

Complete the job details and label requirements in the top half of the form (Part 1 of the spray plan)

For example, a summer fallow application using a 36.6-metre boom, (20-inch nozzle spacing = 0.508m)

Part 1 of the spray plan is about the sprayer, the products and the label requirements.

In this example the spray plan includes two situations Setup 1: Winter application of 2,4-D Minimum legal requirements for a 2,4-D application (VC spray quality) and setup 2: Summer Application of 2,4-D (XC spray quality to further reduce spray drift potential)

Example of a completed spray plan.

Note

This is a generic example. It does not include actual product names.

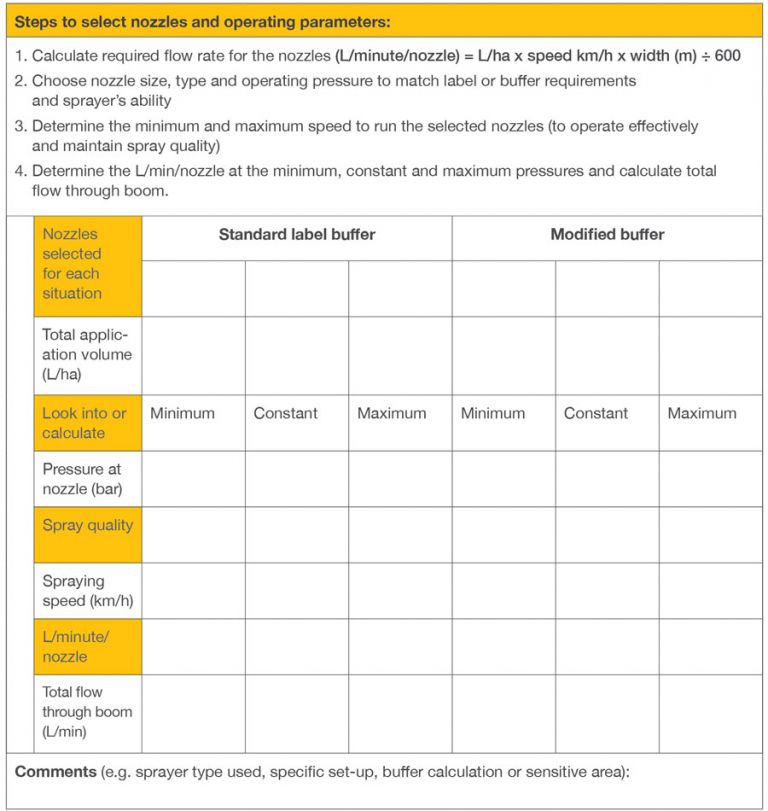

Part 2 of the spray plan includes nozzle selection details and operating parameters to match the sprayer set-ups identified in Part 1 of the spray plan.

Select nozzles and operating parameters for the job (part 2 of the spray plan)

Step 1. Determine the required flow rate (nozzle size and pressure)

Once we have determined the total application volume (total litres per hectare), a decision about nozzle orifice size and pressure needs to be made.

To do this we need to determine the required flow rate for each nozzle (litres/minute/ nozzle).

From our example:

Setup 1:

60L/hectare, very coarse spray quality, 16–24km/h, nozzle spacing (W) = 0.508m*

Note

Note that because the nozzle spacing is 0.508m we have to calculate the required L/minute/nozzle. If the nozzle spacing was 0.5m we could use a standard nozzle chart to select the nozzle orifice size and pressure.

Formula required: L/min/nozzle = L/ha x width (m) x speed (km/h) ÷ 600

at 24km/h L/min/nozzle = 60 x 0.508 (m) x 24 ÷ 600

= 1.22 litres per minute per nozzle (at 24.0km/h)

at 16km/h L/min/nozzle = 60 x 0.508 (m) x 16 ÷ 600

= 0.81 litres per minute per nozzle (at 16.0km/h)

Once you have established the required L/minute/nozzle, look up the nozzle sizes and flow rates using a manufacturer’s nozzle chart to achieve 1.22L/min/nozzle and 0.81L/minute/nozzle.

Choices:

1.22L/minute/nozzle (24.0km/h)

02 orifice at 7.0 bar

025 orifice at 4.5 bar

03 orifice at between 3.0 bar and 3.5 bar

04 orifice between 1.5 bar and 2.0 bar

0.81L/minute/nozzle (16.0km/h)

02 orifice between 3 bar and 3.5 bar

025 orifice at 2.0 bar

03 orifice between 1.0 bar and 1.5 bar

04 orifice less than 1.0 bar

Decide on a practical nozzle orifice size and pressure to suit your machine.

The 03 and 04 orifices will reduce in pressure too much when you slow down.

The 02 orifice would require that the machine can operate at 7.0 bar and that a nozzle can operate at that pressure and produce a very coarse droplet, which would limit the choice to only a few high-pressure air-induction nozzles.

The 025 orifice at 4.5 bar at 24.0km/h is probably the best choice for this example.

Step 2: Select the nozzle brand and type based on spray quality

Having established that we want to use a nozzle with a 025 orifice (lilac) at 4.5 bar at 24km/h (and 2.0 bar at 16km/h), we have to choose a nozzle brand and type that will produce the very coarse spray quality required across that range of pressures.

From the manufacturer’s spray quality data for lilac 025 orifice low-pressure air- induction nozzles, we find there are several nozzles available, but not all can be used to produce the required spray quality at acceptable operating pressure.

A selection of 025 orifice air-induction nozzles and the spray quality produced at various pressures.

For this example, an ARAG CFA-Ultra110-025 was chosen as the nozzle holds a Very Coarse spray quality up to 5.0 bar. However, care will be needed to minimise the amount of time at the minimum speed where the pressure will be 2.0 bar as with this nozzle the spray quality can become extremely coarse.

Step 3: Calculate the maximum speed for this nozzle to maintain the spray quality at 60L/ha

The ARAG CFA-Ultra 110-025 holds a coarse spray quality up to 5.0 bar.

(Look up the flow rate of an 025 orifice at 5.0 bar which = 1.27L/minute/nozzle.) To determine the maximum spraying speed to maintain a very coarse spray quality:

Formula required: Speed (km/h) = L/min/nozzle x 600 ÷ L/ha ÷ width (m)

= 1.27L/min/nozzle x 600 ÷ 60L/ha ÷ 0.508 (m)

= 25.0km/h

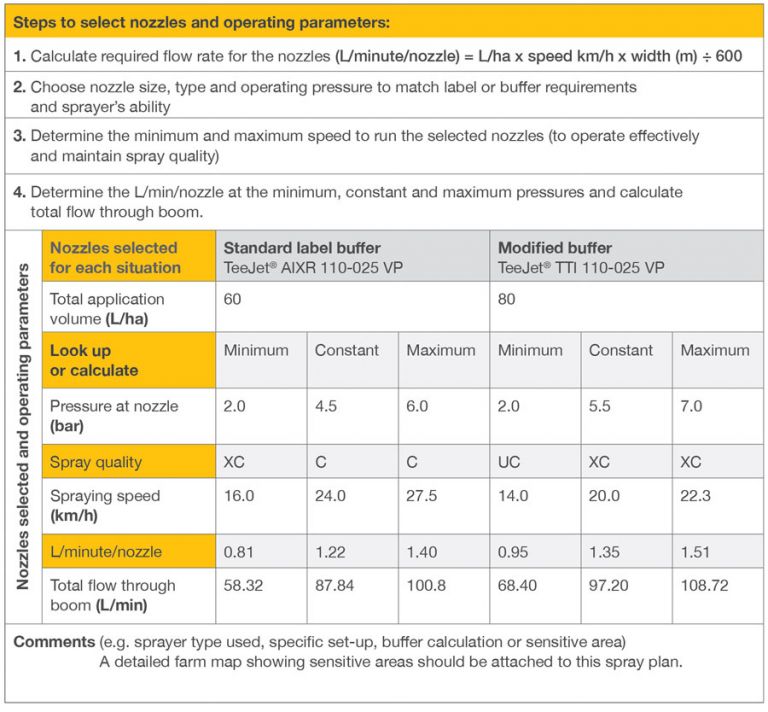

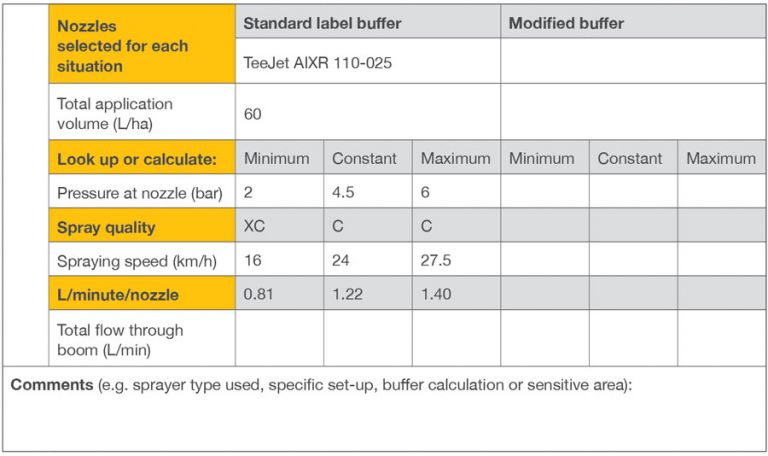

Example completion of Part 2 of the spray plan.

Once you have transferred the calculations you have made so far, you will see there is one piece of information missing – the total flow rate (L/min) through the boom. This is an important piece of information to be able to use the controller display to check how things are running during the spray job.

Step 4: Calculate the total flow rate through the boom

The total flow rate through the boom is based on the number of nozzles being used (72 in this example), and the flow rate of each nozzle (L/minute/nozzle) at each of the spraying speeds

Determine the total flow rate through the boom at each speed with the following formula:

Total flow rate through boom (L/min) = L/minute/nozzle x number of nozzles used at 16km/h

Total flow rate through boom (L/min) = 0.81 x 72 = 58.32 (L/min)

at 24km/h Total flow rate through boom (L/min) = 1.22 x 72 = 87.84 (L/min)

at 25km/h Total flow rate through boom (L/min) = 1.27 x 72 = 91.4 (L/min)

Add this final piece of information to the bottom half of the spray plan to complete the plan for the setup 1 (see Figure 4).

Example with first part of spray plan completed

Steps to select nozzles and operating parameters

Complete the spray plan for a modified buffer (Part 2)

In this instance we are using an Extremely Coarse (XC) spray quality, at 14–20km/h and at a total application volume of 80L/ha (with the addition of a drift-reduction adjuvant).

Use the same process you employed for determining the spray plan for the standard buffer to determine the nozzle type and operating parameters.

Step 1: Determine the required flow rates (litres per minute per nozzle)

Formula required: L/min/nozzle = L/ha x width (m) x speed (km/h) ÷ 600

at 20km/h L/m in/nozzle = 80 x 0.508 (m) x 20 ÷ 600

= 1.35 litres per minute per nozzle (at 24.0km/h)

at 14km/h L/m in/nozzle = 80x 0.508 (mx) x 14 ÷ 600

= 0.95 litres per minute per nozzle (at 14.0km/h)

Once you have established the required L/minute/nozzle look up the nozzle sizes and flow rates using a manufacturer’s nozzle chart to achieve 1.35L/min/nozzle and 0.95L/ min/nozzle.

Choices:

1.35L/min/nozzle (20km/h)

025 orifice at 5.5 bar

03 orifice at 4.0 bar

0.95L/min/nozzle (14km/h)

025 orifice between 2.0 bar and 2.5 bar

03 orifice between 1.0 bar and 1.5 bar

Decide on a practical nozzle size and pressure to suit your machine. The 03 orifices will reduce the pressure too much when you slow down.

The 025 orifice at 5.5 bar at 20.0km/h is probably the best choice for this example.

Step 2: Select the nozzle brand and type based on spray quality

Having established we want to use a nozzle with a 025 orifice (lilac) at 5.5 bar at 20km/h (and 2.0 bar at 14km/h), we now have to choose a nozzle brand and type that will produce the Extremely Coarse (XC) spray quality (or larger) required across that range of pressures.

From the manufacturer’s spray quality data for lilac 025 orifice nozzles (Table 2), one nozzle choice that will match these criteria is the ARAG CFLD-XC110-025 (ARAG compact Fan Low Drift-XC)).

Step 3: Calculate the maximum speed for this nozzle to maintain the spray quality at 80L/ha

The ARAG CFLD-XC110-025 holds an extremely coarse spray quality up to 6.0 bar.

(Look up the flow rate of an 025 orifice at 6.0 bar which = 1.40L/minute/nozzle.)

To determine the maximum spraying speed to maintain an Extremely Coarse (XC) spray quality:

Formula required: Speed (km/h) = L/min/nozzle x 600 ÷ L/ha ÷ width (m)

= 1.40 L/min/nozzle x 600 ÷ 80 L/ha ÷ 0.508 (m)

= 20.7 km/h

Step 4: Calculate the total flow rate through the boom (L/minute)

The total flow rate through the boom is based on the number of nozzles being used – 72 in this example – and the flow rate of each nozzle (L/min/nozzle) at each of the spraying speeds.

Determine the total flow rate through the boom at each speed.

Formula required: Total flow rate through boom (L/min) = L/min/nozzle x number of nozzles used

at 14km/h: Total flow rate through boom (L/min) = 0.95 x 72 = 68.40 (L/min)

at 20km/h: Total flow rate through boom (L/min) = 1.35 x 72 = 97.20 (L/min)

at 20.7km/h: Total flow rate through boom (L/min) = 1.40 x 72 = 100.8 (L/min)

Add this information to the bottom half of the spray plan (Part 2) and the plan for setup 2.

Example of a completed spray plan

Tip

To test the spray plan before spraying to go Module 6: Pre-operational and regular checks.

Steps to select nozzles and operating parameters